About Nuts, Materials, and Finishes

More

Steel Low-Profile Rivet Nuts

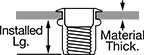

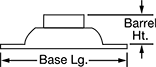

These steel low-profile rivet nuts are about twice as strong as aluminum rivet nuts. They have a low profile for light duty fastening in low-clearance applications. A cadmium or tin-zinc plating provides corrosion resistance and adds lubricity so they collapse smoothly. The threaded portion is drawn into the sleeve when installed, creating pressure against the hole to secure the nut. Drill bit size listed in the table is for material with a 0.030"-0.090" thickness. These rivet nuts may be installed in thicker material, but may require larger holes. Install them using a hand- or power-driven rivet nut tool. Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

For technical drawings and 3-D models, click on a part number.

Steel Low-Profile Rivet Nuts with Installation Tool

Everything you need to add threads to sheet metal in low-clearance areas. Along with low-profile rivet nuts, these kits include mandrels and an installation tool. As you install these nuts, the threaded portion is drawn into the sleeve, reducing how far they stick out the back of your material. They also have a flange that’s half as thick as those on other rivet nuts, so they have a low profile on both sides of your panel. A tin-zinc plating protects from rust in wet environments and reduces friction, so they collapse smoothly. These rivet nuts create permanent threads in surfaces that are too thin to be tapped. Installation requires access to just one side of your material. The flange distributes the load and holds them against the surface.

To install, thread a rivet nut onto the mandrel, insert the nut into a drilled or punched round hole, push down on the tool's T-handle, and turn clockwise.

| Thread Size | For Material Thick. | Includes | No. of Nuts Included | Each | |

Tin-Zinc Plated Steel | |||||

|---|---|---|---|---|---|

| 4-40 | 0.03" to 0.09" | Mandrels, Installation Tool | 100 | 000000000 | 0000000 |

Stainless Steel Low-Profile Rivet Nuts

The most corrosion resistant low-profile rivet nuts we offer, these stand up to chemicals. They're often used for light duty fastening in low-clearance applications. The threaded portion is drawn into the sleeve when installed, creating pressure against the hole to secure the nut. The tin-plating provides lubricity allowing the nut to collapse smoothly. Drill bit size listed in the table is for material with a 0.030"-0.090" thickness. These rivet nuts can be installed in thicker material, but may require larger holes. Install them using a hand- or power-driven rivet nut tool. Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

For technical drawings and 3-D models, click on a part number.

Aluminum Low-Profile Rivet Nuts

These low-profile rivet nuts are one-third the weight of steel rivet nuts. They have a low profile for light duty fastening in low-clearance applications. A cadmium or tin-zinc plating provides corrosion resistance and adds lubricity so they collapse smoothly. The threaded portion is drawn into the sleeve when installed, creating pressure against the hole to secure the nut. Drill bit size listed in the table is for material with a 0.030"-0.090" thickness. These rivet nuts may be installed in thicker material, but may require larger holes. Install them using a hand- or power-driven rivet nut tool. Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

For technical drawings and 3-D models, click on a part number.

Steel Rivet Nuts

Add strong threads to sheet metal and other thin surfaces. Zinc plating protects these rivet nuts from degrading in wet environments. They’re also known as blind inserts—installation requires access to just one side of your material. Install them in a drilled or punched round hole using a rivet nut tool. The tool collapses the nut, creating a backside flange that holds the nut to the material.

Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

For technical drawings and 3-D models, click on a part number.

Body | Flange | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Drill Bit Size | For Material Thick. | Type | Dia. | Lg. | Installed Lg. | Dia. | Thick. | Pkg. Qty. | Pkg. | |

Zinc-Plated Steel | |||||||||||

| 4-40 | 5/32" | 0.010" to 0.060" | Smooth | 0.16" | 0.345" | 0.230" | 0.270" | 0.025" | 1 | 000000000 | 00000 |

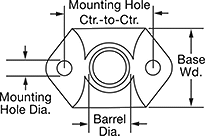

Mil. Spec. Rivet-Mount Nuts

Create threads in hard-to-work areas—where you can’t reach the back of a workpiece, or material is too thin to be tapped. For a strong grip, these nuts have distorted threads that increase friction with bolts. Because they mount with two rivets, they won’t spin when you’re tightening screws. However, these nuts do move inside their retainers, which lets you install bolts at a slight angle; use them to align with off-center parts. All meet military guidelines for dimensions and material.

