Rosin Flux-Core Solder for Electronics and Electrical Applications

Rosin flux is quick acting with strong cleaning action, but it leaves residue that requires flux remover. This solder is electrically conductive, so it’s good for electronics and electronic applications. Product regulations restrict sales to the listed jurisdictions/areas.

Lead-free solder is safer to use than leaded solder and helps meet industry regulations.

For technical drawings and 3-D models, click on a part number.

Material Composition | ||||||||

|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Silver | Lead | Melting Temperature, °F | Dia. | Wt. | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||||

| Sn40Pb60 | 40% | __ | 60% | 460° | 0.015" | 1 lbs. | 00000000 | 000000 |

| Sn40Pb60 | 40% | __ | 60% | 460° | 0.020" | 1 lbs. | 00000000 | 00000 |

| Sn40Pb60 | 40% | __ | 60% | 460° | 0.031" | 1 lbs. | 00000000 | 00000 |

| Sn40Pb60 | 40% | __ | 60% | 460° | 0.050" | 1 lbs. | 00000000 | 00000 |

| Sn40Pb60 | 40% | __ | 60% | 460° | 0.062" | 1 lbs. | 0000000 | 00000 |

| Sn40Pb60 | 40% | __ | 60% | 460° | 0.093" | 1 lbs. | 000000 | 00000 |

| Sn40Pb60 | 40% | __ | 60% | 460° | 0.093" | 5 lbs. | 000000 | 000000 |

| Sn50Pb50 | 50% | __ | 50% | 420° | 0.015" | 1 lbs. | 00000000 | 00000 |

| Sn50Pb50 | 50% | __ | 50% | 420° | 0.020" | 1 lbs. | 00000000 | 00000 |

| Sn50Pb50 | 50% | __ | 50% | 420° | 0.032" | 1 lbs. | 00000000 | 00000 |

| Sn50Pb50 | 50% | __ | 50% | 420° | 0.040" | 1 lbs. | 00000000 | 00000 |

| Sn50Pb50 | 50% | __ | 50% | 420° | 0.050" | 1 lbs. | 00000000 | 00000 |

| Sn50Pb50 | 50% | __ | 50% | 420° | 0.062" | 1 lbs. | 0000000 | 00000 |

| Sn50Pb50 | 50% | __ | 50% | 420° | 0.093" | 1 lbs. | 00000000 | 00000 |

| Sn50Pb50 | 50% | __ | 50% | 420° | 0.125" | 1 lbs. | 00000000 | 00000 |

| Sn60Pb40 | 60% | __ | 40% | 370° | 0.015" | 1 lbs. | 00000000 | 00000 |

| Sn60Pb40 | 60% | __ | 40% | 370° | 0.020" | 1 lbs. | 00000000 | 00000 |

| Sn60Pb40 | 60% | __ | 40% | 370° | 0.025" | 1 lbs. | 0000000 | 00000 |

| Sn60Pb40 | 60% | __ | 40% | 370° | 0.031" | 1 lbs. | 000000 | 00000 |

| Sn60Pb40 | 60% | __ | 40% | 370° | 0.040" | 1 lbs. | 00000000 | 00000 |

| Sn60Pb40 | 60% | __ | 40% | 370° | 0.050" | 1 lbs. | 0000000 | 00000 |

| Sn60Pb40 | 60% | __ | 40% | 370° | 0.062" | 1 lbs. | 000000 | 00000 |

| Sn60Pb40 | 60% | __ | 40% | 370° | 0.062" | 5 lbs. | 000000 | 000000 |

| Sn60Pb40 | 60% | __ | 40% | 370° | 0.093" | 1 lbs. | 0000000 | 00000 |

| Sn60Pb40 | 60% | __ | 40% | 370° | 0.125" | 8 oz. | 0000000 | 00000 |

| Sn62Pb36Ag2 | 62% | 2% | 36% | 370° | 0.020" | 1 lbs. | 00000000 | 000000 |

| Sn62Pb36Ag2 | 62% | 2% | 36% | 370° | 0.031" | 1 lbs. | 0000000 | 000000 |

| Sn63Pb37 | 63% | __ | 37% | 370° | 0.010" | 1 lbs. | 00000000 | 000000 |

| Sn63Pb37 | 63% | __ | 37% | 370° | 0.015" | 1 lbs. | 0000000 | 00000 |

| Sn63Pb37 | 63% | __ | 37% | 370° | 0.020" | 1 lbs. | 00000000 | 00000 |

| Sn63Pb37 | 63% | __ | 37% | 370° | 0.025" | 1 lbs. | 0000000 | 00000 |

| Sn63Pb37 | 63% | __ | 37% | 370° | 0.031" | 1 lbs. | 0000000 | 00000 |

