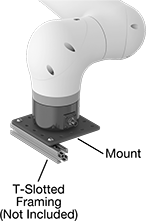

Robot Tool Mounts for T-Slotted Framing

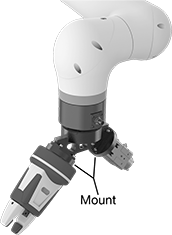

Connect your robot arm to tools or extensions made from T-slotted framing. These mounts are often used to support custom tools for uniquely shaped items, such as a rig to lift chairs off of a line, or as a mounting base for a screwdriver. They use ISO mounting patterns, an industry standard for arm connections. These mounts are made of aluminum, so they’re corrosion resistant, lightweight, and machinable. The lightness helps you keep robot arms under their payload, or weight limit, and the machinability means you can drill your own holes. Mounts come with all the hardware needed to connect them to robot arms, but not the bolts required to connect T-slotted framing to the mounts. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility.

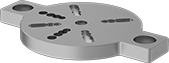

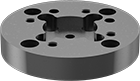

Round mounts are compatible with several ISO mounting patterns, so they connect to a wide variety of robot arms. They’re also lighter and smaller than other mounts, so they fit in tight spaces. However, with only two mounting holes for T-slotted framing, they have fewer attachment options than other mounts.

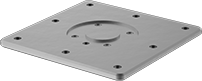

Square mounts have 16 mounting holes for T-slotted framing, giving you more mounting options than round mounts. They’re heavier, however, and take up more space.

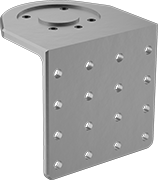

L-shaped mounts create a 90° mounting angle, so you can position tools to point down or forward. These mounts are also commonly used to connect tools that don’t have standard ISO mounting patterns and can’t bolt directly to robot arms.

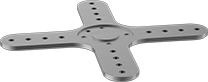

X-shaped mounts have a broad surface area, spreading out T-slotted framing or robot tools for handling large objects.

Use robot tool mounts (sold separately) with square, L-shaped, and X-shaped mounts for compatibility with different ISO mounting patterns.

For technical drawings and 3-D models, click on a part number.

End of Robot Arm (Bolt On) | For Rail Ht. | T-Slotted Framing (Bolt On) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mounting Fasteners Included | Single | Double and Quad | Triple | For Bolt Size (No. of) | Mounting Fasteners Included | Max. Load Cap. | Wt. | For Robot Arm Manufacturer (Series/Model Number) | Each | |

Aluminum | |||||||||||

| 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) 63 mm (ISO 63) | Yes | 1" | 2" | 3" | M6 (2) | No | 110 lbs./ 50 kg | 0.31 lbs./ 0.14 kg | ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1520ID; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S; HC 10T; SIA 10D, 10F) Precise Automation (PAVP6; PF3400; PP100) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Omron (TM 5, 12, 14) Staubli (TX2 90) Productive Robotics (OB7) | 0000000 | 000000 |

End of Robot Arm (Bolt On) | For Rail Ht. | T-Slotted Framing (Bolt On) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mounting Fasteners Included | Single | Double and Quad | Triple | For Bolt Size (No. of) | Mounting Fasteners Included | Max. Load Cap. | Wt. | For Robot Arm Manufacturer (Series/Model Number) | Each | |

Powder-Coated Aluminum | |||||||||||

| 50 mm (ISO 50) | Yes | 1" | 2" | 3" | 1/4"-20 (8) | No | 35 lbs./ 16 kg | 0.78 lbs./ 0.35 kg | ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Omron (TM 5, 12, 14) Staubli (TX2 90) Productive Robotics (OB7) | 0000000 | 0000000 |

End of Robot Arm (Bolt On) | For Rail Ht. | T-Slotted Framing (Bolt On) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mounting Fasteners Included | Single | Double and Quad | Triple | For Bolt Size (No. of) | Mounting Fasteners Included | Max. Load Cap. | Wt. | For Robot Arm Manufacturer (Series/Model Number) | Each | |

Powder-Coated Aluminum | |||||||||||

| 50 mm (ISO 50) | Yes | 1" | 2" | 3" | 1/4"-20 (16) | No | 35 lbs./ 16 kg | 0.75 lbs./ 0.34 kg | ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Omron (TM 5, 12, 14) Staubli (TX2 90) Productive Robotics (OB7) | 0000000 | 0000000 |

End of Robot Arm (Bolt On) | For Rail Ht. | T-Slotted Framing (Bolt On) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mounting Fasteners Included | Single | Double and Quad | Triple | For Bolt Size (No. of) | Mounting Fasteners Included | Max. Load Cap. | Wt. | For Robot Arm Manufacturer (Series/Model Number) | Each | |

