About Carbon Steel, Alloy Steel, Spring Steel, and Cast Iron

More

About Shafts

More

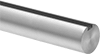

Keyed Rotary Shafts

Combine these shafts with a machine key (not included) to transmit torque to gears, sprockets, and other power transmission components. All have an ANSI standard keyway (keys not included; see our selection of key stock). Their edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, or polished to tight diameter and straightness tolerances.

Steel shafts are generally stronger than aluminum and stainless steel shafts but not as corrosion resistant. 1045 carbon steel shafts balance high strength and good machinability, making them ideal for general purpose use.

For technical drawings and 3-D models, click on a part number.

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. | Wd. | Dp. | ANSI Keys Included | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Metric—1045 Carbon Steel | ||||||||||

50mm Dia. (Tolerance: -0.076mm to 0mm) | ||||||||||

| 300mm | 300mm | 14mm | 5.5mm | No | 0.33 mm per 300 mm | Chamfered | Medium | Rockwell B95 | 00000000 | 0000000 |

| 500mm | 500mm | 14mm | 5.5mm | No | 0.33 mm per 300 mm | Chamfered | Medium | Rockwell B95 | 00000000 | 000000 |

| 1,000mm | 1,000mm | 14mm | 5.5mm | No | 0.33 mm per 300 mm | Chamfered | Medium | Rockwell B95 | 00000000 | 000000 |

| 1,200mm | 1,200mm | 14mm | 5.5mm | No | 0.33 mm per 300 mm | Chamfered | Medium | Rockwell B95 | 00000000 | 000000 |

| 1,500mm | 1,500mm | 14mm | 5.5mm | No | 0.33 mm per 300 mm | Chamfered | Medium | Rockwell B95 | 00000000 | 000000 |

| 1,800mm | 1,800mm | 14mm | 5.5mm | No | 0.33 mm per 300 mm | Chamfered | Medium | Rockwell B95 | 0000000 | 000000 |

Linear Motion Shafts

Smooth, hard, and wear resistant, these shafts work with linear bearings to reduce friction in manual and automated systems, such as those found in packing, machine tool, and material handling operations. All are turned, ground, and polished to tight diameter and straightness tolerances.

Steel shafts are generally stronger than aluminum and stainless steel shafts but not as corrosion resistant. Carbon steel shafts are good for general purpose use.

Stainless steel shafts are more corrosion resistant than steel shafts; however, they’re not as hard as steel shafts and can be more difficult to machine. 420 and 440C stainless steel shafts have good corrosion resistance and are harder than 17-4 PH stainless steel shafts, so they better resist wear.

Surface smoothness—The lower the microinch value, the smoother the finish and the less friction and wear it will cause on the bearing.

For technical drawings and 3-D models, click on a part number.

| Lg., mm | Lg. Tolerance, mm | Straightness Tolerance | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Heat Treatment | Each | |

50 mm Dia. (Tolerance: -0.016 mm to 0 mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 200 | -0.5 to 0.5 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 00000000 | 000000 |

| 500 | -0.8 to 0.8 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 000000 |

| 1,000 | -0.8 to 0.8 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 000000 |

| 1,200 | -1.2 to 1.2 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 000000 |

| 1,500 | -1.2 to 1.2 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 000000 |

| 2,000 | -1.2 to 1.2 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 000000 |

| 2,500 | -2 to 2 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 000000 | 000000 |

| Lg., mm | Lg. Tolerance, mm | Straightness Tolerance | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Heat Treatment | Each | |

50 mm Dia. (Tolerance: -0.016 mm to 0 mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 500 | -0.8 to 0.8 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C52 | Case Hardened | 00000000 | 0000000 |

Linear Motion Shafts with Material Certification

For your compliance and quality assurance needs, these shafts come with a material certificate with a traceable lot number. These shafts work with linear bearings to reduce friction in manual and automated systems, such as packing, machine tool, and material handling operations. All are turned, ground, and polished to tight diameter and straightness tolerances. This allows them to evenly distribute loads, reduce vibration, and improve accuracy and stability.

Made from carbon steel, they’re strong and good for general purpose use. Their surface is hardened while the center remains soft enough to absorb stress from shifting loads. All have chamfered edges to remove sharp corners, reducing damage to bearings, housings, and other components during installation.

Surface smoothness—The lower the microinch value, the smoother the finish and the less friction and wear it will cause on the bearing.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Lg. | Length Tolerance | Straightness Tolerance | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Heat Treatment | Each | |

Metric—1060 Carbon Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

50mm Dia. (Tolerance: -0.015mm to 0mm) | |||||||||

| 152mm | 1.5mm to 3.2mm | 0.050 mm per 300 mm | 10 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 000000 |

| 305mm | 1.5mm to 3.2mm | 0.050 mm per 300 mm | 10 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 000000 |

| 914mm | 1.5mm to 3.2mm | 0.050 mm per 300 mm | 10 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 000000 |

| 1,829mm | 1.5mm to 3.2mm | 0.050 mm per 300 mm | 10 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 000000 |

Low-Carbon Steel Rods and Discs

- Yield Strength: See table

- Hardness: See table

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: See table

- Fabrication: See table

- Specifications Met: See table

Also known as mild steel, low-carbon steel is easy to machine, form, and weld. It's widely fabricated into low-strength fasteners, pins, and axles. You can surface harden this material for added wear resistance. All have been manufactured to meet ASTM standards for quality and performance.

Cold-worked rods and discs have a finished look and quality. The cold-working process gives the steel consistent strength, hardness, and dimensions throughout.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Dia., mm | Dia. Tolerance, mm | Yield Strength, psi | Fabrication | Hardness | Max. Hardness After Heat Treatment | Mechanical Finish | Specifications Met | 1 ft. Lg. | 3 ft. Lg. | 6 ft. Lg. | |

| 50 | -0.02 to 0 | 50,000 | Cold Worked | Rockwell B70 (Medium) | Not Rated | Ground, Polished, Turned | ASTM A108 | 00000000 | |||

| 50 | -0.07 to 0 | 60,000 | Cold Worked | Rockwell B70 (Medium) | Not Rated | __ | ASTM A108 | 0000000 |

Tight-Tolerance Ultra-Machinable 12L14 Carbon Steel Rods

- Yield Strength: 65,000 psi

- Hardness: Rockwell B80 (Medium)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Rockwell C65

- Fabrication: Cold Worked

- Specifications Met: ASTM A108

Ready for turning in a lathe, these rods are precision ground and held to a strict straightness tolerance. The lead additive acts as a lubricant, which allows 12L14 carbon steel to withstand very fast machining. It's used to fabricate a wide variety of machine parts, such as shaft couplings, studs, and pins. These rods meet ASTM A108 quality and performance standards. For added wear resistance, they can be surface hardened with heat treating.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Chrome-Plated Hardened Multipurpose 4140 Alloy Steel Rods

- Yield Strength: 100,000 psi

- Hardness: Rockwell C30 (Hard)

- Fabrication: Hot Rolled

A chrome plating on these rods increases their corrosion resistance. They're also hardened, which makes them more resistant to impacts and abrasion. Also known as chrome-moly steel, this versatile alloy steel is used for a wide range of parts, such as gears, axles, shafts, collets, and die holders. It resists fracturing from repeated stress.

Note: Rods may be made from either 4140 or 4142 alloy steel. They are interchangeable in most applications.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Tight-Tolerance Multipurpose 4140 Alloy Steel Rods

- Yield Strength: 60,000 psi

- Hardness: Rockwell B90 (Medium)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Rockwell C60

- Specifications Met: ASTM A108

Ready for turning in your lathe, these rods are precision ground and held to a strict straightness tolerance. Also known as chrome-moly steel, this versatile 4140 alloy steel is used for a wide range of parts, such as gears, axles, shafts, collets, and die holders. It resists fracturing from repeated stress.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

High-Strength Multipurpose 4140 Alloy Steel Rods

- Yield Strength: 130,000 psi

- Hardness: Rockwell C32 (Hard)

- Specifications Met: ASTM A108

Often called ETD-150, these rods are made from a modified version of 4140 alloy steel and have been drawn at high temperatures for excellent strength. Also known as chrome-moly steel, they are used for a wide range of parts, such as gears, axles, shafts, collets, and die holders. They resist fracturing from repeated stress.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Tight-Tolerance High-Strength 17-4 PH Stainless Steel

Each piece is precision ground to offer tighter tolerances than standard 17-4 PH stainless steel. With a higher chromium content than 15-5 PH stainless steel, this high-strength material offers better corrosion resistance. It's also known as 630 stainless steel. It maintains its corrosion resistance in temperatures up to 1100° F.

Rods are held to a strict diameter tolerance, so they’re ready for turning in your lathe.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength: 118,000 psi

- Hardness: See table

- Heat Treatment: Annealed (Softened)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Rockwell C47

- Specifications Met: ASTM A564

Hardened Tight-Tolerance Easy-to-Machine 416 Stainless Steel

Hardened for superior wear resistance, these rods are precision ground to a tight diameter tolerance so they’re ready for turning in a lathe. One of the most machinable types of stainless steel available, 416 contains sulfur for fast machining without clogging cutting tools. It's used for gears, screws, and shafts. It maintains its corrosion resistance in temperatures up to 1200° F.

Metric rods are also known as Project 70+.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength: 138,000 psi

- Hardness: Rockwell C30 (Hard)

- Heat Treatment: Hardened

- Specifications Met: ASTM A582

Tight-Tolerance Multipurpose 6061 Aluminum Rods and Discs

These rods and discs are precision ground to offer tighter tolerances than standard 6061 rods and discs. The most widely used aluminum, 6061 is fabricated into everything from pipe fittings and containers to automotive and aerospace parts. It is strong and corrosion resistant, plus it's easy to machine and weld.

Rods are held to a strict straightness tolerance, so they’re all set for turning in your lathe.

For technical drawings and 3-D models, click on a part number.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.