About Gears

More

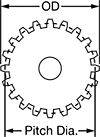

Metal Worms and Worm Gears

Worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle. They transmit motion from worm to gear and cannot be reversed. For gears and worms to mesh correctly, they must have the same pressure angle, pitch/module, number of thread starts, and thread direction. These worms are compatible with plastic worm gears.

Speed ratio is the ratio by which output shaft speed is reduced. As speed decreases, torque increases.

1045 carbon steel worms have rolled threads. Hardened 1045 carbon steel worms have ground threads, which are more durable and precise than rolled threads.

303 stainless steel worms won’t rust in wet environments, so they’re commonly used in food-processing plants and other areas with frequent cleaning.

4140 alloy steel worms are already mounted on a shaft, so they’re ready to use with no machining required. The threads are ground into the shaft for higher precision than rolled threads, and hardened for additional durability and precision.

Cast iron gears are strong and durable.

Bronze gears have low friction and dissipate heat better than cast iron gears to provide a long service life for both the gear and the worm. They’re also more corrosion resistant than cast iron gears.

For technical drawings and 3-D models, click on a part number.

Keyway | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gear Pitch | Pressure Angle | Worm Length | Gear Pitch Dia. | OD | For Shaft Dia. | Number of Thread Starts | Wd. | Dp. | Thread Direction | Teeth Heat Treatment | Teeth Fabrication | Each | |

Keyed Bore—1144 Carbon Steel | |||||||||||||

| 12 | 14 1/2° | 1 1/8" | 1" | 1.17" | 1/2" | 1 | 0.125" | 0.063" | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 14 1/2° | 1 3/8" | 1 1/4" | 1.45" | 5/8" | 1 | 0.188" | 0.094" | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 8 | 14 1/2° | 1 3/4" | 1 1/2" | 1.75" | 3/4" | 1 | 0.188" | 0.094" | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 6 | 14 1/2° | 2 1/2" | 2" | 2.33" | 7/8" | 1 | 0.188" | 0.094" | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

Hub | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Pressure Angle | Worm Lg., mm | Gear Pitch Dia., mm | OD, mm | For Shaft Dia., mm | Number of Thread Starts | Dia., mm | Material | Thread Direction | Teeth Heat Treatment | Teeth Fabrication | Set Screw Included | Each | |

Round Bore—Black-Oxide 1045 Carbon Steel | ||||||||||||||

| 0.5 | 20° | 18 | 11 | 12 | 5 | 1 | __ | __ | Right Hand | Not Hardened | Not Ground | Yes | 000000000 | 000000 |

| 0.5 | 20° | 18 | 11 | 12 | 5 | 2 | __ | __ | Right Hand | Not Hardened | Not Ground | Yes | 000000000 | 00000 |

| 0.8 | 20° | 30 | 14 | 15.6 | 6 | 1 | __ | __ | Right Hand | Not Hardened | Not Ground | Yes | 000000000 | 00000 |

| 0.8 | 20° | 30 | 14 | 15.6 | 6 | 2 | __ | __ | Right Hand | Not Hardened | Not Ground | Yes | 000000000 | 00000 |

| 1 | 20° | 32 | 16 | 18 | 6 | 1 | __ | __ | Right Hand | Not Hardened | Not Ground | Yes | 000000000 | 00000 |

| 1 | 20° | 32 | 16 | 18 | 6 | 2 | __ | __ | Right Hand | Not Hardened | Not Ground | Yes | 000000000 | 00000 |

| 1 | 20° | 32 | 16 | 18 | 8 | 1 | __ | __ | Right Hand | Hardened | Ground | Yes | 000000000 | 00000 |

| 1.25 | 20° | 37 | 21 | 23.5 | 8 | 1 | __ | __ | Right Hand | Not Hardened | Not Ground | Yes | 000000000 | 00000 |

| 1.5 | 20° | 40 | 25 | 28 | 8 | 1 | 20 | 1045 Carbon Steel | Right Hand | Not Hardened | Not Ground | No | 000000000 | 00000 |

