How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Thick-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 80 pipe. With thicker, stronger walls than standard-wall fittings, they can handle heavy duty supply applications, such as water processing, wastewater treatment, and irrigation. Fittings are plastic for good corrosion resistance. They meet ASTM specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

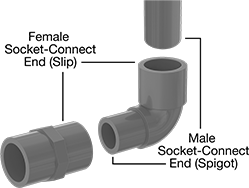

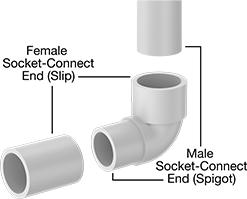

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a sealant to the male threads. For plastic threads, apply a non-hardening, plastic-compatible sealant sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections. Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 372, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Schedule 80 PVC Plastic

Saddle-tap tees allow you to create additional outlets and connections in metal or plastic pipe. To install, shut down your line and drill a hole in the pipe where you want to create a connection. Position the saddle over the hole so the gasket and lip are fully engaged and secure with the included nuts, bolts, and washers.

| Pipe Size | Socket Depth | For Pipe Size | For Pipe OD | For Hole Dia. | Material | Color | Max. Pressure | Each | |

| 1 | 5/16" | 2 | 2 3/8" | 1 1/8" | PVC Plastic | Dark Gray | 315 psi @ 72° F | 0000000 | 000000 |

| 2 | 11/16" | 6 | 6 5/8" | 2 1/4" | PVC Plastic | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

| 3 | 17/32" | 4 | 4 1/2" | 3" | PVC Plastic | Dark Gray | 185 psi @ 72° F | 0000000 | 000000 |

| 3 | 11/16" | 6 | 6 5/8" | 3" | PVC Plastic | Dark Gray | 185 psi @ 72° F | 0000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 Aluminum, Iron, PVC Plastic, Stainless Steel, Steel

- Flanges: Use Class 150 PVC Plastic

Fittings with stainless steel collar have a reinforcement on the female threads to prevent the threads from cracking.

Saddle-tap tees allow you to create additional outlets and connections in metal or plastic pipe. To install, shut down your line and drill a hole in the pipe where you want to create a connection. Position the saddle over the hole so the gasket and lip are fully engaged and secure with the included nuts, bolts, and washers.

| Pipe Size | For Pipe Size | For Pipe OD | For Hole Dia. | Material | Collar Material | Color | Max. Pressure | Each | |

NPT Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 2 | 2 3/8" | 3/4" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

| 1/2 | 3 | 3 1/2" | 7/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 00000 |

| 1/2 | 4 | 4 1/2" | 1 1/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

| 3/4 | 2 | 2 3/8" | 7/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 00000 |

| 3/4 | 3 | 3 1/2" | 7/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 00000 |

| 3/4 | 4 | 4 1/2" | 1 1/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

| 1 | 2 | 2 3/8" | 1 1/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 00000 |

| 1 | 3 | 3 1/2" | 1 1/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 00000 |

| 1 | 4 | 4 1/2" | 1 1/8" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

| 1 | 6 | 6 5/8" | 1 1/8" | PVC Plastic | Stainless Steel | Dark Gray | 315 psi @ 72° F | 0000000 | 000000 |

| 1 1/2 | 3 | 3 1/2" | 2 1/4" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 00000 |

| 1 1/2 | 4 | 4 1/2" | 1 3/4" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

| 2 | 3 | 3 1/2" | 2 1/4" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 00000 |

| 2 | 4 | 4 1/2" | 2 1/4" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

| 2 | 6 | 6 5/8" | 2 1/4" | PVC Plastic | Stainless Steel | Dark Gray | 200 psi @ 72° F | 0000000 | 000000 |

| 3 | 4 | 4 1/2" | 3" | PVC Plastic | Stainless Steel | Dark Gray | 185 psi @ 72° F | 0000000 | 000000 |

| 3 | 6 | 6 5/8" | 3" | PVC Plastic | Stainless Steel | Dark Gray | 185 psi @ 72° F | 0000000 | 000000 |