Powder-Coated Aluminum | |||||||||||

| 50 mm (ISO 50) | Yes | 1" | 2" | 3" | 1/4"-20 (16) | No | 35 lbs./ 16 kg | 0.93 lbs./ 0.42 kg | ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Omron (TM 5, 12, 14) Staubli (TX2 90) Productive Robotics (OB7) | 0000000 | 0000000 |

| 50 mm (ISO 50) | Yes | 1" | 2" | 3" | 1/4"-20 (28) | No | 35 lbs./ 16 kg | 1.2 lbs./ 0.52 kg | ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Omron (TM 5, 12, 14) Staubli (TX2 90) Productive Robotics (OB7) | 0000000 | 000000 |

Robot Tool (Bolt On) | End of Robot Arm (Bolt On) | |||||||

|---|---|---|---|---|---|---|---|---|

| Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Bolt Hole Thread Size (No. of) | Mounting Fasteners Included | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mounting Fasteners Included | Wt. | Max. Load Cap. | Each | |

Black Anodized Aluminum | ||||||||

| 50 mm (ISO 50) | M6 × 1 mm (4) | No | 31.5 mm (ISO 31.5) 40 mm (ISO 40) 63 mm (ISO 63) | Yes | 0.36 lbs./ 0.16 kg | 110 lbs./ 50 kg | 0000000 | 0000000 |

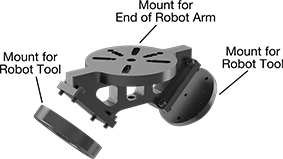

Mounts for Two Robot Tools

Equip your robot arm with two tools at once—these mounts have two offset, angled mounting surfaces for tools. They’re often used to speed up a robot’s work cycle, such as when two grippers swap workpieces in and out of a CNC machine. Or, use them to mount tools with different functions, such as a pick-and-place gripper that puts a workpiece into a vice and a sander that finishes the workpiece. They’re compatible with the most common robot arms, including some models from Universal Robots (UR) and FANUC.

These mounts are made of aluminum, so they’re corrosion resistant, lightweight, and machinable. The lightness helps you keep robot arms under their payload, or weight limit, and the machinability means you can drill your own holes.

For a complete system, you'll need an end-of-robot-arm mount and two tool-side mounts. These mounts include fasteners to attach mounts to your arm, and fasteners to attach tool-side mounts, but not fasteners for attaching your tools.

Bolt-on mounts have a standard ISO mounting pattern—choose one that matches the mounting pattern of your robot arm and tools. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility.

Blank mounts don’t have drilled holes. Machine your own holes for compatibility with unusual mounting patterns. These mounts don’t come with installation hardware.

To extend your robot arm’s reach, use robot tool extensions.

For technical drawings and 3-D models, click on a part number.

Mounting Plate, mm | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Mount Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mounting Fasteners Included | Dia. | Wd. | Max. Load Cap. | Wt. | For Robot Arm Manufacturer (Series/Model Number) | Each | |

Black Anodized Aluminum | |||||||||

| Bolt On | 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) 63 mm (ISO 63) | Yes | 80 | 128 | 110 lbs./ 50 kg | 0.56 lbs./ 0.25 kg | ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1520ID; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S; HC 10T; SIA 10D, 10F) Precise Automation (PAVP6; PF3400; PP100) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Omron (TM 5, 12, 14) Staubli (TX2 90) Productive Robotics (OB7) | 0000000 | 0000000 |

| Blank | __ | Yes | 80 | 128 | 110 lbs./ 50 kg | 0.58 lbs./ 0.26 kg | __ | 0000000 | 000000 |

| Mount Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mounting Fasteners Included | Bolt Hole Thread Size (No. of) | Mounting Plate Dia., mm | Max. Load Cap. | Wt. | Each | |

Black Anodized Aluminum | ||||||||

|---|---|---|---|---|---|---|---|---|

| Bolt On | 31.5 mm (ISO 31.5) | No | M5 × 0.8 mm (4) | 40 | 110 lbs./ 50 kg | 0.14 lbs./ 0.06 kg | 0000000 | 000000 |

| Bolt On | 40 mm (ISO 40) | No | M6 × 1 mm (4) | 50 | 110 lbs./ 50 kg | 0.16 lbs./ 0.07 kg | 0000000 | 00000 |

| Bolt On | 50 mm (ISO 50) | No | M6 × 1 mm (4) | __ | 110 lbs./ 50 kg | 0.18 lbs./ 0.08 kg | 0000000 | 00000 |

| Bolt On | 63 mm (ISO 63) | No | M6 × 1 mm (4) | __ | 110 lbs./ 50 kg | 0.31 lbs./ 0.14 kg | 0000000 | 000000 |

| Blank | __ | No | __ | __ | 110 lbs./ 50 kg | 0.36 lbs./ 0.16 kg | 0000000 | 00000 |

Robot Tool Mounts

Connect robot tools to robot arms that have different ISO mounting patterns. Compatible with some models of Universal Robots (UR) and FANUC robots, these mounts are commonly used to equip robot arms with pick-and-place grippers, vacuum grippers, and sanders. They use ISO mounting patterns, an industry standard for arm connections. Mounts come with all the hardware you need to connect them to robot arms, but not all the hardware required to connect robot tools to mounts. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility.

