Floor-Mount Rotating Cranes

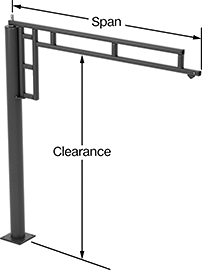

No need to pour a special foundation—you can install these cranes on a reinforced concrete floor. Also known as jib cranes, they rotate 360° to maximize floor space. Use Grade 5 steel Stud Anchors for Concrete (sold separately) to mount cranes to a minimum 6" deep reinforced concrete floor. Avoid any gaps, cracks, or expansion joints, and make sure your anchors are embedded at least 4 3/4" deep.

Blue painted steel cranes have tracks enclosed in the beams to keep debris from collecting on the track, allowing the trolley to move smoothly. The trolley has a mounting bar for your lifting device.

Rotation stops prevent cranes from turning past a certain point to protect surrounding structures. To install, weld the stop to the crane’s mast assembly. Since they’re welded, they’ll permanently limit the crane’s rotation.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Capacity | Beam | Trolley | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| tons | lbs. | Clearance, ft. | Overall Ht. | Wd. | Ht. | Beam Style | Eye Dia. | Bar Dia. | Rotation | Fasteners Included | Mounting Hole Dia. | Specifications Met | Each | |

Blue Painted Steel | ||||||||||||||

6-ft. Span | ||||||||||||||

| __ | 150 | 8 | 8'8" | __ | __ | Enclosed | 1" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 000000000 |

| 1/8 | 250 | 10 | 11'1" | __ | __ | Enclosed | 0.505" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

8-ft. Span | ||||||||||||||

| __ | 150 | 10 | 11'1" | __ | __ | Enclosed | 0.505" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/8 | 250 | 8 | 9'1" | __ | __ | Enclosed | 0.505" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/8 | 250 | 10 | 11'1" | __ | __ | Enclosed | 0.505" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/4 | 500 | 8 | 9'4" | __ | __ | Enclosed | 1 1/8" | 0.75" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/2 | 1,000 | 10 | 11'4" | __ | __ | Enclosed | 1 1/4" | 1" | 360° | No | 1 1/4" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

10-ft. Span | ||||||||||||||

| __ | 150 | 10 | 11'1" | __ | __ | Enclosed | 0.505" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/8 | 250 | 8 | 9'4" | __ | __ | Enclosed | 0.505" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/8 | 250 | 10 | 11'4" | __ | __ | Enclosed | 0.505" | 0.5" | 360° | No | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/4 | 500 | 8 | 9'4" | __ | __ | Enclosed | 3/4" | 0.75" | 360° | Yes | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

12-ft. Span | ||||||||||||||

| 1/4 | 500 | 12 | 13'7" | __ | __ | Enclosed | 1 1/8" | 0.75" | 360° | No | 1 1/4" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/2 | 1,000 | 10 | 11'8" | __ | __ | Enclosed | 1" | 1" | 360° | Yes | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

14-ft. Span | ||||||||||||||

| 1/4 | 500 | 12 | 13'8" | __ | __ | Enclosed | 1" | 1" | 360° | Yes | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

| 1/2 | 1,000 | 10 | 11'10" | __ | __ | Enclosed | 1" | 1" | 360° | Yes | 1" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 000000000 | 00000000 |

Yellow Painted Steel | ||||||||||||||

8-ft. Span | ||||||||||||||

| 1 | 2,000 | 10 | 10'11" | 5 3/4" | 10 1/4" | Open | __ | __ | 360° | No | 15/16" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 00000000 | 00000000 |

10-ft. Span | ||||||||||||||

| 1 | 2,000 | 10 | 10'11" | 5 3/4" | 10 1/4" | Open | __ | __ | 360° | No | 15/16" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 00000000 | 00000000 |

12-ft. Span | ||||||||||||||

| 1 | 2,000 | 10 | 10'11" | 5 3/4" | 10 1/4" | Open | __ | __ | 360° | No | 15/16" | ASME B30.11, OSHA Compliant 29 CFR 1910.179 | 00000000 | 00000000 |

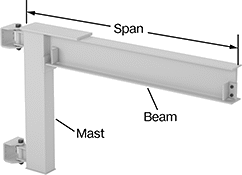

Column-Mount Rotating Cranes

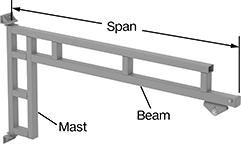

Designed to save valuable floor space, these cranes mount to structural columns. They’re also known as jib cranes. Make sure the column you mount these to can handle the thrust/pull force, which is how much these cranes will push and pull on your column as they lift loads. Use ASTM A325 Structural Bolts to mount these cranes.

