How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About On/Off Valves

More

Sanitary Sampling Valves

- Valve Type: Stop Cock

- For Use With: Food, Beverage

- Specifications Met: FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 177.1550

Take liquid samples in sanitary environments—these sampling valves have a hygienic design, so they’re commonly used in breweries and wineries. With a body made of 316 stainless steel and a PTFE plastic seat, they resist the high temperatures and harsh chemicals of clean-in-place (CIP) processes. These valves have an extremely smooth surface, leaving no space for bacteria to grow. Quick-clamp connections, also known as tri-clamp fittings, are easily taken apart for regular cleaning. These valves are self-draining, so previous samples and cleaning chemicals won’t contaminate future samples. Both the seat and the silicone O-ring comply with FDA standards for direct contact with food and beverage.

To take samples, turn the thumb screw to open valves. Hang a bucket for sample collection from the bucket groove. Valves also have a leak detection port that will release a small amount of liquid to let you know when it’s time to replace all the valve seals.

Valves with a bent spout have a tab for connecting carbon dioxide testing devices. They’re often used for carbonated beverages. They shouldn’t be used with liquids that have solids in them, such as the grape skins or seeds in wine, as those can get caught in the outlet.

For technical drawings and 3-D models, click on a part number.

Inlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Sampling Outlet Spout OD | Flow Pattern | Maximum Pressure | Temperature Range, °F | End-to-End Lg. | Port-to-Port Lg. | Surface Smoothness | Each | |

Quick Clamp Inlet—Straight Sampling Outlet Spout | ||||||||||

316 Stainless Steel | ||||||||||

| 1/2" | 0.984" | 1/2" | L-Pattern | 145 psi @ 70° F | -40° to 450° | 3 5/16" | 1 15/16" | 32 microinch | 0000000 | 0000000 |

| 1" | 2" | 1/2" | L-Pattern | 145 psi @ 70° F | -40° to 450° | 3 5/16" | 1 15/16" | 32 microinch | 0000000 | 000000 |

Quick Clamp Inlet—Bent Sampling Outlet Spout with Tab | ||||||||||

316 Stainless Steel | ||||||||||

| 1/2" | 0.984" | 13/32" | L-Pattern | 145 psi @ 70° F | -40° to 450° | 3 5/16" | 2 3/4" | 32 microinch | 0000000 | 000000 |

| 1" | 2" | 13/32" | L-Pattern | 145 psi @ 70° F | -40° to 450° | 3 5/16" | 2 3/4" | 32 microinch | 0000000 | 000000 |

Sampling Valves for Water

- Valve Type: Ball

- For Use With: Water

- Seal Material: Buna-N Rubber

To test water quality without interrupting flow, turn the handle to drain a small amount of liquid through the sampling outlet. These valves cannot shut off flow. All are standard port, so they slightly restrict flow.

For technical drawings and 3-D models, click on a part number.

| Inlet Pipe Size | Outlet Pipe Size | Sampling Outlet Pipe Size | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Max. Temp., °F | End-to-End Lg. | Each | |

PVC Plastic Body | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 1/2 | 1/4 | T-Pattern | 4 | 125 psi @ 140° F | 140° | 2 1/2" | 0000000 | 000000 |

Sampling Outlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inlet Pipe Size | Outlet Pipe Size | For Tube ID | ForTube OD | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Max. Temp., °F | End-to-End Lg. | Each | |

PVC Plastic Body | ||||||||||

| 1/2 | 1/2 | 1/8" | 1/4" | T-Pattern | 0.6 | 125 psi @ 140° F | 140° | 2 1/2" | 0000000 | 000000 |

Inlet | Outlet | Sampling Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube ID | For Tube OD | For Tube ID | For Tube OD | Pipe Size | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Max. Temp., °F | End-to-End Lg. | Each | |

PVC Plastic Body | |||||||||||

| 1/8" | 3/8" | 1/8" | 3/8" | 1/4 | T-Pattern | 1.6 | 125 psi @ 140° F | 140° | 3 15/16" | 0000000 | 000000 |

| 1/8" | 1/2" | 1/8" | 1/2" | 1/4 | T-Pattern | 3.8 | 125 psi @ 140° F | 140° | 3 15/16" | 0000000 | 00000 |

Inlet | Outlet | Sampling Outlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube ID | For Tube OD | For Tube ID | For Tube OD | For Tube ID | For Tube OD | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Max. Temp., °F | End-to-End Lg. | Each | |

