How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

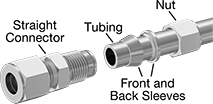

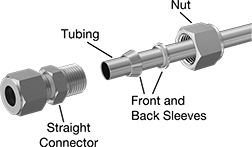

Yor-Lok Fittings for Stainless Steel Tubing

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube (A) | For Tube (B) | |||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/8" | 0.035" | 1/16" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 3/16" | 0.035" | 1/16" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/16" | 0.035" | 1/8" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/4" | 0.035" | 1/16" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/4" | 0.035" | 1/8" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/4" | 0.035" | 3/16" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 5/16" | 0.035" | 1/4" | 0.035" | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 0.035" | 1/16" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 0.035" | 1/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 0.035" | 1/4" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 0.035" | 5/16" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/2" | 0.035" | 1/8" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/2" | 0.035" | 1/4" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/2" | 0.035" | 3/8" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 5/8" | 0.035" | 1/2" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 5/8" | 0.049" | 3/8" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/4" | 0.049" | 1/4" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/4" | 0.049" | 3/8" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/4" | 0.049" | 1/2" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1" | 0.065" | 1/2" | 0.065" | 316 Stainless Steel | 1,500 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 1" | 0.065" | 3/4" | 0.065" | 316 Stainless Steel | 1,500 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 6mm | 1mm | 4mm | 1mm | 316 Stainless Steel | 3,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 6mm | 1 to 1.5 mm | 2mm | 0.5mm | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 0000000 | 00000 |

| 8mm | 1 to 1.5 mm | 6mm | 1mm | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 10mm | 1.5mm | 6mm | 1mm | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 10mm | 1.5mm | 8mm | 1 to 1.5 mm | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 12mm | 2mm | 10mm | 1.5mm | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

For Tube (A) | For Tube (B) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | For Hole Dia. | For Max. Wall Thick. | Each | |

| 1/4" | 0.028" to 0.065" | 1/8" | 0.028" to 0.065" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 5/16" | 1/2" | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube (A) | For Tube (B) | |||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/4" | 0.035" | 1/8" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 3/8" | 0.035" | 1/4" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/2" | 0.035" | 1/4" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 1/2" | 0.035" | 3/8" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 3/4" | 0.049" | 1/2" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 6mm | 1 to 1.5 mm | 1/4" | 0.028 to 0.065 " | 316 Stainless Steel | 4,100 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 8mm | 1 to 1.5 mm | 1/4" | 0.028 to 0.065 " | 316 Stainless Steel | 4,100 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 10mm | 1 to 1.5 mm | 1/4" | 0.028 to 0.065 " | 316 Stainless Steel | 3,400 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 10mm | 1 to 1.5 mm | 3/8" | 0.035 to 0.065 " | 316 Stainless Steel | 3,300 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Inline tees are also known as branch tees.

For Tube (A) | For Tube (B) | |||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/4" | 0.035" | 1/8" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000000 |

| 3/8" | 0.035" | 1/4" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/2" | 0.035" | 1/4" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 1/2" | 0.035" | 3/8" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 3/4" | 0.049" | 3/8" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 3/4" | 0.049" | 1/2" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/16" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1/4" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 5/16" | 0.035" | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1/2" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 5/8" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/4" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1" | 0.065" | 316 Stainless Steel | 1,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 4mm | 1mm | 316 Stainless Steel | 3,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 6mm | 1mm | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 8mm | 1mm | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 10mm | 0.5mm | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 12mm | 0.5mm | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/16" | 0.02" | 316 Stainless Steel | 9,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/16" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1/4" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 5/16" | 0.035" | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1/2" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 5/8" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/4" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1" | 0.065" | 316 Stainless Steel | 1,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 4mm | 1mm | 316 Stainless Steel | 3,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 6mm | 1mm | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 8mm | 1mm | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 10mm | 0.5mm | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 12mm | 0.5mm | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

PTFE sleeves are plastic instead of stainless steel, so they won’t damage tubing.

| For Tube OD | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/16" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 000000 |

| 1/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 3/16" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

| 1/4" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 5/16" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 3/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 1/2" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 5/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

| 3/4" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

| 1" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

Tube supports are recommended for soft plastic tubing to prevent the tube from collapsing.

