How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Duct Connections

More

About Fire-Fighting Hose Threads

More

About Conduit

More

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

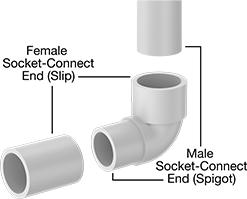

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Fittings that meet ASTM D1784, ASTM D1785, and ASTM D4066 adhere to specifications and testing requirements for material quality.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

(A) | (B) | ||||||

|---|---|---|---|---|---|---|---|

| Pipe Size | Socket Depth | Pipe Size | Socket Depth | Material | Color | Each | |

| 3/4 | 23/32" | 1/2 | 11/16" | PVC Plastic | White | 00000000 | 00000 |

| 1 | 7/8" | 1/2 | 11/16" | PVC Plastic | White | 00000000 | 0000 |

| 1 | 7/8" | 3/4 | 23/32" | PVC Plastic | White | 00000000 | 0000 |

| 1 1/4 | 15/16" | 1 | 7/8" | PVC Plastic | White | 00000000 | 00000 |

| 1 1/2 | 1 3/32" | 3/4 | 23/32" | PVC Plastic | White | 00000000 | 00000 |

| 1 1/2 | 1 3/32" | 1 | 7/8" | PVC Plastic | White | 00000000 | 00000 |

| 1 1/2 | 1 3/32" | 1 1/4 | 15/16" | PVC Plastic | White | 00000000 | 00000 |

| 2 | 1 5/32" | 1 | 7/8" | PVC Plastic | White | 00000000 | 00000 |

| 2 | 1 5/32" | 1 1/2 | 1 3/32" | PVC Plastic | White | 00000000 | 00000 |

| 3 | 1 7/8" | 2 | 1 5/32" | PVC Plastic | White | 00000000 | 00000 |

| 4 | 2" | 2 | 1 5/32" | PVC Plastic | White | 00000000 | 00000 |

| 4 | 2" | 3 | 1 7/8" | PVC Plastic | White | 00000000 | 00000 |

| 6 | 2 7/8" | 4 | 2 7/32" | PVC Plastic | White | 00000000 | 000000 |

Thick-Wall Plastic Pipe Fittings for Water

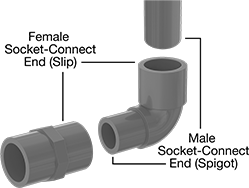

Connect these fittings to Schedule 80 pipe. With thicker, stronger walls than standard-wall fittings, they can handle heavy duty supply applications, such as water processing, wastewater treatment, and irrigation. Fittings are plastic for good corrosion resistance. They meet ASTM specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Pipe Size | Socket Depth | ||||||