| Sn63Pb37 | 63% | __ | 37% | 370° | 0.040" | 1 lbs. | 00000000 | 00000 |

| Sn63Pb37 | 63% | __ | 37% | 370° | 0.050" | 1 lbs. | 0000000 | 00000 |

| Sn63Pb37 | 63% | __ | 37% | 370° | 0.062" | 1 lbs. | 0000000 | 00000 |

| Sn63Pb37 | 63% | __ | 37% | 370° | 0.093" | 1 lbs. | 00000000 | 00000 |

| Sn63Pb37 | 63% | __ | 37% | 370° | 0.125" | 1 lbs. | 00000000 | 00000 |

Material Composition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Silver | Antimony | Copper | Lead | Melting Temperature, °F | Dia. | Wt. | Cannot Be Sold To | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | |||||||||||

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | __ | 0.5% | 0% | 460° | 0.015" | 1 lbs. | __ | 00000000 | 0000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | __ | 0.5% | 0% | 460° | 0.020" | 1 lbs. | __ | 0000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | __ | 0.5% | 0% | 460° | 0.025" | 1 lbs. | __ | 00000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | __ | 0.5% | 0% | 460° | 0.031" | 1 lbs. | __ | 0000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | __ | 0.5% | 0% | 460° | 0.040" | 5/8 oz. | Outside United States and Canada | 0000000 | 00000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | __ | 0.5% | 0% | 460° | 0.040" | 1 lbs. | __ | 0000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | __ | 0.5% | 0% | 460° | 0.062" | 1 lbs. | __ | 0000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | __ | 0.5% | 0% | 460° | 0.093" | 1 lbs. | __ | 0000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | __ | 0.5% | 0% | 460° | 0.125" | 1 lbs. | __ | 00000000 | 000000 |

| Sn97Cu2Sb0.8Ag0.2 | 97% | 0.2% | 0.8% | 2% | 0% | 460° | 0.015" | 1 lbs. | __ | 00000000 | 00000 |

| Sn97Cu2Sb0.8Ag0.2 | 97% | 0.2% | 0.8% | 2% | 0% | 460° | 0.025" | 1 lbs. | __ | 00000000 | 00000 |

| Sn97Cu2Sb0.8Ag0.2 | 97% | 0.2% | 0.8% | 2% | 0% | 460° | 0.050" | 1 lbs. | __ | 00000000 | 00000 |

| Sn97Cu2Sb0.8Ag0.2 | 97% | 0.2% | 0.8% | 2% | 0% | 460° | 0.125" | 1 lbs. | __ | 00000000 | 00000 |

| Sn97Cu3 | 97% | __ | __ | 3% | 0% | 480° | 0.015" | 1 lbs. | __ | 00000000 | 00000 |

| Sn97Cu3 | 97% | __ | __ | 3% | 0% | 480° | 0.025" | 1 lbs. | __ | 00000000 | 00000 |

| Sn97Cu3 | 97% | __ | __ | 3% | 0% | 480° | 0.031" | 1 lbs. | __ | 0000000 | 00000 |

| Sn97Cu3 | 97% | __ | __ | 3% | 0% | 480° | 0.050" | 1 lbs. | __ | 00000000 | 00000 |

| Sn97Cu3 | 97% | __ | __ | 3% | 0% | 480° | 0.062" | 1 lbs. | __ | 00000000 | 00000 |

| Sn97Cu3 | 97% | __ | __ | 3% | 0% | 480° | 0.093" | 1 lbs. | __ | 00000000 | 00000 |

| Sn97Cu3 | 97% | __ | __ | 3% | 0% | 480° | 0.125" | 1 lbs. | __ | 0000000 | 00000 |

| Sn99.3Cu0.7 | 99.3% | __ | __ | 0.7% | 0% | 440° | 0.015" | 1 lbs. | __ | 00000000 | 000000 |

| Sn99.3Cu0.7 | 99.3% | __ | __ | 0.7% | 0% | 440° | 0.020" | 1 lbs. | __ | 00000000 | 000000 |

| Sn99.3Cu0.7 | 99.3% | __ | __ | 0.7% | 0% | 440° | 0.032" | 1 lbs. | __ | 00000000 | 00000 |

| Sn99.3Cu0.7 | 99.3% | __ | __ | 0.7% | 0% | 440° | 0.062" | 1 lbs. | __ | 00000000 | 00000 |

| Sn99.3Cu0.7 | 99.3% | __ | __ | 0.7% | 0% | 440° | 0.093" | 1 lbs. | __ | 00000000 | 000000 |

