How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Air Preparation

More

Aluminum Quick-Connect Pipe Fittings for Compressed Air

Twist these fittings onto aluminum pipe for quick, sealed connections—no threading, soldering, or welding necessary. Use them to build a compressed air system in half the time it would take to build a copper or steel system. Also known as Unipipe fittings, they’re part of a quick-connect system that’s compatible with pipe from Unipipe, Transair, and Infinity.

Finger tighten the collar on the end of these fittings, then use a wrench for the final quarter turn. The inside of these fittings has a compression ring and O-ring to seal against the pipe. They’re easy to take apart as needed to modify your setup.

Choose fittings with a blue or gray collar for easy identification. Fittings with a blue collar are often used for compressed air systems. Fittings with a gray collar are often used for vacuum systems.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Coolant, Nitrogen, Oil

- Temperature Range: 0° to 210° F

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- Pipe Nipples and Pipe: Use Quick-Disconnect Aluminum

These adapters have pipe threads on one end to connect to your compressor or other component.

Threaded connections can be taken apart as needed for maintenance and repair.

Gray Collar | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Pipe OD (A) | Pipe Size (B) | Socket Dp., mm | Lg., mm | Material | Color | Max. Pressure | Each | |

NPT Threads | ||||||||

| 1 1/2" (40 mm) | 1 1/2 | 57 | 81 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 000000 |

- For Use With: Air, Coolant, Nitrogen, Oil

- Temperature Range: 0° to 210° F

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- Pipe Nipples and Pipe: Use Quick-Disconnect Aluminum

These adapters have pipe threads on one end to connect to your compressor or other component.

Threaded connections can be taken apart as needed for maintenance and repair.

(A) | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Pipe OD | Socket Dp., mm | Pipe Size (B) | Lg., mm | Material | Color | Max. Pressure | Each | |

Blue Collar | ||||||||

NPT Threads | ||||||||

| 3/4" (20 mm) | 35 | 1/2 | 55 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 000000 |

| 1" (25 mm) | 37 | 3/4 | 57 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

| 1 1/2" (40 mm) | 57 | 1 1/4 | 80 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

Gray Collar | ||||||||

NPT Threads | ||||||||

| 3/4" (20 mm) | 35 | 1/2 | 55 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

| 1" (25 mm) | 37 | 3/4 | 57 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

| 1 1/2" (40 mm) | 57 | 1 1/4 | 80 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

- For Use With: Air, Coolant, Nitrogen, Oil

- Temperature Range: 0° to 210° F

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- Pipe Nipples and Pipe: Use Quick-Disconnect Aluminum

These adapters have pipe threads on one end to connect to your compressor or other component.

Threaded connections can be taken apart as needed for maintenance and repair.

(A) | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Pipe OD | Socket Dp., mm | Pipe Size (B) | Lg., mm | Material | Color | Max. Pressure | Each | |

Blue Collar | ||||||||

NPT Threads | ||||||||

| 3/4" (20 mm) | 35 | 1/2 | 49 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 000000 |

| 1" (25 mm) | 37 | 1/2 | 55 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

| 1" (25 mm) | 37 | 3/4 | 55 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

| 1 1/2" (40 mm) | 57 | 1 1/4 | 81 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

Gray Collar | ||||||||

NPT Threads | ||||||||

| 3/4" (20 mm) | 35 | 1/2 | 49 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

| 1" (25 mm) | 37 | 1/2 | 55 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

| 1" (25 mm) | 37 | 3/4 | 55 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

| 1 1/2" (40 mm) | 57 | 1 1/4 | 81 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

- For Use With: Air, Coolant, Nitrogen, Oil

- Temperature Range: 0° to 210° F

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- Pipe Nipples and Pipe: Use Quick-Disconnect Aluminum

Use these adapters with a connector (sold separately) to change the line's size. The male end of these adapters should match the size of the connector. The female end of these adapters will reduce the size of the line. To install, remove and discard the connector's nut, grip ring, and collar. Thread the male end of the adapter into the female end of the connector.

(B) | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Pipe OD (A) | For Pipe OD | Socket Dp., mm | Lg., mm | Material | Color | Max. Pressure | Each | |

Blue Collar | ||||||||

| 3/4" (20 mm) | 1" (25 mm) | 35 | 46 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 000000 |

| 3/4" (20 mm) | 1 1/2" (40 mm) | 35 | 59.5 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

| 1" (25 mm) | 1 1/2" (40 mm) | 37 | 60.5 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

Gray Collar | ||||||||

| 3/4" (20 mm) | 1" (25 mm) | 35 | 46 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

| 3/4" (20 mm) | 1 1/2" (40 mm) | 35 | 59.5 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

| 1" (25 mm) | 1 1/2" (40 mm) | 37 | 60.5 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

- For Use With: Air, Coolant, Nitrogen, Oil

- Temperature Range: 0° to 210° F

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

Threaded connections can be taken apart as needed for maintenance and repair.