For Tube | |||||

|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Temp. Range, °F | Each | |

| 3/16" | 1/8" | 316 Stainless Steel | -420° to 1200° | 00000000 | 000000 |

| 1/4" | 1/8" | 316 Stainless Steel | -420° to 1200° | 00000000 | 0000 |

| 1/4" | 0.17" | 316 Stainless Steel | -420° to 1200° | 00000000 | 0000 |

| 1/4" | 0.188" | 316 Stainless Steel | -420° to 1200° | 00000000 | 0000 |

| 5/16" | 1/4" | 316 Stainless Steel | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 1/4" | 316 Stainless Steel | -420° to 1200° | 00000000 | 0000 |

| 1/2" | 1/4" | 316 Stainless Steel | -420° to 1200° | 00000000 | 00000 |

| 5/8" | 3/8" | 316 Stainless Steel | -420° to 1200° | 00000000 | 00000 |

| 3/4" | 1/2" | 316 Stainless Steel | -420° to 1200° | 00000000 | 00000 |

| 1" | 3/4" | 316 Stainless Steel | -420° to 1200° | 00000000 | 00000 |

Ultra-High-Polish Gasket Fittings for Stainless Steel Tubing

- For Use With: Ammonia, Argon, Butane, Carbon Dioxide, Chloride, Fluoride, Fluorocarbon, Germane, Halide, Helium, Hydrogen, Krypton, Laser Gas, Natural Gas, Neon, Nitrogen, Oxygen, Silane, Sulfur Hexafluoride, Tungsten Hexafluoride, Xenon

- Temperature Range: -420° to 1000° F

- Tubing: Use with 316/316L stainless steel

- Compatible With: Swagelok® VCR

Polished to at least a 15 Ra finish on the inside, these fittings have an ultra-smooth interior surface that helps prevent contamination. Also known as ultra-high-purity fittings, they’re packed in a Class 100 clean room, cleaned, and double bagged. They are commonly used in semiconductor applications. Fittings use a metal gasket (sold separately), which generates fewer particles than a rubber gasket and creates a strong seal in high-pressure and high-vacuum applications. Fittings are 316 stainless steel for excellent corrosion resistance.

To assemble, place a gasket between the gasket ends before gently rotating the female-threaded fitting onto the male-threaded fitting. Tighten until 1/8 of a turn past finger tight.

Choose threaded fittings to attach directly to other fittings. Or, choose one of the following types of fittings to attach directly to tubing:

Yor-Lok fittings have two sleeves that bite into tubing as you tighten the nut, creating a strong steal without the need for welding. They're also known as instrumentation fittings.

Tube stem fittings connect to Yor-Lok fittings (sold separately).

For technical drawings and 3-D models, click on a part number.

For Tube (Yor-Lok) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube OD (Gasket) | OD | Wall Thick. | Material | Max. Pressure | Max. Vacuum | Interior Smoothness, Ra | Environmental Rating | Each | |

| 1/4" | 1/8" | 0.035" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | 5 | Fed. Std. Class 100 | 00000000 | 000000 |

| 1/4" | 3/8" | 0.035" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | 5 | Fed. Std. Class 100 | 00000000 | 00000 |

Adapters with an unthreaded gasket fitting connection are also known as glands.

| For Tube OD (Gasket) | Tube Stem OD | Wall Thick. | Material | Max. Pressure | Max. Vacuum | Interior Smoothness, Ra | Environmental Rating | Each | |

| 1/2" | 3/8" | 0.049" | 316L Stainless Steel | 3,750 psi @ 72° F | 10 -11 torr @ 72° F | 5 | Fed. Std. Class 100 | 00000000 | 000000 |

| For Tube OD | Nut Material | Max. Pressure | Max. Vacuum | Lg. | Each | |

Male | ||||||

|---|---|---|---|---|---|---|

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | 17/32" | 00000000 | 00000 |

