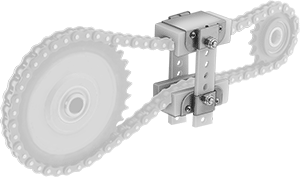

Spring-Loaded Adjustable-Arm Roller Chain and Belt Tensioners

Tensioners take up slack and allow you to adjust tension on your roller chain or belt. A built-in spring allows the adjustment arm to apply continuous tension. They are for use with idler sprockets or pulleys.

For technical drawings and 3-D models, click on a part number.

Tensioners | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting Plate | Replacement Springs | ||||||||||||

| Thread Size | Tension Force, lbs. | Ht. | Wd. | Tension Arm Lg. | Deflection Angle | Overall Dp. | Material | Arm Rotation | Includes | Each | Each | ||

Vertical Mount | |||||||||||||

| 3/8"-16 | 45 | 5" | 3 1/2" | 5" | ±45° | 2 7/8" | Steel | 180° | Idler Shaft, Internal Spring | 000000000 | 0000000 | 00000000 | 000000 |

| 1/2"-13 | 45 | 5" | 3 1/2" | 5" | ±45° | 2 7/8" | Steel | 180° | Idler Shaft, Internal Spring | 00000000 | 000000 | 00000000 | 00000 |

| 5/8"-11 | 45 | 5" | 3 1/2" | 5" | ±45° | 2 7/8" | Steel | 180° | Idler Shaft, Internal Spring | 00000000 | 000000 | 00000000 | 00000 |

| 3/4"-10 | 45 | 5" | 3 1/2" | 5" | ±45° | 2 7/8" | Steel | 180° | Idler Shaft, Internal Spring | 00000000 | 000000 | 00000000 | 00000 |

Horizontal Mount | |||||||||||||

| 3/8"-16 | 45 | 3 1/8" | 4" | 5" | ±45° | 2 1/2" | Steel | 180° | Idler Shaft, Internal Spring | 000000000 | 000000 | 00000000 | 00000 |

| 1/2"-13 | 45 | 3 1/8" | 4" | 5" | ±45° | 2 1/2" | Steel | 180° | Idler Shaft, Internal Spring | 00000000 | 000000 | 00000000 | 00000 |

| 5/8"-11 | 45 | 3 1/8" | 4" | 5" | ±45° | 2 1/2" | Steel | 180° | Idler Shaft, Internal Spring | 00000000 | 000000 | 00000000 | 00000 |

| 3/4"-10 | 45 | 3 1/8" | 4" | 5" | ±45° | 2 1/2" | Steel | 180° | Idler Shaft, Internal Spring | 00000000 | 000000 | 00000000 | 00000 |

Heavy Duty Spring-Loaded Adjustable-Arm Belt and Roller Chain Tensioners

Maintain correct drive tension to ensure smooth operation for maximum power and a long service life. Designed for use on large belt and chain drives, tensioners are spring loaded to provide constant tension and automatic adjustments for pulsating loads. Adjust the arm to control tension in a 360° arc. Idler shaft (sold separately) is required.

For technical drawings and 3-D models, click on a part number.

Overall | Thread | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Lg. | Lg. | Dia. | Size | Lg. | Edge Type | Fabrication | Hardness Rating | Hardness | Includes | Each | |

Inch with Shaft Collar—1215 Carbon Steel | ||||||||||||

| 1" | 1 1/2" | 3 3/8" | 1 1/2" | 3/4"-16 | 7/8" | Chamfered | Hardened | Very Hard | Rockwell C58 | Grease Fitting | 000000 | 000000 |

| 1" | 2 1/2" | 4 3/8" | 1 1/2" | 3/4"-16 | 7/8" | Chamfered | Hardened | Very Hard | Rockwell C58 | Grease Fitting | 000000 | 00000 |

| 1" | 3 1/2" | 5 3/8" | 1 1/2" | 3/4"-16 | 7/8" | Chamfered | Hardened | Very Hard | Rockwell C58 | Grease Fitting | 000000 | 00000 |

Heavy Duty Spring-Loaded Belt and Roller Chain Tensioners

Designed for large belt and chain drives, these tensioners maintain correct drive tension for smooth operation, maximum power, and a long service life. They're spring loaded, which keeps constant tension on a belt or chain and automatically adjusts for changes in loads. An idler shaft (sold separately) is required.

For technical drawings and 3-D models, click on a part number.

