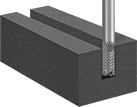

Spiral Router Bits for Steel and Stainless Steel

The aluminum-titanium-nitride (AlTiN) coating on these bits resists heat and wear when cutting steel and stainless steel. They have a square cut style for creating slots, pockets, and edges. They're made of solid carbide for longer tool life and faster cutting speeds than high-speed steel. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the bit from breaking. With spiral flutes, they leave a smoother finish than straight-flute bits and are good for making plunge cuts. The flutes lift chips up from the workpiece for applications that require a smooth finish on the bottom edge of the cut. Securely clamp your material before routing to prevent lifting. Bits with more flutes produce a smoother finish.

For technical drawings and 3-D models, click on a part number.

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Number of Flutes | For Tool Type | Each | |

Aluminum Titanium Nitride (AlTiN) Coated Carbide | |||||||

|---|---|---|---|---|---|---|---|

Spiral Flutes with Upward Chip Removal | |||||||

| 1/32" | 1/16" | 1/8" | 1 1/2" | 4 | CNC Machine | 00000000 | 000000 |

| 1/16" | 3/16" | 1/8" | 1 1/2" | 4 | CNC Machine | 00000000 | 00000 |

| 1/8" | 3/8" | 1/4" | 1 1/2" | 4 | CNC Machine | 00000000 | 00000 |

| 1/4" | 5/8" | 1/4" | 2 3/8" | 4 | CNC Machine | 00000000 | 00000 |

| 1/4" | 1 1/8" | 1/4" | 3" | 4 | CNC Machine | 00000000 | 00000 |

Drill/Rout Router Bits

Drill, rout, and trim with the same bit. The unique shape on these bits was originally used for aircraft panels. They have a pointed end and spiral flutes, like a drill bit, making downward plunge cuts easier than with square-cut and straight-flute bits. The spiral flutes also leave a smoother finish. The flutes lift chips up from the workpiece for applications that require a clean finish on the bottom edge of the cut. Securely clamp your material before routing to prevent lifting.

These bits are made of high-speed steel for general purpose use. They can be used with hand tools, router tables, and CNC machines. These bits do not have a pilot, so guide your router along a straight edge when hand routing to make accurate cuts.

Bits with four flutes produce a smoother finish than three-flute bits.

For technical drawings and 3-D models, click on a part number.

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Number of Flutes | For Tool Type | For Use On | Each | |

Uncoated High-Speed Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

Spiral Flutes with Upward Chip Removal | ||||||||

| 7/32" | 1 1/4" | 1/4" | 2 3/4" | 4 | Hand Router, Router Table, CNC Machine | Cast Iron, Copper, Stainless Steel, Steel, Titanium | 00000000 | 000000 |

Diamond-Coated Router Bits for Composites

With a diamond coating, these bits resist wear when used on abrasive materials, making them last about 50 times longer than uncoated bits. Their sharp cutting edges and flute shapes are specifically designed to cut through tough materials such as composites with minimal resistance. This means less strain on your router and more control when cutting, leading to a smooth cut. Bits are made of solid carbide for longer tool life and faster cutting speeds than high-speed steel.

Spiral Flutes—Leave a smoother finish than straight-flute bits and make plunge cuts more easily (for plunge-cutting bits).

Roughed-Spiral Flutes—Nicks on the edges of the spirals reduce the amount of force required to cut through composites, giving you more control as you cut.

Herringbone-Pattern Flutes—Have both upward and downward spiral flutes in an alternating pattern. This quickly and effectively clears chips, which prevents overheating and produces clean cuts.

Use bits with a square cut style to cut slots, pockets, and edges.

Plunge-cutting bits let you cut directly into the workpiece from above. Other bits are best for operations where the peripheral teeth do most of the work such as trimming, contouring, and finishing.

Bits with upward chip removal lift chips up for applications that require a smooth finish on the bottom edge of the cut. Securely clamp the workpiece before routing to prevent lifting.

Bits with upward and downward chip removal are also known as compression bits. Acting similar to scissors, they move chips away from the top and bottom edges of the cut for a smooth finish on both. Bits with higher compression angles cut more efficiently than bits with lower compression angles, reducing the amount of force required to cut through your material. They are also more resistant to wear.

For technical drawings and 3-D models, click on a part number.

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Number of Flutes | Cut Type | For Tool Type | For Use On | Each | |

Diamond-Coated Carbide | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Roughed Spiral Flutes with a Square Cut Style—Upward Chip Removal | |||||||||

| 15/64" | 3/4" | 1/4" | 2 1/2" | 4 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 0000000 |

| 1/4" | 1/2" | 1/4" | 2 1/2" | 4 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

| 1/4" | 3/4" | 1/4" | 2 1/2" | 4 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

| 1/4" | 1" | 1/4" | 3" | 4 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

45° Compression Angle Spiral Flutes with a Square Cut Style—Upward and Downward Chip Removal | |||||||||

| 1/4" | 3/4" | 1/4" | 3" | 4 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

| 3/8" | 3/4" | 3/8" | 3" | 4 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

| 3/8" | 2" | 3/8" | 4" | 4 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

| 1/2" | 1" | 1/2" | 3" | 4 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

| 1/2" | 2" | 1/2" | 4" | 4 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

30° Compression Angle Herringbone-Pattern Flutes with a Square Cut Style—Upward and Downward Chip Removal | |||||||||

| 1/8" | 9/16" | 1/8" | 1 1/2" | 4 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

| 1/4" | 3/4" | 1/4" | 2 1/2" | 4 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

| 3/8" | 7/8" | 3/8" | 3" | 4 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

| 1/2" | 1 1/2" | 1/2" | 3" | 4 | Plunge | CNC Machine, Router Table | Carbon Fiber, Fiberglass | 00000000 | 000000 |

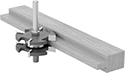

Router Bits for Wood Joining

Create shapes that fit together to form wood joints commonly used to build doors and frames.

Tongue and groove bits have a solid pilot that guides the bit while routing. Solid pilots are more durable than ball bearing bits. All other bits do not have a pilot, so guide your router along a straight edge when hand routing to make accurate cuts.

Tongue and Groove—To cut the tongue, use the fully assembled bit. To cut the groove, remove one of the two cutters and adjust the height of the bit.

For technical drawings and 3-D models, click on a part number.

| Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Pilot Type | Number of Flutes | Flute Type | For Tool Type | For Use On | Each | |

Uncoated Carbide-Tipped Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 7/8" | 3/4" | 1/4" | 2 27/32" | Solid | 4 | Straight | Hand Router, Router Table | Particleboard, Plywood, Wood | 0000000 | 000000 |