Filter by

System of Measurement

Thickness

Material

Temper Rating

REACH

Backing Type

RoHS

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Specifications Met

Color

Sold As

Magnetic Properties

Minimum Hardness

Form

Shim Stock

|

Cut into custom shapes to create shims that suit your needs. With thickness tolerances as fine as a strand of hair, the shims will precisely align, space, and level components on dies, presses, and machinery.

You can stack multiple shims to achieve your exact thickness, but stacking more than four may cause them to shift. Remember, fewer shims are better, so a couple of thicker shims are more stable than a bunch of thin shims.

18-8 Stainless Steel—The choice for wet and outdoor areas because it resists rust. However, it will corrode or pit when exposed to salt water and chemicals.

Carbon Steel—Best for dry areas since moisture will cause it to rust.

Temper Rating—Choose half hard to create shims that you’ll need to bend or shape. Opt for full hard to make stronger shims that will maintain their shape

under loads.

Certificate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk., mm | Thk. Tolerance, mm | Temper Rating | Type | Form | Specs. Met | Form | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

150 mm Wide × 1,250 mm Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4 | -0.02 to 0.02 | Full Hard | Material Certificate | Paper | ASTM A666 | Roll | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

150 mm Wide × 2,500 mm Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4 | -0.02 to 0.02 | Full Hard | Material Certificate | Paper | ASTM A109, Fed. Spec. QQ-S-698 | Roll | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Slotted Shims

|

|

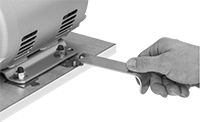

Tab End |

Slip these shims around existing mounting fasteners to precisely align and level components such as pumps, compressors, and gearboxes with motors, all without disassembling them. They’re also good for leveling machines on uneven surfaces. To reduce sizing errors, these shims are either labeled with their thickness so there's no need to measure or color coded by thickness to quickly spot the right size.

You can stack multiple shims to achieve your exact thickness, but stacking more than four may cause them to shift. Remember, fewer shims are better, so a couple of thicker shims are more stable than a bunch of thin shims.

18-8 Stainless Steel—The choice for wet and outdoor environments, these shims resist rust. However, they’ll corrode or pit when exposed to salt water and chemicals.

Insertion Tools—Ease shim insertion and removal, keeping your fingers clear in the process.

Shims | Insertion Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Slot, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thk., mm | Thk. Tolerance, mm | For Max. Screw Size | Wd. | Dp. | Min. Hardness | Identification Type | End Shape | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50 mm Lg. × 50 mm Wd. (Shim Trade Size A) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4 | -0.032 to 0.032 | M15 | 15.9 | 25.4 | Rockwell C40 | Labeled | Tab | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

75 mm Lg. × 75 mm Wd. (Shim Trade Size B) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4 | -0.032 to 0.032 | M22 | 22.3 | 38.1 | Rockwell C40 | Labeled | Tab | 00000000 | 0000 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

100 mm Lg. × 100 mm Wd. (Shim Trade Size C) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4 | -0.032 to 0.032 | M30 | 31.8 | 50.8 | Rockwell C40 | Labeled | Tab | 00000000 | 0000 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

125 mm Lg. × 125 mm Wd. (Shim Trade Size D) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4 | -0.032 to 0.032 | M40 | 41.3 | 84.1 | Rockwell C40 | Labeled | Tab | 00000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heavy-Vibration-Resistant Spring Lock Washers

|

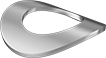

With a grip that's second only to wedge lock, these washers stop nuts and screws from wiggling loose under constant, vigorous vibration. They are ideal for engines, turbines, generators, and other heavy duty equipment. Similar to a spring, they flatten under pressure to add tension between mating surfaces. As long as the washers aren't deformed or otherwise damaged, you can reuse them indefinitely without losing locking strength. Also known as conical washers and Belleville washers.

Stack multiple washers in the same direction to double or triple how much weight they can bear. Stack washers in opposite directions for better deflection, which means they compress further and withstand more shock and movement without loosening.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

High-Strength 17-7 PH Stainless Steel—The strongest stainless steel washers we offer, these are comparable to high-strength Grade 8 steel. They won’t rust in wet and outdoor environments, but they can’t handle the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Phosphate-Coated Steel—Paint adheres evenly to the surface of these washers, so you can add your own decorative finish. They are more durable than zinc-plated steel washers to withstand wet and outdoor environments. However, they won't hold up to the harsh chemicals that stainless steel can.

Steel—Best for dry environments since moisture will cause these washers to rust.

DIN 432—These washers have a small tab that presses up against the flats of your nut or screw for extra security.

For Screw Size | ID, mm | OD, mm | Thk., mm | Overall Ht., mm | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.4 | 0.6 | DIN 6796 | 50 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.4 | 0.6 | DIN 6796 | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.3 | 14.0 | 0.4 | 2.0 | DIN 432 | 50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength 17-7 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.2 | 8.0 | 0.4 | 0.8 | — | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.4 | 0.6 | DIN 6796 | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Phosphate-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.4 | 0.6 | DIN 6796 | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.4 | 0.6 | DIN 6796 | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.3 | 14.0 | 0.4 | 2.0 | DIN 432 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Curved Spring Lock Washers

|

The curvy, spring-like shape adds a small amount of tension to prevent nuts and screws from backing out due to mild vibration. These washers also flex slightly to compensate for uneven surfaces. While more secure than a standard flat washer, these have the least amount of gripping power of all our lock washers. They are best suited for electrical panels, light fixtures, and other light duty assemblies. These washers hold their shape when untightened, so you can reuse them a handful of times without losing strength.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Tab Lock Washers

|

1 Tab |

Instead of relying on friction, these washers lock mechanically for more holding power than split and tooth lock washers. Bend the tabs with a wrench to stop both the fastener and washer from rotating. They are often used in applications with moderate vibration, such as motors, mixers, and pumps. These washers are not reusable because the tabs will weaken if you bend them repeatedly.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

1 Tab—Bend the tab down over the edge of your mounting surface, and bend the side of the washer up against the nut or screw.

For Screw Size | ID, mm | OD, mm | Thk., mm | No. of Tabs | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.3 | 14.0 | 0.4 | 1 | DIN 93 | 100 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||