Telescoping Robot Workstations

For technical drawings and 3-D models, click on a part number.

Raise and lower your robot arm on these workstations, placing them at the right height for each task. Manually adjust the work surface at 1-in. intervals, or add a hydraulic lift kit (sold separately) for faster and more precise positioning. These workstations have swivel casters for easy transport from one job to the next—use the leveling pads to balance them on uneven floors. When using these workstations with a large arm, such as the FANUC CRX-25iA, anchor them to ensure stability and safety. Workstations have ample room for storing your controller, teach pendant, and other robot accessories.

Overall | Capacity, lbs. | Robot Mount. Location | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model No.) | Ht. | Wd. | Dp. | Ht. | Adjustment Increments | Top | Overall | Foot Type | Mount. Hole Thread Size (No. of Holes) | Mount. Fasteners Included | Each | |

White Painted Steel | ||||||||||||

| FANUC (CR 4, CR 7, CR 7L; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Doosan (M0609, M0617, M1013, M1509) Omron (TM 5, TM 12, TM 14) Universal Robots (UR3, UR3e, UR5, UR5e, UR10, UR10e, UR16, UR16e) | 38" | 40 1/4" | 36" | 30"-38" | 1" | 1,400 | 1,800 | Caster | M6 (4) M8 (24) M10 (8) M12 (6) | Yes | 0000000 | 000000000 |

Hydraulic lift kits save you time spent manually lifting or lowering the work surface, which requires adjusting bolts on all four workstation legs. These kits also allow for more precise positioning than manual adjustment, which only lets you set the height at 1-in. intervals. When used with a lift kit, top capacity for workstations is 700 lbs.

Cylinder | Cylinder Mtg. Holes | Pump Mtg. Holes | Switch Mtg. Holes | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Material | No. of | Dia. | No. of | Dia. | No. of | Dia. | Mtg. Fasteners Included | Cord Lg., ft. | Specifications Met | Each | |

| 1 1/2" | Aluminum | 4 | 1/4" | 7 | 1/4" | 2 | 3/16" | No | 8 | CSA Certified, UL Listed | 00000000 | 000000000 |

Sliding electrical enclosures slide out for easy access to electrical components. Push them back beneath the workstation to keep them out of the way. Rated IP66, these enclosures block out dust and water.

Workstation Mount. Location | |||||||

|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Environmental Rating | Mount. Hole Dia. (No. of Holes) | Mount. Fasteners Included | Each | |

Black Painted Steel | |||||||

| 19 11/16" | 23 5/8" | 8 5/16" | IP66 NEMA 4 NEMA 12 | 6.6 mm (4) | Yes | 0000000 | 000000000 |

Attach mounting plates for compressed air devices to secure components such as filters, regulators, and lubricators for your compressed air system.

Compressed Air Devices Mount. Location | Workstation Mount. Location | |||||||

|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Mount. Hole Thread Size (No. of Holes) | Mount. Fasteners Included | Mount. Hole Dia. (No. of Holes) | Mount. Fasteners Included | Each | |

White Painted Steel | ||||||||

| 14 3/16" | 16 1/2" | 2" | M4 (4) M6 (2) | No | 6.6 mm (2) | Yes | 0000000 | 0000000 |

Robot Workstations

For technical drawings and 3-D models, click on a part number.

These stations are a portable working home for your robot arm. Roll them between jobs and lock the casters in place while working. Keep the work surface even by adjusting the leveling feet. A controller mount secures your controller beneath the arm, out of harm’s way but easy to access.

Overall | Capacity, lbs | Robot Mount. Location | Controller Mount. Location | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model No.) | Ht. | Wd. | Dp. | Top Thick. | Top | Overall | Foot Type | Includes | Mount. Hole Thread Size (No. of Holes) | Mount. Fasteners Included | Mount. Hole Thread Size (No. of Holes) | Mount. Fasteners Included | Each | |

Gray Powder-Coated Steel | ||||||||||||||

| FANUC (CRX 5iA, 10iA, 10iA/L) Universal Robots (UR3, UR3e, UR5, UR5e, UR10, UR10e, UR16, UR16e) Omron (TM 5, TM 12, TM 14) | 37 1/4" | 47 1/4" | 27 1/2" | 1/4" | 250 | 400 | Caster | Four Leveling Feet | M10 (8) M6 (4) | No | 5/16"-18 (12) | No | 0000000 | 000000000 |

Top extensions expand the work surface. Fold them down to save space.