Cranes with a mast let you lift loads from higher than cranes with a tie rod because the beam can be mounted closer to your ceiling. These cranes generally push and pull less on your column than cranes with a tie rod. Cranes with a tie rod are suspended overhead, allowing trolleys to travel over a longer span without a mast obstructing their movement. However, they require more space above the beam than cranes with a mast.

Cranes with an enclosed track prevent debris from collecting on the track, so trolleys run smoothly. The included trolley has a mounting eye for your lifting device. Those with an open track accommodate most trolleys. Stops on the beam limit trolley travel.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Also Available: Other spans of cranes with an open-track beam up to 20 ft. and capacities up to 10,000 lbs. Select 3729T999 and specify span and capacity.

Cranes | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Capacity | Beam | Replacement Mounting Bracket Sets | ||||||||||||||

| tons | lbs. | Thrust/Pull Force, lbs. | Overall Ht. | Wd. | Ht. | Rotation | Trolley Eye Dia. | Material | Fasteners Included | Mounting Hole Dia. | Features | Specifications Met | Each | Each | ||

Enclosed Track | ||||||||||||||||

8-ft. Span | ||||||||||||||||

| 1/16 | 150 | 610 | 3' | __ | 9" | 200° | 1/2" | Blue Painted Steel | No | 11/16" | __ | OSHA Compliant 29 CFR 1910.179 | 00000000 | 000000000 | 000000 | 00 |

| 1/8 | 250 | 960 | 3' | __ | 9" | 200° | 1/2" | Blue Painted Steel | No | 11/16" | __ | OSHA Compliant 29 CFR 1910.179 | 00000000 | 00000000 | 000000 | 00 |

| 1/4 | 500 | 1,390 | 4' | __ | 12" | 200° | 3/4" | Blue Painted Steel | No | 11/16" | __ | OSHA Compliant 29 CFR 1910.179 | 00000000 | 00000000 | 000000 | 00 |

| 1/2 | 1,000 | 2,720 | 4' | __ | 12" | 200° | 1" | Blue Painted Steel | No | 11/16" | __ | OSHA Compliant 29 CFR 1910.179 | 00000000 | 00000000 | 000000 | 00 |

Open Track | ||||||||||||||||

8-ft. Span | ||||||||||||||||

| 1/4 | 500 | 1,290 | 4'9" | 4" | 6 1/4" | 180° | __ | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 0000000 |

| 1/2 | 1,000 | 2,430 | 4'9" | 5 1/4" | 8 1/4" | 180° | __ | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 1 | 2,000 | 4,740 | 4'9" | 5 1/4" | 8 1/4" | 180° | __ | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 2 | 4,000 | 9,450 | 4'11" | 6 1/2" | 12 1/2" | 200° | __ | Yellow Painted Steel | No | 13/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 00000000 | 00000000 | 000000 | 00 |

10-ft. Span | ||||||||||||||||

| 1/4 | 500 | 1,680 | 4'9" | 4" | 6 1/4" | 180° | __ | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 1/2 | 1,000 | 3,080 | 4'9" | 5 1/4" | 8 1/4" | 180° | __ | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 1 | 2,000 | 5,000 | 5'9" | 5 3/4" | 10 1/2" | 180° | __ | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 2 | 4,000 | 12,210 | 4'11" | 6 1/2" | 12 1/2" | 200° | __ | Yellow Painted Steel | No | 13/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 00000000 | 00000000 | 000000 | 00 |

12-ft. Span | ||||||||||||||||

| 1/4 | 500 | 2,090 | 4'9" | 4" | 6 1/4" | 180° | __ | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 1/2 | 1,000 | 3,730 | 4'9" | 5 1/4" | 8 1/4" | 180° | __ | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 1 | 2,000 | 6,040 | 5'9" | 5 3/4" | 10 1/2" | 180° | __ | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 2 | 4,000 | 15,000 | 4'11" | 6 1/2" | 12 1/2" | 180° | __ | Yellow Painted Steel | No | 13/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 000000 | 00 |

14-ft. Span | ||||||||||||||||

| 1/2 | 1,000 | 4,750 | 4'9" | 5 1/4" | 8 1/4" | 180° | __ | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 1 | 2,000 | 7,080 | 5'9" | 5 3/4" | 10 1/2" | 180° | __ | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

20-ft. Span | ||||||||||||||||

| 1/2 | 1,000 | 5,350 | 6'9" | 6 1/2" | 12 1/2" | 180° | __ | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 1 | 2,000 | 9,510 | 6'9" | 7" | 16" | 180° | __ | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 00000000 | 00000000 | 0000000 | 000000 |

| 2 | 4,000 | 17,300 | 7'5" | 8 1/4" | 21" | 180° | __ | Yellow Painted Steel | No | 13/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 00000000 | 00000000 | 000000 | 00 |

Also Available: Other spans up to 30 ft. and capacities up to 10,000 lbs. Select 3245T999 and specify span and capacity.