Overall | Mounting Plate | Mounting Holes | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tension Force, lbs. | For Idler ID | Travel Ht. | Ht. | Dp. | Wd. | Ht. | Material | No. of | Lg. | Mounting Fasteners Included | Each | |

| 84 | 1 1/2" | 3" | 18 5/16" | 3 3/16" | 6" | 7" | Cast Iron | 4 | 1 7/8" | Yes | 0000000 | 0000000 |

Overall | Thread | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Lg. | Lg. | Dia. | Size | Lg. | Edge Type | Fabrication | Hardness Rating | Hardness | Includes | Each | |

Inch with Shaft Collar—1215 Carbon Steel | ||||||||||||

| 1 1/2" | 3 1/4" | 5 11/16" | 2 1/4" | 1"-14 | 1 5/16" | Chamfered | Hardened | Very Hard | Rockwell C58 | Grease Fitting | 00000000 | 000000 |

| 1 1/2" | 5 1/4" | 7 11/16" | 2 1/4" | 1"-14 | 1 5/16" | Chamfered | Hardened | Very Hard | Rockwell C58 | Grease Fitting | 00000000 | 00000 |

Adjustable-Screw Roller Chain and Belt Tensioners

Tensioners take up slack and allow you to adjust tension on your roller chain or belt. Precisely apply tension in a straight line by moving the adjustment screw. They are for use with idler sprockets or pulleys.

For technical drawings and 3-D models, click on a part number.

Mounting Plate | |||||||

|---|---|---|---|---|---|---|---|

| For Idler ID | Ht. | Wd. | Overall Dp. | Material | Includes | Each | |

Vertical/Horizontal Mount | |||||||

| 1/4" | 5 7/8" | 1 1/2" | 3 1/8" | Steel | Idler Shaft | 00000000 | 0000000 |

| 3/8" | 5 7/8" | 1 1/2" | 3 1/8" | Steel | Idler Shaft | 00000000 | 000000 |

| 1/2" | 5 7/8" | 1 1/2" | 3 1/8" | Steel | Idler Shaft | 000000 | 000000 |

| 5/8" | 9" | 2" | 4 5/16" | Steel | Idler Shaft | 00000000 | 000000 |

| 3/4" | 9" | 2" | 4 5/16" | Steel | Idler Shaft | 00000000 | 000000 |

| 7/8" | 9" | 2" | 4 5/16" | Steel | Idler Shaft | 000000 | 000000 |

| 1 1/8" | 13" | 3" | 6" | Steel | Idler Shaft | 000000 | 000000 |

Adjustable-Arm Roller Chain and Belt Tensioners

Mounting Plate | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Ht. | Wd. | Tension Arm Lg. | Overall Dp. | Material | Arm Rotation | Includes | Each | |

Vertical Mount | |||||||||

| 3/8"-16 | 3 1/4" | 2" | 2 1/2" | 1 3/8" | Steel | 360° | Idler Shaft | 00000000 | 0000000 |

| 1/2"-13 | 5" | 3 1/2" | 3 13/16" | 2" | Steel | 360° | Idler Shaft | 00000000 | 000000 |

| 5/8"-11 | 5" | 3 1/2" | 3 13/16" | 2" | Steel | 360° | Idler Shaft | 00000000 | 000000 |

| 3/4"-10 | 5" | 3 1/2" | 3 13/16" | 2" | Steel | 360° | Idler Shaft | 00000000 | 000000 |

Horizontal Mount | |||||||||

| 3/8"-16 | 2 5/16" | 2 1/4" | 2 1/2" | 2" | Steel | 360° | Idler Shaft | 00000000 | 000000 |

| 1/2"-13 | 3 1/4" | 4" | 3 13/16" | 3 3/8" | Steel | 360° | Idler Shaft | 00000000 | 000000 |

| 5/8"-11 | 3 1/4" | 4" | 3 13/16" | 3 3/8" | Steel | 360° | Idler Shaft | 00000000 | 000000 |

| 3/4"-10 | 3 1/8" | 4" | 4" | 3 3/8" | Steel | 360° | Idler Shaft | 00000000 | 000000 |

| 1"-14 | 7 3/8" | 7 1/2" | 6 1/2" | 11 1/4" | Cast Iron | 360° | Idler Shaft | 000000000 | 000000 |

Floating Roller Chain Tensioners

Mount these tensioners directly onto your chain drive. They have adjustable straps that take up slack and apply constant tension. Because they engage with the side plates instead of the rollers, they increase the life of your roller chain.

UHMW tensioners are stronger and more durable than PTFE tensioners.

PTFE tensioners handle temperatures up to 450° F, more than twice as high as UHMW and titanium models.

Titanium tensioners stand up to harsh and dirty environments. They're stronger and more durable than plastic tensioners. And with a low coefficient of friction, they work with chain that has little or no lubrication.

