About Nuts, Materials, and Finishes

More

Steel Twist-Resistant Rivet Nuts

Made of steel, these rivet nuts add strong, reusable threads to sheet metal and other material that’s too thin to tap. Their ribbed body grips material better than smooth-body rivet nuts, so they won't twist when you tighten a screw. Also known as blind inserts, they can be installed when you have access to only one side of the material. With a zinc yellow-chromate plating, these nuts resist corrosion in wet environments.

Install these nuts in a drilled or punched round hole using a rivet nut tool. The tool collapses the nut, creating a backside flange that holds the nut to the material.

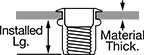

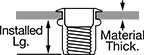

Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

For technical drawings and 3-D models, click on a part number.

Thread | Body | Flange | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Drill Bit Size | For Material Thick., mm | Type | Dia., mm | Lg., mm | Installed Lg., mm | Dia., mm | Thick., mm | Pkg. Qty. | Pkg. | |

Zinc Yellow-Chromate-Plated Steel | ||||||||||||

| M12 | 1.75 | 17.5 mm | 1.6 to 5.1 | Ribbed | 17.4 | 29.2 | 21.6 | 22 | 1.2 | 10 | 000000000 | 000000 |

| M12 | 1.75 | 17.5 mm | 5.1 to 8.9 | Ribbed | 17.4 | 33 | 21.6 | 22 | 1.2 | 10 | 000000000 | 00000 |

| M12 | 1.75 | 17.5 mm | 8.9 to 12.7 | Ribbed | 17.4 | 36.8 | 21.8 | 22 | 1.2 | 5 | 000000000 | 00000 |

Stainless Steel Twist-Resistant Rivet Nuts

Made of 18-8 stainless steel, these rivet nuts withstand water, mild chemicals, and outdoor conditions better than zinc-plated steel nuts. A ribbed body grips surrounding material to hold them in place, keeping them from spinning as you tighten screws. Rivet nuts create permanent threads in sheet metal and other surfaces that are too thin to be tapped. They’re also known as blind inserts—installation requires access to just one side of your material. The flange distributes the load and holds them against the surface.

Secure them in a drilled or punched round hole with a wrench- or power-driven rivet nut tool. The tool collapses the nut, creating a backside flange that holds the nut to the material.

Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

For technical drawings and 3-D models, click on a part number.

Thread | Body | Flange | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Pitch, mm | Drill Bit Size | For Material Thick., mm | Type | Dia., mm | Lg., mm | Installed Lg., mm | Dia., mm | Thick., mm | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel | ||||||||||||

| M12 | 1.75 | 17.5 mm | 1.6 to 5.1 | Ribbed | 17.4 | 29.2 | 21.6 | 22 | 1.2 | 1 | 000000000 | 00000 |

Rivet Nuts for Sandwich Panels

To grip all layers of a sandwich panel—the top, core, and bottom—these rivet nuts have a two-piece construction. They combine a flanged rivet nut that grasps the top and a threaded insert that bonds to the core and bottom with adhesive. Use them to add strong, reusable threads so you can fasten your panel to other components. They won’t budge when you tighten a screw—between the adhesive and the rivet nut’s ribbed body, these nuts grip onto your material. The flange anchors the rivet nut so it doesn’t pull through, and it also helps distribute load from parts you fasten to the panel. Since these rivet nuts are made of 18-8 stainless steel, they stand up to mild chemicals and water.

Place the rivet nut into a drilled hole. Using a rivet nut tool, collapse the rivet nut against your panel to create a backside flange that holds it tight. With a mixing nozzle and dispensing gun, inject structural adhesive (all sold separately) through the rivet nut so the insert can stick to the bottom and core layer beneath. Add the reusable threads by threading the insert into the rivet nut with a slotted screwdriver. The closed end on the insert keeps the adhesive from leaking into the threads.

For technical drawings and 3-D models, click on a part number.

Threaded Insert Thread | Rivet Nut Thread | Body | Flange | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Outer Layer Thick., mm | For Hole Dp., mm | Size | Pitch, mm | Threaded Insert Lg., mm | Size | Pitch, mm | Drill Bit Size, mm | Type | Dia., mm | Dia., mm | Thick., mm | For Use In | Each | |

18-8 Stainless Steel | ||||||||||||||

| 0.5 to 2 | 17.5 to 20 | M8 | 1.25 | 15 | M12 | 1.75 | 15 | Ribbed | 15 | 18 | 1.5 | Composite, Metal | 000000000 | 00000 |

| 0.5 to 3.5 | 25 to 35 | M8 | 1.25 | 25 | M12 | 1.75 | 15 | Ribbed | 15 | 18 | 2 | Composite, Metal | 000000000 | 0000 |

Container | Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Shear, lbs./sq. in. | Peel, lbs./in. wd. | Mix Ratio | Consistency (Viscosity) | Elongation | Temp. Range, °F | Color | Each | |

| 1.58 | Cartridge | 4 min. | 24 hrs. | 3,000 | 35 | 1:1 | Thick Liquid (55,000 cP) | 10% | -65° to 250° | Light Yellow | 00000000 | 000000 |

| For Cartridge Size, oz. | Mix Ratio | Opening ID | Lg. | Mixing Elements | Material | Each | |

Bayonet Connection | |||||||

|---|---|---|---|---|---|---|---|

Taper Tip | |||||||

| 1.58 | 1:1 | 0.07" | 5.9" | 20 | Polypropylene Plastic | 00000000 | 00000 |

| For Cartridge Size, oz. | Includes | Each | |

| 1.58 | 1:1 and 2:1 Mix Ratio Plungers | 00000000 | 000000 |

Flush-Mount Rivet Nuts

With an angled head, these rivet nuts sit flush in countersunk holes. Use them to create reusable threads in sheet metal and other surfaces that are too thin to be tapped. Installation requires access to just one side of your material. Made of steel, all have either a zinc or zinc yellow-chromate plating to resist corrosion in wet environments.

