About Casters and Wheels

More

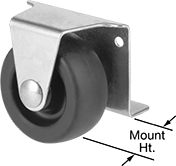

Low-Profile Casters with Polyurethane Wheels

These casters have some of the lowest mount heights in their capacity range. They have abrasion-resistant polyurethane wheels. Use them on smooth or rough floors and in areas with debris.

Dual-wheel casters provide better load distribution and easier turning than single-wheel casters.

Tread-on-core wheels have a metal core that is harder than the tread, balancing strength with cushioning.

Firm wheels are shock absorbing. Hard wheels are impact resistant.

Casters without wheel bearings have a wheel that rides directly on the axle, making them an economical choice for equipment not frequently moved. Casters with ball bearings are the easiest to roll.

Swivel casters with ball bearings have smooth swiveling. Swivel casters with double-ball bearings have the smoothest swiveling.

Shielded bearings protect from dust and debris. Sealed bearings are completely sealed for the best protection against dust and debris.

For technical drawings and 3-D models, click on a part number.

Wheel | Wheel Bearing | Swivel Bearing | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | No. of | Mount Ht. | Cap. per Caster, lbs. | Hardness | Type | Seal Type | Material | Frame Material | Type | Seal Type | Performance Properties | Each | |

Mounting Plate Style 1 | ||||||||||||||

Nonmarking Blue Solid—Hard | ||||||||||||||

| 2 1/2" | 1" | 2 | 3 3/8" | 500 | Durometer 75D | Ball | Shielded | Steel | 301 Stainless Steel | Double Ball | Sealed | __ | 0000000 | 000000 |

Mounting Plate Style 2 | ||||||||||||||

Nonmarking Brown Tread-on-Core—Firm | ||||||||||||||

| 1 3/8" | 1 1/16" | 1 | 2 1/16" | 220 | Durometer 90A | Ball | Sealed | Steel | Zinc-Plated Steel | Double Ball | Sealed | Noise Reducing | 0000000 | 00000 |

Mounting Plate Style 3 | ||||||||||||||

Nonmarking Yellow Tread-on-Core—Firm | ||||||||||||||

| 2" | 9/16" | 2 | 2 1/2" | 350 | Durometer 95A | Without Bearing | __ | __ | Zinc-Plated Iron | Ball | Open | __ | 0000000 | 00000 |

Low-Profile Casters with Nylon Wheels

Stable and easy to turn, these casters have some of the lowest mount heights in their capacity range and offer better load distribution than single-wheel casters. Wheels are impact and wear-resistant nylon. They work well on smooth surfaces.

The wheels ride directly on the axle rather than on bearings, making these casters an economical choice for equipment not frequently moved.

Casters have ball bearings for smooth swiveling.

For technical drawings and 3-D models, click on a part number.

Wheel | Swivel | |||||||

|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Mount Ht. | Cap. per Caster, lbs. | Hardness | Wheel Bearing Type | Frame Material | Each | |

Nonmarking Black Solid Wheels—Hard | ||||||||

| 1 3/8" | 9/16" | 2" | 260 | Durometer 85D | Without Bearing | Zinc-Plated Iron | 0000000 | 000000 |

Nonmarking White Solid Wheels—Hard | ||||||||

| 2" | 9/16" | 2 1/2" | 350 | Durometer 85D | Without Bearing | Zinc-Plated Iron | 0000000 | 00000 |

Low-Profile Casters with Metal Wheels

Stable and easy to turn, these casters have some of the lowest mount heights in their capacity range and offers better load distribution than single-wheel casters. Their iron wheels offer the strength and wear resistance you need for heavy loads and long life. They work well on smooth surfaces.

The wheels ride directly on the axle rather than on bearings, making this caster an economical choice for equipment not frequently moved.

Casters have ball bearings for smooth swiveling.

For technical drawings and 3-D models, click on a part number.