|---|---|---|---|---|---|---|---|

| (A) | (B) | (A) | (B) | Material | Color | Each | |

| 3/4 | 1/2 | 1" | 7/8" | PVC Plastic | Dark Gray | 00000000 | 000000 |

| 1 | 1/2 | 1 1/8" | 7/8" | PVC Plastic | Dark Gray | 00000000 | 00000 |

| 1 | 3/4 | 1 1/8" | 3/4" | PVC Plastic | Dark Gray | 00000000 | 00000 |

| 1 1/2 | 1/2 | 1 3/8" | 7/8" | PVC Plastic | Dark Gray | 00000000 | 00000 |

| 1 1/2 | 3/4 | 1 3/8" | 1" | PVC Plastic | Dark Gray | 00000000 | 00000 |

| 1 1/2 | 1 | 1 3/8" | 1 5/32" | PVC Plastic | Dark Gray | 00000000 | 00000 |

| 2 | 1/2 | 1 1/2" | 7/8" | PVC Plastic | Dark Gray | 00000000 | 00000 |

| 2 | 3/4 | 1 17/32" | 1" | PVC Plastic | Dark Gray | 00000000 | 00000 |

| 2 | 1 | 1 1/2" | 1 1/8" | PVC Plastic | Dark Gray | 00000000 | 00000 |

| 2 | 1 1/2 | 1 1/2" | 1 3/8" | PVC Plastic | Dark Gray | 00000000 | 00000 |

| 3 | 1 1/2 | 1 7/8" | 1 3/8" | PVC Plastic | Dark Gray | 00000000 | 000000 |

| 3 | 2 | 1 7/8" | 1 5/8" | PVC Plastic | Dark Gray | 00000000 | 000000 |

| 4 | 2 | 1 7/8" | 1 1/2" | PVC Plastic | Dark Gray | 00000000 | 000000 |

| 4 | 3 | 2 1/4" | 1 7/8" | PVC Plastic | Dark Gray | 00000000 | 000000 |

| 6 | 4 | 2 31/32" | 2 9/32" | PVC Plastic | Dark Gray | 00000000 | 000000 |

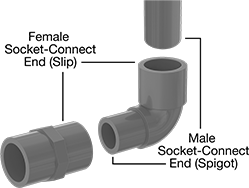

Drain, Waste, and Vent ABS Pipe Fittings for Chemicals

These Schedule 40 fittings are an economical option for gravity-flow chemical waste systems. They are ABS plastic, which has excellent strength and impact resistance and good chemical resistance. Fittings meet ASTM D2661, ASTM D3311, ASTM D3965, and ASTM F1498 specifications and testing requirements for material quality and product dimensions.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with ABS cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

For technical drawings and 3-D models, click on a part number.

- For Use With: Sodium Hydroxide

- Maximum Temperature: 180° F

- Specifications Met: ASTM D2661, ASTM D3311, ASTM D3965, ASTM F1498

- Pipe Nipples and Pipe: Use Schedule 40 ABS Plastic

- Flanges: Use Schedule 40 ABS Plastic

Tight-Seal Plastic Barbed Tube Fittings for Air and Water

Minimize leaks in your line—these fittings have a single barb that creates a smooth clamping surface for extra-tight connections. Fittings are nylon for excellent impact and abrasion resistance.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: -50° to 275° F

- Tubing: Use with firm (Durometer 75A-80A) polyurethane rubber or PVC plastic

- Clarity: Black: Opaque; White: Opaque; Off-White: Semi-Clear

| For Tube ID (A) | For Tube ID (B) | Material | Max. Pressure | Pkg. Qty. | Choose a Color | Pkg. | |

| 1/4" | 1/8" | Nylon Plastic | Not Rated | 10 | White | 00000000 | 000000 |

| 3/8" | 1/4" | Nylon Plastic | Not Rated | 5 | 00000000 | 00000 | |

| 1/2" | 3/8" | Nylon Plastic | Not Rated | 5 | 00000000 | 00000 | |

| 5/8" | 1/2" | Nylon Plastic | Not Rated | 1 | 00000000 | 0000 | |

| 3/4" | 5/8" | Nylon Plastic | Not Rated | 1 | 00000000 | 0000 | |

| 1" | 3/4" | Nylon Plastic | Not Rated | 1 | 00000000 | 0000 |

Plastic Barbed Tube Fittings for Air and Water

Fittings have barbs that grip onto tubing.

Acetal fittings won’t absorb water and lose strength, even in high-humidity environments.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: -40° to 175° F

- Tubing: Use with firm or soft (Durometer 40A-80A) polyurethane rubber or PVC plastic

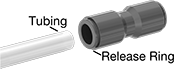

Push-to-Connect Tube Fittings for Air

- Temperature Range: 0° to 170° F, except polybutylene plastic fittings are 32° to 140° F

- Tubing: Use with firm (Durometer 95A-45D) polyethylene plastic or polyurethane rubber

- Specifications Met: ISO 14743, except cartridges and polybutylene plastic fittings

Insert tubing into these fittings and an internal gripping ring and O-ring hold the tubing tight. They are also known as instant fittings. To disconnect, push on the release ring and pull the tubing out of the fitting. Fittings have good corrosion resistance. Use them in low-pressure applications.