For technical drawings and 3-D models, click on a part number.

Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Roller Chain Trade Size | For Roller Chain Strand Type | Ht. | Wd. | Dp. | Housing Material | Strap Material | Max. Temperature, ° F | Each | |

For ANSI Roller Chain | |||||||||

UHMW Plastic | |||||||||

| 25 | Single | 12" | 2 1/2" | 1 3/32" | 304 Stainless Steel | HDPE Plastic | 180° | 000000 | 000000 |

| 35 | Single | 12" | 2 1/2" | 1 3/32" | 304 Stainless Steel | HDPE Plastic | 180° | 000000 | 00000 |

| 40, 41, 52, 25-2 | Single, Double | 12" | 3" | 2 11/16" | 304 Stainless Steel | HDPE Plastic | 180° | 000000 | 00000 |

| 50 | Single | 12" | 3 1/2" | 2 7/8" | 304 Stainless Steel | HDPE Plastic | 180° | 000000 | 000000 |

| 60, 35-2, 40-2, 35-3 | Single, Double, Triple | 12" | 4" | 3 1/8" | 304 Stainless Steel | HDPE Plastic | 180° | 000000 | 000000 |

| 76, 100, 60-2, 40-3 | Single, Double, Triple | 16" | 5" | 4 1/16" | 304 Stainless Steel | HDPE Plastic | 180° | 000000 | 000000 |

| 80, 50-2, 35-4 | Single, Double, Quadruple | 16" | 4 1/2" | 3 3/4" | 304 Stainless Steel | HDPE Plastic | 180° | 000000 | 000000 |

| 120, 80-2, 50-3, 40-4 | Single, Double, Triple, Quadruple | 16" | 5 1/2" | 4 13/16" | 304 Stainless Steel | HDPE Plastic | 180° | 000000 | 000000 |

| 200, 100-2, 80-3, 60-4, 50-5, 40-6 | Single, Double, Triple, Quadruple, Fivefold, Sixfold | 24" | 7 1/2" | 6" | 304 Stainless Steel | HDPE Plastic | 180° | 00000000 | 000000 |

PTFE Plastic | |||||||||

| 35 | Single | 12" | 2 1/2" | 1 3/32" | 304 Stainless Steel | Galvanized Steel | 450° | 00000000 | 000000 |

| 40, 41, 52, 25-2 | Single, Double | 12" | 3" | 2 11/16" | 304 Stainless Steel | Galvanized Steel | 450° | 00000000 | 000000 |

| 50 | Single | 12" | 3 1/2" | 2 7/8" | 304 Stainless Steel | Galvanized Steel | 450° | 00000000 | 000000 |

| 60, 35-2, 40-2, 35-3 | Single, Double | 12" | 4" | 3 1/8" | 304 Stainless Steel | Galvanized Steel | 450° | 00000000 | 000000 |

Titanium | |||||||||

| 25 | Single | 12" | 2 1/2" | 1 3/32" | 304 Stainless Steel | HDPE Plastic | 180° | 00000000 | 000000 |

| 35 | Single | 12" | 2 1/2" | 1 3/32" | 304 Stainless Steel | HDPE Plastic | 180° | 00000000 | 000000 |

| 40, 41, 52, 25-2 | Single, Double | 12" | 3" | 2 11/16" | 304 Stainless Steel | HDPE Plastic | 180° | 00000000 | 000000 |

| 50 | Single | 12" | 3 1/2" | 2 7/8" | 304 Stainless Steel | HDPE Plastic | 180° | 00000000 | 000000 |

| 60, 35-2, 40-2, 35-3 | Single, Double, Triple | 12" | 4" | 3 1/8" | 304 Stainless Steel | HDPE Plastic | 180° | 00000000 | 000000 |

| 76, 100, 60-2, 40-3 | Single, Double, Triple | 16" | 5" | 4 1/16" | 304 Stainless Steel | HDPE Plastic | 180° | 00000000 | 000000 |

| 80, 50-2, 35-4 | Single, Double, Quadruple | 16" | 4 1/2" | 3 3/4" | 304 Stainless Steel | HDPE Plastic | 180° | 00000000 | 000000 |

| 120, 80-2, 50-3, 40-4 | Single, Double, Triple, Quadruple | 16" | 5 1/2" | 4 13/16" | 304 Stainless Steel | HDPE Plastic | 180° | 00000000 | 000000 |

Channel-Guided Roller Chain Tensioners

Built-in springs put constant tension on roller chain to absorb and buffer shock, reduce vibration, and improve drive performance.