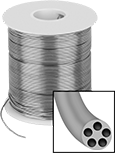

Fast-Flowing Rosin Flux-Core Solder for Electronics and Electrical Applications

The five flux cores allow fast soldering that uses less solder and transmits less heat to the joint. Rosin flux is quick acting with strong cleaning action but leaves residue that requires flux remover. Since this solder is electrically conductive, it’s good for electronics and electrical applications.

Lead-free solder is safer to use than leaded solder and helps meet industry regulations.

For technical drawings and 3-D models, click on a part number.

Material Composition | ||||||||

|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Silver | Melting Temperature, °F | Dia. | Wt., lbs. | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||||

| Sn60Pb40 | 60% | 40% | __ | 375° | 0.015" | 1 | 0000000 | 000000 |

| Sn60Pb40 | 60% | 40% | __ | 375° | 0.020" | 1 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 40% | __ | 375° | 0.025" | 1 | 000000 | 00000 |

| Sn60Pb40 | 60% | 40% | __ | 375° | 0.032" | 1 | 000000 | 00000 |

| Sn60Pb40 | 60% | 40% | __ | 375° | 0.050" | 1 | 000000 | 00000 |

| Sn60Pb40 | 60% | 40% | __ | 375° | 0.062" | 1 | 000000 | 00000 |

| Sn60Pb40 | 60% | 40% | __ | 375° | 0.093" | 1 | 0000000 | 00000 |

| Sn60Pb40 | 60% | 40% | __ | 375° | 0.125" | 1 | 0000000 | 00000 |

| Sn62Pb36Ag2 | 62% | 36% | 2% | 460° | 0.025" | 1 | 0000000 | 000000 |

| Sn62Pb36Ag2 | 62% | 36% | 2% | 460° | 0.032" | 1 | 0000000 | 000000 |

| Sn62Pb36Ag2 | 62% | 36% | 2% | 460° | 0.050" | 1 | 0000000 | 000000 |

| Sn62Pb36Ag2 | 62% | 36% | 2% | 460° | 0.062" | 1 | 0000000 | 000000 |

| Sn63Pb37 | 63% | 37% | __ | 365° | 0.015" | 1 | 000000 | 00000 |

| Sn63Pb37 | 63% | 37% | __ | 365° | 0.020" | 1 | 0000000 | 00000 |

| Sn63Pb37 | 63% | 37% | __ | 365° | 0.025" | 1 | 000000 | 00000 |

| Sn63Pb37 | 63% | 37% | __ | 365° | 0.032" | 1 | 0000000 | 00000 |

| Sn63Pb37 | 63% | 37% | __ | 365° | 0.050" | 1 | 000000 | 00000 |

| Sn63Pb37 | 63% | 37% | __ | 365° | 0.062" | 1 | 000000 | 00000 |

| Sn63Pb37 | 63% | 37% | __ | 365° | 0.093" | 1 | 0000000 | 00000 |

| Sn63Pb37 | 63% | 37% | __ | 365° | 0.125" | 1 | 0000000 | 00000 |

Material Composition | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Silver | Copper | Melting Temperature, °F | Dia. | Wt., lbs. | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | |||||||||

| Sn96.5Ag3Cu0.5 | 96.5% | 0% | 3% | 0.5% | 460° | 0.025" | 1 | 0000000 | 0000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 0% | 3% | 0.5% | 460° | 0.032" | 1 | 0000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 0% | 3% | 0.5% | 460° | 0.040" | 1 | 0000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 0% | 3% | 0.5% | 460° | 0.062" | 1 | 0000000 | 000000 |

| Sn96.5Ag3Cu0.5 | 96.5% | 0% | 3% | 0.5% | 460° | 0.125" | 1 | 0000000 | 000000 |

| Sn96Ag4 | 96% | 0% | 4% | __ | 470° | 0.032" | 1 | 0000000 | 000000 |

| Sn96Ag4 | 96% | 0% | 4% | __ | 470° | 0.062" | 1 | 0000000 | 000000 |

| Sn97Cu3 | 97% | 0% | __ | 3% | 445° | 0.032" | 1 | 0000000 | 00000 |

| Sn97Cu3 | 97% | 0% | __ | 3% | 445° | 0.062" | 1 | 0000000 | 00000 |

| Sn97Cu3 | 97% | 0% | __ | 3% | 445° | 0.125" | 1 | 0000000 | 00000 |

Rosin Flux-Core High-Melting-Point Solder

for Electronics and Electrical Applications

Rosin flux is quick acting with strong cleaning action, but leaves residue that requires flux remover. The high melting point of this solder prevents remelting when soldering successive joints with another solder. It is electrically conductive.

