About Pipe Size

More

About Pressure Gauges

More

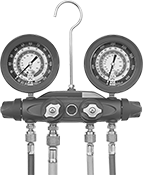

Air Conditioner Charging and Testing Manifolds

Monitor refrigerant pressure with analog gauges when servicing air conditioning systems. All manifolds have double O-ring piston valves. Manifolds with sight glass allow you to view liquid levels.

Replacement gauges are sold separately.

Optional gauge cover sets (sold separately) include one blue and one red gauge cover. They are not for use with the manifolds for R-410A refrigerant.

Hose | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Refrigerant Number | Valve Material | Connection | Lg., ft. | Dia. | Color | Includes | Each | |

Two Valve | ||||||||

| R-134A | Brass | 1/2"-16 Acme × 7/16"-20 UNF × 7/16"-20 UNF | 6 | 2 1/2" | One Blue and One Red | __ | 0000000 | 0000000 |

| R-134A, R-404A, R-407C | Aluminum | 1/4 UN/UNF (SAE 45°) × 1/4 UN/UNF (SAE 45°) × 1/4 UN/UNF (SAE 45°) | 5 | 3 1/8" | One Blue and One Red | Sight Glass | 0000000 | 000000 |

| R-22, R-404A, R-410A | Aluminum | 1/4 UN/UNF (SAE 45°) × 1/4 UN/UNF (SAE 45°) × 1/4 UN/UNF (SAE 45°) | 5 | 3 1/8" | One Blue and One Red | Sight Glass | 0000000 | 000000 |

| R-410A | Brass | 1/4 UN/UNF (SAE 45°) × 1/4 UN/UNF (SAE 45°) × 1/4 UN/UNF (SAE 45°) | 5 | 2 1/2" | One Blue and One Red | __ | 0000000 | 000000 |

Four Valve | ||||||||

| R-134A, R-404A, R-407C | Aluminum | 1/4 UN/UNF (SAE 45°) × 1/4 UN/UNF (SAE 45°) × 1/4 UN/UNF (SAE 45°) × 3/8 UN/UNF (SAE 45°) | 5 | 3 1/8" | One Blue and One Red | Sight Glass | 0000000 | 000000 |

| R-22, R-404A, R-410A | Aluminum | 1/4 UN/UNF (SAE 45°) × 1/4 UN/UNF (SAE 45°) × 1/4 UN/UNF (SAE 45°) × 3/8 UN/UNF (SAE 45°) | 5 | 3 1/8" | One Blue and One Red | Sight Glass | 0000000 | 000000 |

| For Manifold Type | Includes | Each | |

| Two Valve, Four Valve | One Blue Cover, One Red Cover | 0000000 | 000000 |

Digital Air Conditioner Charging and Testing Manifolds

Monitor refrigerant pressure on an LCD when servicing air conditioning systems. This manifold automatically calculates how much refrigerant is needed in a system based on measurements taken with its thermocouples.

Display | |||||||

|---|---|---|---|---|---|---|---|

| For Refrigerant Number | Valve Material | Pipe Connection | Type | Size | Batteries Included | Each | |

Three Valve | |||||||

| R-12, R-134A, R-22, R-404A, R-407C, R-410A, R-502 | Brass | 1/4 NPT × 1/4 NPT × 1/4 NPT | Digital | 5" | Yes | 0000000 | 0000000 |

Refrigeration Pressure and Vacuum Gauges

Often used with chillers and in refrigeration systems, these gauges display the temperature of ammonia relative to the pressure measurement. Also known as compound gauges, these measure both pressure and vacuum.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Ammonia, and Refrigerant

- Accuracy: ±1.6% Full Scale (Grade B)

Available Pressure and Vacuum Ranges | ||||||

|---|---|---|---|---|---|---|

Graduation Marks | Numeric Increments | |||||

| Pressure Range, psi | Vacuum Range, in. of Hg | psi | in. of Hg | psi | in. of Hg | Display Temp. Range, °F |

| 0 to 150 | 30 to 0 | 5 | 5 | 20 | 30 | -60° to 84° |

| 0 to 300 | 30 to 0 | 5 | 5 | 25 | 30 | -60° to 125° |

Extreme Vibration-Resistant Pressure Gauges

Unlike other gauges that have multiple moving parts that can shake loose, these have only one internal part. They are the most shock-resistant gauges we offer and allow for precise readings in high-vibration applications. Use them with pumps, filters, regulators, and in process lines to measure and display pressure. Gauges meet MIL-G-18997 for resistance to salt spray and washdown environments. They have a safety case that blows out in the back under excess pressure, protecting the operator in front. Mount them with the dial face upright.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid, Gasoline, Diesel Fuel, Natural Gas, Refrigerant, and Salt Water

- Accuracy: ±1% Full Scale (Grade 1A)

Available Pressure Ranges | ||

|---|---|---|

| Pressure Range, psi | Graduation Marks, psi | Numeric Increments, psi |

| 0 to 100 | 1 | 10 |

| 0 to 200 | 2 | 20 |

| 0 to 1,000 | 10 | 100 |

| 0 to 2,000 | 20 | 200 |

| 0 to 5,000 | 50 | 500 |

Mounting | Bolt | Flange | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dial Diameter | Pipe Size | Environment Temp. Range, °F | Process Temp. Range, °F | Orientation | Fasteners Included | Circle Dia. | Hole Dia. | No. of Holes | Location | OD | Each | |

Bottom Connection (Flange Mount) | ||||||||||||

NPT Male | ||||||||||||

| 4 1/2" | 1/4 | -65° to 400° | -65° to 600° | Upright | No | 5 3/8" | 7/32" | 3 | Back | 5 13/16" | 0000000 | 0000000 |

Lower Back Connection (Flange Mount) | ||||||||||||

NPT Male | ||||||||||||

| 4 1/2" | 1/4 | -65° to 400° | -65° to 600° | Upright | No | 5 3/8" | 7/32" | 3 | Back | 5 13/16" | 0000000 | 000000 |

Gauge Guards

Also known as isolators or diaphragm seals, these protect gauges from corrosive process media. Fill guards with hydraulic oil (not included) before use.

316 stainless steel guards provide excellent corrosion and chemical resistance and can handle higher temperatures and pressures than plastic guards.

Guards with drain port allow you to remove process media.

For technical drawings and 3-D models, click on a part number.

Pipe Connections | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Gasket Material | For Use With | Min. Pressure, psi | Max. Pressure | Max. Temp., °F | Ht. | Each | |

316 Stainless Steel Body | |||||||||

| 1/4 NPT Female | 1/4 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 1 3/4" | 0000000 | 0000000 |

| 1/2 NPT Female | 1/4 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 1 3/4" | 0000000 | 000000 |

| 1/2 NPT Female | 1/2 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 1 1/2" | 0000000 | 000000 |

316 Stainless Steel Body with 1/4 NPT Female Drain Port | |||||||||

| 1/4 NPT Female | 1/4 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 2" | 0000000 | 000000 |

| 1/2 NPT Female | 1/4 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 2" | 0000000 | 000000 |

| 1/2 NPT Female | 1/2 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 2" | 0000000 | 000000 |