For technical drawings and 3-D models, click on a part number.

Overall | Mounting Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Roller Chain Trade Size | Tension Force, lbs. | Travel Ht. | Ht. | Wd. | Dp. | Material | Housing Material | Dia. | No. of | Mounting Fasteners Included | Max. Temperature, ° F | Each | |

For Single-Strand ANSI Roller Chain | |||||||||||||

Vertical/Horizontal Mount | |||||||||||||

| 35 | 15-40 | 1.05" | 5 15/32" | 2 5/16" | 1" | Plastic | Aluminum | 3/8" | 1 | No | 180° | 0000000 | 0000000 |

| 35 | 15-40 | 1.05" | 5 19/32" | 2 5/16" | 1" | Plastic | Aluminum | 3/8" | 1 | No | 180° | 0000000 | 000000 |

| 40 | 15-40 | 1.05" | 5 15/32" | 2 5/16" | 1" | Plastic | Aluminum | 3/8" | 1 | No | 180° | 0000000 | 000000 |

| 40 | 15-40 | 1.05" | 5 19/32" | 2 5/16" | 1" | Plastic | Aluminum | 3/8" | 1 | No | 180° | 0000000 | 000000 |

| 50 | 20-60 | 1.2" | 6 13/32" | 2 15/16" | 1 3/16" | Plastic | Aluminum | 7/16" | 1 | No | 180° | 0000000 | 000000 |

| 50 | 20-60 | 1.2" | 6 15/32" | 2 15/16" | 1 3/16" | Plastic | Aluminum | 7/16" | 1 | No | 180° | 0000000 | 000000 |

| 60 | 20-60 | 1.2" | 6 13/32" | 2 15/16" | 1 3/16" | Plastic | Aluminum | 7/16" | 1 | No | 180° | 0000000 | 000000 |

| 60 | 20-60 | 1.2" | 6 15/32" | 2 15/16" | 1 3/16" | Plastic | Aluminum | 7/16" | 1 | No | 180° | 0000000 | 000000 |

| 80 | 45-100 | 1.5" | 7 1/2" | 3 17/32" | 1 3/8" | Plastic | Aluminum | 1/2" | 1 | No | 180° | 0000000 | 000000 |

| 80 | 45-100 | 1.5" | 7 25/32" | 3 17/32" | 1 3/8" | Plastic | Aluminum | 1/2" | 1 | No | 180° | 0000000 | 000000 |

| 100 | 45-100 | 1.5" | 7 1/2" | 3 17/32" | 1 3/8" | Plastic | Aluminum | 1/2" | 1 | No | 180° | 0000000 | 000000 |

| 100 | 45-100 | 1.5" | 7 25/32" | 3 17/32" | 1 3/8" | Plastic | Aluminum | 1/2" | 1 | No | 180° | 0000000 | 000000 |

For Double-Strand ANSI Roller Chain | |||||||||||||

Vertical/Horizontal Mount | |||||||||||||

| 40 | 15-40 | 1.05" | 5 15/32" | 2 5/16" | 1" | Plastic | Aluminum | 3/8" | 1 | No | 180° | 0000000 | 000000 |

| 40 | 15-40 | 1.05" | 5 19/32" | 2 5/16" | 1" | Plastic | Aluminum | 3/8" | 1 | No | 180° | 0000000 | 000000 |

| 60 | 20-60 | 1.2" | 6 15/32" | 2 15/16" | 1 3/16" | Plastic | Aluminum | 7/16" | 1 | No | 180° | 0000000 | 000000 |

For Single-Strand ISO Roller Chain | |||||||||||||

Vertical/Horizontal Mount | |||||||||||||

| 06B | 5-30 | 1.05" | 5 19/32" | 2 5/16" | 1" | Plastic | Aluminum | 3/8" | 1 | No | 180° | 0000000 | 000000 |

Ultra-Low-Profile Channel-Guided Roller Chain Tensioners

Able to fit in tight spots, these tensioners are less than 3" tall. Built-in springs put constant tension on roller chain to absorb and buffer shock, reduce vibration, and improve drive performance.

For technical drawings and 3-D models, click on a part number.