Cadmium-plated nuts resist corrosion in industrial and saltwater environments, although will lose their corrosion resistance over 450° F. The cadmium plating also adds lubricity, making these nuts easy to install.

A286 stainless steel nuts are corrosion resistant. Silver-plated stainless steel nuts withstand temperatures up to 800° F. The silver plating also adds lubricity and prevents seizing caused by friction between nuts and bolts.

Lubricated nuts thread onto bolts smoothly.

For technical drawings and 3-D models, click on a part number.

Base | Barrel | Mounting | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Wd. | Thick. | Dia. | Ht. | No. of Holes | Hole Dia. | Hole Ctr.-to-Ctr. | Specifications Met | Each | |

Steel—Unlubricated | |||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 0.125" | 1/16" | 2 | 0.098" | 13/32" | MS21075-04N | 000000000 | 00000 |

Cadmium-Plated Steel—Lubricated | |||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 0.125" | 1/16" | 2 | 0.098" | 13/32" | MS21075L04N | 000000000 | 0000 |

Cadmium-Plated Carbon Steel—Lubricated | |||||||||||

| 4-40 | 61/64" | 13/32" | 1/32" | 0.141" | 9/64" | 2 | 0.098" | 11/16" | MS21059L04 | 000000000 | 0000 |

A286 Stainless Steel—Lubricated | |||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 0.125" | 1/16" | 2 | 0.098" | 13/32" | MS21076L04N | 000000000 | 00000 |

Silver-Plated A286 Stainless Steel—Unlubricated | |||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 0.125" | 1/16" | 2 | 0.098" | 13/32" | MS21076-04N | 000000000 | 00000 |

Low-Profile Rivet Nut Assortments

Use these rivet nuts for light duty fastening in low-clearance applications. Assortments include rivet nuts, mandrels, and an installation tool. Rivet nuts have a cadmium plating that provides corrosion resistance and adds lubricity so they collapse smoothly. The threaded portion is drawn into the sleeve when installed, creating pressure against the hole to secure the nut.

| Number of Pieces | Material | Rivet Nuts Included | For Material Thick. | Includes | Container Type | Each | |

Inch | |||||||

|---|---|---|---|---|---|---|---|

| 282 | Cadmium Plated Steel | 4-40 (50 Pieces) 6-32 (50 Pieces) 8-32 (50 Pieces) 10-32 (50 Pieces) 1/4"-20 (50 Pieces) 5/16"-18 (25 Pieces) | 0.03"-0.09" | Six Mandrels Installation Tool | Plastic Case | 000000000 | 0000000 |

Wrench-Driven Rivet Nut Tools

Use these tools to install most styles of rivet nuts. A wrench and ratchet are required to hold the tool and tighten the nut.

For technical drawings and 3-D models, click on a part number.

| For Thread Size | For Wrench Size | For Ratchet Size | For Rivet Nut Body Type | For Rivet Nut Material | Each | |

| 4-40 | 7/8" | 11/16" | Smooth, Ribbed, Hex, Bulbed, Sleeve | 18-8 Stainless Steel, Aluminum, Steel, Titanium | 000000000 | 000000 |

Hand-Driven Tools for Low-Profile Rivet Nuts

Turn these tools by hand to install low-profile rivet nuts. The required mandrels are sold separately. To use, thread the nut onto a mandrel of the same size, then place it into a hole, push down on the tool's T-handle, and turn clockwise.

| For Thread Size | For Rivet Nut Body Type | For Rivet Nut Material | Overall Lg. | Each | |

| 4-40, 6-32, 8-32, 10-24, 10-32, 12-24, 1/4"-20, 1/4"-28, 5/16"-18, 5/16"-24, 3/8"-16, 3/8"-24, M3, M4, M5, M6, M8, M10 | Sleeve | 18-8 Stainless Steel, Aluminum, Steel | 5 7/8" | 000000000 | 0000000 |