Cranes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Capacity | Beam | Replacement Mounting Bracket Sets | |||||||||||||

| tons | lbs. | Thrust/Pull Force, lbs. | Overall Ht. | Wd. | Ht. | Rotation | Material | Fasteners Included | Mounting Hole Dia. | Features | Specifications Met | Each | Each | ||

Open Track | |||||||||||||||

8-ft. Span | |||||||||||||||

| 1/2 | 1,000 | 3,930 | 3'4" | 4" | 6 1/4" | 200° | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 000000000 | 0000000 | 0000000 |

| 1 | 2,000 | 7,710 | 3'4" | 4" | 6 1/4" | 200° | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

10-ft. Span | |||||||||||||||

| 1/2 | 1,000 | 4,550 | 3'7" | 4" | 6 1/4" | 200° | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 1 | 2,000 | 8,880 | 3'7" | 4" | 6 1/4" | 200° | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

12-ft. Span | |||||||||||||||

| 1/2 | 1,000 | 4,400 | 4'4" | 4" | 6 1/4" | 200° | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 1 | 2,000 | 8,560 | 4'4" | 4" | 6 1/4" | 200° | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

14-ft. Span | |||||||||||||||

| 1/2 | 1,000 | 4,320 | 5'1" | 4" | 6 1/4" | 200° | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 1 | 2,000 | 8,420 | 5'1" | 5 1/4" | 8 1/4" | 200° | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 2 | 4,000 | 16,580 | 5'3" | 5 1/4" | 8 1/4" | 200° | Yellow Painted Steel | No | 13/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 000000 | 00 |

20-ft. Span | |||||||||||||||

| 1/2 | 1,000 | 4,560 | 7'1" | 5 1/4" | 8 1/4" | 200° | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 1 | 2,000 | 8,650 | 7'1" | 5 3/4" | 10 1/2" | 200° | Yellow Painted Steel | No | 11/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 0000000 | 000000 |

| 2 | 4,000 | 16,980 | 7'3" | 6 1/2" | 12 1/2" | 200° | Yellow Painted Steel | No | 13/16" | Beam Stops | OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 000000 | 00 |

Foundation-Mount Rotating Cranes

Install these cranes with anchor bolts (sold separately) set in a reinforced-concrete foundation. They rotate 360° to maximize floor space. Also known as jib cranes, they consist of a mast, head assembly, and flat beam that accommodates most trolleys. Use the included base plate pattern as a template to properly set anchor bolts into the foundation.

Anchor bolts include leveling nuts and securing nuts with washers to hold the mast's base plate.

Rotation stops prevent cranes from turning past a certain point to protect surrounding structures. To install, weld the stop bar to the crane’s mast assembly and the stop angle to the head assembly. Since rotation stops are welded, they’ll permanently limit a crane’s rotation.

Also Available: Other spans (from 10 ft. up to 20 ft.), capacities (up to 10,000 lbs.), and clearances (up to 20 ft.). Select 3244T999 and choose specifications.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Cranes with 360° Rotation | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Capacity | Overall | Beam | For Foundation | Anchor Bolts | ||||||||||||||

| tons | lbs. | Clearance, ft. | Lg. | Wd. | Ht. | Wd. | Ht. | Lg., ft. | Wd., ft. | Dp., ft. | Fasteners Included | Mounting Hole Dia. | Specifications Met | Each | Pkg. Qty. | Pkg. | ||

Yellow Painted Steel | ||||||||||||||||||

10-ft. Span | ||||||||||||||||||

| 1/4 | 500 | 10 | 11' | 2'3" | 10'7" | 4" | 6 1/4" | 4 | 4 | 3 | No | 1 3/16" | Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.179 | 0000000 | 000000000 | 6 | 0000000 | 0000000 |

| 1/2 | 1,000 | 10 | 11' | 2'3" | 10'7" | 4" | 6 1/4" | 4 | 4 | 3 | No | 1 3/16" | Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 6 | 0000000 | 000000 |

| 1 | 2,000 | 10 | 11'3" | 2'8" | 10'9" | 5 1/4" | 8 1/4" | 5 | 5 | 4 | No | 1 7/16" | Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 6 | 0000000 | 000000 |

12-ft. Span | ||||||||||||||||||

| 1/2 | 1,000 | 10 | 13'3" | 2'8" | 10'9" | 5 1/4" | 8 1/4" | 4 | 4 | 3 | No | 1 7/16" | Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 6 | 0000000 | 000000 |

| 1 | 2,000 | 10 | 13'3" | 2'8" | 10'11" | 5 3/4" | 10 1/2" | 6 | 6 | 4 | No | 1 7/16" | Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 6 | 0000000 | 000000 |