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | 23/32" | 0000000 | 0000 |

| 1/2" | 316L Stainless Steel | 3,500 psi @ 72° F | 10 -11 torr @ 72° F | 13/16" | 0000000 | 00000 |

Female | ||||||

| 1/4" | 316L Stainless Steel | 5,100 psi @ 72° F | 10 -11 torr @ 72° F | 13/16" | 0000000 | 0000 |

| 1/2" | 316L Stainless Steel | 3,500 psi @ 72° F | 10 -11 torr @ 72° F | 7/8" | 0000000 | 00000 |

Retaining

Tabs

Nickel gaskets are softer than stainless steel gaskets, so they won’t wear down sealing surfaces as much, and they’re easier to tighten. They’re reactive to carbon monoxide and ozone, so they shouldn’t be used with those chemicals.

Hard and heat resistant, stainless steel gaskets can be used in a wider range of applications than nickel gaskets such as carbon monoxide and ozone. However, they’re harder to tighten than nickel gaskets, and they’ll wear down sealing surfaces more quickly.

Silver-plated stainless steel gaskets are softer than unfinished stainless steel gaskets, so they won’t wear down sealing surfaces as much, and they’re easier to tighten. However, they oxidize when exposed to air, and silver particles might flake off during assembly.

Gaskets with retaining tabs stay in place during installation, so you don’t have to hold the gasket while fastening fittings together. This also means they’re less likely to scratch or nick your fittings by rotating during installation.

| For Tube OD | Max. Vacuum | Environmental Rating | Each | |

Nickel Gasket | ||||

|---|---|---|---|---|

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 00000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

316L Stainless Steel Gasket | ||||

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 0000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 0000000 | 0000 |

Silver-Plated 316L Stainless Steel Gasket | ||||

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

316L Stainless Steel Gasket with Retaining Tabs | ||||

| 1/4" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

| 1/2" | 10 -11 torr @ 72° F | Fed. Std. Class 100 | 00000000 | 0000 |

Yor-Lok Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ASME B31.3

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. Fittings are brass for good corrosion resistance. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

For technical drawings and 3-D models, click on a part number.

For Tube (A) | For Tube (B) | ||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | OD | Wall Thick. | Material | Max. Pressure | Each | |

| 1/8" | 0.035" | 1/16" | 0.028" | Brass | 2,900 psi @ 72° F | 00000000 | 000000 |

| 3/16" | 0.035" | 1/8" | 0.035" | Brass | 2,300 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 0.035" | 1/16" | 0.028" | Brass | 1,600 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 0.035" | 1/8" | 0.035" | Brass | 1,600 psi @ 72° F | 00000000 | 0000 |

| 5/16" | 0.035" | 1/4" | 0.035" | Brass | 1,300 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 0.035" | 1/4" | 0.035" | Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.035" | 1/4" | 0.035" | Brass | 800 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.035" | 3/8" | 0.035" | Brass | 800 psi @ 72° F | 00000000 | 00000 |

| 3/4" | 0.049" | 1/2" | 0.035" | Brass | 700 psi @ 72° F | 00000000 | 00000 |

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 1/16" | Brass | 5,400 psi @ 72° F | 00000000 | 00000 |

| 1/8" | Brass | 2,900 psi @ 72° F | 00000000 | 0000 |

| 3/16" | Brass | 2,300 psi @ 72° F | 00000000 | 0000 |

| 1/4" | Brass | 1,600 psi @ 72° F | 00000000 | 0000 |

| 5/16" | Brass | 1,300 psi @ 72° F | 00000000 | 0000 |

| 3/8" | Brass | 1,000 psi @ 72° F | 00000000 | 0000 |

| 1/2" | Brass | 800 psi @ 72° F | 00000000 | 0000 |

| 3/4" | Brass | 700 psi @ 72° F | 00000000 | 0000 |

| For Tube OD | Sleeve Material | Front Sleeve Lg. | Back Sleeve Lg. | Max. Pressure | Each | |