Wheel | Swivel | ||||||

|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Mount Ht. | Cap. per Caster, lbs. | Wheel Bearing Type | Frame Material | Each | |

Solid Zinc-Plated Steel Wheels—Hard | |||||||

| 2" | 9/16" | 2 1/2" | 600 | Without Bearing | Zinc-Plated Iron | 0000000 | 000000 |

Low-Profile Casters with Rubber Wheels

Used on hotel bellman's carts, these casters have a compact frame for use on small appliances and furniture and offer better load distribution than single-wheel casters. Their nonmarking rubber wheels protect your floor and rolls over smooth and rough surfaces.

Wheels ride directly on the axle rather than on bearings.

Casters have double-ball bearings for the smoothest swiveling. Casters with wheel brake apply pressure to the wheel to stop movement with a press of the foot pedal.

For technical drawings and 3-D models, click on a part number.

Wheel | ||||||||

|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Mount Ht. | Cap. per Caster, lbs. | Hardness | Wheel Bearing Type | Frame Material | Each | |

Swivel | ||||||||

Nonmarking Gray Tread-on-Core Wheels—Firm | ||||||||

| 2" | 13/16" | 2 13/16" | 180 | Durometer 90A | Without Bearing | Zinc-Plated Steel | 000000 | 000000 |

Swivel with Brake | ||||||||

Nonmarking Gray Tread-on-Core Wheels—Firm | ||||||||

| 2" | 13/16" | 2 13/16" | 180 | Durometer 90A | Without Bearing | Zinc-Plated Steel | 000000 | 00000 |

Low-Profile Casters with Phenolic Wheels

Stable and easy to turn, these casters have the lowest mount height in its capacity range. Their dual-wheel design offers better load distribution than single-wheel casters. They have nonmarking phenolic wheels that roll best on smooth surfaces.

Wheels ride directly on the axle rather than on bearings making these casters an economical choice for equipment not frequently moved. Double-ball bearings provide the smoothest swiveling and are completely sealed for the best protection against dust and debris.

For technical drawings and 3-D models, click on a part number.

Wheel | Swivel | |||||||

|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Mount Ht. | Cap. per Caster, lbs. | Hardness | Wheel Bearing Type | Frame Material | Each | |

Nonmarking Black Solid Wheels—Hard | ||||||||

| 2 1/2" | 1" | 3 3/8" | 500 | Durometer 95D | Without Bearing | 301 Stainless Steel | 0000000 | 000000 |

Extra-High-Capacity Low-Profile Casters with Nylon Wheels

These casters have some of the lowest mount heights in their capacity range. Wheels are impact- and wear-resistant glass-filled nylon for more durability than other nylon wheels. They work well on smooth surfaces. A nut in the mounting plate lets you thread directly into the mounting plate with no additional nut.

Casters have sealed ball bearings in the wheel and swivel for smooth rolling and swiveling and the best protection against dust and debris.

Casters with wheel brake apply pressure to the wheel to stop movement.

Wheel | Wheel Bearing | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Mount Ht. | Cap. per Caster, lbs. | Hardness | Type | Material | Frame Material | Each | |

Rigid | |||||||||

Nonmarking Black Solid Wheels—Hard | |||||||||

| 3" | 2" | 4 1/4" | 2,000 | Durometer 85D | Ball | Steel | Zinc-Plated Steel | 0000000 | 000000 |

Rigid with Brake | |||||||||

Nonmarking Black Solid Wheels—Hard | |||||||||

| 3" | 2" | 4 1/4" | 2,000 | Durometer 85D | Ball | Steel | Zinc-Plated Steel | 0000000 | 00000 |

Swivel | |||||||||

Nonmarking Black Solid Wheels—Hard | |||||||||

| 3" | 2" | 4 1/4" | 2,000 | Durometer 85D | Ball | Steel | Zinc-Plated Steel | 0000000 | 00000 |

Swivel with Brake | |||||||||

Nonmarking Black Solid Wheels—Hard | |||||||||

| 3" | 2" | 4 1/4" | 2,000 | Durometer 85D | Ball | Steel | Zinc-Plated Steel | 0000000 | 00000 |

High-Capacity Low-Profile Casters with Nylon Wheels

Choose these casters when you need high capacities and low mounting heights. Their durable glass-filled nylon wheels are impact and wear resistant. They work well on smooth surfaces.

Ball bearings in the wheel provide easy rolling and are completely sealed for the best protection against dust and debris.