14-ft. Span | ||||||||||||||||||

| 1/2 | 1,000 | 10 | 15'3" | 2'8" | 10'9" | 5 1/4" | 8 1/4" | 5 | 5 | 3 | No | 1 7/16" | Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 6 | 0000000 | 000000 |

| 1 | 2,000 | 12 | 15'5" | 3'1" | 13'1" | 6 1/2" | 12 1/2" | 6 | 6 | 4 | No | 1 7/16" | Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 6 | 0000000 | 000000 |

| 2 | 4,000 | 12 | 15'4" | 3'6" | 13'5" | 7" | 16 1/4" | 7 | 7 | 4 | No | 1 7/16" | Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 12 | 0000000 | 000000 |

16-ft. Span | ||||||||||||||||||

| 1 | 2,000 | 12 | 17'4" | 4' | 13'1" | 6 1/2" | 12 1/2" | 7 | 7 | 4 | No | 1 7/16" | Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 12 | 0000000 | 000000 |

| 2 | 4,000 | 12 | 17'4" | 4' | 13'6" | 7 1/2" | 18 1/8" | 8 | 8 | 4 | No | 1 7/16" | Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 12 | 0000000 | 000000 |

18-ft. Span | ||||||||||||||||||

| 1 | 2,000 | 12 | 19'4" | 4' | 13'5" | 7" | 16 1/8" | 7 | 7 | 4 | No | 1 7/16" | Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 | 12 | 0000000 | 000000 |

| Pair | ||

| 00000000 | 000000 |

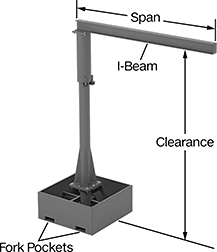

Movable Rotating Cranes

Transport these cranes anywhere they’re needed in your facility. Made with fork pockets in the base, they can be lifted and moved with a fork truck—saving you from taking your load to a mounted crane or having multiple cranes around your building. The first time you use these cranes, fill the base with concrete to keep them stable. Also known as jib cranes, they have an I-beam that rotates 360°, which makes it easy to position loads. The beam can accommodate most trolleys.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Capacity | Overall | Beam | For Max. Fork | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| tons | lbs. | Clearance, ft. | Lg. | Wd. | Ht. | Wd. | Ht. | Fork Pocket Spacing Ctr.-to-Ctr. | For Min. Fork Lg. | Wd. | Ht. | Rotation | Specifications Met | Each | |

Blue Painted Steel | |||||||||||||||

8-ft. Span | |||||||||||||||

| 1/8 | 250 | 10 | 9'4" | 3'6" | 10'6" | 4" | 6" | 24" | 42" | 7 1/2" | 2 1/2" | 360° | ASME B30.11, CMAA Specification No. 74, OSHA Compliant 29 CFR 1910.179 | 0000000 | 000000000 |

| 1/4 | 500 | 10 | 9'4" | 3'6" | 10'6" | 4" | 6" | 24" | 42" | 7 1/2" | 2 1/2" | 360° | ASME B30.11, CMAA Specification No. 74, OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 |

| 1/2 | 1,000 | 10 | 9'3" | 3'6" | 10'10" | 4" | 10" | 24" | 42" | 7 1/2" | 2 1/2" | 360° | ASME B30.11, CMAA Specification No. 74, OSHA Compliant 29 CFR 1910.179 | 0000000 | 00000000 |

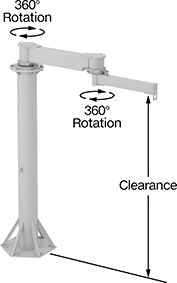

Articulating Cranes

Reach around corners and into tight spaces to precisely place loads. With two joints that each swivel 360°, these cranes are easier to maneuver around obstacles than our standard rotating cranes. They’re often used to move material around machinery, through doorways, and in other complex lifting jobs. Instead of swinging a load in a circle at a fixed distance, these cranes let you position it almost anywhere within their span.

Install with anchor bolts (sold separately) set in a reinforced concrete foundation.

