Filter by

System of Measurement

Thickness

Sold As

Finish

Magnetic Properties

Minimum Hardness

Export Control Classification Number (ECCN)

REACH

RoHS

End Shape

Number of Slots

Shaft Type

Identification Type

Specifications Met

Shims

|

With thickness tolerances as fine as a strand of hair, these shims precisely align, space, and level components on shafts, arbors, and machinery.

You can stack multiple shims to achieve your exact thickness, but stacking more than four may cause them to shift. Remember, fewer shims are better, so a couple of thicker shims are more stable than a bunch of thin shims.

18-8 Stainless Steel—The choice for wet and outdoor environments, these shims resist rust. However, they’ll corrode or pit when exposed to salt water and chemicals.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these shims won't degrade when exposed to harsh weather, salt water, and most chemicals.

Carbon Steel—Best for dry environments since moisture will cause these shims to rust.

Thk. | Thk. Tolerance | ID Tolerance | OD Tolerance | Min. Hardness | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" ID × 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.004" to 0.004" | 0" to 0.011" | -0.002" to 0.002" | Rockwell B70 | ASTM A240 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" ID × 1 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.003" to 0.005" | -0.005" to 0.005" | -0.005" to 0.005" | Rockwell B70 | ASTM A240 | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" ID × 5/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.0073" to 0.0067" | -0.005" to 0.005" | -0.005" to 0.005" | Rockwell B67 | — | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" ID × 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.0073" to 0.0067" | -0.005" to 0.005" | -0.005" to 0.005" | Rockwell B67 | — | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" ID × 1" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.0073" to 0.0067" | -0.005" to 0.005" | -0.005" to 0.005" | Rockwell B67 | — | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" ID × 1 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.0073" to 0.0067" | -0.005" to 0.005" | -0.005" to 0.005" | Rockwell B67 | — | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" ID × 1 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.0073" to 0.0067" | -0.005" to 0.005" | -0.005" to 0.005" | Rockwell B67 | — | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Slotted Shims

|

|

Tab End |

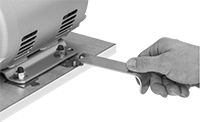

Slip these shims around existing mounting fasteners to precisely align and level components such as pumps, compressors, and gearboxes with motors, all without disassembling them. They’re also good for leveling machines on uneven surfaces. To reduce sizing errors, these shims are either labeled with their thickness so there's no need to measure or color coded by thickness to quickly spot the right size.

You can stack multiple shims to achieve your exact thickness, but stacking more than four may cause them to shift. Remember, fewer shims are better, so a couple of thicker shims are more stable than a bunch of thin shims.

18-8 Stainless Steel—The choice for wet and outdoor environments, these shims resist rust. However, they’ll corrode or pit when exposed to salt water and chemicals.

Insertion Tools—Ease shim insertion and removal, keeping your fingers clear in the process.