| 1.5 | 20° | 40 | 25 | 28 | 8 | 2 | 20 | 1045 Carbon Steel | Right Hand | Not Hardened | Not Ground | No | 000000000 | 00000 |

| 1.5 | 20° | 40 | 25 | 28 | 10 | 1 | 20 | 1045 Carbon Steel | Right Hand | Hardened | Ground | No | 000000000 | 00000 |

| 2 | 14 1/2° | 46 | 31 | 35 | 12 | 1 | 25 | 1045 Carbon Steel | Left Hand | Not Hardened | Not Ground | No | 000000000 | 00000 |

| 2 | 14 1/2° | 46 | 31 | 35 | 12 | 1 | 25 | 1045 Carbon Steel | Right Hand | Not Hardened | Not Ground | No | 000000000 | 00000 |

| 2 | 14 1/2° | 46 | 31 | 35 | 12 | 2 | 25 | 1045 Carbon Steel | Right Hand | Not Hardened | Not Ground | No | 000000000 | 00000 |

| 2.5 | 20° | 63 | 37 | 42 | 15 | 2 | 30 | 1045 Carbon Steel | Right Hand | Not Hardened | Not Ground | No | 000000000 | 00000 |

Round Bore—303 Stainless Steel | ||||||||||||||

| 0.5 | 20° | 18 | 11 | 12 | 5 | 1 | __ | __ | Right Hand | Not Hardened | Not Ground | Yes | 000000000 | 00000 |

| 0.5 | 20° | 18 | 11 | 12 | 5 | 2 | __ | __ | Right Hand | Not Hardened | Not Ground | Yes | 000000000 | 00000 |

| 0.8 | 20° | 30 | 14 | 15.6 | 6 | 1 | __ | __ | Right Hand | Not Hardened | Not Ground | Yes | 000000000 | 00000 |

| 1 | 20° | 32 | 16 | 18 | 6 | 1 | __ | __ | Right Hand | Not Hardened | Not Ground | Yes | 000000000 | 00000 |

| 1 | 20° | 32 | 16 | 18 | 6 | 2 | __ | __ | Right Hand | Not Hardened | Not Ground | Yes | 000000000 | 00000 |

| 1.5 | 20° | 40 | 25 | 28 | 8 | 2 | 20 | 303 Stainless Steel | Right Hand | Not Hardened | Not Ground | No | 000000000 | 00000 |

Shaft | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Pressure Angle | Worm Lg., mm | Gear Pitch Dia., mm | OD, mm | Dia., mm | Lg., mm | Number of Thread Starts | Thread Direction | Teeth Heat Treatment | Teeth Fabrication | Each | |

4140 Alloy Steel | ||||||||||||

| 0.5 | 20° | 12 | 9 | 10 | 6 | 65 | 1 | Right Hand | Hardened | Ground | 000000000 | 000000 |

| 0.5 | 20° | 12 | 9 | 10 | 6 | 65 | 2 | Right Hand | Hardened | Ground | 000000000 | 00000 |

| 0.8 | 20° | 20 | 12 | 14 | 8 | 85 | 1 | Right Hand | Hardened | Ground | 000000000 | 00000 |

| 0.8 | 20° | 20 | 12 | 14 | 8 | 85 | 2 | Right Hand | Hardened | Ground | 000000000 | 00000 |

| 1 | 20° | 30 | 16 | 18 | 18 | 140 | 1 | Right Hand | Hardened | Ground | 000000000 | 000000 |

| 1.5 | 20° | 40 | 25 | 28 | 26 | 190 | 1 | Right Hand | Hardened | Ground | 000000000 | 000000 |

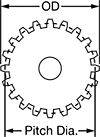

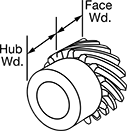

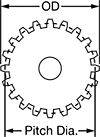

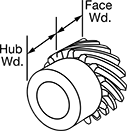

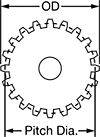

Hub | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gear Pitch | Speed Ratio | Number of Teeth | Pressure Angle | Gear Pitch Dia. | For Number of Thread Starts | OD | Face Wd. | Overall Wd. | For Shaft Dia. | Dia. | Wd. | Material | For Thread Direction | Teeth Heat Treatment | Teeth Fabrication | Each | |