| 1/16" | Brass | 3/32" | 1/16" | 5,400 psi @ 72° F | 00000000 | 00000 |

| 1/8" | Brass | 3/16" | 3/32" | 2,900 psi @ 72° F | 00000000 | 0000 |

| 3/16" | Brass | 3/16" | 3/32" | 2,300 psi @ 72° F | 00000000 | 0000 |

| 1/4" | Brass | 3/16" | 3/32" | 1,600 psi @ 72° F | 00000000 | 0000 |

| 5/16" | Brass | 3/16" | 3/32" | 1,300 psi @ 72° F | 00000000 | 0000 |

| 3/8" | Brass | 3/16" | 3/32" | 1,000 psi @ 72° F | 00000000 | 0000 |

| 1/2" | Brass | 19/64" | 5/32" | 800 psi @ 72° F | 00000000 | 0000 |

| 3/4" | Brass | 19/64" | 5/32" | 700 psi @ 72° F | 00000000 | 0000 |

Yor-Lok Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: See table

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. Fittings are zinc-plated steel for fair corrosion resistance. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

For technical drawings and 3-D models, click on a part number.

For Tube (A) | For Tube (B) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 1/4" | 0.035" | 1/8" | 0.035" | Zinc-Plated Steel | 4,900 psi @ 72° F | -20° to 395° | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A108 | 00000000 | 000000 |

| 3/8" | 0.035" | 1/4" | 0.049" | Zinc-Plated Steel | 3,100 psi @ 72° F | -20° to 395° | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A108 | 00000000 | 00000 |

| 1/2" | 0.035" | 1/4" | 0.035" | Zinc-Plated Steel | 2,300 psi @ 72° F | -20° to 395° | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A108 | 00000000 | 00000 |

| 1/2" | 0.035" | 3/8" | 0.065" | Zinc-Plated Steel | 2,300 psi @ 72° F | -20° to 395° | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A108 | 00000000 | 00000 |

| 3/4" | 0.049" | 1/2" | 0.035" | Zinc-Plated Steel | 2,200 psi @ 72° F | -20° to 395° | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A108 | 00000000 | 00000 |

| 6mm | 0.8mm | 1/4" | 0.028" | Zinc-Plated Steel | 3,700 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 8mm | 1mm | 1/4" | 0.028" | Zinc-Plated Steel | 3,700 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 10mm | 1mm | 3/8" | 0.035" | Zinc-Plated Steel | 3,100 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 12mm | 1mm | 1/2" | 0.049" | Zinc-Plated Steel | 2,700 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 1/8" | 0.035" | Zinc-Plated Steel | 6,800 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 00000 |

| 1/4" | 0.035" | Zinc-Plated Steel | 4,900 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 0000 |

| 3/8" | 0.035" | Zinc-Plated Steel | 3,100 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 0000 |

| 1/2" | 0.035" | Zinc-Plated Steel | 2,300 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 0000 |

| 3/4" | 0.049" | Zinc-Plated Steel | 2,200 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 0000 |

| 6mm | 0.8mm | Zinc-Plated Steel | 4,400 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 8mm | 1mm | Zinc-Plated Steel | 4,200 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 10mm | 1mm | Zinc-Plated Steel | 3,300 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 12mm | 1mm | Zinc-Plated Steel | 2,700 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Front Sleeve Material | Back Sleeve Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 1/8" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 6,800 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

| 1/4" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 4,850 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 3/8" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 3,100 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

| 1/2" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 2,300 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

| 3/4" | 0.049" | Zinc-Plated Steel | 316 Stainless Steel | 2,150 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

| 6mm | 0.8mm | Zinc-Plated Steel | 316 Stainless Steel | 4,400 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 8mm | 1mm | Zinc-Plated Steel | 316 Stainless Steel | 4,200 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 10mm | 1mm | Zinc-Plated Steel | 316 Stainless Steel | 3,300 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 12mm | 1mm | Zinc-Plated Steel | 316 Stainless Steel | 2,700 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |