About Set Screws

More

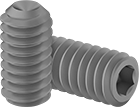

Alloy Steel Cup-Point Set Screws

Made from alloy steel, these set screws have a thin edge that digs into hard surfaces for a secure hold. Length listed is the overall length.

Black-oxide alloy steel set screws resist corrosion in dry environments.

For technical drawings and 3-D models, click on a part number.

| Lg. | Drive Size | Hardness | Specifications Met | Pkg. Qty. | Pkg. | |

Black-Oxide Alloy Steel | ||||||

|---|---|---|---|---|---|---|

4-48 | ||||||

| 3/32" | 0.050" | Rockwell C45 | ASME B18.3, ASTM F912 | 10 | 000000000 | 00000 |

| 1/8" | 0.050" | Rockwell C45 | ASME B18.3, ASTM F912 | 100 | 000000000 | 00000 |

| 3/16" | 0.050" | Rockwell C45 | ASME B18.3, ASTM F912 | 100 | 000000000 | 00000 |

| 1/4" | 0.050" | Rockwell C45 | ASME B18.3, ASTM F912 | 100 | 000000000 | 00000 |

| 5/16" | 0.050" | Rockwell C45 | ASME B18.3, ASTM F912 | 25 | 000000000 | 00000 |

| 3/8" | 0.050" | Rockwell C45 | ASME B18.3, ASTM F912 | 10 | 000000000 | 0000 |

| 1/2" | 0.050" | Rockwell C45 | ASME B18.3, ASTM F912 | 25 | 000000000 | 00000 |

| 5/8" | 0.050" | Rockwell C45 | ASME B18.3, ASTM F912 | 25 | 000000000 | 00000 |

18-8 Stainless Steel Cup-Point Set Screws

Made from 18-8 stainless steel, these set screws are chemical resistant and may be mildly magnetic. They have a thin edge that digs into the contact surface for a secure hold. Length listed is the overall length.

For technical drawings and 3-D models, click on a part number.

| Lg. | Drive Size | Hardness | Specifications Met | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | ||||||

|---|---|---|---|---|---|---|

4-48 | ||||||

| 1/16" | 0.050" | Rockwell B80 | ASME B18.3 | 25 | 000000000 | 00000 |

| 3/32" | 0.050" | Rockwell B80 | ASME B18.3 | 25 | 000000000 | 0000 |

| 1/8" | 0.050" | Rockwell B80 | ASME B18.3 | 25 | 000000000 | 0000 |

| 5/32" | 0.050" | Rockwell B80 | ASME B18.3 | 25 | 000000000 | 0000 |

| 3/16" | 0.050" | Rockwell B80 | ASME B18.3 | 25 | 000000000 | 0000 |

| 1/4" | 0.050" | Rockwell B80 | ASME B18.3 | 25 | 000000000 | 0000 |

| 5/16" | 0.050" | Rockwell B80 | ASME B18.3 | 25 | 000000000 | 0000 |

| 3/8" | 0.050" | Rockwell B80 | ASME B18.3 | 25 | 000000000 | 0000 |

| 7/16" | 0.050" | Rockwell B80 | ASME B18.3 | 25 | 000000000 | 0000 |

| 1/2" | 0.050" | Rockwell B80 | ASME B18.3 | 25 | 000000000 | 0000 |

| 5/8" | 0.050" | Rockwell B80 | ASME B18.3 | 10 | 000000000 | 0000 |

| 3/4" | 0.050" | Rockwell B80 | ASME B18.3 | 10 | 000000000 | 0000 |

| 1" | 0.050" | Rockwell B80 | ASME B18.3 | 10 | 000000000 | 0000 |

Alloy Steel Knurl-Grip Cup-Point Set Screws

Made from black-oxide alloy steel, these set screws resist corrosion in dry environments. They dig into hard surfaces for a secure hold and have serrations on the cup edge that grip the material surface to resist loosening. Length listed is the overall length.

For technical drawings and 3-D models, click on a part number.

| Lg. | Drive Size | Hardness | Specifications Met | Pkg. Qty. | Pkg. | |

Black-Oxide Alloy Steel | ||||||

|---|---|---|---|---|---|---|

4-48 | ||||||

| 1/8" | 0.050" | Rockwell C45 | ASME B18.3 | 50 | 000000000 | 000000 |

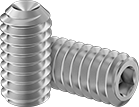

Alloy Steel Cone-Point Set Screws

These alloy steel set screws have a pointed tip that wedges into the contact surface for a secure hold on soft materials such as brass. Length listed is the overall length.

