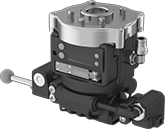

Robot-Ready Vacuum Lifters

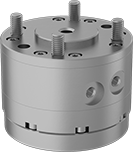

With robot tool mounts and connectors, these vacuum lifters come ready to attach to robot arms with standard ISO mounting hole patterns. Use them with compressed air to grip, lift, and move items with curves, angles, and varied heights. Also known as venturi devices, they generate suction without an installed vacuum system. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility.

Lifters and lifters with cups have two arms with vacuum cup connections. You can adjust the width of the arms to handle large items as well as tilt them to better grip uneven shapes. You can even remove an arm for applications that require only one cup. All of these lifters have a digital display for viewing the status of the lifter and controlling the vacuum. They’re protected from dust and water splashes. Lifters don’t include cups. Add vacuum cups that meet your specific needs. Lifters with cups include eight silicone and polyurethane rubber cups with different sizes and number of bellows. Cups with more bellows are better for handling items that have more variations in shape.

Lifters with a foam pad have an EPDM foam pad that’s soft enough to conform to items without damaging them. They’re best for delicate surfaces as well as porous surfaces where cups cannot obtain an airtight grip. They are not protected from dust and water splashes.

Lifters with PNP signal output communicate proximity with a positive signal, while those with NPN signal output send a negative signal.

Choose lifters with an additional port if you’d like to add a pressure transmitter (not included). Your transmitter will convert air pressure to an electrical signal for viewing air measurements on remote displays and programmable logic controllers (PLCs).

Optional sensors can be added to lifters with a foam pad for communicating the grip position to a controller. They require an A-code micro M12 power cord (sold separately).

Warning: Never use to lift people or items over people.

Female Air Connection | End of Robot Arm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model Number) | Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Pipe Size | Thread Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Signal Output Type | Each | |

For Smooth and Textured Surfaces | |||||||||||

With Additional Port | |||||||||||

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 31.5 mm (ISO 31.5) | No | NPN, PNP | 00000000 | 000000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 40 mm (ISO 40) | No | NPN, PNP | 00000000 | 00000000 |

Female Air Connection | End of Robot Arm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model Number) | Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Pipe Size | Thread Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Signal Output Type | Each | |

For Smooth and Textured Surfaces—Polyurethane and Silicone Rubber Cups | |||||||||||

With Additional Port | |||||||||||

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 31.5 mm (ISO 31.5) | No | NPN, PNP | 00000000 | 000000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 40 mm (ISO 40) | No | NPN, PNP | 00000000 | 00000000 |

Female Air Connection | End of Robot Arm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model Number) | Pad Ht., mm | Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Pipe Size | Thread Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Each | |

For Smooth and Textured Surfaces—EPDM Foam Pad | |||||||||||

With Additional Port | |||||||||||

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 10 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 31.5 mm (ISO 31.5) | No | 00000000 | 000000000 |

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 20 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 31.5 mm (ISO 31.5) | No | 00000000 | 00000000 |

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 30 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 31.5 mm (ISO 31.5) | No | 00000000 | 00000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 10 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 40 mm (ISO 40) | No | 00000000 | 00000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 20 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 40 mm (ISO 40) | No | 00000000 | 00000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 30 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 40 mm (ISO 40) | No | 00000000 | 00000000 |

| Output Voltage | Connection Type | Gender | Housing Thread Size | Number of Poles | Each | |

| 1-5V DC | Nano M8 | Male | M8 | 8 | 00000000 | 0000000 |

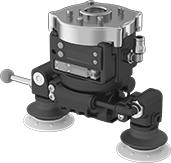

Robot-Ready Electric Soft Grippers

Mimicking a human hand, these grippers have soft, flexible silicone fingers that curl around items to pick them up. Unlike standard grippers with rigid fingers, these grippers can grasp fruit, bagged items, and other delicate objects without crushing them. They are powered and actuated entirely by your robot, so there's no need for an air supply or control valves. Connect them to terminals on your robot controller with the included 9 1/2 ft. electrical cord. A simple toggle on your controller’s digital outputs opens and closes the fingers. Mount them to most robot arms, like FANUC CRX and Universal Robots arms, thanks to their mounting slots that match a variety of ISO mounting patterns.