Identification rings (sold separately) snap over the release ring so you can color-code your lines.

Clips (sold separately) align and organize your tubing and fittings.

For technical drawings and 3-D models, click on a part number.

| For Tube OD (A) | For Tube OD (B) | Material | Color | Release Ring Color | Max. Pressure | Each | |

| 1/4" | 1/8" | Nylon Plastic | Black | Black | 290 psi @ 72° F | 00000000 | 000000 |

| 1/4" | 5/32" | Nylon Plastic | Black | Black | 290 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 1/4" | Nylon Plastic | Black | Black | 290 psi @ 72° F | 00000000 | 00000 |

| 6mm | 4mm | Nylon Plastic | Black | Black | 290 psi @ 72° F | 0000000 | 0000 |

| 8mm | 6mm | Nylon Plastic | Black | Black | 290 psi @ 72° F | 0000000 | 00000 |

| 10mm | 8mm | Nylon Plastic | Black | Black | 290 psi @ 72° F | 0000000 | 00000 |

| 12mm | 10mm | Nylon Plastic | Black | Black | 290 psi @ 72° F | 0000000 | 00000 |

Stainless Steel Barbed Tube Fittings for Food and Beverage

- Temperature Range: -20° to 750° F

- Tubing: Use with soft or firm (Durometer 65A-90A) polyurethane rubber or PVC plastic

- Specifications Met: See table

Made of stainless steel, these fittings are more durable than plastic barbed tube fittings for food and beverage. They have single or multiple barbs that grip onto tubing.

For technical drawings and 3-D models, click on a part number.

Push-to-Connect Fittings for Food and Beverage

- Temperature Range: 35° to 140° F

- Tubing: See table

- Specifications Met: See table

Also known as instant fittings, these connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect fittings with a release ring, push on the release ring and pull the tubing out of the fitting.

Polypropylene fittings have excellent impact and abrasion resistance. They meet NSF/ANSI standards for safe use with food. Some are also FDA compliant for indirect contact with food.

For technical drawings and 3-D models, click on a part number.

| For Tube OD (A) | For Tube OD (B) | Material | Release Ring Color | Max. Pressure | For Tube Hardness Rating | For Tube Hardness | Specifications Met | Each | |

White | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 3/8" | 1/4" | Polypropylene Plastic | White | 150 psi @ 72° F | Firm, Hard | Durometer 50D-90D | NSF/ANSI 51, NSF/ANSI 61 | 00000000 | 00000 |

Plastic Push-to-Connect Tube Fittings for Chemicals

- For Use With: Inch: Alcohol, Hydrochloric Acid, Nitric Acid, Sodium Carbonate, Sulfuric Acid

Metric: Acetic Acid, Alcohol, Arsenic Acid, Benzoic Acid, Fluoboric Acid, Sodium Carbonate, Sulfuric Acid - Temperature Range: Inch: 0° to 270° F

Metric: 32° to 175° F - Tubing: Use with hard (Durometer 55D-60D) FEP plastic

Also known as instant fittings, these chemical-resistant plastic fittings connect to tubing with a push. An internal gripping ring holds the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. Use these fittings in low-pressure applications.

PVDF fittings offer excellent chemical resistance, and can be used with hydrochloric acid and nitric acid. They withstand temperatures up to 270° F, higher than other push-to-connect fittings for chemicals. They are produced in a clean room and are bagged individually to prevent dirt and moisture from contaminating the inside. PVDF is also known as Kynar.

For technical drawings and 3-D models, click on a part number.

Barbed Fittings for Plastic and Rubber Tubing—High-Purity

- For Use With: Beverage, Food

- Temperature Range: -80° to 220° F

- Tubing: Use with soft or firm (Durometer 50A-80A) plastic blend, polyethylene plastic, polyurethane rubber, PVC plastic, or silicone rubber

- Specifications Met: FDA Compliant 21 CFR 177.2510, FDA Compliant 21 CFR 177.1520

Fittings have a single barb that creates a smooth clamping surface for extra-tight connections that minimize leaks. Designed for high-purity applications, they are produced in a clean room and are double bagged to prevent dirt and moisture from contaminating the inside. Fittings are PVDF (also known as Kynar), which has excellent strength.