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a sealant to the male threads. Threaded connections can be taken apart as needed for maintenance and repair. For plastic threads, apply a non-hardening, plastic-compatible sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections. Fittings that meet ASTM D1784, ASTM D1785, and ASTM D4066 adhere to specifications and testing requirements for material quality.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: See table

- Pipe Nipples and Pipe:

Pipe Size 1/2 to 1: Use PVC Plastic

Pipe Size 1 1/2 to 3: Use Aluminum, Iron, PVC Plastic, Stainless Steel, Steel - Flanges: Use Class 150 PVC Plastic

Saddle-tap tee adapters allow you to create additional outlets and connections in metal or plastic pipe. To install, shut down your line and drill a hole in the pipe where you want to create a connection. Position the saddle over the hole so the gasket and lip are fully engaged and secure with the included nuts, bolts, and washers.

| Pipe Size | For Pipe Size | Socket Depth | For Pipe OD | For Hole Dia. | OD | ID | Wall Thick. | Material | Color | Max. Pressure | Specifications Met | Each | |

| 1/2 | 2 | 5/16" | 2 3/8" | 3/4" | 27/32" | 0.622" | 0.109" | PVC Plastic | White | 300 psi @ 72° F | ASTM D1784, NSF/ANSI 372, NSF/ANSI 61 | 0000000 | 000000 |

| 1/2 | 3 | 11/16" | 3 1/2" | 7/8" | 27/32" | 0.622" | 0.109" | PVC Plastic | White | 300 psi @ 72° F | ASTM D1784, NSF/ANSI 372, NSF/ANSI 61 | 0000000 | 00000 |

| 1/2 | 4 | 1" | 4 1/2" | 1 1/8" | 27/32" | 0.622" | 0.109" | PVC Plastic | White | 300 psi @ 72° F | ASTM D1784, NSF/ANSI 372, NSF/ANSI 61 | 0000000 | 00000 |

| 3/4 | 3 | 9/32" | 3 1/2" | 7/8" | 1 1/16" | 0.824" | 0.113" | PVC Plastic | White | 240 psi @ 72° F | ASTM D1784, NSF/ANSI 372, NSF/ANSI 61 | 0000000 | 00000 |

| 3/4 | 4 | 13/16" | 4 1/2" | 1 1/8" | 1 1/16" | 0.824" | 0.113" | PVC Plastic | White | 240 psi @ 72° F | ASTM D1784, NSF/ANSI 372, NSF/ANSI 61 | 0000000 | 000000 |

| 1 | 3 | 9/32" | 3 1/2" | 1 1/8" | 1 5/16" | 1.049" | 0.133" | PVC Plastic | White | 225 psi @ 72° F | ASTM D1784, NSF/ANSI 372, NSF/ANSI 61 | 0000000 | 00000 |

| 1 | 4 | 13/32" | 4 1/2" | 1 1/8" | 1 5/16" | 1.049" | 0.133" | PVC Plastic | White | 225 psi @ 72° F | ASTM D1784, NSF/ANSI 372, NSF/ANSI 61 | 0000000 | 000000 |

| 1 1/2 | 3 | 29/32" | 3 1/2" | 2 1/4" | 1 29/32" | 1.61" | 0.145" | PVC Plastic | White | 200 psi @ 72° F | ASTM D1784, NSF/ANSI 61 | 0000000 | 00000 |

| 1 1/2 | 4 | 1/2" | 4 1/2" | 1 3/4" | 1 29/32" | 1.61" | 0.145" | PVC Plastic | White | 200 psi @ 72° F | ASTM D1784, NSF/ANSI 61 | 0000000 | 000000 |

| 2 | 3 | 3/8" | 3 1/2" | 2 1/4" | 2 3/8" | 2.067" | 0.154" | PVC Plastic | White | 200 psi @ 72° F | ASTM D1784, NSF/ANSI 61 | 0000000 | 00000 |

| 2 | 4 | 7/16" | 4 1/2" | 2 1/4" | 2 3/8" | 2.067" | 0.154" | PVC Plastic | White | 200 psi @ 72° F | ASTM D1784, NSF/ANSI 61 | 0000000 | 000000 |

| 2 | 6 | 11/16" | 6 5/8" | 2 1/4" | 2 3/8" | 2.067" | 0.154" | PVC Plastic | White | 200 psi @ 72° F | ASTM D1784, NSF/ANSI 61 | 0000000 | 000000 |

| 3 | 4 | 1/2" | 4 1/2" | 3" | 3 1/2" | 3.068" | 0.216" | PVC Plastic | White | 200 psi @ 72° F | ASTM D1784, NSF/ANSI 61 | 0000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 372, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 Aluminum, Iron, PVC Plastic, Stainless Steel, Steel

- Flanges: Use Class 150 PVC Plastic

Fittings with stainless steel collar have a reinforcement on the female threads to prevent the threads from cracking.