To program their range of motion and position, you’ll have access to a simple web-based interface from any smartphone or laptop. You don’t have to worry about hooking these up to your network. They generate their own wireless network like a hotspot, so you can connect your device to the setup interface to program them. If you are using these grippers with a Universal Robots arm, you can download a URCap plugin from the manufacturer's website for user-friendly control through your teach pendant software.

The fingers are made of FDA-compliant silicone for direct contact with food.

Grippers with fixed grip force apply the same amount of force every time. This helps them pick up most items successfully.

Grippers with adjustable grip force are the best choice to grip extremely sensitive items, such as baked goods or fragile glassware, because you can fine-tune the gripping force. These grippers also have part confirmation, which means they can send a signal to one of your robot controller's digital inputs to tell it whether a part has been successfully picked up. If the pickup fails, you can program your robot to try the pickup again.

2-finger grippers are good at picking up objects with uniform shapes, such as bottles and boxes.

4-finger grippers are a good choice if you plan to pick up irregularly shaped objects and need additional points of contact for a secure hold. They work well with fruits and vegetables, fabrics and flexible packaging.

Finger covers (sold separately) protect the gripper fingers from residue left from the material you're picking. These silicone covers slide over the fingers for picking and slide off for cleaning. They are FDA compliant for direct contact with food.

Stroke width describes the maximum total change in distance between fingers when the gripper actuates.

O'all | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Finger Configuration | External Gripping Force, lbs. | Max. Gripping Cap. | Cycles per Sec. | Stroke Wd., mm | Max. Finger Spacing, mm | Mounting Hole Pattern Compatibility | Dia., mm | Lg., mm | Each | |

Aluminum Housing and Silicone Rubber Fingers | ||||||||||

| 2-Finger | 1.1 | 3.3 lbs. / 1.5 kg | 1 | 0-175 | 175 | ISO 31.5 ISO 40 ISO 50 ISO 63 | 105 | 172 | 00000000 | 000000000 |

| 4-Finger | 1.1 | 3.3 lbs. / 1.5 kg | 1 | 0-190 | 190 | ISO 31.5 ISO 40 ISO 50 ISO 63 | 119 | 187 | 00000000 | 00000000 |

O'all | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Finger Configuration | External Gripping Force Range, lbs. | Max. Gripping Cap. | Cycles per Sec. | Stroke Wd., mm | Max. Finger Spacing, mm | Mounting Hole Pattern Compatibility | Dia., mm | Lg., mm | Each | |

Aluminum Housing and Silicone Rubber Fingers | ||||||||||

| 2-Finger | 0.23-1.1 | 3.3 lbs. / 1.5 kg | 1 | 0-175 | 175 | ISO 31.5 ISO 40 ISO 50 ISO 63 | 105 | 172 | 00000000 | 000000000 |

| 4-Finger | 0.23-1.1 | 3.3 lbs. / 1.5 kg | 1 | 0-190 | 190 | ISO 31.5 ISO 40 ISO 50 ISO 63 | 119 | 187 | 00000000 | 00000000 |

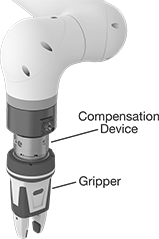

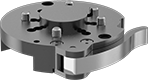

Robot-Ready Gripper Compensation Devices

Ready to mount between your robot arm and gripper, these devices have standard ISO mounting hole patterns and allow grippers to adjust, so they can grab parts that are misaligned or have different tolerances. They also compensate when aligning parts during placement, which increases efficiency and reliability in your process, while protecting parts and robots from wear. Use them to avoid jams and keep automated assembly, bin picking, and machine tending jobs running smoothly. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility.

Devices for X and Y axes tilt grippers and move them side-to-side to make angled and horizontal adjustments. Use them to help grippers grab items on an incline and center items, such as a pin, above a hole.

Devices with spring actuation and spring reset use compression springs to position your grippers. Use the set screws to adjust the force of the springs.