Rotation stops (sold separately) prevent cranes from turning past a certain point to protect nearby machines and walls.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Capacity | Overall | Beam | For Foundation | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| tons | lbs. | Clearance, ft. | Lg. | Wd. | Ht. | Wd. | Ht. | Eye Dia. | Rotation | Lg., ft. | Wd., ft. | Dp., ft. | Fasteners Included | Mounting Hole Dia. | Specifications Met | Each | |

Yellow Painted Steel | |||||||||||||||||

8-ft. Span | |||||||||||||||||

| 1/2 | 1,000 | 10 | 9'7" | 3'3" | 11'10" | 6" | 10" | 2 1/2" | 360° | 4 | 4 | 4 | No | 1" | ASME B30.11, CMAA Specification No. 74, OSHA Compliant 29 CFR 1910.179 | 0000000 | 0000000000 |

10-ft. Span | |||||||||||||||||

| 1/2 | 1,000 | 10 | 11'7" | 3'3" | 11'10" | 6" | 10" | 2 1/2" | 360° | 4 | 4 | 4 | No | 1" | ASME B30.11, CMAA Specification No. 74, OSHA Compliant 29 CFR 1910.179 | 0000000 | 000000000 |

| Material | Lg. | Includes | Pkg. Qty. | Pkg. | |

| Steel | 48" | Leveling Nuts, Securing Nuts, Washers | 6 | 0000000 | 0000000 |

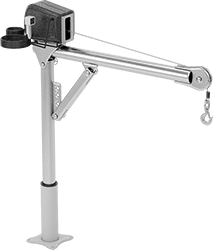

Hand-Winch Cranes

Also known as davit cranes, these lift objects out of holes such as sewers. An automatic brake holds your load securely when the handle is released.

Styles D and E can be disassembled for convenient transport and storage.

Powder-coated steel cranes offer some corrosion resistance. Stainless steel cranes have the most corrosion resistance.

Install additional bases throughout your plant and move your hand-winch crane between them to use a single crane in multiple locations. They can also be used to replace existing bases.

Replacement headache balls keep cable taut when no load is attached.

Warning: Never use to lift people or items over people.

Retracted Arm Cap. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Arm Lg. | tons | lbs. | Lift Lg., ft. | O'all Ht. | Rotation | Roller Chain Material | Hook Material | Hook Opening Wd. | Hook Movement | Base Material | Fasteners Included | Mounting Hole Dia. | Specifications Met | Each | |

Powder-Coated Steel | ||||||||||||||||

| A | 21" | 1/4 | 500 | 6 | 5'4" | 360° | Steel | Steel | 3/4" | 360° Swivel | Powder-Coated Steel | No | 3/4" | ASME B30.16, OSHA Compliant 29 CFR 1926.1501 | 0000000 | 000000000 |

Retracted Arm Cap. | Extended Arm Cap. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Arm Lg. | tons | lbs. | tons | lbs. | Lift Lg., ft. | O'all Ht. | Rotation | Wire Rope Material | Hook Material | Hook Opening Wd. | Hook Movement | Base Material | Fasteners Included | Mounting Hole Dia. | Each | |

Powder-Coated Steel | |||||||||||||||||

| B | 42" | 1/4 | 500 | __ | __ | 34 | 4'8" | 360° | Galvanized Steel | Steel | 7/8" | 360° Swivel | Powder-Coated Steel | No | 9/16" | 00000000 | 000000000 |

| B | 36"-66" | 1/2 | 1,000 | 1/4 | 500 | 47 | 5' | 360° | Galvanized Steel | Steel | 7/8" | 360° Swivel | Powder-Coated Steel | No | 11/16" | 00000000 | 00000000 |

| B | 46"-82" | 1 | 2,000 | 1/2 | 1,100 | 45 | 5'4" | 360° | Galvanized Steel | Steel | 7/8" | 360° Swivel | Powder-Coated Steel | No | 11/16" | 00000000 | 00000000 |

| C | 42" | 1/4 | 500 | __ | __ | 34 | 3'6" | 360° | Galvanized Steel | Steel | 7/8" | 360° Swivel | Powder-Coated Steel | No | 9/16" | 00000000 | 00000000 |

| C | 36"-66" | 1/2 | 1,000 | 1/4 | 500 | 47 | 3'10" | 360° | Galvanized Steel | Steel | 7/8" | 360° Swivel | Powder-Coated Steel | No | 11/16" | 00000000 | 00000000 |

| C | 46"-82" | 1 | 2,000 | 1/2 | 1,100 | 45 | 4'2" | 360° | Galvanized Steel | Steel | 7/8" | 360° Swivel | Powder-Coated Steel | No | 11/16" | 00000000 | 00000000 |

Stainless Steel | |||||||||||||||||

| B | 42" | 1/4 | 500 | __ | __ | 34 | 4'8" | 360° | Stainless Steel | Stainless Steel | 7/8" | Rigid | Stainless Steel | No | 9/16" | 00000000 | 00000000 |

| B | 36"-66" | 1/2 | 1,000 | 1/4 | 500 | 47 | 5' | 360° | Stainless Steel | Stainless Steel | 3/4" | Rigid | Stainless Steel | No | 11/16" | 00000000 | 00000000 |

| B | 46"-82" | 1 | 2,000 | 1/2 | 1,100 | 45 | 5'1" | 360° | Stainless Steel | Stainless Steel | 3/4" | Rigid | Stainless Steel | No | 11/16" | 000000000 | 00000000 |

| C | 42" | 1/4 | 500 | __ | __ | 34 | 3'6" | 360° | Stainless Steel | Stainless Steel | 7/8" | Rigid | Stainless Steel | No | 9/16" | 00000000 | 00000000 |