Swivel casters have double-ball bearings for the smoothest swiveling. Casters with wheel brake apply pressure to the wheel to stop movement with a press of the foot pedal.

For technical drawings and 3-D models, click on a part number.

Wheel | Wheel Bearing | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Mount Ht. | Cap. per Caster, lbs. | Hardness | Type | Material | Frame Material | Each | |

Rigid | |||||||||

Nonmarking Black Solid Wheels—Hard | |||||||||

| 3" | 1 13/16" | 3 31/32" | 700 | Durometer 85D | Ball | Steel | Zinc-Plated Steel | 0000000 | 000000 |

| 3" | 1 13/16" | 4 1/32" | 1,000 | Durometer 85D | Ball | Steel | Zinc-Plated Steel | 0000000 | 00000 |

Rigid with Wheel Brake | |||||||||

Nonmarking Black Solid Wheels—Hard | |||||||||

| 3" | 1 13/16" | 3 31/32" | 700 | Durometer 85D | Ball | Steel | Zinc-Plated Steel | 0000000 | 00000 |

| 3" | 1 13/16" | 4 1/32" | 1,000 | Durometer 85D | Ball | Steel | Zinc-Plated Steel | 0000000 | 00000 |

Swivel | |||||||||

Nonmarking Black Solid Wheels—Hard | |||||||||

| 3" | 1 13/16" | 3 31/32" | 700 | Durometer 85D | Ball | Steel | Zinc-Plated Steel | 0000000 | 00000 |

| 3" | 1 13/16" | 4 1/32" | 1,000 | Durometer 85D | Ball | Steel | Zinc-Plated Steel | 0000000 | 00000 |

Swivel with Wheel Brake | |||||||||

Nonmarking Black Solid Wheels—Hard | |||||||||

| 3" | 1 13/16" | 3 31/32" | 700 | Durometer 85D | Ball | Steel | Zinc-Plated Steel | 0000000 | 00000 |

| 3" | 1 13/16" | 4 1/32" | 1,000 | Durometer 85D | Ball | Steel | Zinc-Plated Steel | 0000000 | 00000 |

Edge-Mount Bracket Casters

Mount these casters to the bottom edge of equipment to keep them out of sight. They have a lightweight polypropylene wheel that rides directly on the axle making these casters an economical option for equipment on smooth surfaces that is not frequently moved.

For technical drawings and 3-D models, click on a part number.

Wheel | Mounting Plate | Rigid | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Mount Ht. | Cap. per Caster, lbs. | Hardness | No. of Mounting Holes | Lg. | Wd. | Dp. | Mounting Hole Ctr.-to-Ctr. Wd. | For Screw Size | Frame Material | Each | |

Nonmarking Black Solid Polypropylene Plastic Wheels—Hard | |||||||||||||

| 2" | 7/8" | 1/2" | 100 | Durometer 70D | 3 | 1 3/4" | 2 1/4" | 0.625" | 1 13/16" | 1/8" | Zinc-Plated Steel | 0000000 | 00000 |

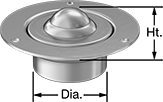

Recessed Flange-Mount Ball Transfers

Transfers recess into the mounting surface for a low profile. These ball transfers can be used in an angled working orientation to form support stands.

Steel balls are durable. Stainless steel balls offer the most corrosion resistance. They don’t need to be lubricated. Nylon balls are nonmarking.

Capacity is given for the ball up orientation. Using these ball transfers in a ball down or angled orientation could reduce the capacity stated.

For technical drawings and 3-D models, click on a part number.

