About Composites

More

About Plastic

More

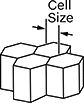

Corrosion-Resistant 3000 Series Aluminum Honeycomb Panels

- Yield Strength: Not Rated

- Hardness: Not Rated

- Temper: Not Rated

A honeycomb core is bonded between two aluminum sheets for rigidity. These panels offer a higher strength-to-weight ratio than solid sheets, so they're often used as a lightweight alternative to solid aluminum. They're also used for sound insulation. They are painted white and covered with a protective peel-off film. 3000 series aluminum stands up to outdoor use, as well as exposure to chemicals. It offers a good combination of strength, formability, and weldability.

| Thick. | Thick. Tolerance | Honeycomb Cell Size | Max. Load Capacity, lbs. | Deflection @ lb. Load | Cell Wall Thick. | Face Thick. | Temperature Range, °F | Each | |

12" × 12" | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/8" | -0.020" to 0.020" | 3/8" | 250 | 0.1" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 00000000 | 000000 |

| 1/4" | -0.020" to 0.020" | 3/8" | 525 | 0.02" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 00000000 | 00000 |

| 3/8" | -0.020" to 0.020" | 1/4" | 825 | 0.01" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 00000 |

| 1/2" | -0.020" to 0.020" | 1/4" | 1,125 | 0.01" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 00000 |

| 3/4" | -0.020" to 0.020" | 1/4" | 1,725 | 0.005" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 00000 |

| 1" | -0.020" to 0.020" | 3/4" | 2,125 | 0.005" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 00000 |

24" × 24" | |||||||||

| 1/8" | -0.020" to 0.020" | 3/8" | 250 | 0.4" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 00000000 | 000000 |

| 1/4" | -0.020" to 0.020" | 3/8" | 525 | 0.1" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 00000000 | 000000 |

| 3/8" | -0.020" to 0.020" | 1/4" | 825 | 0.04" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

| 1/2" | -0.020" to 0.020" | 1/4" | 1,125 | 0.02" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

| 3/4" | -0.020" to 0.020" | 1/4" | 1,725 | 0.01" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

| 1" | -0.020" to 0.020" | 3/4" | 2,125 | 0.01" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

24" × 48" | |||||||||

| 1/8" | -0.020" to 0.020" | 3/8" | 125 | 2.8" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 00000000 | 000000 |

| 1/4" | -0.020" to 0.020" | 3/8" | 250 | 0.7" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 00000000 | 000000 |

| 3/8" | -0.020" to 0.020" | 1/4" | 400 | 0.3" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

| 1/2" | -0.020" to 0.020" | 1/4" | 550 | 0.2" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

| 3/4" | -0.020" to 0.020" | 1/4" | 850 | 0.1" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

| 1" | -0.020" to 0.020" | 3/4" | 1,125 | 0.04" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

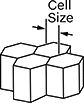

Composite Fiber Aluminum Honeycomb Panels

- Yield Strength: Not Rated

- Hardness: Not Rated

- Temper: Not Rated

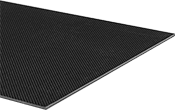

An aluminum honeycomb core sandwiched between carbon fiber keeps these sheets strong yet lightweight. The carbon fiber facing gives you the same strength as a honeycomb panel that's entirely made from aluminum but without the weight. Compared to aramid honeycomb panels, these panels have better shear strength. These panels are often used in the automotive and aerospace industry in place of solid aluminum sheets thanks to their high strength-to-weight ratio.

For technical drawings and 3-D models, click on a part number.

| Thick. | Thick. Tolerance | Honeycomb Cell Size | Face Thick. | Temperature Range, °F | Each | |

12" × 12" | ||||||

|---|---|---|---|---|---|---|

| 1/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 0000000 |

| 1/2" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 3/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 1" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

24" × 24" | ||||||

| 1/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 1/2" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 3/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 1" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

24" × 48" | ||||||

| 1/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 00000000 |

| 1/2" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 00000000 |

| 3/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 00000000 |

| 1" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 00000000 |

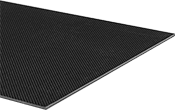

Composite Fiber Aramid Honeycomb Panels

- Face Color: Black

- Temperature Range: -100° to 250° F

- Yield Strength: Not Rated

- For Use Outdoors: No

With an aramid honeycomb core sandwiched between carbon fiber or fiberglass for rigidity, these panels are strong, but lightweight, and won’t conduct heat. Often used as wall panels in structural and insulating applications, they’re a lightweight alternative to solid composite and aluminum honeycomb panels.