Overall | Workstation Mount. Location | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Top Style | Ht. | Wd. | Dp. | Top Thick. | Top Capacity, lbs. | Mount. Hole Thread Size (No. of Holes) | Mount. Fasteners Included | Each | |

Gray Powder-Coated Steel | |||||||||

| Left Fold-Down Leaf | 8 3/16" | 47 1/4" | 14 11/16" | 1/4" | 100 | 10-32 (8) | Yes | 0000000 | 0000000 |

| Right Fold-Down Leaf | 8 3/16" | 47 1/4" | 14 11/16" | 1/4" | 100 | 10-32 (8) | Yes | 0000000 | 000000 |

Use platforms to set up workpieces at a 15° angle—they’re often used for machine tending jobs where robot arms might load and unload parts in CNC machines. To mount these platforms where needed for your application, drill holes in your workstation surface. All include locating pins and hairpin clips to align and secure your plates. Install the clips into different grooves along the locating pins to adjust the spacing between the plate and platform and handle parts of various heights.

Attach plates to platforms to keep workpieces positioned for easy, repeatable access. All include handles and locator mounting holes for securing them to platforms. Made of stainless steel, the plates stand up to corrosion.

Diamond plates are good for holding rectangular or cylindrical parts. Peg plates accept pegs (not included), which can be moved around to create custom layouts for parts with unique shapes. They come with rest pads that attach to the pegs for supporting heavy parts. Use blank plates for machining custom holes for your specific parts or when you want to weld components to the plate.

For short parts, you may need to add a blank plate for support, so the part can be accessed. For taller parts, you’ll need to use two plates spaced apart to act as a brace. Make sure the part’s center of gravity falls below the plate that is on top.

Overall | Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Thick. | Lg. | Wd. | Dia. | Center-to-Center | No. of Holes | No. of Columns | No. of Rows | Each | |

Stainless Steel | |||||||||||

Diamond Plates | |||||||||||

| 27 3/4" | 20 3/4" | 0.135" | 1 3/16" | 1 3/16" | __ | 2" | 96 | 8 | 12 | 0000000 | 0000000 |

| 27 3/4" | 20 3/4" | 0.135" | 2 3/8" | 2 3/8" | __ | 3 15/16" | 24 | 4 | 6 | 0000000 | 000000 |

| 27 3/4" | 20 3/4" | 0.135" | 3 9/16" | 3 9/16" | __ | 5 1/2" | 12 | 3 | 4 | 0000000 | 000000 |

Peg Plates | |||||||||||

| 27 3/4" | 20 3/4" | 0.135" | __ | __ | 9/32" | 1" | 384 | 16 | 24 | 0000000 | 000000 |

Blank Plates | |||||||||||

| 27 3/4" | 20 3/4" | 0.135" | __ | __ | __ | __ | __ | __ | __ | 0000000 | 000000 |

Use pegs to create custom layouts on part presentation plates with peg holes. Each peg comes with a screw. Thread the screw through the peg hole from the back of the plate to mount the peg to the front of the plate. Another peg can be stacked on top of the mounted peg to support tall parts.

Overall | ||||||

|---|---|---|---|---|---|---|

| Lg. | Wd. | Stackable | Mount Type | Mounting Fasteners Included | Each | |

Aluminum | ||||||

| 1 1/8" | 3/8" | Yes | Threaded Insert | Yes | 0000000 | 000000 |

Build-Your-Own Robot Workstations

Mix and match a variety of components to create a custom workstation for moving parts in and out of CNC machines or other similar applications.

For technical drawings and 3-D models, click on a part number.

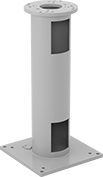

Made from steel, the bases are strong and built to last—they’re also machinable and weldable, so you can modify the mounting plates to suit your application. They’re only for use at collaborative speeds and not designed for robots moving at high speeds. All of these bases have cable routing holes, so you can feed cables, wires, and tubes through the center column to keep your cables organized and out of the way. Bases with holes for leveling use threaded fasteners (not included) to compensate for uneven floors.

If your robot arm model isn't listed, it may not be compatible with these bases. To check if your arm is compatible, you’ll need the following: the mounting hole pattern, the maximum vertical and horizontal force your arm will exert in your application, how high the center of gravity is, and whether it has any other anchoring systems. The taller the base, the higher its center of gravity, so the heavier its anchoring system will need to be to maintain stability.

Overall | Robot Mounting Location | Floor Mounting Location | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model No.) | Height | Length | Width | Static Load Capacity, lbs. | Mounting Fasteners Included | Mounting Hole Diameter (No. of Holes) | Mounting Plate Diameter | Mounting Hole Diameter (No. of Holes) | Mounting Plate Length | Mounting Plate Width | Features | Each | |

Gray Powder-Coated Steel | |||||||||||||

| FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L) Universal Robots (UR3, UR3e, UR5, UR5e, UR10, UR10e, UR16, UR16e) Omron (TM 5, TM 12, TM 14) | 24" | 11 7/8" | 11 7/8" | 200 | No | 0.236" (4) 0.315" (2) | 8" | 9/16" (4) | 11 7/8" | 11 7/8" | 1/2"-13 Holes for Leveling, Cable Routing Hole | 0000000 | 0000000 |

| FANUC (CRX 5iA, 10iA, 10iA/L) Universal Robots (UR3, UR3e, UR5, UR5e, UR10, UR10e, UR16, UR16e) Omron (TM 5, TM 12, TM 14) | 30" | 11 7/8" | 11 7/8" | 200 | No | 0.236" (4) 0.315" (2) | 8" | 9/16" (4) | 11 7/8" | 11 7/8" | 1/2"-13 Holes for Leveling, Cable Routing Hole | 0000000 | 000000 |

| FANUC (CRX 5iA, 10iA, 10iA/L) Universal Robots (UR3, UR3e, UR5, UR5e, UR10, UR10e, UR16, UR16e) Omron (TM 5, TM 12, TM 14) | 36" | 11 7/8" | 11 7/8" | 200 | No | 0.236" (4) 0.315" (2) | 8" | 9/16" (4) | 11 7/8" | 11 7/8" | 1/2"-13 Holes for Leveling, Cable Routing Hole | 0000000 | 000000 |

| FANUC (CRX 5iA, 10iA, 10iA/L) Universal Robots (UR3, UR3e, UR5, UR5e, UR10, UR10e, UR16, UR16e) Omron (TM 5, TM 12, TM 14) | 42" | 11 7/8" | 11 7/8" | 200 | No | 0.236" (4) 0.315" (2) | 8" | 9/16" (4) | 11 7/8" | 11 7/8" | 1/2"-13 Holes for Leveling, Cable Routing Hole | 0000000 | 000000 |

| FANUC (CRX 5iA, 10iA, 10iA/L) Universal Robots (UR3, UR3e, UR5, UR5e, UR10, UR10e, UR16, UR16e) Omron (TM 5, TM 12, TM 14) | 48" | 11 7/8" | 11 7/8" | 200 | No | 0.236" (4) 0.315" (2) | 8" | 9/16" (4) | 11 7/8" | 11 7/8" | 1/2"-13 Holes for Leveling, Cable Routing Hole | 0000000 | 000000 |

Platforms mount to bases to hold your part presentation plates horizontally or at a 45° angle. They include locating pins and hairpin clips to align and secure your plates in place. Install the clips into different grooves along the locating pin to handle parts of various heights.

Attach part presentation plates to platforms to keep parts positioned for easy, repeatable access by workers, robots, and other machines. All include handles, mounting holes for hanging them onto a plate storage rack, and locator mounting holes for securing them to platforms that have locating pins. They can also be bolted to other surfaces if necessary. Made of stainless steel, the plates stand up to corrosion.

Plates with diamond-shaped holes are good for holding rectangular or cylindrical parts. Those with peg holes accept pegs (not included), which can be moved around to create custom layouts for parts with unique shapes. They come with rest pads that attach to the pegs for supporting heavy parts. Use blank plates for machining custom holes for your specific parts or when you want to weld components to the plate.

For short parts, you may need to add a blank plate for support, so the part can be accessed. For taller parts, you’ll need to use two part presentation plates spaced apart to act as a brace. Make sure the part’s center of gravity falls below the plate that is on top.

Overall | Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Length | Width | Thickness | Length | Width | Diameter | Center-to-Center | No. of Holes | No. of Columns | No. of Rows | Each | |

Stainless Steel | |||||||||||

Diamond Plates | |||||||||||

| 27 3/4" | 20 3/4" | 0.135" | 1 3/16" | 1 3/16" | __ | 2" | 96 | 8 | 12 | 0000000 | 0000000 |

| 27 3/4" | 20 3/4" | 0.135" | 2 3/8" | 2 3/8" | __ | 3 15/16" | 24 | 4 | 6 | 0000000 | 000000 |

| 27 3/4" | 20 3/4" | 0.135" | 3 9/16" | 3 9/16" | __ | 5 1/2" | 12 | 3 | 4 | 0000000 | 000000 |

Peg Plates | |||||||||||

| 27 3/4" | 20 3/4" | 0.135" | __ | __ | 9/32" | 1" | 384 | 16 | 24 | 0000000 | 000000 |

Blank Plates | |||||||||||

| 27 3/4" | 20 3/4" | 0.135" | __ | __ | __ | __ | __ | __ | __ | 0000000 | 000000 |

Use pegs to create custom layouts on part presentation plates with peg holes. Each peg comes with a screw. Thread the screw through the peg hole from the back of the plate to mount the peg to the front of the plate. Another peg can be stacked on top of the mounted peg to support tall parts.