Round Bore—Cast Iron | |||||||||||||||||

| 12 | 18:1 | 18 | 14 1/2° | 1 1/2" | 1 | 1.69" | 1/2" | 1.125" | 1/2" | 1.25" | 0.625" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 12 | 20:1 | 20 | 14 1/2° | 1.67" | 1 | 1.85" | 1/2" | 1.125" | 1/2" | 1.25" | 0.625" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 12 | 30:1 | 30 | 14 1/2° | 2 1/2" | 1 | 2.69" | 1/2" | 1.125" | 1/2" | 1.25" | 0.625" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 12 | 40:1 | 40 | 14 1/2° | 3.33" | 1 | 3.52" | 1/2" | 1.25" | 5/8" | 1.5" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 12 | 60:1 | 60 | 14 1/2° | 5" | 1 | 5.19" | 1/2" | 1.25" | 5/8" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 20:1 | 20 | 14 1/2° | 2" | 1 | 2.22" | 5/8" | 1.375" | 1/2" | 1.25" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 30:1 | 30 | 14 1/2° | 3" | 1 | 3.22" | 5/8" | 1.375" | 5/8" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 40:1 | 40 | 14 1/2° | 4" | 1 | 4.22" | 5/8" | 1.375" | 5/8" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 50:1 | 50 | 14 1/2° | 5" | 1 | 5.22" | 5/8" | 1.375" | 3/4" | 2" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 100:1 | 100 | 14 1/2° | 10" | 1 | 10.22" | 5/8" | 1.375" | 3/4" | 2.5" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 8 | 20:1 | 20 | 14 1/2° | 2 1/2" | 1 | 2.78" | 3/4" | 1.5" | 3/4" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 8 | 30:1 | 30 | 14 1/2° | 3 3/4" | 1 | 4.03" | 3/4" | 1.5" | 3/4" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 8 | 40:1 | 40 | 14 1/2° | 5" | 1 | 5.28" | 3/4" | 1.625" | 1" | 2.375" | 0.875" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 6 | 20:1 | 20 | 14 1/2° | 3.33" | 1 | 3.71" | 1" | 1.875" | 3/4" | 1.875" | 0.875" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 6 | 24:1 | 24 | 14 1/2° | 4" | 1 | 4.37" | 1" | 1.875" | 3/4" | 1.875" | 0.875" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 6 | 30:1 | 30 | 14 1/2° | 5" | 1 | 5.37" | 1" | 1.875" | 7/8" | 2.25" | 0.875" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 6 | 40:1 | 40 | 14 1/2° | 6.67" | 1 | 7.04" | 1" | 1.875" | 1" | 2.5" | 0.875" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 6 | 72:1 | 72 | 14 1/2° | 12" | 1 | 12.37" | 1" | 2.25" | 1 1/4" | 3" | 1.25" | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

Round Bore—Bronze | |||||||||||||||||

| 12 | 20:1 | 20 | 14 1/2° | 1.67" | 1 | 1.87" | 1/2" | 1" | 1/2" | 1.25" | 0.5" | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 12 | 30:1 | 30 | 14 1/2° | 2 1/2" | 1 | 2.7" | 1/2" | 1.12" | 1/2" | 1.19" | 0.62" | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 12 | 40:1 | 40 | 14 1/2° | 3.33" | 1 | 3.54" | 1/2" | 1.12" | 5/8" | 1.44" | 0.62" | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 20:1 | 20 | 14 1/2° | 2" | 1 | 2.24" | 5/8" | 1.245" | 1/2" | 1.25" | 0.62" | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 30:1 | 30 | 14 1/2° | 3" | 1 | 3.24" | 5/8" | 1.245" | 5/8" | 1.69" | 0.62" | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 40:1 | 40 | 14 1/2° | 4" | 1 | 4.24" | 5/8" | 1.245" | 5/8" | 1.69" | 0.62" | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 10 | 50:1 | 50 | 14 1/2° | 5" | 1 | 5.24" | 5/8" | 1.375" | 3/4" | 1.94" | 0.75" | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