Carbon-fiber-faced panels are stronger and more rigid than fiberglass-faced panels, so they resist deforming from bending, twisting, or buckling. They will, however, splinter from high-impact blows. These panels are lighter than fiberglass-faced panels. However, they conduct electricity, so don’t use them around electrical components.

Fiberglass-faced panels are often used around electrical components because they are good electrical insulators. They resist cracks from bumps and hits better than carbon-fiber-faced panels, but are not as strong or lightweight.

| Thickness | Thickness Tolerance | Honeycomb Cell Size | Each | |

12" × 12" | ||||

|---|---|---|---|---|

Carbon Fiber Face | ||||

| 1/8" | -0.03" to 0.03" | 0.125" | 00000000 | 0000000 |

| 1/4" | -0.03" to 0.03" | 0.125" | 00000000 | 000000 |

| 1/2" | -0.06" to 0.06" | 0.125" | 00000000 | 000000 |

Fiberglass Face | ||||

| 1/8" | -0.03" to 0.03" | 0.125" | 00000000 | 000000 |

| 1/4" | -0.03" to 0.03" | 0.125" | 00000000 | 000000 |

| 1/2" | -0.06" to 0.06" | 0.125" | 00000000 | 000000 |

Ultra-Strength Lightweight Carbon Fiber Sheets with Foam Core

- Color: Black

- Temperature Range: 0° F to 250° F

- Tensile Strength: 120,000-175,000 psi (Excellent)

- Fiber Tensile Stiffness: Standard (33-36 msi)

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: No

A layer of foam is sandwiched between two pieces of carbon fiber to make these sheets even lighter than standard carbon fiber sheets. Carbon fiber is the strongest composite we offer. It’s comparable in strength to 6061 aluminum and is often used to build frames and structures.

For technical drawings and 3-D models, click on a part number.

12" × 12" | ||||

|---|---|---|---|---|

| Thickness | Thick. Tolerance | Appearance | Each | |

| 1/4" | -0.02" to 0.02" | Checked | 0000000 | 0000000 |

Impact-Resistant Ultra-Strength Carbon Fiber Sheets with Kevlar Core

- Color: Black

- Temperature Range: -100° to 190° F

- Tensile Strength: 177,000 psi (Excellent)

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: No

Often used to build frames and structures, these lightweight sheets combine the strength and stiffness of carbon fiber with the impact resistance of Kevlar. With carbon fiber on the outer layers, these sheets are extremely difficult to bend—they’re nearly as stiff as pure carbon fiber. The carbon fiber layers also provide good strength under tension, comparable to 6061 aluminum. Sandwiched between the carbon fiber layers of these sheets is a Kevlar core. Known for its toughness, the Kevlar core helps prevent sheets from failing under a variety of stresses, such as punctures, cuts, impact, and wear. The Kevlar core also has a lower density than carbon fiber, making these sheets even lighter than sheets made from carbon fiber alone.

Sheets with 0.09 in. thickness have thicker layers of carbon fiber, making them stiffer than those with 0.06 in. thickness.

For technical drawings and 3-D models, click on a part number.

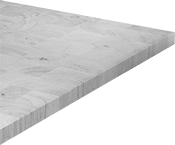

Balsa Wood Cores

Lighter in weight than any other wood, yet still strong, these balsa cores stiffen composite sandwiches without weighing them down. They resist damage from impact and repeated use. Because they don’t let heat or sound pass through quickly, these cores are good natural insulators. They also resist chemicals. All come from balsa trees grown in FSC (Forest Stewardship Council) certified forests. They cannot be sold to Canada due to import regulations.

Rigid cores are often used in panels for partitions, industrial tanks, and other stiff structures.

Flexible cores are best for forming complex shapes.

For technical drawings and 3-D models, click on a part number.

| Thickness | Width | Length | Compressive Strength, psi | Temperature Range, °F | Cannot Be Sold To | Each | |

| 1/4" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 000000 |

| 3/8" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 1/2" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 5/8" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 3/4" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 1" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 2" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| Thickness | Width | Length | Compressive Strength, psi | Temperature Range, °F | Cannot Be Sold To | Each | |

| 1/4" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 000000 |

| 3/8" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 1/2" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 3/4" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

| 1" | 24" | 48" | 1,500 | -100° to 325° | Canada | 00000000 | 00000 |

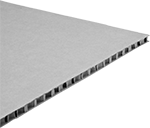

Corrugated Plastic Box and Pallet Liners

Plastic liners resist punctures, moisture, and many acids. Use them between pallets or layers of stacked material, or to reinforce the bottom of shipping boxes.

