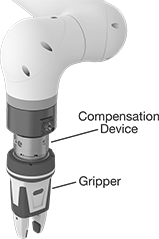

Robot-Ready Gripper Compensation Devices

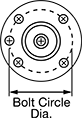

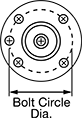

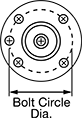

Ready to mount between your robot arm and gripper, these devices have standard ISO mounting hole patterns and allow grippers to adjust, so they can grab parts that are misaligned or have different tolerances. They also compensate when aligning parts during placement, which increases efficiency and reliability in your process, while protecting parts and robots from wear. Use them to avoid jams and keep automated assembly, bin picking, and machine tending jobs running smoothly. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility.

For technical drawings and 3-D models, click on a part number.

Devices for X and Y axes tilt grippers and move them side-to-side to make angled and horizontal adjustments. Use them to help grippers grab items on an incline and center items, such as a pin, above a hole.

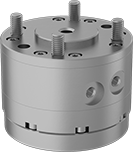

Devices with spring actuation and spring reset use compression springs to position your grippers. Use the set screws to adjust the force of the springs.

Devices with air actuation use compressed air to vary the pressure and force you'll need for making small to large gripper adjustments. Those with a position lock secure parts in place for an additional task. For example, once an item is aligned, it can be held in place to apply adhesive to it.

Compensation (Deflection) | End of Robot Arm | Gripper | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| X-Axis | Y-Axis | Resetting Force Range | Locking Force | Bolt Circle Dia. (Mount. Hole Pattern Compatibilty) | Mount. Fasteners Included | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | For Robot Arm Manufacturer (Series/Model Number) | Each | |

Anodized Aluminum Housing—Spring Actuation and Spring Reset | ||||||||||

±1.5 mm Horizontal Compensation | ||||||||||

| __ | __ | 0.34-0.79 lbs. / 0.15-0.36 kgf | __ | 31.5 mm (ISO 31.5) | Yes | __ | No | ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 200iD/7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 00000000 | 000000000 |

| __ | __ | 0.9-1.3 lbs. / 0.41-0.56 kgf | __ | 31.5 mm (ISO 31.5) | Yes | __ | No | ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 200iD/7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 00000000 | 00000000 |

| __ | __ | 1.3-1.5 lbs. / 0.56-0.71 kgf | __ | 31.5 mm (ISO 31.5) | Yes | __ | No | ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 200iD/7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 00000000 | 00000000 |

±2 mm Horizontal Compensation | ||||||||||

| __ | __ | 0.67-1.1 lbs. / 0.31-0.51 kgf | __ | 40 mm (ISO 40) | Yes | __ | No | ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 00000000 | 00000000 |

| __ | __ | 0.9-1.5 lbs. / 0.41-0.71 kgf | __ | 40 mm (ISO 40) | Yes | __ | No | ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 00000000 | 00000000 |

| __ | __ | 1-2 lbs. / 0.46-0.92 kgf | __ | 40 mm (ISO 40) | Yes | __ | No | ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 00000000 | 00000000 |

±4 mm Horizontal Compensation | ||||||||||

| __ | __ | 2.7-5.6 lbs. / 1.22-2.55 kgf | __ | 63 mm (ISO 63) | Yes | __ | No | ABB (IRB 1520ID) Yaskawa/Motoman (HC 10T; SIA 10D, 10F) | 00000000 | 00000000 |

| __ | __ | 3.6-8.5 lbs. / 1.63-3.87 kgf | __ | 63 mm (ISO 63) | Yes | __ | No | ABB (IRB 1520ID) Yaskawa/Motoman (HC 10T; SIA 10D, 10F) | 00000000 | 00000000 |

| __ | __ | 4.5-12.3 lbs. / 2.1-5.6 kgf | __ | 63 mm (ISO 63) | Yes | __ | No | ABB (IRB 1520ID) Yaskawa/Motoman (HC 10T; SIA 10D, 10F) | 00000000 | 00000000 |