PVC Plastic Body | ||||||||||||

| 1/8" | 3/8" | 1/8" | 3/8" | 1/8" | 1/4" | T-Pattern | 0.6 | 125 psi @ 140° F | 140° | 3 15/16" | 0000000 | 000000 |

| 1/8" | 1/2" | 1/8" | 1/2" | 1/8" | 1/4" | T-Pattern | 0.6 | 125 psi @ 140° F | 140° | 3 15/16" | 0000000 | 00000 |

Sampling Valves for Fuel

- Valve Type: Ball

- For Use With: Butane, Diesel Fuel, Fuel Oil, Gasoline, Kerosene, Propane

- Seal Material: Graphite

- Specifications Met: American Petroleum Institute Standard 607, Edition 5

Fire-tested to meet American Petroleum Institute (API) 607, Edition 5, these valves are designed to securely isolate fluid and prevent the spread of fire. They’re often installed on petroleum loading arms to drain a small amount of fuel for inspection without interrupting flow. Turn the handle to divert a small amount of media to the sampling outlet or to shut off flow. Body is 316 stainless steel for excellent corrosion resistance. All valves are full port, so they do not restrict flow.

| Pipe Size | Flow Pattern | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

NPT Female × NPT Male—NPT Female Bottom Sampling Outlet | ||||||

|---|---|---|---|---|---|---|

316 Stainless Steel Body | ||||||

| 1/2 | T-Pattern | 6000 psi @ 100° F | -40° to 600° | 4 1/16" | 000000 | 0000000 |

| 3/4 | T-Pattern | 6000 psi @ 100° F | -40° to 600° | 4 11/16" | 000000 | 000000 |

| 1 | T-Pattern | 6000 psi @ 100° F | -40° to 600° | 5 3/8" | 000000 | 000000 |

Fast-Acting Panel-Mount Threaded On/Off Valves

Start or stop flow with the flip of a toggle switch or the push of a button. These valves are often used in testing and sampling applications where you need to dispense a small amount of liquid. They fit through a cutout, so the body of the valve stays safe inside your instrumentation panel.

Nickel-plated brass valves resist corrosion better than plain brass valves. 316 stainless steel valves stand up to corrosion better than both plain and nickel-plated brass valves.

Manual-return valves stay open until you flip the toggle off. Since they don't need to be held open, they’re often used to dispense larger samples than spring-return valves. It’s also easy to check if these valves are open or not based on the toggle’s position. Spring-return valves automatically close when you release the toggle or push button. They’re ideal for intermittent use and precise flow control to prevent spills.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Stem

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon

- Seal Material: See table

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Return Actuation | Toggle Material | Seal Material | End-to-End Lg. | Panel Cutout Dia. | Each | |

NPTF Female × NPTF Female | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/8 | 0.3 | 200 psi @ 70° F | -15° to 250° | Manual | Metal | Fluoroelastomer Rubber | 1 7/16" | 9/16" | 0000000 | 000000 |

| 1/4 | 1.2 | 125 psi @ 70° F | -15° to 250° | Manual | Metal | Fluoroelastomer Rubber | 1 7/8" | 9/16" | 0000000 | 00000 |

NPT Male × NPT Male | ||||||||||

| 1/8 | 0.1 | 300 psi @ 200° F | -20° to 200° | Manual | Plastic | PTFE Plastic | 1 3/4" | 17/32" | 0000000 | 00000 |

| 1/4 | 0.2 | 300 psi @ 200° F | -20° to 200° | Manual | Plastic | PTFE Plastic | 2 1/4" | 17/32" | 0000000 | 00000 |

- Valve Type: Stem

- For Use With: See table

- Seal Material: See table

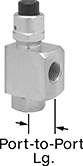

| Pipe Size | Thread Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Valve Starting Position | Return Actuation | Toggle Material | Seal Material | Port-to-Port Lg. | Panel Cutout Dia. | For Use With | Each | |

NPTF Female × NPTF Female | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/8 | __ | 0.3 | 200 psi @ 70° F | -15° to 250° | __ | Manual | Metal | Fluoroelastomer Rubber | 3/4" | 9/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 0000000 | 000000 |

| 1/4 | __ | 1.2 | 125 psi @ 70° F | -15° to 250° | __ | Manual | Metal | Fluoroelastomer Rubber | 3/4" | 9/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | 0000000 | 00000 |