End of Robot Arm | Gripper | |||||

|---|---|---|---|---|---|---|

| Resetting Force Range | Bolt Circle Dia. (Mount. Hole Pattern Compatibilty) | Mount. Fasteners Included | Mount. Fasteners Included | For Robot Arm Manufacturer (Series/Model Number) | Each | |

Anodized Aluminum Housing—Spring Actuation and Spring Reset | ||||||

±1.5 mm Horizontal Compensation | ||||||

| 0.34-0.79 lbs. / 0.15-0.36 kgf | 31.5 mm (ISO 31.5) | Yes | No | ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 200iD/7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 00000000 | 000000000 |

| 0.9-1.3 lbs. / 0.41-0.56 kgf | 31.5 mm (ISO 31.5) | Yes | No | ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 200iD/7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 00000000 | 00000000 |

| 1.3-1.5 lbs. / 0.56-0.71 kgf | 31.5 mm (ISO 31.5) | Yes | No | ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 200iD/7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 00000000 | 00000000 |

±2 mm Horizontal Compensation | ||||||

| 0.67-1.1 lbs. / 0.31-0.51 kgf | 40 mm (ISO 40) | Yes | No | ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 00000000 | 00000000 |

| 0.9-1.5 lbs. / 0.41-0.71 kgf | 40 mm (ISO 40) | Yes | No | ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 00000000 | 00000000 |

| 1-2 lbs. / 0.46-0.92 kgf | 40 mm (ISO 40) | Yes | No | ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 00000000 | 00000000 |

Sensors detect gripper positions by responding to magnets in the compensation devices. They signal whether the grippers are open or closed, and use that information to trigger other actions in your system. Two sensors are required for each device. Select sensors that match the electrical connections on your robot arm. PNP sensors communicate gripper positions with a positive signal, while NPN send a negative signal.

| Electrical Connection Type | Plug Type | Number of Wire Leads | Switch Starting Position | Current | Voltage | Cord Length, ft. | Number of Sensing Positions | Each | |

PNP | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Hardwire | __ | 4 | 1 Off (Normally Open) and 1 On (Normally Closed) | 100 mA | 24V DC | 2 | 2 | 00000000 | 0000000 |

| Plug | 4-Pin M8 | __ | 1 Off (Normally Open) and 1 On (Normally Closed) | 100 mA | 24V DC | 6 1/2 | 2 | 00000000 | 000000 |

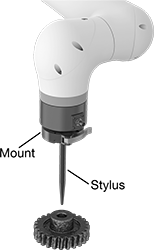

Calibration Styli for Quick-Connect Robot Tool Changers

Align your robot arm with work areas using these styli to make sure it will perform automated tasks accurately and won’t damage workpieces. Slide these styli into the quick-connect clamp on an end-of-robot-arm mount (sold separately). They show you exactly where your tool will touch, so you don’t have to test your application with trial and error. These styli are often used to guide robots to hole centers when attaching fasteners, or to help them find objects in pick-and-place applications. You can also use them to help your machine-vision camera recognize patterns and locations.

| Lg., mm | Wt. | Color | For Robot-Arm Mounting Adapter Material | Each | |

Anodized Aluminum | |||||

|---|---|---|---|---|---|

| 154 | 0.29 lbs. / 0.13 kg | Black | Aluminum | 00000000 | 000000 |

These mounts have standard ISO mounting hole patterns, so they’re compatible with the mounting hole patterns on most robot arms and tools. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility.

| Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mounting Plate Dia., mm | Max. Load Cap. | Wt. | Lg., mm | Includes | Features | For Robot Arm Manufacturer (Series/Model Number) | Each | |

Low Profile—Black PTFE-Coated Aluminum (Bolt On) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) | 83 | 110 lbs. / 50 kg | 0.53 lbs. / 0.24 kg | 19 | __ | __ | ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Omron (TM 5, 12, 14) Precise Automation (PAVP6; PF3400; PP100) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 00000000 | 0000000 |

Utility—Black PTFE-Coated Aluminum (Bolt On) | |||||||||

| 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) | 83 | 110 lbs. / 50 kg | 0.71 lbs. / 0.32 kg | 74 | Power/Signal Connector with 5-ft. Wire Leads | Dual 6 mm Pneumatic Pass-Throughs, M8 8-Pin Power/Signal Pass-Through | ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Omron (TM 5, 12, 14) Precise Automation (PAVP6; PF3400; PP100) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 00000000 | 00000000 |