Flange | Mounting Hole | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Dia. | Cap., lbs. | Ht. | Dp. | Dia. | Working Orientation | Lg. | Wd. | Dia. | No.of Mounting Holes | Dia. | Ctr.-to-Ctr. | Temperature Range, °F | Each | ||

Steel Ball | |||||||||||||||

Zinc-Plated Steel Housing | |||||||||||||||

| A | 1" | 75 | 3/4" | 1/2" | 1 3/4" | Ball Up, Ball Down, Angle | 2 1/8" | 2 3/4" | __ | 2 | 7/32" | 2 3/16" | __ | 0000000 | 00000 |

| B | 5/8" | 25 | 13/32" | 5/16" | 7/8" | Ball Up, Ball Down, Angle | __ | __ | 1 5/8" | 2 | 1/8" | 1 3/16" | __ | 0000000 | 00000 |

| B | 3/4" | 55 | 13/32" | 15/32" | 1 3/16" | Ball Up, Ball Down, Angle | __ | __ | 2 13/32" | 2 | 7/32" | 1 3/4" | __ | 0000000 | 0000 |

| B | 1" | 55 | 9/16" | 5/8" | 1 1/2" | Ball Up, Ball Down, Angle | __ | __ | 2 7/8" | 2 | 3/16" | 2 3/16" | __ | 0000000 | 00000 |

| B | 1 1/4" | 275 | 5/8" | 25/32" | 1 25/32" | Ball Up, Ball Down, Angle | __ | __ | 2 29/32" | 2 | 3/16" | 2 5/16" | __ | 0000000 | 00000 |

| B | 1 9/16" | 495 | 27/32" | 1 1/16" | 2 7/16" | Ball Up, Ball Down, Angle | __ | __ | 3 23/32" | 3 | 9/32" | 3" | __ | 0000000 | 00000 |

Black-Oxide Steel Housing | |||||||||||||||

| C | 11/16" | 90 | 27/32" | 5/32" | 21/32" | Ball Up, Ball Down, Angle | __ | __ | 1 5/16" | 3 | 1/8" | 31/32" | __ | 0000000 | 00000 |

| C | 1" | 135 | 1 1/8" | 1/8" | 59/64" | Ball Up, Ball Down, Angle | __ | __ | 1 23/32" | 3 | 5/32" | 1 9/32" | __ | 0000000 | 00000 |

| C | 1 1/8" | 180 | 1 1/4" | 5/32" | 31/32" | Ball Up, Ball Down, Angle | __ | __ | 1 13/16" | 3 | 5/32" | 1 11/32" | __ | 0000000 | 00000 |

| C | 1 1/4" | 225 | 1 3/8" | 1/8" | 1 1/16" | Ball Up, Ball Down, Angle | __ | __ | 2" | 3 | 5/32" | 1 15/32" | __ | 0000000 | 00000 |

| D | 11/16" | 90 | 27/32" | 5/32" | 21/32" | Ball Up, Ball Down, Angle | 1 15/64" | 31/32" | __ | 4 | 1/8" | 11/16", 31/32" | __ | 0000000 | 00000 |

| D | 1" | 135 | 1 1/8" | 1/8" | 59/64" | Ball Up, Ball Down, Angle | 1 3/4" | 1 3/8" | __ | 4 | 5/32" | 1", 1 3/8" | __ | 0000000 | 00000 |

| D | 1 1/8" | 180 | 1 1/4" | 5/32" | 31/32" | Ball Up, Ball Down, Angle | 1 3/4" | 1 3/8" | __ | 4 | 5/32" | 1", 1 3/8" | __ | 0000000 | 00000 |

Steel Housing | |||||||||||||||

| B | 5/8" | 40 | 3/8" | 3/8" | 31/32" | Ball Up, Ball Down, Angle | __ | __ | 1 11/16" | 2 | 1/8" | 1 1/4" | __ | 0000000 | 0000 |

Nylon Plastic Ball | |||||||||||||||

Zinc-Plated Steel Housing | |||||||||||||||

| A | 1" | 75 | 3/4" | 1/2" | 1 3/4" | Ball Up, Ball Down, Angle | 2 1/8" | 2 3/4" | __ | 2 | 7/32" | 2 3/16" | 32° to 195° | 0000000 | 00000 |

| E | 1" | 40 | 1/2" | 27/32" | 1 1/16" | Ball Up, Ball Down, Angle | __ | __ | 1 11/32" | 2 | 7/32" | 1 7/8" | __ | 00000000 | 00000 |

Stainless Steel Ball | |||||||||||||||

Zinc-Plated Steel Housing | |||||||||||||||

| A | 1" | 75 | 3/4" | 1/2" | 1 3/4" | Ball Up, Ball Down, Angle | 2 1/8" | 2 3/4" | __ | 2 | 7/32" | 2 3/16" | __ | 0000000 | 00000 |

| B | 5/8" | 25 | 13/32" | 5/16" | 7/8" | Ball Up, Ball Down, Angle | __ | __ | 1 5/8" | 2 | 1/8" | 1 3/16" | __ | 0000000 | 00000 |

Stainless Steel Housing | |||||||||||||||

| A | 1" | 75 | 3/4" | 1/2" | 1 3/4" | Ball Up, Ball Down, Angle | 2 1/8" | 2 3/4" | __ | 2 | 7/32" | 2 3/16" | __ | 0000000 | 00000 |

| B | 5/8" | 25 | 13/32" | 5/16" | 7/8" | Ball Up, Ball Down, Angle | __ | __ | 1 5/8" | 2 | 1/8" | 1 3/16" | __ | 0000000 | 00000 |

| B | 3/4" | 55 | 13/32" | 15/32" | 1 3/16" | Ball Up, Ball Down, Angle | __ | __ | 2 13/32" | 2 | 7/32" | 1 3/4" | __ | 0000000 | 00000 |

| B | 1" | 120 | 9/16" | 9/16" | 1 3/8" | Ball Up, Ball Down, Angle | __ | __ | 2 7/32" | 2 | 3/16" | 1 25/32" | __ | 0000000 | 00000 |

| B | 1" | 120 | 9/16" | 5/8" | 1 1/2" | Ball Up, Ball Down, Angle | __ | __ | 2 7/8" | 2 | 3/16" | 2 3/16" | __ | 0000000 | 00000 |

| B | 1 1/4" | 275 | 5/8" | 25/32" | 1 25/32" | Ball Up, Ball Down, Angle | __ | __ | 2 29/32" | 3 | 3/16" | 2 5/16" | __ | 0000000 | 00000 |

Heavy Duty Recessed Flange-Mount Ball Transfers

These ball transfers recess into the mounting surface for a low profile. Position them at an angle to form support stands. They are made of steel, so they are durable.

Capacity is given for the ball up orientation. Using these ball transfers in a ball down or angled orientation could reduce the capacity stated.

For technical drawings and 3-D models, click on a part number.

Flange | Mounting Hole | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Ball Dia. | Cap., lbs. | Ht. | Dp. | Dia. | Working Orientation | Lg. | Wd. | Dia. | No.of Mounting Holes | Dia. | Ctr.-to-Ctr. | Each | |

Steel Ball with Top Flange | ||||||||||||||

Black-Oxide Steel Housing | ||||||||||||||

| A | 1/2" | 120 | 5/16" | 5/8" | 15/16" | Ball Up, Ball Down, Angle | 1 7/8" | 1 1/4" | __ | 2 | 5/32" | 1 3/8" | 0000000 | 000000 |

| B | 1" | 500 | 15/32" | 1 5/32" | 1 3/4" | Ball Up, Ball Down, Angle | 2 1/4" | 2 1/4" | __ | 4 | 7/32" | 1 3/4" | 0000000 | 000000 |

| B | 1" | 705 | 1/2" | 1 1/4" | 2" | Ball Up, Ball Down, Angle | 3" | 3" | __ | 4 | 9/32" | 2 9/32" | 0000000 | 000000 |

| B | 1" | 850 | 1/2" | 1 1/4" | 2" | Ball Up, Ball Down, Angle | 3" | 3" | __ | 4 | 5/16" | 2 9/32" | 0000000 | 000000 |

| B | 1 1/2" | 2,240 | 1" | 1 3/8" | 2 3/8" | Ball Up, Ball Down, Angle | 3" | 3" | __ | 4 | 5/16" | 2 9/32" | 0000000 | 000000 |

Zinc-Plated Steel Housing | ||||||||||||||

| C | 1 1/4" | 550 | 15/16" | 13/16" | 2" | Ball Up, Ball Down, Angle | __ | __ | 3" | 2 | 3/16" | 2 15/32" | 0000000 | 000000 |

Shock-Absorbing Recessed Flange-Mount Ball Transfers

The ball in these transfers is spring-loaded to absorb impact. They are recessed for a low profile.