Hub | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Speed Ratio | Number of Teeth | Pressure Angle | Gear Pitch Dia., mm | For Number of Thread Starts | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Dia., mm | Wd., mm | Material | For Thread Direction | Teeth Heat Treatment | Teeth Fabrication | Each | |

Round Bore—Cast Iron | |||||||||||||||||

| 1 | 120:1 | 120 | 20° | 120 | 1 | 123 | 10 | 20 | 10 | 40 | 10 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 000000 |

| 1 | 60:1 | 60 | 20° | 60 | 1 | 63 | 10 | 20 | 10 | 30 | 10 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1 | 100:1 | 100 | 20° | 100 | 1 | 103 | 10 | 20 | 10 | 40 | 10 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1 | 80:1 | 80 | 20° | 80 | 1 | 83 | 10 | 20 | 10 | 35 | 10 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1.5 | 30:1 | 30 | 20° | 45 | 1 | 49.5 | 12 | 22 | 10 | 30 | 10 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1.5 | 40:1 | 40 | 20° | 60 | 1 | 64.5 | 12 | 22 | 12 | 30 | 10 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 2 | 20:1 | 20 | 14 1/2° | 40 | 1 | 46 | 22 | 35 | 12 | 33 | 13 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 2 | 10:1 | 20 | 14 1/2° | 40 | 2 | 46 | 22 | 35 | 12 | 33 | 13 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 2.5 | 10:1 | 20 | 20° | 50 | 2 | 57.5 | 22 | 36 | 12 | 35 | 14 | Cast Iron | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

Round Bore—Bronze | |||||||||||||||||

| 0.5 | 15:1 | 30 | 20° | 15 | 2 | 16 | 5 | 12 | 4 | 12 | 7 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.5 | 20:1 | 20 | 20° | 10 | 1 | 11 | 5 | 12 | 4 | 9 | 7 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.5 | 30:1 | 30 | 20° | 15 | 1 | 16 | 5 | 12 | 4 | 12 | 7 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.5 | 40:1 | 40 | 20° | 20 | 1 | 21 | 5 | 12 | 5 | 15 | 7 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.5 | 50:1 | 50 | 20° | 25 | 1 | 26 | 5 | 12 | 5 | 20 | 7 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.5 | 60:1 | 60 | 20° | 30 | 1 | 31 | 5 | 12 | 5 | 25 | 7 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.5 | 10:1 | 20 | 20° | 10 | 2 | 11 | 5 | 12 | 4 | 9 | 7 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.8 | 20:1 | 20 | 20° | 16 | 1 | 17.6 | 9 | 18 | 5 | 12 | 9 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.8 | 30:1 | 30 | 20° | 24 | 1 | 25.6 | 9 | 18 | 5 | 18 | 9 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.8 | 40:1 | 40 | 20° | 32 | 1 | 33.6 | 9 | 18 | 6 | 20 | 9 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 0.8 | 10:1 | 20 | 20° | 16 | 2 | 17.6 | 9 | 18 | 5 | 12 | 9 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1 | 30:1 | 30 | 20° | 30 | 1 | 33 | 10 | 20 | 6 | 20 | 10 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1 | 10:1 | 20 | 20° | 20 | 2 | 23 | 10 | 20 | 6 | 16 | 10 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1.25 | 20:1 | 20 | 20° | 25 | 1 | 28.75 | 10 | 20 | 6 | 20 | 10 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1.5 | 15:1 | 30 | 20° | 45 | 2 | 49.5 | 12 | 22 | 10 | 30 | 10 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1.5 | 20:1 | 20 | 20° | 30 | 1 | 34.5 | 12 | 22 | 8 | 22 | 10 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1.5 | 30:1 | 30 | 20° | 45 | 1 | 49.5 | 12 | 22 | 10 | 30 | 10 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

| 1.5 | 10:1 | 20 | 20° | 30 | 2 | 34.5 | 12 | 22 | 8 | 22 | 10 | Bronze | Right Hand | Not Hardened | Not Ground | 000000000 | 00000 |

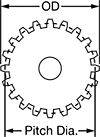

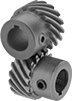

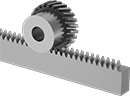

High-Power Metal Gears

and Crossed Left-Hand

Gear (Sold Separately)

Right-Hand Teeth

(Sold Separately)

The helical teeth on these gears stay in contact for longer than straight teeth, which allows them to transmit higher loads at higher speeds than spur gears.

