Benchtop Rolling Mills

With hardened rollers and precision-machined gears, these rolling mills stand up to heavy use. They’re often used to compress sheets to an uncommon gauge size, convert scrap metal into sheets or wire, or create different thicknesses in a single piece of metal without welding multiple pieces together. After several passes through the mill, you may need to anneal your metal to soften it and prevent cracking.

Manual mills are gear driven, making them easier to turn than direct-drive rolling mills. Their rollers have grooves so you can form square and half-round wire in addition to sheets.

Electric mills do not require hand cranking, so they provide the power you need to complete high volumes of work. They have flat rollers for creating uniform sheets.

Gear speed ratio indicates the force it takes to turn the output gear. For instance, the manual rolling mill has a 4:1 gear ratio, meaning that you rotate the handle four times to turn the gear powering the rollers once.

For Max. Steel | Roller | Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Thick. | Square Wire Size | Half-Round Wire Size | Gear Speed Ratio | Ht. | Wd. | Dp. | Handle Lg. | Dia. | No. of | Material | Frame Material | Mounting Fasteners Included | No. of | Dia. | Each | |

For Aluminum, Brass, Stainless Steel, Steel | |||||||||||||||||

| 2 9/16" | 3/16" | 3/64", 5/64", 1/8", 5/32", 3/16", 13/64", 7/32", 15/64", 1/4" | 0.098", 0.118", 0.157" | 4:1 | 14" | 12" | 8" | 12" | 2 1/2" | 2 | Steel | Cast Iron | No | 6 | 3/8" | 0000000 | 0000000 |

For Max. Steel | Roller | Mounting Holes | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Thick. | Gear Speed Ratio | Ht. | Wd. | Dp. | Dia. | No. of | Material | Frame Material | Horsepower, hp | Max. rpm | Current, A | Voltage | Cord Lg., ft. | Mounting Fasteners Included | No. of | Dia. | Each | |

For Aluminum, Brass, Stainless Steel, Steel | |||||||||||||||||||

| 6 1/4" | 3/16" | 100:1 | 19" | 22" | 15" | 2 1/2" | 2 | Steel | Cast Iron | 1/2 | 13 | 1.7 | 120V AC | 5 | No | 4 | 1/2" | 0000000 | 000000000 |

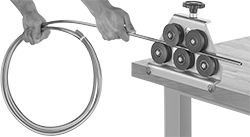

Wire, Rod, and Flat Stock Curvers

Also known as ring rollers, these curvers shape wire, rods, and flat stock into curves and circles. Turn the handle to drive material through the steel rollers. With each pass through the rollers, tighten the tensioner knob in small increments to gradually increase the curve.

Curvers with stand come with three sets of rollers—one for flat stock and two for wire and rods. They can apply pressure from either side of the bottom roller, creating more curve options.

For Max. Flat Stock | Stand | Mounting Holes | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Wire Dia. | Thick. | Wd. | For Rod Dia. | Min. Bending Radius | Material | Ht. | Wd. | Dp. | Handle Lg. | Roller Dia. | Ht. | Wd. | Dp. | Mounting Fasteners Included | No. of | Dia. | Each | |

For Aluminum, Brass, Copper, Stainless Steel, Steel | ||||||||||||||||||

| 1/4" | 3/16" | 1" | 1/4" | 1 1/2" | Steel | 5 1/2" | 6 1/2" | 5 1/2" | 13 1/2" | 1 1/4" | __ | __ | __ | No | 2 | 3/8" | 0000000 | 0000000 |

| 1/4", 1/2" | 3/16" | 1" | 1/4", 1/2" | 1 3/8" | Steel | 6 3/4" | 5 1/2" | 9 3/4" | 9" | 1 13/16" | 39" | 21" | 21" | Yes | 2 | 5/16" | 0000000 | 000000 |

Sheet Metal Curvers

Create bends, curves, and circles in sheet metal. Also known as slip rolls, these curvers can form a single curve. The rollers also have wire grooves to shape three sizes of wire. They mount to a table or bench top.

Roller | Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Bending Wd. | For Max. Steel Thick. | Min. Bending Radius | For Wire Dia. | Ht. | Wd. | Dp. | Material | Dia. | No. of | Frame Material | Mounting Fasteners Included | No. of | Dia. | Each | |

For Aluminum, Stainless Steel, Steel | |||||||||||||||

| 12" | 1/64" | 1/2" | 1/16", 1/8", 5/32" | 7" | 23" | 6" | Steel | 1" | 3 | Aluminum | No | 2 | 1/4" | 00000000 | 0000000 |

| 24" | 1/32" | 1" | 3/16", 1/4", 5/16" | 19" | 38" | 19" | Steel | 2" | 3 | Cast Iron | No | 4 | 3/8" | 0000000 | 00000000 |

| 36" | 1/32" | 1" | 3/16", 1/4", 5/16" | 19" | 51" | 19" | Steel | 2" | 3 | Cast Iron | No | 4 | 3/8" | 0000000 | 00000000 |

| 42" | 1/64" | 1" | 3/16", 1/4", 5/16" | 19" | 57" | 19" | Steel | 2" | 3 | Cast Iron | No | 4 | 3/8" | 0000000 | 00000000 |