| Wd. | Lg. | Thick. | Color | Material | Pkg. Qty. | Pkg. | |

| 6" | 6" | 1/8" | White | Polypropylene Plastic | 5 | 000000000 | 00000 |

| 12" | 12" | 1/8" | White | Polypropylene Plastic | 5 | 00000000 | 0000 |

| 24" | 24" | 1/8" | White | Polypropylene Plastic | 1 | 00000000 | 0000 |

| 24" | 36" | 1/8" | White | Polypropylene Plastic | 1 | 000000000 | 00000 |

| 24" | 48" | 1/8" | White | Polypropylene Plastic | 1 | 00000000 | 00000 |

| 36" | 36" | 1/8" | White | Polypropylene Plastic | 1 | 000000000 | 00000 |

| 36" | 48" | 1/8" | White | Polypropylene Plastic | 1 | 000000000 | 00000 |

| 48" | 48" | 1/8" | White | Polypropylene Plastic | 1 | 00000000 | 00000 |

| 48" | 60" | 1/8" | White | Polypropylene Plastic | 1 | 000000000 | 00000 |

| 60" | 60" | 1/8" | White | Polypropylene Plastic | 1 | 000000000 | 00000 |

Crush-Resistant Corrugated Cardboard Box and Pallet Liners

These liners have a layer of hexagonal cells instead of typical corrugation, so they distribute loads better than standard cardboard liners. Use them between pallets or layers of stacked material, or to reinforce the bottom of shipping boxes.

| Wd. | Lg. | Thick. | Color | Pkg. Qty. | Pkg. | |

| 20" | 48" | 1/2" | Brown | 4 | 0000000 | 000000 |

Insulated Recycled Paper Liners for Cardboard Boxes

Line your shipping box to absorb condensation and maintain the temperature of your contents for up to 24 hours. These liners are best for small- and medium-sized shipments that would be damaged by heat, such as perishables and electronics. However, they’ll start to break down from prolonged exposure to water. Made of 100% recycled paper, they cushion fragile items just as well as bubble liners but without the waste of plastic. They are, however, bulkier than bubble liners, so they take up more space in your package. There are no special requirements for recycling these liners. Toss them in your recycling bin when you’re done.

To completely insulate your package, you’ll need two liners—one for around the top, side, and bottom, and another for around the other three sides. These liners are easy to cut down if you need to customize the size.

R-value measures the liner’s ability to slow heat flow. The higher the value, the better it insulates. A value of 5.1 means these liners maintain temperatures between 32° and 90° F for short periods.

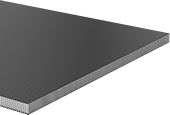

Aluminum-Covered Polyethylene (LDPE)

- Face Color: Black

- Temperature Range: 0° to 170° F

- Tensile Strength: 8,740 psi (Good)

- Impact Strength: Not Rated

- Hardness: Not Rated

- For Use Outdoors: Yes

- Specifications Met: ASTM E84 5/15 for Flame and Smoke, FDA Compliant 21 CFR 177.1380, UL 94 V-0

A layer of soft LDPE is sandwiched between two thin layers of aluminum for strength and rigidity. Use these sheets outdoors as signs, wall panels, canopies, and building cladding. One side is painted black; the painted side is normally exposed.

For technical drawings and 3-D models, click on a part number.

Sound Barrier Panels

Set on top of ceiling tiles to prevent sound penetration. These panels are melamine foam with a vinyl center.

For technical drawings and 3-D models, click on a part number.

| Lg., ft. | Wd., ft. | Thick. | Material | Pkg. Qty. | Pkg. | |

| 2 | 2 | 5/8" | Melamine Foam | 2 | 0000000 | 0000000 |

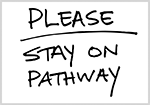

Blank Signs

Fill in the blank with your own custom warnings, labels, and messages. You can write on these signs with markers, add color with paint, or stick on adhesive-back characters. Many even work with printers.

Plain Back

More than twice as thick as our other blank signs, these are a good option for freestanding signs and displays.

Corrugated polypropylene signs are durable enough for temporary use outdoors. They're commonly paired with sign stakes. Polystyrene foam is also called foam core.

Sign Stakes

Drive these stakes into the ground to display your foam or corrugated signs outside.