Retracted Arm Cap. | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Arm Lg. | tons | lbs. | Lift Lg., ft. | O'all Ht. | For Max. Opening Dia., ft. | Rotation | Roller Chain Material | Hook Material | Hook Opening Wd. | Hook Movement | Base Material | No. of Wheel Brakes | Wheel Material | Specifications Met | Each | |

Powder-Coated Steel | |||||||||||||||||

| D | 21" | 1/4 | 500 | 6 | 6'1" | 2 | 30° | Steel | Steel | 3/4" | 360° Swivel | Powder-Coated Steel | 2 | Plastic | ASME B30.16, OSHA Compliant 29 CFR 1926.1501 | 0000000 | 000000000 |

For Retracted Arm Cap. | For Extended Arm Cap. | Mounting Plate | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mounting Location | tons | lbs. | tons | lbs. | For Mast Dia. | Distance Between Legs | Base Ht. | Mounting Hole Dia. | Wd. | Lg. | Thick. | Wheel Configuration | Wheel Material | Each | |

Stationary—Powder-Coated Steel | |||||||||||||||

| Floor | 1/4 | 500 | __ | __ | 2 1/4" | __ | 30 1/2" | 3/4" | 12" | 12" | 1/2" | __ | __ | 0000000 | 0000000 |

| Floor | 1/4 | 500 | __ | __ | 2 7/8" | __ | 14 1/4" | 9/16" | 8 1/8" | 8 1/8" | 1/2" | __ | __ | 00000000 | 000000 |

| Floor | 1/2 | 1,000 | 1/4 | 500 | 3 1/2" | __ | 14 3/8" | 11/16" | 15 7/8" | 15 7/8" | 3/8" | __ | __ | 00000000 | 000000 |

| Floor | 1 | 2,000 | 1/2 | 1,000 | 4 1/2" | __ | 14 3/8" | 11/16" | 15 7/8" | 15 7/8" | 1/2" | __ | __ | 00000000 | 000000 |

| Wall | 1/4 | 500 | __ | __ | 2 7/8" | __ | 14 1/4" | 9/16" | 8 1/8" | 10" | 3/8" | __ | __ | 00000000 | 000000 |

| Wall | 1/2 | 1,000 | 1/4 | 500 | 3 1/2" | __ | 15 7/8" | 11/16" | 15 7/8" | 15 7/8" | 3/8" | __ | __ | 00000000 | 000000 |

Stationary—Stainless Steel | |||||||||||||||

| Floor | 1/4 | 500 | __ | __ | 2 7/8" | __ | 14 1/4" | 9/16" | 8 1/8" | 8 1/8" | 1/2" | __ | __ | 00000000 | 000000 |

| Floor | 1/2 | 1,000 | 1/4 | 500 | 3 1/2" | __ | 14 3/8" | 11/16" | 15 7/8" | 15 7/8" | 3/8" | __ | __ | 00000000 | 00000000 |

| Floor | 1 | 2,000 | 1/2 | 1,000 | 4 1/2" | __ | 14 3/8" | 11/16" | 15 7/8" | 15 7/8" | 1/2" | __ | __ | 00000000 | 00000000 |

| Wall | 1/4 | 500 | __ | __ | 2 7/8" | __ | 14 1/4" | 9/16" | 8 1/8" | 10" | 3/8" | __ | __ | 00000000 | 000000 |

| Wall | 1/2 | 1,000 | 1/4 | 500 | 3 1/2" | __ | 15 7/8" | 11/16" | 15 7/8" | 15 7/8" | 3/8" | __ | __ | 00000000 | 00000000 |

Mobile—Powder-Coated Steel | |||||||||||||||

| Freestanding | 1/4 | 500 | __ | __ | 2 1/4" | 28" | 38 5/8" | __ | __ | __ | __ | Two Swivel and Two Rigid Casters | Plastic | 0000000 | 00000000 |

Lightweight Hand-Winch Cranes

These cranes are half the weight of other hand-winch cranes with similar capacity and can be lifted from their base for easy transport. They're also known as davit cranes. Use them to lift objects out of holes such as sewers. Made from fiberglass, all are corrosion resistant and nonconductive. An automatic brake holds your load securely when the handle is released.

Install additional bases throughout your plant and move your hand-winch crane between them to use a single crane in multiple locations. They can also be used to replace existing bases.

Warning: Never use to lift people or items over people.