For technical drawings and 3-D models, click on a part number.

| For Tube ID | Material | Color | Clarity | Max. Pressure | Each | |

| 3/32" | PVDF Plastic | White | Semi-Clear | Not Rated | 000000000 | 00000 |

| 1/8" | PVDF Plastic | White | Semi-Clear | Not Rated | 000000000 | 0000 |

| 3/16" | PVDF Plastic | White | Semi-Clear | Not Rated | 000000000 | 0000 |

| 1/4" | PVDF Plastic | White | Semi-Clear | Not Rated | 000000000 | 00000 |

| 3/8" | PVDF Plastic | White | Semi-Clear | Not Rated | 000000000 | 00000 |

| 1/2" | PVDF Plastic | White | Semi-Clear | Not Rated | 000000000 | 00000 |

Diverting Valves with Fire-Fighting Hose Fittings

- Valve Type: Ball

- For Use With: Water

- Seal Material: Buna-N Rubber

Control the flow of water in two directions from a single source—these diverting valves have two balls and handles for independent operation of each outlet. They can direct flow to one side outlet at full capacity while shutting off flow to the second side outlet, direct flow to both side outlets at reduced capacity, or shut off flow to both side outlets. Valves have a brass body for good corrosion resistance. They are for use with fire-fighting hose.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

NH/NST (National Hose/National Standard) threads are only compatible with other NH/NST threads. Male NPSH (National Pipe Straight Hose) threads are compatible with female NPSH threads. Female NPSH threads are compatible with male NPSH, NPT, NPTF, and NPSM threads.

For technical drawings and 3-D models, click on a part number.

| Inlet Fire Hose Trade Size | Outlet Fire Hose Trade Sizes | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Brass Body | ||||||||

|---|---|---|---|---|---|---|---|---|

| 2 1/2 | 1 1/2 × 1 1/2 | Y-Pattern | Not Rated | 300 psi @ 150° F | -20° to 150° | 5 5/8" | 000000 | 0000000 |

| Inlet Pipe Size | Outlet Pipe Sizes | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Brass Body | ||||||||

|---|---|---|---|---|---|---|---|---|

| 2 1/2 | 1 1/2 × 1 1/2 | Y-Pattern | Not Rated | 300 psi @ 150° F | -20° to 150° | 5 5/8" | 000000 | 0000000 |

Reducers for Flexible Plastic Conduit

To connect different sizes of conduit, these reducers have tabs on the ends that snap into grooves in the conduit. They help seal out air and liquid when used with flexible plastic conduit. All meet IP68 for prolonged submersion and IP69K for high-pressure, high-temperature washdowns. They withstand vibration, are flame retardant, and resist oil, solvents, and UV light.

For technical drawings and 3-D models, click on a part number.

Conduit Connection | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Conduit Trade Size - 1 | Conduit Trade Size - 2 and - 3 | Conduit Connection Type | Gender | Material | Color | Temperature Range, °F | Environmental Rating | Specifications Met | Each | |

| 5/16 | 1/4 | Snap-In | Female | Nylon | Black | -40° to 245° | IP68, IP69K | UL Recognized Component, UL 94 V-0 | 0000000 | 000000 |

| 3/8 | 5/16 | Snap-In | Female | Nylon | Black | -40° to 245° | IP68, IP69K | UL Recognized Component, UL 94 V-0 | 0000000 | 00000 |

Crush-Resistant Spiral Duct and Fittings

A spiral seam makes this duct strong and rigid. Fittings have male ends with a slightly smaller diameter to press-fit into duct.

PVC-coated steel combines the strength of steel with the corrosion resistance of plastic.

For technical drawings and 3-D models, click on a part number.