For gears to mesh correctly, they must have the same pressure angle and pitch. All of these gears transmit motion in a straight line—make sure to get one left-hand and one right-hand gear. To change speed and torque in your assembly, pair two gears with different numbers of teeth.

Parallel helical components have a 21 1/2° helix angle so they only transmit motion in a straight line since the helix angle is so small. Made from alloy steel, these gears resist abrasion and are stronger than carbon steel gears. Their teeth are ground, so they're more precise than gears with rolled teeth. Pair them with a rack or a gear that has a different tooth direction.

Crossed helical gears, also known as screw gears, can be configured to transmit motion at a 90° angle. To transmit motion at a 90° angle, pair two gears with the same tooth direction. To avoid wearing down gears, which happens when you use the same material, we recommend mating gears with different materials. Made from carbon steel, these gears are strong, but not as strong as alloy steel gears.

Gears with hardened teeth have better wear resistance than gears with teeth that are not hardened.

For technical drawings and 3-D models, click on a part number.

Hub | Keyway | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gear Pitch | Number of Teeth | Helix Angle | Gear Pitch Dia. | OD | Face Wd. | Overall Wd. | For Shaft Dia. | Teeth Heat Treatment | Dia. | Wd. | Wd. | Dp. | Set Screw Thread Size | Each | |

Left Hand | |||||||||||||||

Keyed Bore with Set Screw—1137 Carbon Steel | |||||||||||||||

| 16 | 16 | 45° | 1" | 1.09" | 1/2" | 1" | 1/2" | Hardened | 0.86" | 0.5" | 0.125" | 0.062" | 1/4"-20 | 0000000 | 000000 |

| 16 | 24 | 45° | 1 1/2" | 1.59" | 1/2" | 1" | 5/8" | Hardened | 1.37" | 0.5" | 0.187" | 0.094" | 1/4"-20 | 0000000 | 000000 |

| 16 | 32 | 45° | 2" | 2.09" | 1/2" | 1" | 5/8" | Hardened | 1.87" | 0.5" | 0.187" | 0.094" | 1/4"-20 | 0000000 | 000000 |

| 16 | 48 | 45° | 3" | 3.09" | 1/2" | 1" | 5/8" | Hardened | 2.5" | 0.5" | 0.187" | 0.094" | 1/4"-20 | 0000000 | 000000 |

| 12 | 18 | 45° | 1 1/2" | 1.62" | 3/4" | 1.25" | 5/8" | Hardened | 1.34" | 0.5" | 0.187" | 0.094" | 1/4"-20 | 0000000 | 000000 |

Right Hand | |||||||||||||||

Keyed Bore with Set Screw—1137 Carbon Steel | |||||||||||||||

| 16 | 16 | 45° | 1" | 1.09" | 1/2" | 1" | 1/2" | Hardened | 0.86" | 0.5" | 0.125" | 0.062" | 1/4"-20 | 0000000 | 00000 |

| 16 | 24 | 45° | 1 1/2" | 1.59" | 1/2" | 1" | 5/8" | Hardened | 1.37" | 0.5" | 0.187" | 0.094" | 1/4"-20 | 0000000 | 000000 |

| 16 | 32 | 45° | 2" | 2.09" | 1/2" | 1" | 5/8" | Hardened | 1.87" | 0.5" | 0.187" | 0.094" | 1/4"-20 | 0000000 | 000000 |

| 16 | 48 | 45° | 3" | 3.09" | 1/2" | 1" | 5/8" | Hardened | 2.5" | 0.5" | 0.187" | 0.094" | 1/4"-20 | 0000000 | 000000 |

| 12 | 18 | 45° | 1 1/2" | 1.62" | 3/4" | 1.25" | 5/8" | Hardened | 1.34" | 0.5" | 0.187" | 0.094" | 1/4"-20 | 0000000 | 000000 |

