How to Install Helical Inserts

More

About Helical Insert Length

More

About Nuts, Materials, and Finishes

More

Titanium Helical Inserts

These inserts have a high strength-to-weight ratio and resist acids and salt water better than nickel alloy and stainless steel inserts. Also known as Heli-Coil inserts, they have coils that expand once installed to securely anchor the insert. All have a prong for ease of installation. An installation tool grips the prong and reduces the coil diameter, enabling the insert to fit in tapped holes. Remove the prong to insert the screw. Installation requires a drill bit, a helical insert tap, an installation tool, and a prong break-off tool.

For technical drawings and 3-D models, click on a part number.

Inserts | Through-Hole Taps | Closed-End Hole Taps | Installation Tools | Prong Break-Off Tools | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | Pkg. Qty. | Pkg. | Each | Each | Each | Each | |||||

Titanium | ||||||||||||||

| 4-40 | 0.112" | No. 31 | 0.12" | 1 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 0000000 | 000000000 | 0000000 |

| 4-40 | 0.168" | No. 31 | 0.12" | 1 | 000000000 | 0000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 4-40 | 0.224" | No. 31 | 0.12" | 1 | 000000000 | 0000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 6-32 | 0.207" | No. 25 | 0.1495" | 1 | 000000000 | 0000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 00000 |

| 6-32 | 0.276" | No. 25 | 0.1495" | 1 | 000000000 | 0000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 00000 |

| 10-24 | 0.19" | No. 5 | 0.2055" | 1 | 000000000 | 0000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 10-24 | 0.285" | No. 5 | 0.2055" | 1 | 000000000 | 0000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 10-24 | 0.38" | No. 5 | 0.2055" | 1 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 10-32 | 0.285" | 13/64" | 13/64" | 1 | 000000000 | 0000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 10-32 | 0.38" | 13/64" | 13/64" | 1 | 000000000 | 0000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 1/4"-20 | 1/4" | H | 0.266" | 1 | 000000000 | 0000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 1/4"-20 | 3/8" | H | 0.266" | 1 | 000000000 | 0000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 1/4"-20 | 1/2" | H | 0.266" | 1 | 000000000 | 0000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 5/16"-18 | 0.312" | Q | 0.332" | 1 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 5/16"-18 | 0.469" | Q | 0.332" | 1 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 5/16"-18 | 5/8" | Q | 0.332" | 1 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 3/8"-16 | 3/8" | X | 0.397" | 1 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 3/8"-16 | 0.562" | X | 0.397" | 1 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

| 3/8"-16 | 3/4" | X | 0.397" | 1 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 000000 | 000000000 | 000000 |

Titanium Twist-Resistant Rivet Nuts

Originally designed for Formula 1 racecars, these titanium rivet nuts are the best choice when you need a high strength-to-weight ratio—they're 40% lighter than steel nuts. They’re also our most corrosion-resistant rivet nuts, standing up to salt water, acids, and chemicals. A ribbed body grips surrounding material to hold the nuts in place, so they won't spin as you tighten screws. These rivet nuts create reusable threads in sheet metal and other surfaces that are too thin to be tapped. Also known as blind inserts, installation requires access to just one side of your material. The flange distributes the load and holds these nuts against the surface.

Secure them in a drilled or punched round hole with a rivet nut tool. The tool collapses the nut, creating a backside flange that holds the nut to the material.

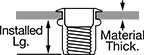

Length is measured from under the flange. Installed length is the maximum length of the barrel when installed.

For technical drawings and 3-D models, click on a part number.