For technical drawings and 3-D models, click on a part number.

Material Composition | ||||||||

|---|---|---|---|---|---|---|---|---|

| Solder Composition | Tin | Lead | Silver | Dia. | Melting Temperature, °F | Wt., lbs. | Each | |

For Joining Brass, Bronze, Copper, Nickel Alloys, Stainless Steel, Steel | ||||||||

| Sn5Pb93Ag2 | 5% | 93% | 2% | 0.032" | 535° | 1 | 0000000 | 000000 |

| Sn5Pb93Ag2 | 5% | 93% | 2% | 0.050" | 580° | 1 | 0000000 | 00000 |

| Sn5Pb93Ag2 | 5% | 93% | 2% | 0.062" | 565° | 1 | 0000000 | 000000 |

| Sn10Pb88Ag2 | 10% | 88% | 2% | 0.031" | 570° | 1 | 0000000 | 00000 |

| Sn10Pb88Ag2 | 10% | 88% | 2% | 0.062" | 570° | 1 | 0000000 | 00000 |

Rosin Flux-Core Solder for HVAC Applications

Rosin flux is quick acting with strong cleaning action, but leaves residue that requires flux remover. The addition of silver in this solder helps it resist vibration to form strong joints in HVAC systems. It is lead-free, so it is safer to use than leaded solder and helps meet industry regulations.

For technical drawings and 3-D models, click on a part number.

Rosin Flux-Core Solder for High-Temperature Applications

Rosin flux is quick acting with strong cleaning action, but leaves residue that requires flux remover. The solder keeps its strength in applications where vibration and frequent and extreme temperature changes occur, such as in water lines and refrigeration equipment. It is lead-free, so it is safer to use than leaded solder and helps meet industry regulations.

For technical drawings and 3-D models, click on a part number.

Fully-Activated Rosin Soldering Flux for Electronics

Providing the strongest cleaning power, this flux leaves residue that must be removed to ensure the reliability of the joint. The residue requires flux remover. Flux cleans and prepares electrical assemblies and printed circuit boards for soldering.

| For Joining | Container Size, gal. | Form | Cleanup Method | Specifications Met | Each | |

| Nickel Alloys, Copper, Brass, Bronze, Zinc | 1 | Liquid | Flux Remover | IPC J-STD-004 | 0000000 | 000000 |

Mildly-Activated Rosin Soldering Flux for Electronics

This flux has strong cleaning action and leaves residue that will not compromise the reliability of the joint. The residue requires flux remover. Use this flux to clean and prepare electrical assemblies and printed circuit boards for soldering.

Paste flux is easy to apply in precise applications.

Container | Tip | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Joining | Size | Net Weight | Type | Shape | Diameter | Form | Cleanup Method | Specifications Met | Each | |

| Copper | 1/5 fl. oz. | __ | Pen | Needle Point | 0.013" | Liquid | Flux Remover | IPC J-STD-004 | 0000000 | 000000 |

| Copper, Nickel Alloys, Brass | 10 ml | __ | Syringe | Needle Point | 0.055" | Paste | Flux Remover | IPC J-STD-004 | 00000000 | 00000 |

| Copper, Nickel Alloys, Brass | __ | 8 oz. | Jar | __ | __ | Paste | Flux Remover | IPC J-STD-004 | 00000000 | 00000 |

| Copper, Nickel Alloys, Brass | __ | 1 lbs. | Jar | __ | __ | Paste | Flux Remover | IPC J-STD-004 | 00000000 | 00000 |

| Copper, Nickel Alloys, Brass, Bronze, Zinc | 1 gal. | __ | Bottle | __ | __ | Liquid | Flux Remover | IPC J-STD-004 | 0000000 | 00000 |

Fully-Activated Rosin Soldering Flux for High-Temperature Electronics

With the strongest cleaning power, this flux is fully activated to clean and prepare electrical assemblies and printed circuit boards for high-temperature soldering applications. However, it requires flux remover to clean residue for a reliable joint.