Overall | ||||||

|---|---|---|---|---|---|---|

| Length | Width | Stackable | Mount Type | Mounting Fasteners Included | Each | |

Aluminum | ||||||

| 1 1/8" | 3/8" | Yes | Threaded Insert | Yes | 0000000 | 000000 |

Plate storage racks mount to your base and have two hooks for hanging your part presentation plates. Use them to keep your plates organized, but out of the way, when they’re not in use.

Overall | |||||

|---|---|---|---|---|---|

| Height | Length | Width | Mounting Fasteners Included | Each | |

Stainless Steel | |||||

| 1 9/16" | 11" | 8 1/2" | No | 0000000 | 000000 |

Mount catch pans to the bottom of your platforms to keep coolant, shavings, and other runoff from dripping onto the floor. They slide in and out of their mounting bracket for easy cleaning and disposal.

Overall | |||||

|---|---|---|---|---|---|

| Height | Length | Width | Mounting Fasteners Included | Each | |

White PTFE/Polypropylene Plastic Blend | |||||

| 5 11/16" | 10" | 21" | Yes | 0000000 | 0000000 |

Use dollies to turn stationary bases into mobile bases. They have three swivel casters with total lock brakes, so you can brake the wheels and lock the swivel motion with the press of a foot pedal. They also have three leveling feet that swivel to compensate for uneven floors. Clearance under and between the dolly legs will let you use a pallet jack to move very heavy or delicate setups.

Overall | Base Mounting Location | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Height | Length | Width | Static Load Capacity, lbs. | Mounting Fasteners Included | Mounting Hole Diameter (No. of Holes) | Mounting Plate Diameter | Mounting Height | Each | |

Gray Powder-Coated Steel | |||||||||

| 7 3/16" | 38 11/16" | 34 1/2" | 500 | Yes | 17/32" (12) | 18" | 5" to 5.5" | 0000000 | 000000000 |

Use anchors to temporarily secure dollies to your floors. Each anchor has a notch that wraps around the stem of the dolly’s leveling foot to hold it in place. Tighten the foot’s wing nut for added holding power. When you need to move the dolly, slide the leveling foot out of the anchor’s notch. To secure one dolly, you’ll need three anchors—one for each leveling foot.

Overall | Floor Mount. Location | ||||||

|---|---|---|---|---|---|---|---|

| Height | Length | Width | Mounting Fasteners Included | Mounting Hole Diameter (No. of Holes) | Mounting Hole Center-to-Center | Each | |

Gray Powder-Coated Steel | |||||||

| 1 13/32" | 6.69" | 2 1/4" | No | 9/16" (2) | 5 3/16" | 0000000 | 000000 |

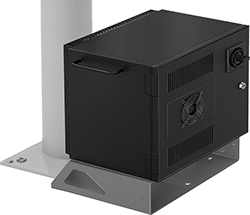

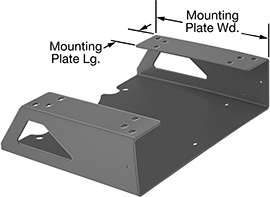

Use these mounts with robot bases to secure your controller near your robot arm for easy access and to cut down on cord lengths. When installed, these mounts elevate your controller off the floor, keeping it out of harm’s way.

Overall | Controller Mounting Location | Base Mounting Location | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model No.) | Height | Length | Width | Mounting Fasteners Included | Mounting Hole Dia. (No. of Holes) | Mounting Plate Lg. | Mounting Plate Wd. | Mounting Fasteners Included | Mounting Hole Dia. (No. of Holes) | Each | |

Gray Powder-Coated Steel | |||||||||||

| FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Universal Robots (UR3, UR3e, UR5, UR5e, UR10, UR10e, UR16, UR16e) Omron (TM 5, TM 12, TM 14) | 4 1/4" | 16 3/4" | 11" | Yes | 1/4" (12) | 3 1/8" | 9" | Yes | 1/4" (5) | 0000000 | 0000000 |