Install them in a drilled or punched countersunk hole with a rivet nut tool. The tool collapses the nut, creating a backside flange that holds the nut to the material.

Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

For technical drawings and 3-D models, click on a part number.

Wrench-Driven Rivet Nut Tools

Use these tools to install most styles of rivet nuts. A wrench and ratchet are required to hold the tool and tighten the nut.

For technical drawings and 3-D models, click on a part number.

| For Thread Size | For Wrench Size | For Ratchet Size | For Rivet Nut Body Type | For Rivet Nut Material | Each | |

| M12 × 1.75 mm | 7/8" | 7/8" | Smooth, Ribbed, Hex, Bulbed, Sleeve | 18-8 Stainless Steel, Aluminum, Steel, Titanium | 000000000 | 000000 |

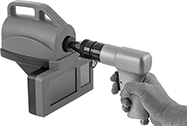

Air-Powered Rivet Nut Tools

Smaller and lighter than cordless and hydraulic rivet nut tools, use these to install thin-walled bulbed, ribbed, sleeve, and smooth rivet nuts. To use, thread the nut onto the included mandrel and press the trigger to spin the nut onto the tool. Place the nut into the material and press the trigger to install the nut. Press the trigger one more time to spin the mandrel off.

Air Connection | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Thread Size | For Rivet Nut Body Type | For Rivet Nut Material | Head Lg. | Overall Ht. | Operating Pressure, psi | Pipe Size | Thread Type | Weight, lbs. | Includes | Each | |

| M12 × 1.75 mm | Bulbed, Ribbed, Sleeve, Smooth | Aluminum, Steel | 7 1/4" | 6" | 90 to 110 | 1/4 | NPT | 4 | Mandrel, Nosepiece | 000000000 | 000000000 |

| For Thread Size | Each | |

| M12 × 1.75 mm | 000000000 | 00000 |

| For Thread Size | Includes | Each | |

| M12 × 1.75 mm | Bearing Set, Hex Drive, Mandrel, Nose Cone | 000000000 | 0000000 |

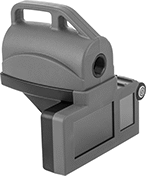

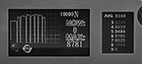

Pull Force Calibrators for Rivet Nut Tools

Avoid failed rivet nuts by periodically testing the pull force of your rivet nut tool. These calibrators work with air-powered and hydraulic/air-powered rivet nut tools. They display force measurements on two digital touch screens. The left screen shows a graph and read-out of current pulling force, while the right screen shows the results of the last seven tests. Track performance to plan maintenance—they store test data on the included microSD card.

An anvil and mandrel assembly (sold separately) is required. Choose a thread size that matches your tool. Thread the anvil and mandrel assembly onto the calibrator to begin testing.

| For Thread Size | Capacity | Accuracy | Measuring Increments | Ht. | Wd. | Dp. | Housing Material | Electrical Connection Type | Cord Lg., ft. | Includes | Each | |

| 6-32, 8-32, 10-24, 10-32, 1/4"-20, 1/4"-28, 5/16"-18, 5/16"-24, 3/8"-16, 3/8"-24, 1/2"-13, M4, M5, M6, M8, M10, M12 | 11,000 lbs. (English) 5,000 kg (Metric) 50,000 N (Newtons) | ±3% | 1 lbs. (English) 1 kg (Metric) 1 N (Newtons) | 6 3/8" | 8 1/4" | 9 3/4" | Plastic | Plug | 3 | microSD Card, microSD Card Reader, USB Power Adapter | 00000000 | 000000000 |

| For Thread Size | Each | |

| 6-32 | 00000000 | 0000000 |

| 8-32 | 00000000 | 000000 |

| 10-24 | 00000000 | 000000 |

| 10-32 | 00000000 | 000000 |

| 1/4"-20 | 00000000 | 000000 |

| 1/4"-28 | 00000000 | 000000 |

| 5/16"-18 | 00000000 | 000000 |

| 5/16"-24 | 00000000 | 000000 |

| 3/8"-16 | 00000000 | 000000 |

| 3/8"-24 | 00000000 | 000000 |

| 1/2"-13 | 00000000 | 000000 |

| M4 × 0.7 mm | 00000000 | 000000 |

| M5 × 0.8 mm | 00000000 | 000000 |

| M6 × 1 mm | 00000000 | 000000 |

| M8 × 1.25 mm | 00000000 | 000000 |

| M10 × 1.5 mm | 00000000 | 000000 |

| M12 × 1.75 mm | 00000000 | 000000 |