Saddle-tap tee adapters allow you to create additional outlets and connections in metal or plastic pipe. To install, shut down your line and drill a hole in the pipe where you want to create a connection. Position the saddle over the hole so the gasket and lip are fully engaged and secure with the included nuts, bolts, and washers.

| Pipe Size | For Pipe Size | Socket Depth | For Pipe OD | For Hole Dia. | OD | ID | Wall Thick. | Material | Collar Material | Color | Max. Pressure | Each | |

NPT Threads | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 2 | 5/16" | 2 3/8" | 3/4" | 27/32" | 0.622" | 0.109" | PVC Plastic | Stainless Steel | White | 200 psi @ 72° F | 0000000 | 000000 |

| 1/2 | 3 | 13/16" | 3 1/2" | 7/8" | 27/32" | 0.622" | 0.109" | PVC Plastic | Stainless Steel | White | 300 psi @ 72° F | 0000000 | 000000 |

| 1/2 | 4 | 1 1/16" | 4 1/2" | 1 1/8" | 27/32" | 0.622" | 0.109" | PVC Plastic | Stainless Steel | White | 300 psi @ 72° F | 0000000 | 000000 |

| 3/4 | 2 | 5/16" | 2 3/8" | 7/8" | 1 3/64" | 0.824" | 0.113" | PVC Plastic | Stainless Steel | White | 200 psi @ 72° F | 0000000 | 00000 |

| 3/4 | 3 | 19/32" | 3 1/2" | 7/8" | 1 1/16" | 0.824" | 0.113" | PVC Plastic | Stainless Steel | White | 240 psi @ 72° F | 0000000 | 000000 |

| 3/4 | 4 | 27/32" | 4 1/2" | 1 1/8" | 1 3/64" | 0.824" | 0.113" | PVC Plastic | Stainless Steel | White | 200 psi @ 72° F | 0000000 | 000000 |

| 1 | 2 | 5/16" | 2 3/8" | 1 1/8" | 1 5/16" | 1.049" | 0.133" | PVC Plastic | Stainless Steel | White | 200 psi @ 72° F | 0000000 | 00000 |

| 1 | 3 | 17/32" | 3 1/2" | 1 1/8" | 1 5/16" | 1.049" | 0.133" | PVC Plastic | Stainless Steel | White | 225 psi @ 72° F | 0000000 | 000000 |

| 1 | 4 | 7/16" | 4 1/2" | 1 1/8" | 1 5/16" | 1.049" | 0.133" | PVC Plastic | Stainless Steel | White | 200 psi @ 72° F | 0000000 | 000000 |

| 1 1/2 | 3 | 1 3/16" | 3 1/2" | 2 1/4" | 1 29/32" | 1.61" | 0.145" | PVC Plastic | Stainless Steel | White | 165 psi @ 72° F | 0000000 | 000000 |

| 1 1/2 | 4 | 7/8" | 4 1/2" | 1 3/4" | 1 29/32" | 1.61" | 0.145" | PVC Plastic | Stainless Steel | White | 165 psi @ 72° F | 0000000 | 000000 |

| 2 | 4 | 1" | 4 1/2" | 2" | 2 3/8" | 2.067" | 0.154" | PVC Plastic | Stainless Steel | White | 140 psi @ 72° F | 0000000 | 000000 |

| 2 | 6 | 11/16" | 6 5/8" | 2 1/4" | 2 3/8" | 2.067" | 0.154" | PVC Plastic | Stainless Steel | White | 200 psi @ 72° F | 0000000 | 000000 |

| 3 | 4 | 1" | 4 1/2" | 3" | 3 1/2" | 3.068" | 0.216" | PVC Plastic | Stainless Steel | White | 130 psi @ 72° F | 0000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Tee outlets allow you to create additional outlets and connections in plastic pipe. Use a PVC primer and cement to secure the tee outlet into position, then drill a hole through the fitting and pipe. They are also known as branch connectors.