(A) | |||||||

|---|---|---|---|---|---|---|---|

| For Pipe OD | Socket Dp., mm | Pipe Size (B) | Material | Color | Max. Pressure | Each | |

Blue Collar | |||||||

NPT Threads | |||||||

| 3/4" (20 mm) | 35 | 1/2 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 000000 |

| 1" (25 mm) | 37 | 1/2 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

| 1" (25 mm) | 37 | 3/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

| 1 1/2" (40 mm) | 57 | 1 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

| 1 1/2" (40 mm) | 57 | 2 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

Gray Collar | |||||||

NPT Threads | |||||||

| 3/4" (20 mm) | 35 | 1/2 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

| 1" (25 mm) | 37 | 1/2 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

| 1" (25 mm) | 37 | 3/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

| 1 1/2" (40 mm) | 57 | 1 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

| 1 1/2" (40 mm) | 57 | 2 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 00000000 | 00000 |

- For Use With: Air, Coolant, Nitrogen, Oil

- Temperature Range: 0° to 210° F

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- Pipe Nipples and Pipe: Use Quick-Disconnect Aluminum

Threaded connections can be taken apart as needed for maintenance and repair.

(A) | |||||||

|---|---|---|---|---|---|---|---|

| For Pipe OD | Socket Dp., mm | Pipe Size (B) | Material | Color | Max. Pressure | Each | |

Blue Collar | |||||||

NPT Threads | |||||||

| 3/4" (20 mm) | 35 | 1/2 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 000000 |

| 1" (25 mm) | 37 | 3/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

| 1 1/2" (40 mm) | 57 | 1 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

Gray Collar | |||||||

NPT Threads | |||||||

| 3/4" (20 mm) | 35 | 1/2 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

| 1" (25 mm) | 37 | 3/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

| 1 1/2" (40 mm) | 57 | 1 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | 0000000 | 00000 |

Use measuring tools to mark your pipe’s proper insertion depth so you know if it’s inserted far enough into the fitting.

| Max. Dp. Measured, mm | Lg., mm | Wd., mm | Material | Each | |

| 160 | 224 | 39 | Plastic | 0000000 | 000000 |

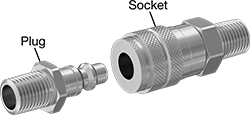

Industrial Quick-Disconnect Hose Couplings for Air

A complete coupling consists of a plug and a socket (both sold separately or in a set) that connect and disconnect quickly. Use them if you need frequent access to a line. They are also known as industrial interchange couplings. All Industrial plugs are compatible with any of the Industrial sockets of the same coupling size, regardless of the pipe size or barbed hose ID.

Steel is stronger and more durable than other metals. Zinc-plated steel has fair corrosion resistance and should be used primarily in dry environments. Brass is softer than other metals, so it’s easier to thread together. It has good corrosion resistance. NPTF (Dryseal) threads are compatible with NPT threads.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

For technical drawings and 3-D models, click on a part number.

- Maximum Pressure: 300 psi @ 72° F

- Temperature Range: -40° to 225° F

- Specifications Met: Fed. Spec. A-A-59439, ISO 6150/B, except 3/8 Coupling Size Sets: ISO 6150/B

A complete coupling consists of a plug and a socket (both sold separately) that connect and disconnect quickly. Use them if you need frequent access to a line. They are also known as industrial interchange couplings. All Industrial plugs are compatible with any of the Industrial sockets of the same coupling size, regardless of the pipe size or barbed hose ID.

Plugs are also known as nipples.

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Sleeve-lock sockets connect by sliding back the sleeve on the socket, inserting the plug, and releasing the sleeve. To disconnect, slide the sleeve back and pull out the plug.

Pipe Size | Plug Tip | |||||

|---|---|---|---|---|---|---|

| Plug | Socket | Coupling Size | Lg. | Dia. | Each | |

Zinc-Plated Steel Plug and Brass Socket | ||||||

| 1/4 | 3/8 | 1/4 | 3/16" | 5/16" | 0000000 | 000000 |

- Maximum Pressure: 300 psi @ 72° F

- Temperature Range: -40° to 225° F

- Specifications Met: Fed. Spec. A-A-59439, ISO 6150/B, except 3/8 Coupling Size Sets: ISO 6150/B

Plugs are also known as nipples.

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Sleeve-lock sockets connect by sliding back the sleeve on the socket, inserting the plug, and releasing the sleeve. To disconnect, slide the sleeve back and pull out the plug.

Pipe Size | Plug Tip | |||||

|---|---|---|---|---|---|---|

| Plug | Socket | Coupling Size | Lg. | Dia. | Each | |

Zinc-Plated Steel Plug and Brass Socket | ||||||

| 1/4 | 3/8 | 1/4 | 3/16" | 5/16" | 0000000 | 000000 |

- Maximum Pressure: 300 psi @ 72° F

- Temperature Range: -40° to 225° F

- Specifications Met: Fed. Spec. A-A-59439, ISO 6150/B, except 3/8 Coupling Size Sets: ISO 6150/B

Plugs are also known as nipples.