Shims | Insertion Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Slot | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thk. | Thk. Tolerance | For Max. Screw Size | Wd. | Dp. | Min. Hardness | Identification Type | End Shape | 1-9 | 10-Up | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" Lg. × 1" Wd. (Shim Trade Size AAA) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.002" to 0.002" | 1/4" | 5/16" | 5/8" | Rockwell B70 | Labeled | Tab | 000000000 | 00000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" Lg. × 1 1/2" Wd. (Shim Trade Size AA) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.002" to 0.002" | 3/8" | 7/16" | 61/64" | Rockwell B85 | Labeled | Tab | 000000000 | 0000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2" Lg. × 2" Wd. (Shim Trade Size A) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.002" to 0.002" | 1/2" | 9/16" | 1 9/32" | Rockwell B85 | Labeled | Tab | 0000000 | 0000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 1/2" Lg. × 2 1/2" Wd. (Shim Trade Size BB) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.002" to 0.002" | 5/8" | 11/16" | 1 19/32" | Rockwell B85 | Labeled | Tab | 000000000 | 0000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3" Lg. × 3" Wd. (Shim Trade Size B) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.002" to 0.002" | 3/4" | 13/16" | 1 29/32" | Rockwell B85 | Labeled | Tab | 0000000 | 0000 | 0000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4" Lg. × 4" Wd. (Shim Trade Size C) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.002" to 0.002" | 1 1/8" | 1 3/16" | 2 19/32" | Rockwell B85 | Labeled | Tab | 0000000 | 0000 | 0000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5" Lg. × 5" Wd. (Shim Trade Size D) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.002" to 0.002" | 1 1/2" | 1 9/16" | 3 9/32" | Rockwell B85 | Labeled | Tab | 0000000 | 00000 | 0000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Lg. × 5" Wd. (Shim Trade Size DD) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.002" to 0.002" | 1 1/2" | 1 9/16" | 4 1/2" | Rockwell B70 | Labeled | Tab | 000000000 | 00000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Lg. × 6" Wd. (Shim Trade Size E) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.002" to 0.002" | 1 7/8" | 1 15/16" | 4" | Rockwell B85 | Labeled | Tab | 000000000 | 00000 | 00000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Lg. × 6" Wd. (Shim Trade Size G) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.002" to 0.002" | 2 1/4" | 2 5/16" | 4 3/16" | Rockwell B85 | Labeled | Tab | 000000000 | 00000 | 00000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8" Lg. × 8" Wd. (Shim Trade Size H) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.002" to 0.002" | 2 1/4" | 2 5/16" | 5 3/16" | Rockwell B85 | Labeled | Tab | 000000000 | 00000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wide-Rim Shims

|

Spread loads across a wider surface area than standard shims to minimize costly wear between components. With thickness tolerances as fine as a strand of hair, these shims precisely align, space, and level components on shafts, arbors, and machinery.

You can stack multiple shims to achieve your exact thickness, but stacking more than four may cause them to shift. Remember, fewer shims are better, so a couple of thicker shims are more stable than a bunch of thin shims.

18-8 Stainless Steel—The choice for wet and outdoor environments, these shims resist rust. However, they’ll corrode or pit when exposed to salt water and chemicals.

Carbon Steel—Best for dry environments since moisture will cause these shims to rust.

Zinc-Plated Carbon Steel—A common choice for areas with occasional exposure to moisture.

Thk. | Thk. Tolerance | ID Tolerance | OD Tolerance | Min. Hardness | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" ID × 7/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | -0.01" to 0.01" | -0.005" to 0.025" | Rockwell B20 | 5 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

9/16" ID × 1" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" ID × 1 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | -0.01" to 0.01" | -0.005" to 0.025" | Rockwell B20 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" ID × 1 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | -0.01" to 0.01" | -0.005" to 0.025" | Rockwell B20 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" ID × 1 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | -0.01" to 0.01" | -0.005" to 0.025" | Rockwell B20 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" ID × 1 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" ID × 2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | -0.01" to 0.01" | -0.005" to 0.025" | Rockwell B20 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/4" ID × 1 7/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | -0.01" to 0.01" | -0.005" to 0.025" | Rockwell B20 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" ID × 2 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | -0.01" to 0.01" | -0.005" to 0.025" | Rockwell B20 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" ID × 7/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

9/16" ID × 1" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" ID × 1" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" ID × 1 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" ID × 1 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" ID × 1 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/8" ID × 1 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/8" ID × 1 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" ID × 1 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" ID × 2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/8" ID × 1 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/4" ID × 1 7/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/4" ID × 2 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 3/8" ID × 2 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" ID × 2 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" ID × 3" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 5/8" ID × 2 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 3/4" ID × 2 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2" ID × 3" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3" ID × 4 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" ID × 5/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" ID × 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" ID × 7/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

9/16" ID × 1" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" ID × 1" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8" ID × 1 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" ID × 1 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" ID × 1 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/8" ID × 1 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" ID × 1 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" ID × 2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/8" ID × 1 3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/4" ID × 1 7/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/4" ID × 2 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 3/8" ID × 2 1/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" ID × 2 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" ID × 3" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 5/8" ID × 2 3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 3/4" ID × 2 1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2" ID × 3" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3" ID × 4 1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.075" | -0.007" to 0.007" | 0.01" to 0.025" | -0.01" to 0.01" | Rockwell B38 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||