±5 mm Horizontal Compensation | ||||||||||

| __ | __ | 8.8-15.7 lbs. / 3.9-7.1 kgf | __ | 80 mm (ISO 80) | Yes | __ | No | ABB (IRB 1660ID; IRB 2600ID) Yaskawa/Motoman (SIA 10D, 10F) | 0000000 | 00000000 |

| __ | __ | 19.1-29.2 lbs. / 8.7-13.2 kgf | __ | 80 mm (ISO 80) | Yes | __ | No | ABB (IRB 1660ID; IRB 2600ID) Yaskawa/Motoman (SIA 10D, 10F) | 00000000 | 00000000 |

| __ | __ | 20.3-33.7 lbs. / 9.2-15.3 kgf | __ | 80 mm (ISO 80) | Yes | __ | No | ABB (IRB 1660ID; IRB 2600ID) Yaskawa/Motoman (SIA 10D, 10F) | 00000000 | 00000000 |

Anodized Aluminum Housing—Air Actuation | ||||||||||

±2.5 mm Horizontal Compensation | ||||||||||

| ±12° | ±12° | __ | 52 lbs. @ 87 psi | 50 mm (ISO 50) | Yes | 50 mm (ISO 50) | No | ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 00000000 | 00000000 |

±3 mm Horizontal Compensation | ||||||||||

| ±12° | ±12° | __ | 83 lbs. @ 87 psi | 63 mm (ISO 63) | Yes | 63 mm (ISO 63) | No | ABB (IRB 1520ID) Yaskawa/Motoman (HC 10T; SIA 10D, 10F) | 00000000 | 00000000 |

±4 mm Horizontal Compensation | ||||||||||

| ±16° | ±16° | __ | 130 lbs. @ 87 psi | 80 mm (ISO 80) | Yes | 80 mm (ISO 80) | No | ABB (IRB 1660ID; IRB 2600ID) Yaskawa/Motoman (SIA 10D, 10F) | 00000000 | 00000000 |

Anodized Aluminum Housing—Air Actuation and Position Lock | ||||||||||

±2.5 mm Horizontal Compensation | ||||||||||

| ±12° | ±12° | __ | 52 lbs. @ 87 psi | 50 mm (ISO 50) | Yes | 50 mm (ISO 50) | No | ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 00000000 | 00000000 |

±3 mm Horizontal Compensation | ||||||||||

| ±12° | ±12° | __ | 83 lbs. @ 87 psi | 63 mm (ISO 63) | Yes | 63 mm (ISO 63) | No | ABB (IRB 1520ID) Yaskawa/Motoman (HC 10T; SIA 10D, 10F) | 00000000 | 00000000 |

±4 mm Horizontal Compensation | ||||||||||

| ±16° | ±16° | __ | 130 lbs. @ 87 psi | 80 mm (ISO 80) | Yes | 80 mm (ISO 80) | No | ABB (IRB 1660ID; IRB 2600ID) Yaskawa/Motoman (SIA 10D, 10F) | 00000000 | 00000000 |

Devices for Z axis turn grippers as well as move them up and down to make rotational, vertical, and compression adjustments. Use them to help grippers pivot items for correct alignment and even screw components together.

Devices with spring and air actuation use compression springs for making small gripper adjustments, or add compressed air to vary the force for larger gripper adjustments.