Overall | Mounting Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Roller Chain Trade Size | Tension Force, lbs. | Travel Ht. | Ht. | Wd. | Dp. | Material | Housing Material | Dia., mm | No. of | Mounting Fasteners Included | Max. Temperature, ° F | Each | |

For Single-Strand ANSI Roller Chain | |||||||||||||

Vertical/Horizontal Mount | |||||||||||||

| 35 | 2-4 | 0.6" | 2 9/16" | 2" | 19/32" | Plastic | 304 Stainless Steel | 5 | 2 | No | 140° | 000000 | 0000000 |

| 35 | 13-19 | 0.6" | 2 9/16" | 2" | 19/32" | Plastic | 304 Stainless Steel | 5 | 2 | No | 140° | 0000000 | 000000 |

Low-Profile Channel-Guided Roller Chain Tensioners

At less than 4" in height, these tensioners are good for use on low-clearance drives. Built-in springs put constant tension on roller chain to absorb and buffer shock, reduce vibration, and improve drive performance.

For technical drawings and 3-D models, click on a part number.

Overall | Mounting Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Roller Chain Trade Size | Tension Force, lbs. | Travel Ht. | Ht. | Wd. | Dp. | Material | Housing Material | Dia., mm | No. of | Mounting Fasteners Included | Max. Temperature, ° F | Each | |

For Single-Strand ANSI Roller Chain | |||||||||||||

Vertical/Horizontal Mount | |||||||||||||

| 25, 35 | 7-13 | 1.6" | 3 25/32" | 2 25/32" | 1 1/4" | Plastic | Steel | 6 | 2 | No | 140° | 000000 | 0000000 |

| 25, 35 | 13-29 | 1.6" | 3 25/32" | 2 25/32" | 1 1/4" | Plastic | Steel | 6 | 2 | No | 140° | 000000 | 000000 |

| 40 | 7-13 | 1.6" | 3 25/32" | 2 25/32" | 1 1/4" | Plastic | Steel | 6 | 2 | No | 140° | 000000 | 000000 |

| 40 | 13-29 | 1.6" | 3 25/32" | 2 25/32" | 1 1/4" | Plastic | Steel | 6 | 2 | No | 140° | 000000 | 000000 |

| 50 | 7-13 | 1.6" | 3 25/32" | 2 25/32" | 1 1/4" | Plastic | Steel | 6 | 2 | No | 140° | 000000 | 000000 |

| 50 | 13-29 | 1.6" | 3 25/32" | 2 25/32" | 1 1/4" | Plastic | Steel | 6 | 2 | No | 140° | 000000 | 000000 |

| 60 | 7-13 | 1.6" | 3 25/32" | 2 25/32" | 1 1/4" | Plastic | Steel | 6 | 2 | No | 140° | 000000 | 000000 |

| 60 | 13-29 | 1.6" | 3 25/32" | 2 25/32" | 1 1/4" | Plastic | Steel | 6 | 2 | No | 140° | 000000 | 000000 |

Roller Chain Tensioning Rings

Install these rings between strands of chain to absorb slack without the need for realignment, lubrication, or tools—good for use in confined spaces where maintenance may be difficult.

For technical drawings and 3-D models, click on a part number.

| For Roller Chain Trade Size | Tension Force, lbs. | OD | Max. Speed, fpm | Maximum Temperature, ° F | Material | Each | |

For Single-Strand ANSI Roller Chain | |||||||

|---|---|---|---|---|---|---|---|

| 35 | 1 | 3.539" | 1,020 | 155° | Plastic | 000000 | 0000000 |

For Single-Strand ANSI, ISO Roller Chain | |||||||

| 40, 08B | 3 | 4.154" | 1,470 | 155° | Plastic | 000000 | 000000 |

| 40, 08B | 3 | 4.783" | 1,470 | 155° | Plastic | 0000000 | 000000 |

| 40, 08B | 3 | 4.783" | 1,690 | 155° | Plastic | 0000000 | 000000 |

| 40, 08B | 4 | 5.413" | 1,730 | 155° | Plastic | 0000000 | 000000 |

| 50, 10B | 6 | 5.055" | 1,500 | 155° | Plastic | 000000 | 000000 |

| 50, 10B | 10 | 6.693" | 1,730 | 155° | Plastic | 0000000 | 000000 |

| 60, 12B | 7 | 7.173" | 1,220 | 155° | Plastic | 000000 | 000000 |

| 60, 12B | 8 | 6.102" | 1,060 | 155° | Plastic | 000000 | 000000 |

| 60, 12B | 15 | 8.169" | 1,250 | 155° | Plastic | 0000000 | 000000 |

| 80, 16B | 21 | 8.15" | 1,120 | 155° | Plastic | 000000 | 000000 |

| 100, 20B | 18 | 11.957" | 1,370 | 100° | Plastic | 0000000 | 000000 |

For Single-Strand ISO Roller Chain | |||||||

| 05B | 0.5 | 3.012" | 980 | 155° | Plastic | 00000000 | 000000 |