UNF Female × UNF Female | |||||||||||||

| __ | 10-32 | 6.8 | 150 psi @ 70° F | 35° to 230° | Normally Closed | Spring | Plastic | Buna-N Rubber | 5/16" | 15/32" | Water, Oil, Air | 0000000 | 00000 |

| __ | 10-32 | 7.3 | 150 psi @ 70° F | 35° to 230° | __ | Manual | Metal | Buna-N Rubber | 5/16" | 15/32" | Water, Oil, Air | 0000000 | 00000 |

NPT Male × UNF Female | |||||||||||||

| 1/8 | 10-32 | 7.3 | 150 psi @ 70° F | 35° to 230° | __ | Manual | Metal | Buna-N Rubber | 5/16" | 15/32" | Water, Oil, Air | 0000000 | 00000 |

| 1/8 | 10-32 | 8 | 150 psi @ 70° F | 35° to 230° | __ | Manual | Plastic | Buna-N Rubber | 5/16" | 15/32" | Water, Oil, Air | 0000000 | 00000 |

| 1/8 | 10-32 | 8 | 150 psi @ 70° F | 35° to 230° | Normally Closed | Spring | Metal | Buna-N Rubber | 5/16" | 15/32" | Water, Oil, Air | 0000000 | 00000 |

NPT Male × NPT Male | |||||||||||||

| 1/4 | __ | 0.2 | 300 psi @ 200° F | -20° to 200° | __ | Manual | Plastic | PTFE Plastic | 1" | 17/32" | Water, Air, Argon, Helium, Krypton, Neon, Xenon | 0000000 | 00000 |

- Valve Type: Stem

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon

- Seal Material: Buna-N Rubber Seal

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Return Actuation | Toggle Material | Port-to-Port Lg. | Panel Cutout Dia. | Each | |

NPT Female × NPT Female | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/8 | 0.2 | 125 psi @ 70° F | -40° to 180° | Manual | Plastic | 1/2" | 15/32" | 0000000 | 000000 |

- Valve Type: Stem

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon

- Seal Material: Buna-N Rubber Seal

| Pipe Size | Thread Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Valve Starting Position | Return Actuation | Push-Button Material | Port-to-Port Lg. | Panel Cutout Dia. | Each | |

NPT Female × NPT Female | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/8 | __ | 0.2 | 125 psi @ 70° F | -40° to 180° | Normally Closed | Spring | Plastic | 1/2" | 15/32" | 0000000 | 000000 |

UNF Female × UNF Female | |||||||||||

| __ | 10-32 | 0.1 | 125 psi @ 70° F | -40° to 180° | Normally Closed | Spring | Plastic | 1/4" | 15/32" | 0000000 | 00000 |

- Valve Type: Stem

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon

- Seal Material: Buna-N Rubber Seal

| Thread Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Valve Starting Position | Return Actuation | Push-Button Material | Port-to-Port Lg. | Panel Cutout Dia. | Each | |

UNF Female × UNF Female | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10-32 | 0.1 | 125 psi @ 70° F | -40° to 180° | Normally Closed | Spring | Plastic | 5/16" | 15/32" | 0000000 | 000000 |

- Valve Type: Stem

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon

- Seal Material: PTFE Plastic Seal

- Valve Type: Stem

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon

- Seal Material: PTFE Plastic Seal

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Return Actuation | Toggle Material | Port-to-Port Lg. | Panel Cutout Dia. | Each | |

NPT Male × NPT Male | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/4 | 0.2 | 300 psi @ 200° F | -20° to 200° | Manual | Plastic | 1" | 17/32" | 0000000 | 0000000 |

Fast-Acting Threaded On/Off Valves

Push a button or flip a toggle switch to start or stop flow. Often used in testing and sampling, these valves are useful when you need to dispense a small amount of liquid.

Nickel-plated brass valves resist corrosion better than plain brass valves.

Push-button valves automatically open or close when you take your finger off the button. They’re ideal for intermittent use and applications where you want to monitor flow closely to avoid spills. The button is colored to make it easy to tell different valves apart. Normally open valves close when you push their button. Normally closed valves open when you push their button.

Toggle valves stay open until you flip them closed. Since they don't need to be held open, they’re often used to dispense larger samples than push-button valves. You can see if these valves are open or not based on the toggle's position.

Valves with an exhaust port release extra air or liquid when they close. When these valves open, the exhaust port closes.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

with Compact

Push Button

with Mushroom

Push Button

- Valve Type: Stem

- For Use With: See table

- Seal Material: Buna-N Rubber

| Pipe Size | Thread Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Port-to-Port Lg. | Features | For Use With | Choose a Push-Button Color | Each | |

Compact Push Button | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Normally Open | ||||||||||

NPT Female × NPT Female | ||||||||||

| 1/8 | __ | 0.21 | 150 psi @ 180° F | 35° to 230° | 9/16" | __ | Water, Oil, Air | Black | 0000000 | 000000 |

| 1/8 | __ | 0.47 | 150 psi @ 180° F | 35° to 230° | 9/16" | Exhaust Port | Air | Black | 0000000 | 00000 |

Normally Closed | ||||||||||

NPT Female × NPT Female | ||||||||||

| 1/8 | __ | 0.44 | 300 psi @ 180° F | 35° to 230° | 9/16" | __ | Water, Oil, Air | Black | 0000000 | 00000 |

| 1/8 | __ | 0.47 | 300 psi @ 180° F | 35° to 230° | 9/16" | Exhaust Port | Air | Black | 0000000 | 00000 |

| 1/8 | __ | 0.51 | 300 psi @ 180° F | 35° to 230° | 9/16" | __ | Water, Oil, Air | 00000000 | 00000 | |

UNF Female × UNF Female | ||||||||||

| __ | 10-32 | 0.12 | 300 psi @ 180° F | 35° to 230° | 5/16" | __ | Water, Oil, Air | Black | 0000000 | 00000 |

Mushroom Push Button | ||||||||||

Normally Open | ||||||||||

NPT Female × NPT Female | ||||||||||

| 1/8 | __ | 0.21 | 150 psi @ 180° F | 35° to 230° | 9/16" | __ | Water, Oil, Air | Black | 0000000 | 00000 |

| 1/8 | __ | 0.47 | 150 psi @ 180° F | 35° to 230° | 9/16" | Exhaust Port | Air | Black | 0000000 | 00000 |

UNF Female × UNF Female | ||||||||||

| __ | 10-32 | 0.18 | 150 psi @ 180° F | 35° to 230° | 5/16" | __ | Water, Oil, Air | Black | 0000000 | 00000 |

Normally Closed | ||||||||||

NPT Female × NPT Female | ||||||||||

| 1/8 | __ | 0.44 | 300 psi @ 180° F | 35° to 230° | 9/16" | __ | Water, Oil, Air | Black | 0000000 | 00000 |

| 1/8 | __ | 0.47 | 300 psi @ 180° F | 35° to 230° | 9/16" | Exhaust Port | Air | Black | 0000000 | 00000 |

| 1/8 | __ | 0.51 | 300 psi @ 180° F | 35° to 230° | 9/16" | __ | Water, Oil, Air | 00000000 | 00000 | |

UNF Female × UNF Female | ||||||||||

| __ | 10-32 | 0.12 | 300 psi @ 180° F | 35° to 230° | 5/16" | __ | Water, Oil, Air | Black | 0000000 | 00000 |

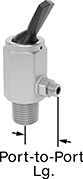

- Valve Type: Stem

- For Use With: Air, Oil, Water

- Seal Material: Buna-N Rubber

| Pipe Size | Thread Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Port-to-Port Lg. | Toggle Color | Each | |

NPT Female × UNF Female | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/8 | 10-32 | 0.15 | 125 psi @ 180° F | -25° to 180° | 5/16" | Black | 00000000 | 000000 |

NPT Female × UNF Male | ||||||||

| 1/8 | 10-32 | 0.15 | 125 psi @ 180° F | -25° to 180° | 9/16" | Black | 00000000 | 00000 |

NPT Male × UNF Female | ||||||||

| 1/8 | 10-32 | 0.15 | 125 psi @ 180° F | -25° to 180° | 5/16" | Black | 00000000 | 00000 |

NPT Male × UNF Male | ||||||||

| 1/8 | 10-32 | 0.15 | 125 psi @ 180° F | -25° to 180° | 9/16" | Black | 00000000 | 00000 |

- Valve Type: Stem

- For Use With: Air, Oil, Water

- Seal Material: Buna-N Rubber

| Pipe Size | Thread Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Port-to-Port Lg. | Push-Button Style | Push-Button Color | Each | |

Normally Closed | |||||||||

|---|---|---|---|---|---|---|---|---|---|

NPT Female × UNF Female | |||||||||

| 1/8 | 10-32 | 0.15 | 125 psi @ 180° F | -25° to 180° | 5/16" | Compact | Black | 00000000 | 000000 |

NPT Female × UNF Male | |||||||||

| 1/8 | 10-32 | 0.15 | 125 psi @ 180° F | -25° to 180° | 9/16" | Compact | Black | 00000000 | 00000 |

NPT Male × UNF Female | |||||||||

| 1/8 | 10-32 | 0.15 | 125 psi @ 180° F | -25° to 180° | 5/16" | Compact | Black | 00000000 | 00000 |

NPT Male × UNF Male | |||||||||

| 1/8 | 10-32 | 0.15 | 125 psi @ 180° F | -25° to 180° | 9/16" | Compact | Black | 00000000 | 00000 |

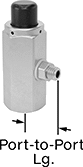

Fast-Acting Panel-Mount On/Off Valves with Yor-Lok Fittings

- Valve Type: Stem

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: PTFE Plastic

Flip the toggle to quickly turn these valves on and off. All have threads and a hex nut below the handle for installation in instrument panels. For extra gripping power and a strong seal, they have Yor-Lok fittings with two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings.

316 stainless steel valves are more corrosion resistant than brass valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Straight | 90° Elbow | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Panel Cutout Dia. | End-to-End Lg. | Each | Port-to-Port Lg. | Each | ||

Brass Body | ||||||||||

Yor Lok × Yor Lok | ||||||||||

| 1/8" | 0.1 | 300 psi @ 200° F | -20° to 200° | 17/32" | 1 15/16" | 0000000 | 000000 | __ | 000000 | 00 |

| 1/4" | 0.2 | 300 psi @ 200° F | -20° to 200° | 17/32" | 2 1/4" | 0000000 | 00000 | 1 1/8" | 0000000 | 000000 |

316 Stainless Steel Body | ||||||||||

Yor Lok × Yor Lok | ||||||||||

| 1/8" | 0.1 | 300 psi @ 200° F | -20° to 200° | 17/32" | 1 15/16" | 0000000 | 000000 | __ | 000000 | 00 |

| 1/4" | 0.2 | 300 psi @ 200° F | -20° to 200° | 17/32" | 2 1/4" | 0000000 | 000000 | 1 1/8" | 0000000 | 000000 |

Sanitary Sampling Stainless Steel Tube Fittings

- For Use With: Dairy, Beverage, Water, Air, Food

- Tubing: Use with welded 316/316L stainless steel

- Specifications Met: 3-A Certified 63-03

Take samples in sanitary environments—these tube fittings won’t contaminate your lines or force you to pause them. Made of 316L stainless steel, they’ll stand up to harsh cleaners and sanitizers without corroding. They also have polished internal surfaces, minimizing the space where bacteria could grow. With quick-clamp connections, they are easy to take apart for cleaning or reconfiguring your line. All are 3-A certified to meet sanitary design standards, so they’re often used in food and beverage, pharmaceutical, and biotech applications.

All fittings require pierceable lids (sold separately) to draw samples through a hypodermic needle. Each lid is good for seven samples, and each sample leaves a hole mark, so you know when it’s time to unscrew the nut on the tube fitting and swap in a new lid. To help prevent dust and moisture from accumulating on the lid, all tube fittings have a dust cover. These lids are FDA compliant, so they keep contaminants from entering your line and also are approved for direct contact with food if they break off and fall in. Manufactured free of contaminants and allergens, all are BPA-, latex-, and phthalate-free. They’re also TSE/BSE compliant, meaning they’ve never come into contact with any animal products.

Pair these tube fittings with liquid samplers for a sample. They use gravity to draw out liquid through the needle directly into the bag.

For technical drawings and 3-D models, click on a part number.

Bag | Needle | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, ml | Ht. | Wd. | Thick., mil | Gauge | Lg. | ID | OD | Material | Connection Type | Color | Specifications Met | Each | |

PVC Plastic | |||||||||||||

| 250 | 8" | 5" | 14 | 18 | 1 1/2" | 0.033" | 0.05" | 304 Stainless Steel | Luer Lock | Clear | ISO 10993, USP Class VI | 0000000 | 00000 |

| 2,000 | 14" | 7" | 14 | 18 | 1 1/2" | 0.033" | 0.05" | 304 Stainless Steel | Luer Lock | Clear | ISO 10993, USP Class VI | 0000000 | 0000 |

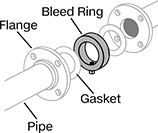

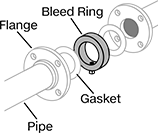

Steel Bleed Rings

- For Use With: Air, Natural Gas, Oil, Steam, Water

Access the inside of a pipe line to vent pressure, drain liquid, or take samples. These bleed rings act as a port where two pipe flanges meet, so you don’t have to disassemble your flanges to get inside. They include a plug, or you can attach your own fitting, valve, or probe. Made of steel, these bleed rings should be used in noncorrosive environments to prevent rusting.

Install these bleed rings between two pipe flanges along with a gasket on both sides to avoid leaks. They’re designed to fit flanges that meet ASME B16.5.

For technical drawings and 3-D models, click on a part number.

Plug | Steel | |||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | ID | Width | Wall Thickness | Pipe Size | Thread Type | Each | |

For Flange Class 125 or 150 | ||||||||

| 2 | 4" | 2.375" | 1.5" | 0.813" | 1/2 | NPT | 0000000 | 0000000 |

| 3 | 5 1/4" | 3.5" | 1.5" | 0.875" | 1/2 | NPT | 0000000 | 000000 |

| 4 | 6 3/4" | 4.5" | 1.5" | 1.125" | 1/2 | NPT | 0000000 | 000000 |

| 6 | 8 5/8" | 6.625" | 1.5" | 1" | 1/2 | NPT | 0000000 | 000000 |

For Flange Class 300 | ||||||||

| 4 | 7" | 4.5" | 1.5" | 1.25" | 1/2 | NPT | 0000000 | 000000 |

| 6 | 9 3/4" | 6.625" | 1.5" | 1.563" | 1/2 | NPT | 0000000 | 000000 |

For Flange Class 600 | ||||||||

| 2 | 4 1/4" | 2.375" | 1.5" | 0.938" | 1/2 | NPT | 0000000 | 000000 |

| 3 | 5 3/4" | 3.5" | 1.5" | 1.125" | 1/2 | NPT | 0000000 | 000000 |

Stainless Steel Bleed Rings

- For Use With: Air, Natural Gas, Oil, Steam, Water

Create an access point in a pipe line where corrosion is a concern. Often used to relieve pressure or siphon and sample liquids, these bleed rings act as a port between two pipe flanges, eliminating the need to take apart your flanges to get inside. They include a plug, or replace the plug with your own fitting, valve, or probe. Made of stainless steel, these bleed rings resist rusting.

Install these bleed rings between two pipe flanges along with a gasket on both sides to avoid leaks. They’re designed to fit flanges that meet ASME B16.5.

304 stainless steel bleed rings keep corrosion at bay in wet conditions but will start to corrode when exposed to salt water. 316 stainless steel bleed rings withstand wet conditions as well as chemicals and salt water.

For technical drawings and 3-D models, click on a part number.

Plug | 304/304L Stainless Steel | 316/316L Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | ID | Width | Wall Thickness | Pipe Size | Thread Type | Each | Each | ||

For Flange Class 125 or 150 | ||||||||||

| 2 | 4" | 2.375" | 1.5" | 0.813" | 1/2 | NPT | 0000000 | 0000000 | 0000000 | 0000000 |

| 3 | 5 1/4" | 3.5" | 1.5" | 0.875" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

| 4 | 6 3/4" | 4.5" | 1.5" | 1.125" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

| 6 | 8 5/8" | 6.625" | 1.5" | 1" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

For Flange Class 300 | ||||||||||

| 4 | 7" | 4.5" | 1.5" | 1.25" | 1/2 | NPT | 0000000 | 000000 | 000000 | 00 |

| 6 | 9 3/4" | 6.625" | 1.5" | 1.563" | 1/2 | NPT | 0000000 | 000000 | 000000 | 00 |

For Flange Class 600 | ||||||||||

| 2 | 4 1/4" | 2.375" | 1.5" | 0.938" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

| 3 | 5 3/4" | 3.5" | 1.5" | 1.125" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

Gas Sampling Valves for Syringes

- Valve Type: Plug

- For Use With: Butane, Carbon Dioxide, Natural Gas, Nitrogen, Oxygen

Convert an everyday syringe into a gas sampling syringe. These valves allow you to collect, transport, and store gas samples without worrying about evaporation or leaks. Slide the female end over the base of your syringe and attach a needle to the male side.

For technical drawings and 3-D models, click on a part number.

| Flow Pattern | Maximum Pressure | Temperature Range | End-to-End Lg. | Autoclavable | Each | |

Plastic Body with Standard Lever Handle | ||||||

|---|---|---|---|---|---|---|

Female Luer Lock × Male Luer Lock | ||||||

| Straight | 100 psi @ 70° F | Not Rated | 1" | Yes | 0000000 | 0000000 |