Hub | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Number of Teeth | Helix Angle | Gear Pitch Dia., mm | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Teeth Heat Treatment | Dia., mm | Wd., mm | Each | |

Left Hand | ||||||||||||

Round Bore—4140 Alloy Steel | ||||||||||||

| 1 | 20 | 21 1/2° | 20 | 22 | 8 | 18 | 6 | Hardened | 17 | 10 | 00000000 | 000000 |

| 1 | 30 | 21 1/2° | 30 | 32 | 8 | 18 | 10 | Hardened | 25 | 10 | 00000000 | 000000 |

| 1 | 44 | 21 1/2° | 44 | 46 | 8 | 18 | 10 | Hardened | 30 | 10 | 00000000 | 000000 |

Right Hand | ||||||||||||

Round Bore—4140 Alloy Steel | ||||||||||||

| 1 | 20 | 21 1/2° | 20 | 22 | 8 | 18 | 6 | Hardened | 17 | 10 | 00000000 | 00000 |

| 1 | 30 | 21 1/2° | 30 | 32 | 8 | 18 | 10 | Hardened | 25 | 10 | 00000000 | 000000 |

| 1 | 44 | 21 1/2° | 44 | 46 | 8 | 18 | 10 | Hardened | 30 | 10 | 00000000 | 000000 |

Hub | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Number of Teeth | Helix Angle | Gear Pitch Dia., mm | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Teeth Heat Treatment | Dia., mm | Wd., mm | Each | |

Left Hand | ||||||||||||

Round Bore—Black-Oxide 1045 Carbon Steel | ||||||||||||

| 1 | 13 | 45° | 18 | 20.38 | 10 | 20 | 6 | Not Hardened | 15 | 10 | 00000000 | 000000 |

| 1 | 26 | 45° | 36 | 38.77 | 10 | 20 | 10 | Not Hardened | 30 | 10 | 00000000 | 00000 |

| 1 | 30 | 45° | 42 | 44.43 | 10 | 20 | 10 | Not Hardened | 35 | 10 | 00000000 | 00000 |

| 1.5 | 10 | 45° | 21 | 24.21 | 15 | 25 | 8 | Not Hardened | 16 | 10 | 00000000 | 00000 |

| 1.5 | 13 | 45° | 27 | 30.58 | 15 | 25 | 10 | Not Hardened | 23 | 10 | 00000000 | 00000 |

| 1.5 | 26 | 45° | 55 | 58.15 | 15 | 25 | 12 | Not Hardened | 40 | 10 | 00000000 | 00000 |

Right Hand | ||||||||||||

Round Bore—Black-Oxide 1045 Carbon Steel | ||||||||||||

| 1 | 13 | 45° | 18 | 20.38 | 10 | 20 | 6 | Not Hardened | 15 | 10 | 00000000 | 00000 |

| 1 | 26 | 45° | 36 | 38.77 | 10 | 20 | 10 | Not Hardened | 30 | 10 | 00000000 | 00000 |

| 1 | 30 | 45° | 42 | 44.43 | 10 | 20 | 10 | Not Hardened | 35 | 10 | 00000000 | 00000 |

| 1.5 | 10 | 45° | 21 | 24.21 | 15 | 25 | 8 | Not Hardened | 16 | 10 | 00000000 | 00000 |

| 1.5 | 13 | 45° | 27 | 30.58 | 15 | 25 | 10 | Not Hardened | 23 | 10 | 00000000 | 00000 |

| 1.5 | 26 | 45° | 55 | 58.15 | 15 | 25 | 12 | Not Hardened | 40 | 10 | 00000000 | 00000 |

Plastic Worm Gears

These plastic gears are lighter and quieter than metal gears—pair them with metal worms for lubrication-free operation. Worm gears use screw threads to make large reductions to shaft speed while transmitting motion at a right angle. They transmit motion from worm to gear and cannot be reversed. For gears and worms to mesh correctly, they must have the same pressure angle, pitch/module, number of thread starts, and thread direction.