Bolt-on mounts have ISO mounting patterns on the tool side.

Blank mounts don’t have drilled holes on the tool side. Machine your own holes for compatibility with unusual mounting patterns.

Threaded mounts have a universal female-threaded connection on the tool side for attaching threaded tools, pipe, rods, and other components to robot arms. If you need a male-threaded connection, choose one with an included universal thread adapter. For other thread types and sizes, add a universal thread adapter.

Aluminum mounts are a lightweight metal alternative to stainless steel, helping your robot arm stay under its payload limit, or the total capacity a robot can lift. They’re also more machinable than stainless steel, so you can drill your own holes for robots with unusual mounting patterns. These mounts resist corrosion.

Acetal plastic mounts are lightweight and strong. Often used in food-processing plants, they won’t corrode from frequent washdowns with harsh cleaners.

To extend your robot arm’s reach, use robot tool extensions.

For technical drawings and 3-D models, click on a part number.

Robot Tool | End of Robot Arm (Bolt On) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Bolt Hole Thread Size (No. of) | Mounting Fasteners Included | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mounting Fasteners Included | Wt. | Max. Load Cap. | For Robot Arm Manufacturer (Series/Model Number) | Each | |

Bolt On | |||||||||

| 31.5 mm (ISO 31.5) | M5 × 0.8 mm (4) | No | 40 mm (ISO 40) 50 mm (ISO 50) 63 mm (ISO 63) | Yes | 0.36 lbs./ 0.16 kg | 110 lbs./ 50 kg | ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410 IRB 1520ID; IRB 1600; IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; M-20 iA) Omron (TM 5, 12, 14) Precise Automation (PP100) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 10T, MH 10D, 10F) | 0000000 | 0000000 |

| 40 mm (ISO 40) | M6 × 1 mm (4) | No | 31.5 mm (ISO 31.5) 50 mm (ISO 50) 63 mm (ISO 63) | Yes | 0.36 lbs./ 0.16 kg | 110 lbs./ 50 kg | ABB (IRB 120; IRB 1200; IRB 1520ID; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L) KUKA Robotics (KR 10 R1100-2) Omron (TM 5, 12, 14) Precise Automation (PAVP6; PF3400) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S; HC 10T; SIA 10D, 10F) | 0000000 | 000000 |

| 50 mm (ISO 50) | M6 × 1 mm (4) | No | 31.5 mm (ISO 31.5) 40 mm (ISO 40) 63 mm (ISO 63) | Yes | 0.36 lbs./ 0.16 kg | 110 lbs./ 50 kg | ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1520ID; IRB 1600) FANUC (CR 4iA, 7iA; 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400; PP100) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S; HC 10T; SIA 10D, 10F) | 0000000 | 000000 |

| 63 mm (ISO 63) | M6 × 1 mm (4) | No | 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) | Yes | 0.36 lbs./ 0.16 kg | 110 lbs./ 50 kg | ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Omron (TM 5, 12, 14) Precise Automation (PAVP6; PF3400; PP100) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 0000000 | 000000 |

Blank | |||||||||

| __ | __ | No | 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) 63 mm (ISO 63) | Yes | 0.4 lbs./ 0.18 kg | 110 lbs./ 50 kg | ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1520ID; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Omron (TM 5, 12, 14) Precise Automation (PAVP6; PF3400; PP100) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S; HC 10T; SIA 10D, 10F) | 0000000 | 000000 |

Robot Tool | End of Robot Arm (Bolt On) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Gender | Mounting Fasteners Included | Bolt Circle Dia. (Mounting Hole Pattern Compatibility) | Mounting Fasteners Included | Max. Load Cap. | Includes | For Robot Arm Manufacturer (Series/Model Number) | Each | |

Threaded | |||||||||

| 3/8 | Female | No | 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) 63 mm (ISO 63) | Yes | 110 lbs. / 50 kg | __ | ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1520ID; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Omron (TM 5, 12, 14) Precise Automation (PAVP6; PF3400; PP100) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S; HC 10T; SIA 10D, 10F) | 00000000 | 0000000 |

| 3/8 | Female | Yes | 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) 63 mm (ISO 63) | Yes | 110 lbs. / 50 kg | Universal 1/4 Male Thread Adapter | ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1520ID; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Omron (TM 5, 12, 14) Precise Automation (PAVP6; PF3400; PP100) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S; HC 10T; SIA 10D, 10F) | 00000000 | 000000 |

| 3/8 | Female | Yes | 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) 63 mm (ISO 63) | Yes | 110 lbs. / 50 kg | Universal 1/8 Male Thread Adapter | ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1520ID; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Omron (TM 5, 12, 14) Precise Automation (PAVP6; PF3400; PP100) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S; HC 10T; SIA 10D, 10F) | 00000000 | 000000 |