How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Selecting and Measuring Expansion Joints

For information about selecting pipe size, see Selecting and Measuring Pipe & Fittings.

More

Standard-Wall Butt-Weld Stainless Steel Unthreaded Pipe Fittings

Also known as Schedule 40 fittings, these have thicker walls than our thin-wall stainless steel unthreaded butt-weld fittings. They have beveled ends that, when flush to pipe, create a trough for a strong weld that permits maximum flow.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Water

- Specifications Met: ASME B16.9, ASTM A403, MSS SP-43

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Flanges: Use Class 150 stainless steel

Thin-Wall Butt-Weld Stainless Steel Unthreaded Pipe Fittings

Also known as Schedule 10 fittings, these are thin and lightweight. They have beveled ends that, when flush to pipe, create a trough for a strong weld that permits maximum flow.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Water

- Specifications Met: ASME B16.9, ASTM A403, MSS SP-43

- Pipe: Use Schedule 10 stainless steel

Standard-Wall Butt-Weld Steel Unthreaded Pipe Fittings

Butt-weld fittings allow for a smooth connection that provides maximum flow. They have beveled ends that, when flush to pipe, create a trough for a strong, permanent weld. Fittings are also known as Schedule 40. They are for use in noncorrosive environments.

Offset straight reducers are also known as eccentric reducers; they connect one pipe to another smaller-diameter pipe and have the centers offset so your line can drain.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Specifications Met: ASTM A234, ASME B16.9

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Flanges: Use Class 150 steel

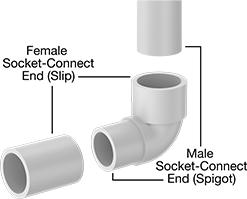

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a sealant to the male threads. Threaded connections can be taken apart as needed for maintenance and repair. For plastic threads, apply a non-hardening, plastic-compatible sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections. Fittings that meet ASTM D1784, ASTM D1785, and ASTM D4066 adhere to specifications and testing requirements for material quality.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

(A) | (B) | |||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | Socket Depth | Pipe Size | Socket Depth | Material | Color | Specifications Met | Each | |

| 8 | 4" | 2 | 1 5/32" | PVC Plastic | White | ASTM D1784, ASTM D1785, NSF/ANSI 61 | 00000000 | 0000000 |

| 8 | 4" | 4 | 2" | PVC Plastic | White | ASTM D1784, NSF/ANSI 61 | 00000000 | 00000 |

| 8 | 4 1/2" | 6 | 3 1/2" | PVC Plastic | White | ASTM D1784, NSF/ANSI 61 | 00000000 | 00000 |

| 10 | 5" | 8 | 4" | PVC Plastic | White | ASTM D1784, NSF/ANSI 61 | 00000000 | 000000 |

| 12 | 6" | 8 | 4" | PVC Plastic | White | ASTM D1784, NSF/ANSI 61 | 00000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

(A) | |||||||

|---|---|---|---|---|---|---|---|

| Pipe Size | Socket Depth | Pipe Size (B) | Material | Color | Specifications Met | Each | |

NPT Threads | |||||||

| 8 | 4" | 6 | PVC Plastic | White | ASTM D1784, ASTM D1785, NSF/ANSI 61 | 00000000 | 0000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Inline tees are also known as branch tees.

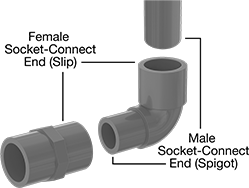

Thick-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 80 pipe. With thicker, stronger walls than standard-wall fittings, they can handle heavy duty supply applications, such as water processing, wastewater treatment, and irrigation. Fittings are plastic for good corrosion resistance. They meet ASTM specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a sealant to the male threads. For plastic threads, apply a non-hardening, plastic-compatible sealant sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections. Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Offset straight reducers are also known as eccentric reducers. Used to connect two pipes with different diameters, they have a tapered body that aligns the two pipes for continuous, unobstructed flow in either direction.

