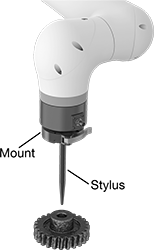

Calibration Styli for Quick-Connect Robot Tool Changers

Align your robot arm with work areas using these styli to make sure it will perform automated tasks accurately and won’t damage workpieces. Slide these styli into the quick-connect clamp on an end-of-robot-arm mount (sold separately). They show you exactly where your tool will touch, so you don’t have to test your application with trial and error. These styli are often used to guide robots to hole centers when attaching fasteners, or to help them find objects in pick-and-place applications. You can also use them to help your machine-vision camera recognize patterns and locations.

For technical drawings and 3-D models, click on a part number.

| Lg., mm | Wt. | Color | For Robot-Arm Mounting Adapter Material | Each | |

Anodized Aluminum | |||||

|---|---|---|---|---|---|

| 154 | 0.29 lbs. / 0.13 kg | Black | Aluminum | 00000000 | 0000000 |

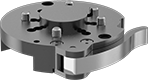

These mounts have standard ISO mounting hole patterns, so they’re compatible with the mounting hole patterns on most robot arms and tools. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility.

| Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mounting Plate Dia., mm | Max. Load Cap. | Wt. | Lg., mm | Includes | Features | For Robot Arm Manufacturer (Series/Model Number) | Each | |

Low Profile—Black PTFE-Coated Aluminum (Bolt On) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) | 83 | 110 lbs. / 50 kg | 0.53 lbs. / 0.24 kg | 19 | __ | __ | ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Omron (TM 5, 12, 14) Precise Automation (PAVP6; PF3400; PP100) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 00000000 | 0000000 |

Utility—Black PTFE-Coated Aluminum (Bolt On) | |||||||||

| 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) | 83 | 110 lbs. / 50 kg | 0.71 lbs. / 0.32 kg | 74 | Power/Signal Connector with 5-ft. Wire Leads | Dual 6 mm Pneumatic Pass-Throughs, M8 8-Pin Power/Signal Pass-Through | ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Omron (TM 5, 12, 14) Precise Automation (PAVP6; PF3400; PP100) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 00000000 | 00000000 |