Cranes | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Extended Arm Cap. | Retracted Arm Cap. | Additional Bases | |||||||||||||||||

| Mounting Location | Arm Lg. | tons | lbs. | tons | lbs. | Lift Lg., ft. | Overall Ht. | Rotation | Wire Rope Material | Hook Style | Hook Material | Hook Opening Wd. | Hook Movement | Fasteners Included | Mounting Hole Dia. | Each | Each | ||

Painted Fiberglass | |||||||||||||||||||

| Floor | 36"-66" | 1/8 | 400 | 1/2 | 1,200 | 45 | 5'4" | 360° | Galvanized Steel | Latching | Steel | 3/4" | 360° Swivel | No | 11/16" | 0000000 | 000000000 | 00000000 | 0000000 |

| Wall | 36"-66" | 1/8 | 400 | 1/2 | 1,200 | 45 | 5'4" | 360° | Galvanized Steel | Latching | Steel | 3/4" | 360° Swivel | No | 11/16" | 0000000 | 00000000 | 00000000 | 000000 |

Desktop Cranes

Mount these cranes to a workbench or utility cart to lift and position loads in tight workspaces. They’re often used in repair or assembly tasks to lift heavy tools and parts. Their compact size makes them easy to move from one base to another. Additional bases are sold separately. Turn the hand wheel clockwise to lift your load. An automatic brake holds your load securely in place when you let go of the wheel. These cranes rotate a full 360°, making it easy to position a load on your workbench or on nearby equipment such as a CNC machine.

Cranes with a roller chain winch move at a more consistent speed than those with a wire rope winch. Since the roller chain moves around a sprocket, raising loads doesn’t require additional force as you go—unlike wire rope on a spool. Cranes with a wire rope winch are best for dirty environments because there are no chain links that could trap debris. These cranes also move more smoothly, because there’s less jerking as the wire rope moves around the spool than there is with a roller chain on a sprocket.

Cranes with a lever lowering mechanism require you to release the brake lever next to the hand wheel. As you do, lightly press your palm on the hand wheel to control how fast your load descends. Cranes with a hand-winch lowering mechanism are easier to use and give you more control than cranes that lower with a lever. Simply turn the hand wheel counterclockwise to lower.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Cranes | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Additional Bases | ||||||||||||||||

| Arm Lg. | tons | lbs. | Lift Lg., ft. | O'all Ht. | Lowering Mechanism | Rotation | Roller Chain Material | Hook Material | Hook Opening Wd. | Hook Movement | Fasteners Included | Mount. Hole Dia. | Specifications Met | Each | Each | ||

Powder-Coated Steel | |||||||||||||||||

| 21" | 1/4 | 500 | 6 | 3'6" | Lever | 360° | Steel | Steel | 5/8" | 360° Swivel | No | 9/16" | ASME B30.16, OSHA Compliant 29 CFR 1926.1501 | 0000000 | 000000000 | 0000000 | 0000000 |

Cranes | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Additional Bases | ||||||||||||||||

| Arm Lg. | tons | lbs. | Lift Lg., ft. | O'all Ht. | Lowering Mechanism | Rotation | Wire Rope Material | Hook Material | Hook Opening Wd. | Hook Movement | Fasteners Included | Mount. Hole Dia. | Specifications Met | Each | Each | ||

Powder-Coated Steel | |||||||||||||||||

| 21" | 1/4 | 500 | 8 | 3'6" | Lever | 360° | Steel | Steel | 5/8" | 360° Swivel | No | 9/16" | ASME B30.16, OSHA Compliant 29 CFR 1926.1501 | 00000000 | 000000000 | 0000000 | 0000000 |

| 21" | 1/4 | 500 | 8 | 3'6" | Hand Winch | 360° | Steel | Steel | 5/8" | 360° Swivel | No | 9/16" | ASME B30.16, OSHA Compliant 29 CFR 1926.1501 | 00000000 | 00000000 | 0000000 | 000000 |

Articulating Desktop Cranes

With two joints that each rotate 360°, these cranes make it easy to position a load exactly where you need it. Unlike standard desktop cranes that swing loads in a circle at a fixed distance, these cranes let you place it almost anywhere within their arm’s reach. Mount them to workbenches and utility carts to save room in tight workspaces. They’re often used to raise heavy tools and parts for repair or assembly. Since they’re compact, they’re easy to move from one base to another. Additional bases are sold separately. Turn the hand wheel clockwise to raise a load and counterclockwise to lower it. An internal brake controls the descent, keeping it slow and steady, and holds the load in place if you let go of the hand wheel.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Cranes | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Additional Bases | ||||||||||||||||

| Arm Lg. | tons | lbs. | Lift Lg., ft. | O'all Ht. | Rotation | Wire Rope Material | Hook Style | Hook Material | Hook Opening Wd. | Hook Movement | Fasteners Included | Mounting Hole Dia. | Specifications Met | Each | Each | ||