Combination Sheet Metal Shears, Benders, and Curvers

Save space in your shop by cutting, bending, and curving sheet metal with a single machine. Also known as shear brake rolls. Use the blade on the shear to make clean, straight cuts; it has two cutting edges for twice the life. A press brake makes bends up to 90°. Create curves and circles with the slip roll.

When using the shear or press brake, set the manual back gauge to precisely position the sheet metal for consistent cuts or bends.

Max. Bending | For Max. Thick. | Roller | Mounting Holes | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Angle | Aluminum | Brass | Copper | Stainless Steel | Steel | Min. Bending Radius | Cut Lg. | Ht. | Wd. | Dp. | Dia. | No. of | Blade Material | Mounting Fasteners Included | No. of | Dia. | Each | |

For Aluminum, Brass, Copper, Stainless Steel, Steel | |||||||||||||||||||

| 12" | 90° | 1/32" | 1/32" | 1/32" | 1/64" | 1/32" | 3/4" | 12" | 15" | 14" | 11" | 1 1/2" | 3 | Steel | No | 4 | 0.32" | 0000000 | 0000000 |

| 30" | 90° | 3/64" | 1/32" | 1/32" | 1/64" | 1/32" | 3/4" | 30" | 23" | 32 1/2" | 14 1/2" | 1 1/2" | 3 | Steel | No | 4 | 0.32" | 0000000 | 00000000 |

| 40" | 90° | 3/64" | 1/32" | 1/32" | 1/64" | 1/32" | 7/8" | 40" | 23" | 42 1/2" | 14 1/2" | 1 5/8" | 3 | Steel | No | 4 | 0.32" | 0000000 | 00000000 |

Hand-Held Sheet Metal Edge Shapers

With a single tool, create both sharp creases and soft curves along the edges of sheet metal. Also known as edge rollers, these tools slide back and forth along edges to create even bends. Unlike benchtop sheet metal tools, these shapers are portable, so they’re often used on-site by roofers. Use 1/8” markings to set up precise bends.

| Throat Dp. | For Max. Steel Thick. | Max. Bending Angle | Graduation Marks | Numeric Increments | Lg. | Material | Each | |

For Aluminum, Stainless Steel, Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 3/8"-8" | 1/32" | 90° | 8ths | 1" | 13 1/2" | Steel | 0000000 | 0000000 |

Wire Straighteners

Flatten bumps, bends, and curves on coiled wire with these straighteners. They have roller wheels that apply consistent pressure along the wire for a smooth, straight result. Grooves in the wheels hold the wire in place as you manually move it through, so you don't need a wire feeder. To straighten wire with different diameters, twist the adjustment knob to change the spacing between wheels. The aluminum body resists corrosion from moisture. It's also nonmagnetic, so copper and other metal wire won't get stuck.

Roller | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Maximum Wire Diameter | Length | Width | Height | Material | Diameter | Number of | Material | Adjustment Style | Features | Each | |

Aluminum, Brass, Copper, Stainless Steel, Steel, Titanium | |||||||||||

| 0.052" | 5 1/2" | 2" | 3" | Aluminum | 1 3/16" | 3 | Hardened Tool Steel | Knob | Acetal Plastic Wire Guides | 0000000 | 0000000 |

| 0.188" | 5 1/2" | 2" | 3" | Aluminum | 1 3/16" | 3 | Hardened Tool Steel | Knob | Acetal Plastic Wire Guides | 0000000 | 000000 |

Tube Straighteners

Pull coiled tubing through these straighteners to make it smooth and level. They have acetal roller wheels that press your tubing into shape without marring the finish. Unlike pliers, which create kinks and bends that can restrict flow, these straighteners won't damage your tubing. To straighten tubing with different diameters, twist the adjustment knob to change the space between the wheels. Keep these straighteners steady by clamping them into your vise or mounting them to a work surface through holes on the base.

Roller | Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD Range | Length | Width | Height | Material | Diameter | Number of | Material | Adjustment Style | Mounting Location | Mounting Fasteners Included | Number of | Diameter | Each | |

For Aluminum, Copper, Stainless Steel, Steel | ||||||||||||||

| 3/16"-1/2" | 10" | 4" | 10" | Steel | 2 3/8" | 5 | Acetal Plastic | Knob | Benchtop, Vise | No | 2 | 3/8" | 0000000 | 0000000 |