| Pipe Size | For Pipe Size | Material | Color | Specifications Met | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/8 | 1/2 | PVC Plastic | White | ASTM D1784, NSF/ANSI 61 | 00000000 | 00000 |

| 1/8 | 3/4 | PVC Plastic | White | ASTM D1784, NSF/ANSI 61 | 00000000 | 0000 |

| 1/2 | 1/2 | PVC Plastic | White | ASTM D1784, NSF/ANSI 61 | 00000000 | 0000 |

| 1/2 | 3/4 | PVC Plastic | White | ASTM D1784, NSF/ANSI 61 | 00000000 | 0000 |

| 1/2 | 1 | PVC Plastic | White | ASTM D1784, NSF/ANSI 61 | 00000000 | 0000 |

| 3/4 | 3/4 | PVC Plastic | White | ASTM D1784, NSF/ANSI 61 | 00000000 | 0000 |

| 3/4 | 1 | PVC Plastic | White | ASTM D1784, NSF/ANSI 61 | 00000000 | 0000 |

| 1 | 1 | PVC Plastic | White | ASTM D1784, NSF/ANSI 61 | 00000000 | 0000 |

Clamps for Easy-Access CPVC Pipe Fittings for Chemicals

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Hydrochloric Acid, Phosphoric Acid, Salt Water, Sodium Hydroxide, Sulfuric Acid (80%), Water

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D1784, ASTM F441

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

Use these clamps to connect easy-access CPVC pipe fittings and pipe. Clamps are enamel-coated iron for excellent strength and durability. They have a two-piece housing that can remain intact for installation. Clamps are also known as Victaulic clamps. They meet ASTM D1784 and ASTM F441 specifications and testing requirements for material quality.

For technical drawings and 3-D models, click on a part number.

Clamp connectors let you connect CPVC grooved-end pipe fittings and pipe.

Clamp adapters let you connect CPVC grooved-end pipe fittings and pipe to metal grooved-end pipe fittings and pipe.

Clamp reducers allow you to connect CPVC grooved-end pipe fittings and pipe and transition from a larger pipe size to a smaller pipe size.

| For Pipe Size | For Pipe OD | Material | Color | Gasket Material | Max. Pressure | Each | |

| 3 × 2 | 3 1/2" × 2 3/8" | Enamel-Coated Iron | Orange | EPDM Rubber | 300 psi @ 72° F | 0000000 | 000000 |

| 4 × 2 | 4 1/2" × 2 3/8" | Enamel-Coated Iron | Orange | EPDM Rubber | 300 psi @ 72° F | 0000000 | 000000 |

| 4 × 3 | 4 1/2" × 3 1/2" | Enamel-Coated Iron | Orange | EPDM Rubber | 300 psi @ 72° F | 0000000 | 000000 |

Clamps for Easy-Access UV-Resistant

Polypropylene Pipe Fittings for Chemicals

Use these clamps to connect easy-access UV-resistant polypropylene pipe fittings to pipe. The clamp-together design allows you to access your line for routine maintenance. Clamps are 302 stainless steel for very good chemical and corrosion resistance.

Low-Pressure Clamp-On Connectors for Drain, Waste, and Vent

To make installing and maintaining systems easy, these connectors come with clamps that form a strong seal on pipe and fittings once tightened.

Saddle-tap adapters allow you to tap into an existing pipeline. They have wraparound clamps that provide nearly 360° contact with pipe; as the clamps are tightened, pressure is uniformly distributed around the pipe for maximum support. To install, shut down your line and drill a hole in the pipe where you want to create a connection. Position the saddle over the hole and tighten the clamps.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water

- Temperature Range: 0° to 110° F

- For Pipe Material: PVC Plastic

- For Use With: Air, Water

- Temperature Range: 0° to 110° F

- For Pipe Material: PVC Plastic