Locking Force | End of Robot Arm | Gripper | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Spring Force Range | Extended | Retracted | Bolt Circle Dia. (Mount. Hole Pattern Compatibilty) | Mount. Fasteners Included | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | For Robot Arm Manufacturer (Series/Model Number) | Each | |

Anodized Aluminum Housing—Spring and Air Actuation | |||||||||

±8 mm Vertical Compensation | |||||||||

| 4.5-9 lbs. / 2-4 kgf | 110 lbs. @ 87 psi | 65 lbs. @ 87 psi | 50 mm (ISO 50) | Yes | 50 mm (ISO 50) | No | ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 00000000 | 000000000 |

| 9-13.4 lbs. / 4-6.1 kgf | 110 lbs. @ 87 psi | 60 lbs. @ 87 psi | 50 mm (ISO 50) | Yes | 50 mm (ISO 50) | No | ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 00000000 | 00000000 |

| 9-13.4 lbs. / 4-6.1 kgf | 200 lbs. @ 87 psi | 175 lbs. @ 87 psi | 63 mm (ISO 63) | Yes | 63 mm (ISO 63) | No | ABB (IRB 1520ID) Yaskawa/Motoman (HC 10T; SIA 10D, 10F) | 00000000 | 00000000 |

| 13.5-22.4 lbs. / 6.1-10.2 kgf | 200 lbs. @ 87 psi | 165 lbs. @ 87 psi | 63 mm (ISO 63) | Yes | 63 mm (ISO 63) | No | ABB (IRB 1520ID) Yaskawa/Motoman (HC 10T; SIA 10D, 10F) | 00000000 | 00000000 |

±10 mm Vertical Compensation | |||||||||

| 15.8-22.4 lbs. / 7.2-10.2 kgf | 335 lbs. @ 87 psi | 325 lbs. @ 87 psi | 80 mm (ISO 80) | Yes | 80 mm (ISO 80) | No | ABB (IRB 1660ID; IRB 2600ID) Yaskawa/Motoman (SIA 10D, 10F) | 00000000 | 00000000 |

| 20.3-26.9 lbs. / 9.1-12.2 kgf | 335 lbs. @ 87 psi | 325 lbs. @ 87 psi | 80 mm (ISO 80) | Yes | 80 mm (ISO 80) | No | ABB (IRB 1660ID; IRB 2600ID) Yaskawa/Motoman (SIA 10D, 10F) | 00000000 | 00000000 |

Devices for X, Y, and Z axes tilt, turn, and move grippers side-to-side as well as up and down to make angled, rotational, horizontal, vertical, and compression adjustments. Use them to help grippers grab items on an incline; center items, such as a pin, above a hole; pivot items for correct alignment; and even screw components together.

Devices with spring and air actuation use compression springs for making small gripper adjustments, or add compressed air to vary the force for larger gripper adjustments.

Compensation (Deflection) | End of Robot Arm | Gripper | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| X-Axis | Y-Axis | Z-Axis | Spring Force Range | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | For Robot Arm Manufacturer (Series/Model Number) | Each | |

Anodized Aluminum Housing—Spring and Air Actuation | ||||||||||

±2.7 mm Horizontal Compensation and ±6.1 mm Vertical Compensation | ||||||||||

| ±3° | ±3° | ±8° | 8.1-20.6 lbs. / 3.7-9.3 kgf | 50 mm (ISO 50) | Yes | 50 mm (ISO 50) | No | ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 00000000 | 000000000 |

Sensors detect gripper positions by responding to magnets in the compensation devices. They signal whether the grippers are open or closed, and use that information to trigger other actions in your system. Two sensors are required for each device. Select sensors that match the electrical connections on your robot arm. PNP sensors communicate gripper positions with a positive signal, while NPN send a negative signal.

| Electrical Connection Type | Plug Type | Number of Wire Leads | Switch Starting Position | Current | Voltage | Cord Length, ft. | Number of Sensing Positions | Each | |

NPN | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Hardwire | __ | 3 | 1 Off (Normally Open) | 50 mA | 24V DC | 6 1/2 | 1 | 00000000 | 0000000 |

| Plug | 3-Pin M8 | __ | 1 Off (Normally Open) | 50 mA | 24V DC | 1 | 1 | 00000000 | 000000 |