| For Thread Size | Each | |

| 4-40 | 000000000 | 000000 |

| 6-32 | 000000000 | 00000 |

| 8-32 | 000000000 | 00000 |

| 10-24 | 000000000 | 00000 |

| 10-32 | 000000000 | 00000 |

| 12-24 | 000000000 | 00000 |

| 1/4"-20 | 000000000 | 00000 |

| 1/4"-28 | 000000000 | 00000 |

| 5/16"-18 | 000000000 | 00000 |

| 5/16"-24 | 000000000 | 00000 |

| 3/8"-16 | 000000000 | 00000 |

| 3/8"-24 | 000000000 | 00000 |

| M3 × 0.5 mm | 000000000 | 00000 |

| M4 × 0.7 mm | 000000000 | 00000 |

| M5 × 0.8 mm | 000000000 | 00000 |

| M6 × 1 mm | 000000000 | 00000 |

| M8 × 1.25 mm | 000000000 | 00000 |

| M10 × 1.5 mm | 000000000 | 00000 |

Air-Powered Rivet Nut Tools

Smaller and lighter than cordless and hydraulic rivet nut tools, use these to install thin-walled bulbed, ribbed, sleeve, and smooth rivet nuts. To use, thread the nut onto the included mandrel and press the trigger to spin the nut onto the tool. Place the nut into the material and press the trigger to install the nut. Press the trigger one more time to spin the mandrel off.

Air Connection | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Thread Size | For Rivet Nut Body Type | For Rivet Nut Material | Head Lg. | Overall Ht. | Operating Pressure, psi | Pipe Size | Thread Type | Weight, lbs. | Includes | Each | |

| 4-40 | Bulbed, Ribbed, Sleeve, Smooth | Aluminum, Steel | 6" | 6" | 35 to 45 | 1/4 | NPT | 3 | Mandrel, Nosepiece | 000000000 | 0000000 |

| For Thread Size | Each | |

| 4-40 | 000000000 | 00000 |

| For Thread Size | Includes | Each | |

| 4-40 | Bearing Set, Hex Drive, Mandrel, Nose Cone | 000000000 | 0000000 |

Hydraulic/Air-Powered Rivet Nut Tools

Quickly install all styles of rivet nuts at 1.5-second intervals. The tool includes nosepiece assemblies to install M4, M5, M6, and M8 rivet nuts (additional sizes sold separately). To use, thread the nut onto the included mandrel and press the trigger to spin the nut onto the tool. Place the nut into the material and press the trigger to install the nut. Press the trigger one more time to spin the mandrel off.

Body | Air Connection | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Thread Size | For Rivet Nut Body Type | For Rivet Nut Material | Dia. | Wd. | Head Lg. | Overall Ht. | Max. Stroke Lg. | Pulling Force | Operating Pressure, psi | Pipe Size | Thread Type | Weight, lbs. | Each | |

| 4-40, 8-32, 10-24, 10-32, 1/4"-20, 1/4"-28, 5/16"-18, 5/16"-24, 3/8"-16, 3/8"-24, M4, M5, M6, M8, M10 | Smooth, Ribbed, Hex, Bulbed, Sleeve, Stud | Aluminum, Steel | 3 3/4" | 1 1/16" | 9 5/8" | 10 3/4" | 0.275" | 3,960 lbs | 75 to 100 | 1/4 | NPT | 3 1/2 | 000000000 | 000000000 |

| For Thread Size | Each | |

| 4-40 | 000000000 | 000000 |

| 8-32 | 000000000 | 000000 |

| 10-24 | 000000000 | 000000 |

| 10-32 | 000000000 | 000000 |

| 1/4"-20 | 000000000 | 000000 |

| 1/4"-28 | 000000000 | 000000 |

| 5/16"-18 | 000000000 | 000000 |

| 5/16"-24 | 000000000 | 000000 |

| 3/8"-16 | 000000000 | 000000 |

| 3/8"-24 | 000000000 | 000000 |

| M4 × 0.7 mm | 000000000 | 000000 |

| M5 × 0.8 mm | 000000000 | 000000 |

| M6 × 1 mm | 000000000 | 000000 |

| M8 × 1.25 mm | 000000000 | 000000 |

| M10 × 1.5 mm | 000000000 | 000000 |

| Includes | Each | |

| Hex Key Wrench, Pin-Removal Punch, Spanner Wrench | 000000000 | 000000 |