Pipe Size | Socket Depth | ||||||

|---|---|---|---|---|---|---|---|

| (A) | (B) | (A) | (B) | Material | Color | Each | |

| 8 | 6 | 4" | 3" | PVC Plastic | Dark Gray | 00000000 | 0000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

(A) | (B) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | ID | Wall Thick. | Pipe Size | Socket Depth | Material | Color | Each | |

| 8 | 8 5/8" | 7.625" | 0.5" | 2 | 1 1/2" | PVC Plastic | Dark Gray | 00000000 | 0000000 |

| 8 | 8 5/8" | 7.625" | 0.5" | 3 | 1 7/8" | PVC Plastic | Dark Gray | 00000000 | 000000 |

| 8 | 8 5/8" | 7.625" | 0.5" | 4 | 2 1/4" | PVC Plastic | Dark Gray | 00000000 | 000000 |

| 8 | 8 5/8" | 7.625" | 0.5" | 6 | 3" | PVC Plastic | Dark Gray | 00000000 | 00000 |

| 10 | 10 3/4" | 9.564" | 0.593" | 8 | 4 1/32" | PVC Plastic | Dark Gray | 00000000 | 000000 |

| 12 | 12 3/4" | 11.376" | 0.687" | 8 | 4" | PVC Plastic | Dark Gray | 00000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Inline tees are also known as branch tees.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Inline tees are also known as branch tees.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Pipe Size | Socket Depth | ||||||

|---|---|---|---|---|---|---|---|

| (A) | (B) | (A) | (B) | Material | Color | Each | |

| 8 | 6 | 2 1/4" | 3 1/4" | PVC Plastic | Dark Gray | 00000000 | 0000000 |

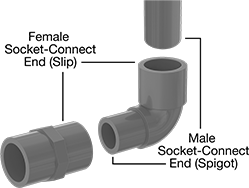

CPVC Pipe Fittings for Hot Water

Made of CPVC, these fittings can handle high temperatures. They have thick, strong walls to handle heavy duty industrial plumbing and water supply applications, such as water processing and waste water treatment. They also have good corrosion resistance. These fittings are comparable to Corzan. Some meet ASTM D1784 specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Schedule 80 fittings have thick, strong walls for heavy duty, industrial applications.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: See table

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

(A) | (B) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Socket Depth | Pipe Size | Socket Depth | For Use With | Material | Schedule | Color | Max. Pressure | Each | |

| 8 | 4" | 4 | 2 1/4" | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000000 |

| 8 | 4" | 6 | 3" | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

- For Use With: See table

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

(A) | (B) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | ID | Wall Thick. | Pipe Size | Socket Depth | For Use With | Material | Schedule | Color | Max. Pressure | Each | |

| 8 | 8 5/8" | 7.625" | 0.5" | 6 | 3 1/16" | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000000 |

- For Use With: See table

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

Inline tees are also known as branch tees.

(A) | (B) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Socket Depth | Pipe Size | Socket Depth | For Use With | Material | Schedule | Color | Max. Pressure | Each | |

| 8 | 4" | 6 | 3" | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000000 |

Low-Pressure Clamp-On Connectors for Drain, Waste, and Vent

To make installing and maintaining systems easy, these connectors come with clamps that form a strong seal on pipe and fittings once tightened.

Straight offset reducers connect one pipe to a smaller-diameter pipe, keeping your pipes aligned for obstruction-free flow in either direction. They are also known as eccentric reducers.

Connectors with a stainless steel sleeve reinforce the connection to increase shear strength.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water

- Temperature Range: -40° to 120° F

- Specifications Met: See table

- For Pipe Material:

Pipe: Cast Iron, Steel, Copper, Lead, PVC Plastic, CPVC Plastic, Polyethylene

Socket-Connect Pipe: PVC Plastic, CPVC Plastic, Polyethylene Plastic

| For Pipe OD | For Pipe Size | Lg. | Max. Pressure | Max. Vacuum | Material | Clamp Material | Flexibility | Specifications Met | Each | |

Pipe End × Pipe End | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 8 5/8" | 8 | 6" | 4 psi @ 72° F | Not Rated | PVC Plastic | 316 Stainless Steel | Flexible | ASTM C1173, ASTM D5926, CSA Certified | 0000000 | 000000 |

Pipe End × Pipe End—300 Series Stainless Steel Sleeve | ||||||||||

| 8 5/8" | 8 | 6" | 4 psi @ 72° F | Not Rated | PVC Plastic | 300 Series Stainless Steel | Flexible | ASTM C1173, ASTM D5926 | 00000000 | 000000 |