PNP | |||||||||

| Hardwire | __ | 3 | 1 Off (Normally Open) | 50 mA | 24V DC | 6 1/2 | 1 | 00000000 | 000000 |

| Hardwire | __ | 4 | 1 Off (Normally Open) and 1 On (Normally Closed) | 100 mA | 24V DC | 2 | 2 | 00000000 | 000000 |

| Plug | 3-Pin M8 | __ | 1 Off (Normally Open) | 50 mA | 24V DC | 1 | 1 | 0000000 | 000000 |

| Plug | 4-Pin M8 | __ | 1 Off (Normally Open) and 1 On (Normally Closed) | 100 mA | 24V DC | 6 1/2 | 2 | 00000000 | 000000 |

Gripper Compensation Devices

Avoid jams and keep automated assembly, bin picking, and machine tending jobs running smoothly. These compensation devices mount between your gripper and robot arm and have rubber pads that compress slightly when pressure is applied, allowing your grippers to adjust and grasp misaligned parts. These pads also compensate when aligning parts during placement, which increases efficiency and reliability in your process, while protecting parts and robots from wear.

These devices tilt and rotate on three axes, so grippers can grab parts in horizontal, vertical, and angled positions. They do not communicate with controllers, so there’s no need for electrical connections.

For technical drawings and 3-D models, click on a part number.

Capacity | Compensation (Deflection) | O'all | Robot Arm Side | Gripper Side | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| English | Metric | Newtons | For X-Axis | For Y-Axis | For Z-Axis | Wt. | Dia., mm | Lg., mm | Wd., mm | Dp., mm | Bolt Hole Thread Size (No. of) | Mounting Fasteners Included | Bolt Hole Thread Size (No. of) | Mounting Fasteners Included | Each | |

Anodized Aluminum Housing | ||||||||||||||||

| 245 lbs. | 110 kg | 1,100 N | ±1° | ±1.5° | ±2° | 0.18 lbs. / 0.08 kg | __ | 19.5 | 52 | 36 | M4 × 0.7 mm (4) | Yes | M4 × 0.7 mm (4) | No | 00000000 | 0000000 |

| 245 lbs. | 110 kg | 1,100 N | ±1° | ±1° | ±1° | 0.33 lbs. / 0.15 kg | 64 | 19.6 | __ | __ | M4 × 0.7 mm (3) | Yes | M5 × 0.8 mm (3) | No | 00000000 | 000000 |

| 335 lbs. | 150 kg | 1,500 N | ±1° | ±1.5° | ±2° | 0.22 lbs. / 0.1 kg | __ | 19.6 | 63 | 42 | M4 × 0.7 mm (4) | Yes | M4 × 0.7 mm (4) | No | 00000000 | 000000 |

| 335 lbs. | 150 kg | 1,500 N | ±1° | ±1° | ±1° | 0.66 lbs. / 0.3 kg | 80 | 20.4 | __ | __ | M6 × 1 mm (3) | Yes | M6 × 1 mm (3) | No | 00000000 | 000000 |

| 450 lbs. | 200 kg | 2,000 N | ±1° | ±1.5° | ±1.2° | 0.49 lbs. / 0.22 kg | __ | 22.6 | 81 | 50 | M5 × 0.8 mm (4) | Yes | M5 × 0.8 mm (4) | No | 00000000 | 000000 |

| 450 lbs. | 200 kg | 2,000 N | ±1° | ±1° | ±1° | 1.03 lbs. / 0.47 kg | 100 | 22.6 | __ | __ | M6 × 1 mm (3) | Yes | M6 × 1 mm (3) | No | 00000000 | 000000 |

| 625 lbs. | 285 kg | 2,800 N | ±1° | ±1.5° | ±1.5° | 0.66 lbs. / 0.3 kg | __ | 23.6 | 100 | 60 | M6 × 1 mm (4) | Yes | M6 × 1 mm (4) | No | 00000000 | 00000000 |