Speed ratio is the ratio by which output shaft speed is reduced. As speed decreases, torque increases.

Acetal gears are lightweight, and resist corrosion and chemicals. They absorb less moisture than nylon gears, so they’re less prone to dimensional changes. They’re best suited for light duty applications, such as prototyping.

Nylon gears are lightweight and stronger than acetal gears.

For technical drawings and 3-D models, click on a part number.

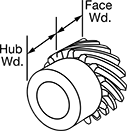

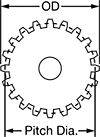

Hub | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Speed Ratio | Number of Teeth | Pressure Angle | Gear Pitch Dia., mm | For Number of Thread Starts | OD, mm | Face Width, mm | Overall Width, mm | For Shaft Diameter, mm | Material | Fabrication | Color | Diameter, mm | Width, mm | For Thread Direction | Each | |

Round Bore | |||||||||||||||||

| 0.5 | 10:1 | 20 | 20° | 10 | 2 | 11 | 5 | 12 | 4 | Acetal Plastic | Molded | White | 9 | 7 | Right Hand | 00000000 | 000000 |

| 0.5 | 20:1 | 20 | 20° | 10 | 1 | 11 | 5 | 12 | 4 | Acetal Plastic | Molded | White | 9 | 7 | Right Hand | 00000000 | 00000 |

| 0.5 | 30:1 | 30 | 20° | 15 | 1 | 16 | 5 | 12 | 4 | Acetal Plastic | Molded | White | 12 | 7 | Right Hand | 00000000 | 00000 |

| 0.5 | 40:1 | 40 | 20° | 20 | 1 | 21 | 5 | 12 | 5 | Acetal Plastic | Molded | White | 15 | 7 | Right Hand | 00000000 | 00000 |

| 0.5 | 50:1 | 50 | 20° | 25 | 1 | 26 | 5 | 12 | 5 | Acetal Plastic | Molded | White | 20 | 7 | Right Hand | 00000000 | 00000 |

| 0.5 | 60:1 | 60 | 20° | 30 | 1 | 31 | 5 | 12 | 5 | Acetal Plastic | Molded | White | 25 | 7 | Right Hand | 00000000 | 00000 |

| 0.8 | 10:1 | 20 | 20° | 16 | 2 | 17.6 | 9 | 18 | 5 | Acetal Plastic | Molded | White | 12 | 9 | Right Hand | 00000000 | 00000 |

| 0.8 | 50:1 | 50 | 20° | 40 | 1 | 41.6 | 9 | 18 | 8 | Acetal Plastic | Molded | White | 25 | 9 | Right Hand | 00000000 | 00000 |

| 0.8 | 60:1 | 60 | 20° | 48 | 1 | 49.6 | 9 | 18 | 8 | Acetal Plastic | Molded | White | 25 | 9 | Right Hand | 00000000 | 00000 |

| 1 | 10:1 | 20 | 20° | 20 | 2 | 23 | 10 | 20 | 6 | Nylon Plastic | Molded | Blue | 16 | 10 | Right Hand | 00000000 | 00000 |

| 1 | 30:1 | 30 | 20° | 30 | 1 | 33 | 10 | 20 | 6 | Nylon Plastic | Molded | Blue | 20 | 10 | Right Hand | 00000000 | 00000 |

| 1 | 50:1 | 50 | 20° | 50 | 1 | 53 | 10 | 20 | 8 | Nylon Plastic | Molded | Blue | 30 | 10 | Right Hand | 00000000 | 00000 |

| 1.5 | 10:1 | 20 | 20° | 30 | 2 | 34.5 | 12 | 22 | 8 | Nylon Plastic | Molded | Blue | 22 | 10 | Right Hand | 00000000 | 00000 |