Hollow Rivets

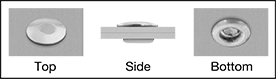

Use these rivets to fasten soft material such as leather, fabric, and plastic. Installation requires access to both sides of the material. Use a hollow rivet tool (sold separately) and a hammer to flare out the hollow portion of the rivet.

Hollow-end rivets are also known as semi-tubular and brake-lining rivets. The bottom half of the body is hollow and because it is the only part of the rivet that expands during installation, they are often used as pivot points.

For technical drawings and 3-D models, click on a part number.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Internal Hole Dp. | Countersink Angle | Material | Pkg. Qty. | Pkg. | |

9/64" Dia. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.159"-0.173" | 0.25" | 0.156" | No. 23 | 0.313" | 0.047" | 0.125" | 150° | Brass | 100 | 000000000 | 000000 |

| 0.19"-0.204" | 0.281" | 0.156" | No. 23 | 0.313" | 0.047" | 0.125" | 150° | Brass | 100 | 000000000 | 00000 |

| 0.221"-0.235" | 0.313" | 0.156" | No. 23 | 0.313" | 0.047" | 0.125" | 150° | Brass | 100 | 000000000 | 00000 |

| 0.221"-0.235" | 0.313" | 0.156" | No. 23 | 0.375" | 0.047" | 0.125" | 150° | Brass | 100 | 000000000 | 00000 |

| 0.284"-0.298" | 0.375" | 0.156" | No. 23 | 0.313" | 0.047" | 0.125" | 150° | Brass | 100 | 000000000 | 00000 |

| 0.284"-0.298" | 0.375" | 0.156" | No. 23 | 0.375" | 0.047" | 0.125" | 150° | Brass | 100 | 000000000 | 00000 |

| 0.346"-0.36" | 0.438" | 0.156" | No. 23 | 0.313" | 0.047" | 0.125" | 150° | Brass | 100 | 000000000 | 00000 |

| 0.346"-0.36" | 0.438" | 0.156" | No. 23 | 0.375" | 0.047" | 0.125" | 150° | Brass | 100 | 000000000 | 00000 |

| 0.409"-0.423" | 0.5" | 0.156" | No. 23 | 0.313" | 0.047" | 0.125" | 150° | Brass | 100 | 000000000 | 00000 |

| 0.409"-0.423" | 0.5" | 0.156" | No. 23 | 0.375" | 0.047" | 0.125" | 150° | Brass | 100 | 000000000 | 00000 |

| 0.534"-0.548" | 0.625" | 0.156" | No. 23 | 0.375" | 0.047" | 0.125" | 150° | Brass | 50 | 000000000 | 00000 |

| 0.659"-0.673" | 0.75" | 0.156" | No. 23 | 0.375" | 0.047" | 0.125" | 150° | Brass | 50 | 000000000 | 00000 |

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Internal Hole Dp. | Countersink Angle | Material | Pkg. Qty. | Pkg. | |

9/64" Dia. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.147"-0.167" | 0.25" | 0.152" | No. 24 | 0.313" | 0.047" | 0.219" | 150° | Copper-Plated Steel | 50 | 000000000 | 000000 |

| 0.272"-0.292" | 0.375" | 0.152" | No. 24 | 0.313" | 0.047" | 0.313" | 150° | Copper-Plated Steel | 50 | 000000000 | 00000 |

| For Rivet Dia. | Each | |

| 9/64" | 000000 | 000000 |

Nickel-Plated Steel Split Rivets

The nickel-plated finish provides good corrosion resistance. These rivets require access to both sides of the material. To install, use the rounded end of a ball peen hammer to bend the legs outward to hold your material.

For technical drawings and 3-D models, click on a part number.

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Pkg. Qty. | Pkg. | |

9/64" Dia. | ||||||||

|---|---|---|---|---|---|---|---|---|

| 0.125"-0.187" | 0.313" | 0.141" | No. 27 | 0.313" | 0.047" | 100 | 000000000 | 00000 |

| 0.156"-0.25" | 0.375" | 0.141" | No. 27 | 0.313" | 0.047" | 100 | 000000000 | 0000 |

| 0.218"-0.312" | 0.438" | 0.141" | No. 27 | 0.313" | 0.047" | 100 | 000000000 | 00000 |

| 0.25"-0.375" | 0.5" | 0.141" | No. 27 | 0.313" | 0.047" | 100 | 000000000 | 00000 |

| 0.375"-0.5" | 0.625" | 0.141" | No. 27 | 0.313" | 0.047" | 100 | 000000000 | 00000 |

| 0.5"-0.625" | 0.75" | 0.141" | No. 27 | 0.313" | 0.047" | 100 | 000000000 | 00000 |

Brass Split Rivets

Brass rivets are electrically conductive and have good corrosion resistance. They require access to both sides of the material. To install, use the rounded end of a ball peen hammer to bend the legs outward to hold your material.

For technical drawings and 3-D models, click on a part number.