Filter by

Bracket Type

Screw Size

Thickness

Rail Height

Outside Height

Outside Width

Wall Thickness

Finish

T-Slotted Framing Component

Bolt-Together Framing Component

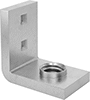

Corner Bracket Style

Strut Channel Framing Component

Mounting Location

DFARS Specialty Metals

Building and Machinery Hardware

Raw Materials

Containers, Storage, and Furniture

Material Handling

Power Transmission

Fabricating and Machining

Fastening and Joining

Measuring and Inspecting