Filter by

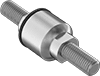

Shank Thread Size

ID

Rod End Type

Shank Thread Direction

Shank Center Length

Static Radial Load Capacity

Shank Threading

Ball Material

Lubrication

Ball Finish

Relubrication

DFARS Specialty Metals

Export Control Classification Number (ECCN)

About Rod Ends

More