Steel balls are durable. Stainless steel balls offer the most corrosion resistance. They also don’t need to be lubricated.

For technical drawings and 3-D models, click on a part number.

Mounting Hole | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Dia. | Cap., lbs. | Max. Deflection @ Load Cap. | Ht. | Dp. | Dia. | Working Orientation | Flange Dia. | No.of Mounting Holes | Dia. | Ctr.-to-Ctr. | Each | |

Steel Ball | ||||||||||||

Zinc-Plated Steel Housing | ||||||||||||

| 1" | 125 | 1/4" @ 65 lbs. | 1/2" | 15/16" | 1 11/16" | Ball Up | 3 1/8" | 3 | 3/16" | 2 3/8" | 0000000 | 000000 |

Stainless Steel Ball | ||||||||||||

Stainless Steel Housing | ||||||||||||

| 1" | 125 | 1/4" @ 65 lbs. | 1/2" | 15/16" | 1 11/16" | Ball Up | 3 1/8" | 3 | 3/16" | 2 3/8" | 0000000 | 000000 |

Washdown Recessed Flange-Mount Ball Transfers

With a ball recessed into the mounting surface, these ball transfers have a low profile. Their double-sealed ball keeps out dirt and debris, and side vents expel contaminants. Because their ball is stainless steel, they resist corrosion. They also don’t need to be lubricated. If you orient them at an angle, you can use them to build support stands.

Capacity is given for the ball up orientation. Using these ball transfers in a ball down or angled orientation could reduce the capacity stated.

For technical drawings and 3-D models, click on a part number.

Flange | Mounting Hole | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Dia. | Cap., lbs. | Ht. | Dp. | Dia. | Working Orientation | Housing Color | Lg. | Wd. | No.of Mounting Holes | Dia. | Ctr.-to-Ctr. | Temperature Range, °F | Each | |

Stainless Steel Ball | ||||||||||||||

Nylon Plastic Housing | ||||||||||||||

| 1" | 525 | 1/2" | 1 1/4" | 2" | Ball Up, Ball Down, Angle | Black | 3" | 3" | 4 | 1/4" | 2 9/32" | -22° to 128° | 0000000 | 0000000 |

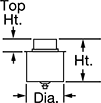

Pop-Up Ball Transfers and Stops

These ball transfers and stops rise when you supply air and retract into the housing when air supply ceases. Drop-in design makes for easy installation.

Ball transfers let you move and divert material without lifting. Steel balls are durable. Stainless steel balls are durable and offer the most corrosion resistance. They also don’t need to be lubricated.

Stops hold a load in place when raised.

For technical drawings and 3-D models, click on a part number.

Air Inlet Connection | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., lbs. | Ht. | Top Ht. | Dp. | Dia. | Ball Dia. | Flange Dia. | Working Orientation | Air Pressure, psi | For Inlet Tube ID | Type | Material | Each | |

Steel Ball—Galvanized Steel Housing | |||||||||||||

| 15 | 1 5/8" | 3/8" | 1 1/4" | 1 9/16" | 1" | 1 27/32" | Ball Up | 50 | 1/16" | Barbed | Brass | 0000000 | 000000 |

Stainless Steel Ball—Galvanized Steel Housing | |||||||||||||

| 15 | 1 5/8" | 3/8" | 1 1/4" | 1 9/16" | 1" | 1 27/32" | Ball Up | 50 | 1/16" | Barbed | Brass | 00000000 | 00000 |

Air Inlet Connection | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., lbs. | Ht. | Top Ht. | Dp. | Dia. | Flange Dia. | Working Orientation | Air Pressure, psi | For Inlet Tube ID | Type | Material | Temperature Range, °F | Each | |

Polyurethane Rubber Pad—Galvanized Steel Housing | |||||||||||||

| 30 | 1 11/16" | 7/16" | 1 1/4" | 1 9/16" | 1 27/32" | Ball Up | 50 | 1/16" | Barbed | Brass | 32° to 100° | 0000000 | 000000 |