Black-oxide alloy steel set screws resist corrosion in dry environments.

For technical drawings and 3-D models, click on a part number.

| Lg. | Cone Point Angle | Drive Size | Hardness | Specifications Met | Pkg. Qty. | Pkg. | |

Black-Oxide Alloy Steel | |||||||

|---|---|---|---|---|---|---|---|

4-48 | |||||||

| 1/8" | 118° | 0.050" | Rockwell C45 | ASME B18.3, ASTM F912 | 25 | 000000000 | 000000 |

| 3/16" | 90° | 0.050" | Rockwell C45 | ASME B18.3, ASTM F912 | 25 | 000000000 | 00000 |

| 1/4" | 90° | 0.050" | Rockwell C45 | ASME B18.3, ASTM F912 | 10 | 000000000 | 0000 |

| 5/16" | 90° | 0.050" | Rockwell C45 | ASME B18.3, ASTM F912 | 10 | 000000000 | 0000 |

| 3/8" | 90° | 0.050" | Rockwell C45 | ASME B18.3, ASTM F912 | 10 | 000000000 | 0000 |

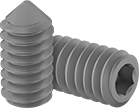

Alloy Steel Hollow-Lock Set Screws

Also known as jam set screws, these lock other screws in place, hold pins, and adjust spring tension. The hollow design allows you to inspect locked parts. A black-oxide finish provides corrosion resistance in dry environments. Length listed is the overall length.

For technical drawings and 3-D models, click on a part number.

| Lg. | Drive Size | Hardness | Pkg. Qty. | Pkg. | |

Black-Oxide Alloy Steel | |||||

|---|---|---|---|---|---|

4-48 | |||||

| 5/64" | 0.050" | Rockwell C45 | 25 | 000000000 | 000000 |

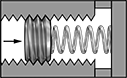

Slotted Ball-Nose Spring Plungers

Install these spring plungers with a screwdriver—they're slotted on one or both ends. The ball nose rolls to minimize wear and allow parts to move in and out of position.

Steel is strong and wear resistant.

440C stainless steel is hard, wear resistant, and mildly chemical resistant.

316 stainless steel is more corrosion resistant than 440C and 18-8 stainless steel and can be used in saltwater environments.

18-8 stainless steel is chemical resistant.

Brass is corrosion resistant in wet environments; brass noses are soft to minimize marring.

Plastic is chemical resistant and lightweight; nylon noses are extra soft to minimize marring soft surfaces such as aluminum.

Spring plungers without thread locker are for use in soft material such as aluminum, in extreme temperatures, and on parts requiring frequent assembly and removal.

Spring plungers with thread locker have a locking element that adds friction to resist loosening.

Extended nose force is the force required to begin to depress the nose. Compressed nose force is the force required to depress the nose flush with the body. When using a plunger as a detent or stop, a lighter nose force with a shallower hole releases more easily, while a heavier force with a deeper hole holds more securely.

For technical drawings and 3-D models, click on a part number.

Nose | Nose Force, lbs. | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Body Lg. | Extended Lg. | Dia. | Temp. Range, °F | Extended | Compressed | Choose a Locking Type | Each | |

Steel Body and 440C Stainless Steel Nose | |||||||||

| 4-48 | 0.187" | 0.02" | 0.062" | __ | 0.1 | 0.5 | 0000000 | 00000 | |

Steel Body and Nylon Plastic Nose | |||||||||

| 4-48 | 0.187" | 0.02" | 0.062" | -20° to 180° | 0.1 | 0.5 | 00000000 | 0000 | |

316 Stainless Steel Body and 316 Stainless Steel Nose | |||||||||

| 4-48 | 0.187" | 0.02" | 0.062" | __ | 0.1 | 0.5 | 0000000 | 00000 | |

18-8 Stainless Steel Body and 440C Stainless Steel Nose | |||||||||

| 4-48 | 0.187" | 0.02" | 0.062" | __ | 0.1 | 0.5 | 0000000 | 0000 | |

18-8 Stainless Steel Body and Nylon Plastic Nose | |||||||||

| 4-48 | 0.187" | 0.02" | 0.062" | -20° to 180° | 0.1 | 0.5 | 00000000 | 0000 | |

Brass Body and Brass Nose | |||||||||

| 4-48 | 0.187" | 0.02" | 0.062" | __ | 0.1 | 0.5 | 0000000 | 0000 | |