- For Use With: Air, Water

- Temperature Range: -40° to 120° F

- Specification Met: See table

- For Pipe Material: Cast Iron, Steel, PVC Plastic, Copper, Lead, CPVC Plastic, Polyethylene Plastic

For Pipe Size | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (A) | (B) | Lg. | Max. Pressure | Max. Vacuum | Material | Clamp Material | Flexibility | Specifications Met | Each | |

Pipe End × Pipe End | ||||||||||

| 8 | 4 | 6" | 4 psi @ 72° F | Not Rated | PVC Plastic | 300 Series Stainless Steel | Flexible | ASTM C1173, ASTM D5926, CSA Certified | 0000000 | 000000 |

| 8 | 6 | 6" | 4 psi @ 72° F | Not Rated | PVC Plastic | 300 Series Stainless Steel | Flexible | ASTM C1173, ASTM D5926, CSA Certified | 0000000 | 00000 |

| 10 | 8 | 6" | 4 psi @ 72° F | Not Rated | PVC Plastic | 300 Series Stainless Steel | Flexible | ASTM C1173, ASTM D5926, CSA Certified | 0000000 | 00000 |

| 10 | 8 | 6" | 4 psi @ 72° F | Not Rated | PVC Plastic | 316 Stainless Steel | Flexible | ASTM C1173, ASTM D5926, CSA Certified | 0000000 | 00000 |

Pipe End × Pipe End—300 Series Stainless Steel Sleeve | ||||||||||

| 8 | 6 | 6" | 4 psi @ 72° F | Not Rated | PVC Plastic | 300 Series Stainless Steel | Flexible | ASTM C1173, ASTM D5926 | 00000000 | 000000 |

- For Use With: Air, Water

- Temperature Range: -30° to 120° F

- Specification Met: See table

- For Pipe Material: Cast Iron, Steel, Copper, Lead, PVC Plastic, CPVC Plastic, Polyethylene Plastic

For Pipe Size | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (A) | (B) | Lg. | Max. Pressure | Max. Vacuum | Material | Clamp Material | Flexibility | Specifications Met | Each | |

Pipe End × Pipe End | ||||||||||

| 8 | 6 | 6 1/4" | 4 psi @ 72° F | Not Rated | PVC Plastic | 300 Series Stainless Steel | Flexible | ASTM C1173, ASTM D5926 | 00000000 | 0000000 |

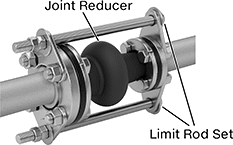

Expansion Joint Reducers with Flanged Ends

Connect different pipe sizes in your line while adding a point of flexibility between them. These expansion joints absorb movement between two connected pipes to reduce stress, vibration, and noise. Their flanged ends mate with same-size Class 150 flanges without the need for a gasket. Each flange is supported by a zinc-plated steel plate. The body of these expansion joints is reinforced with cord for added strength.

Your pipe system must be rigidly anchored on both sides of the expansion joint to control expansion or contraction of the line. When proper anchoring cannot be provided, limit rods (sold separately) are required.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Alcohol, Calcium Chloride, Coolant, Grain Alcohol, Grease, Hydraulic Fluid, Sodium Carbonate (20% in Water), Water

- Temperature Range: -20° to 250° F

- Maximum Pressure: See Table

- Maximum Vacuum: 26 in. of Hg @ 72° F

Unthreaded Bolt Holes | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flange OD | Pipe Size | No. of Bolt Holes | Distance | Bolt Hole Size | ||||||||||||

(A) | (B) | (A) | (B) | Lg. | (A) | (B) | Compression | Expansion | Offset | Max. Pressure | Expansion Joint Type | Flange Material | (A) | (B) | Each | |

EPDM Rubber | ||||||||||||||||

| 13 1/2" | 11" | 8 | 6 | 8" | 8 | 8 | 1 9/16" | 3/4" | 1/2" | 190 psi @ 72° F | Single Bulb | EPDM Rubber | 7/8" | 7/8" | 0000000 | 000000000 |

For Pipe Size | |||||

|---|---|---|---|---|---|

| (A) | (B) | Rod Lg. | Includes | Pkg. | |

| 8 | 6 | 17" | Four Limit Rod Plates, Two Limit Rods with Nuts | 00000000 | 0000000 |