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Sleeve-lock sockets connect by sliding back the sleeve on the socket, inserting the plug, and releasing the sleeve. To disconnect, slide the sleeve back and pull out the plug.

Pipe Size | Plug Tip | |||||

|---|---|---|---|---|---|---|

| Plug | Socket | Coupling Size | Lg. | Dia. | Each | |

Zinc-Plated Steel Plug and Brass Socket | ||||||

| 1/4 | 3/8 | 1/4 | 3/16" | 5/16" | 0000000 | 000000 |

- Maximum Pressure: 300 psi @ 72° F

- Temperature Range: -40° to 225° F

- Specifications Met: Fed. Spec. A-A-59439, ISO 6150/B, except 3/8 Coupling Size Sets: ISO 6150/B

Plugs are also known as nipples.

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Sleeve-lock sockets connect by sliding back the sleeve on the socket, inserting the plug, and releasing the sleeve. To disconnect, slide the sleeve back and pull out the plug.

Pipe Size | Plug Tip | |||||

|---|---|---|---|---|---|---|

| Plug | Socket | Coupling Size | Lg. | Dia. | Each | |

Zinc-Plated Steel Plug and Brass Socket | ||||||

| 1/4 | 3/8 | 1/4 | 3/16" | 5/16" | 0000000 | 000000 |

Manifolds for Supplied-Air Respirators for Plant Air Lines

Divert compressed air from a single line to two respirators. Often used in plants with limited air sources, these manifolds allow two workers to share the same line. Shaped like a briefcase, they’re easy to tote around your facility—use them up to 300 ft. from an air source. The case is polypropylene, so it’s durable enough to hold up to wear and tear.

Overall | Pressure Regulating Max., psi | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inlet Coupling Size | Outlet Coupling Size (No. of Outlets) | Max. Flow Rate, cfm | Max. Pressure, psi | Gauge Included | Wd. | Ht. | Max. Temp., °F | Regulating Accuracy, psi | Inlet | Outlet | Each | |

Aluminum Housing | ||||||||||||

Quick-Disconnect Male Inlet and Female Outlets | ||||||||||||

| 1/2 | 1/4 (2 Regulated) | 100 | 125 | Yes | 19" | 13" | 140° | ±0.1 | 150 | 125 | 0000000 | 0000000 |

Air Filter Monitors for Supplied-Air Respirators for Plant Air Lines

Track the quality of incoming air as it travels from your air line to your respirator. These monitors display air-quality data, including carbon monoxide and water vapor levels, and sound an alarm if the air is unsafe to breathe. They also filter the air three times before it reaches you to remove oil, water, and solid particles.

Monitors with data-logging capabilities record air-quality data and calibration results onto a removable USB drive. Download your data from the USB for compliance reports and recordkeeping. They have a large color screen to easily view the quality and status of air as it flows through the filter. When it is time to calibrate the filter monitor, the screen gives clear, step-by-step instructions.

Calibration kits (sold separately) come with everything you need to test the accuracy of the filter monitor, including a regulator, tubing, and fittings. The components are packed in a carrying case. Air filter monitors should be calibrated monthly to ensure they’re working properly.

Monitors | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

O'all | Calibration Kits | Replacement Filters | ||||||||||||||||||

| For Use With | Inlet Coupling Size | Outlet Coupling Size | Max. Flow Rate | Max. Pressure, psi | Pressure Regulating Range , psi | Regulating Accuracy, psi | Wd. | Ht. | Max. Temp., °F | Battery Type | Batteries Included | Battery Size | No. of Batteries Required | Cord Lg., ft. | Each | Each | Each | |||

Plastic Housing | ||||||||||||||||||||

Quick-Disconnect Male Inlet × Quick-Disconnect Female Outlet | ||||||||||||||||||||

| Solid Particles, Oil, Water | 1/2 | 1/4 | 15 cfm @ 100 psi | 150 | 0-160 | ±1 | 19" | 13" | 120° | Disposable | No | AA | 8 | 10 | 0000000 | 000000000 | 0000000 | 0000000 | 0000000 | 0000000 |

Monitors | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

O'all | Calibration Kits | Replacement Filters | ||||||||||||||||

| For Use With | Inlet Coupling Size | Outlet Coupling Size | Max. Flow Rate | Max. Pressure, psi | Pressure Regulating Range , psi | Regulating Accuracy, psi | Wd. | Ht. | Max. Temp., °F | Battery Type | Batteries Included | Cord Lg., ft. | Each | Each | Each | |||

Plastic Housing | ||||||||||||||||||

Quick-Disconnect Male Inlet × Quick-Disconnect Female Outlet | ||||||||||||||||||

| Solid Particles, Oil, Water | 1/4 | 1/4 | 15 cfm @ 100 psi | 150 | 0-160 | ±1 | 18 1/2" | 13" | 100° | Rechargeable | Yes | 7 | 0000000 | 000000000 | 0000000 | 0000000 | 0000000 | 0000000 |