Powder-Coated Steel | |||||||||||||||||

| 36" | 1/4 | 500 | 8 | 3'6" | 360° | Steel | Latching | Steel | 5/8" | 360° Swivel | No | 9/16" | ASME B30.16, ASME HST-3, OSHA Compliant 29 CFR 1926.1501 | 00000000 | 000000000 | 0000000 | 0000000 |

Electric Winch Cranes

No hand-cranking needed—simply push a button on the handheld control to lift or lower a heavy load. These cranes are also known as davit cranes. The automatic brake holds your load securely in place when you’re not moving it up or down. For precise positioning in all directions, these cranes rotate a full 360°. The arm can be adjusted to four different heights depending on your needs.

Electric-powered cranes work well for long-running jobs because there’s no battery to worry about. They plug into an electrical outlet.

Battery-powered cranes work in locations without electrical outlets. Use the wire leads to connect them to a 12V DC battery (not included).

Install additional bases throughout your facility to make it easy to use your crane in different spots. Make sure the maximum capacity of your crane matches the capacity of the base you choose.

Headache balls keep the cable taut when there’s no load, making the crane more stable for safety.

Note: Capacity is highest for the first layer of rope and decreases as each additional layer of rope is wound on the winch. There are at least five wraps of rope on the winch.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

| Min. Cap., lbs. | Max. Cap., lbs. | Fully Wound Cap., lbs. | Arm Lg. | Lift Lg., ft. | Lifting Speed, fpm | O'all Ht. | Hook Movement | Fasteners Included | Each | |

Floor Mount (Surface) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel with Galvanized Steel Wire Rope | ||||||||||

| 500 | 500 | 500 | 28"-42" | 90 | 16 | 4'2" to 6'5" | 360° Swivel | Yes | 0000000 | 000000000 |

| 550 | 1,000 | 550 | 28"-42" | 45 | 16 | 3'10" to 6'4" | 360° Swivel | Yes | 0000000 | 00000000 |

Floor Mount (Flush) | ||||||||||

Zinc-Plated Steel with Galvanized Steel Wire Rope | ||||||||||

| 500 | 500 | 500 | 28"-42" | 90 | 16 | 4'2" to 6'5" | 360° Swivel | Yes | 0000000 | 00000000 |

| 550 | 1,000 | 550 | 28"-42" | 45 | 16 | 3'10" to 6'4" | 360° Swivel | Yes | 0000000 | 00000000 |

Wall Mount (Surface) | ||||||||||

Zinc-Plated Steel with Galvanized Steel Wire Rope | ||||||||||

| 500 | 500 | 500 | 28"-42" | 90 | 16 | 4'2" to 6'5" | 360° Swivel | Yes | 0000000 | 00000000 |

| 550 | 1,000 | 550 | 28"-42" | 45 | 16 | 3'10" to 6'4" | 360° Swivel | Yes | 0000000 | 00000000 |

| Min. Cap., lbs. | Max. Cap., lbs. | Fully Wound Cap., lbs. | Arm Lg. | Lift Lg., ft. | Lifting Speed, fpm | O'all Ht. | Current, A | Hook Movement | Batteries Included | Fasteners Included | Each | |

Floor Mount (Surface) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel with Galvanized Steel Wire Rope | ||||||||||||

| 500 | 500 | 500 | 28"-42" | 90 | 8 | 4'2" to 6'5" | 70 | 360° Swivel | No | Yes | 0000000 | 000000000 |

| 550 | 1,000 | 550 | 28"-42" | 45 | 8 | 3'10" to 6'4" | 70 | 360° Swivel | No | Yes | 0000000 | 00000000 |

Floor Mount (Flush) | ||||||||||||

Zinc-Plated Steel with Galvanized Steel Wire Rope | ||||||||||||

| 500 | 500 | 500 | 28"-42" | 90 | 8 | 4'2" to 6'5" | 70 | 360° Swivel | No | Yes | 0000000 | 00000000 |

| 550 | 1,000 | 550 | 28"-42" | 45 | 8 | 3'10" to 6'4" | 70 | 360° Swivel | No | Yes | 0000000 | 00000000 |

Wall Mount (Surface) | ||||||||||||

Zinc-Plated Steel with Galvanized Steel Wire Rope | ||||||||||||

| 500 | 500 | 500 | 28"-42" | 90 | 8 | 4'2" to 6'5" | 70 | 360° Swivel | No | Yes | 0000000 | 00000000 |

| 550 | 1,000 | 550 | 28"-42" | 45 | 8 | 3'10" to 6'4" | 70 | 360° Swivel | No | Yes | 0000000 | 00000000 |

| Material | Each | |

| Powder-Coated Steel | 0000000 | 0000000 |