Filter by

Reamers

Finish holes to precise inch, metric, wire gauge, or letter sizes with these reamers.

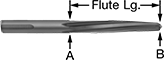

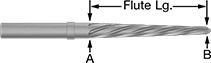

Round Shank

These reamers fit in the chuck of drill presses, turret lathes, and other machine and power tools, making them the most common shank type.

Straight Flute—The most common flute style, these reamers are suitable for a wide range of applications, but not recommended for holes with a keyway or other breaks in the surface.

Spiral Flute—Since these reamers clear chips better than straight flutes, they leave holes with a smoother finish. They're better for holes with breaks in the surface, such as a keyway, because they cut continuously across the breaks instead of moving in and out.

High-Speed Steel—Durable and wear resistant, these are good for general purpose reaming in most materials.

Titanium Nitride (TiN)-Coated High-Speed Steel—Coated to create less friction than uncoated high-speed steel reamers, these run faster and last twice as long.

Cobalt Steel—With better heat and wear resistance than high-speed steel, these reamers run up to 25% faster, last longer, and perform better on hard materials, such as cast iron, hardened steel, titanium, and stainless steel.

Carbide-Tipped Tool Steel—Since these reamers retain a sharper, harder edge at higher temperatures than high-speed steel and cobalt steel, they can be used on hard materials, such as iron, hardened steel, and steel alloys. They aren't as brittle as solid carbide reamers, so they can be used in less rigid setups, such as a hand-held drill.

Carbide—For the highest level of accuracy when cutting hard materials, these are our hardest, strongest, and most wear-resistant reamers. They're used on materials such as iron, hardened steel, steel alloys, and plastic. Their hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the reamer from breaking.

Right-Hand Spiral—These reamers pull chips upward as they cut, so they're often used in blind holes.

Left-Hand Spiral—These reamers push chips downward as they cut, so they're often used in through holes.

Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Dia. | Material | Flute | Overall | No. of Flutes | Spiral Direction | Cutting Dia. Tolerance | For Use On | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4375" (7/16") | High-Speed Steel | 1 3/4" | 7" | 6 | — | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4375" (7/16") | Cobalt Steel | 1 3/4" | 7" | 6 | — | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel, Hardened Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4375" (7/16") | Carbide-Tipped Tool Steel | 1 3/4" | 7" | 4 | — | 0" to 0.0003" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel, Hardened Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4375" (7/16") | Carbide | 1 3/8" | 4" | 6 | — | 0" to 0.0003" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel, Hardened Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4375" (7/16") | High-Speed Steel | 1 3/4" | 7" | 6 | Right Hand | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4375" (7/16") | High-Speed Steel | 1 3/4" | 7" | 6 | Left Hand | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4375" (7/16") | Titanium Nitride (TiN)-Coated High-Speed Steel | 1 3/4" | 7" | 6 | Right Hand | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Expandable Flutes, Round Shank

Straight Flute |

Unlike standard reamers, which are unusable once they become worn, these can be returned to their original size for finishing holes. After the reamer is worn down, tighten the set screw to expand the diameter, grind the reamer to its original size, and get back to work.

These are not designed for producing holes larger than the listed diameter or for producing holes of various sizes. The set screw should not be loosened.

These reamers fit in the chuck of drill presses, turret lathes, and other machine and power tools, making them the most common shank type.

Straight Flute—The most common flute style, these reamers are suitable for a wide range of applications, but not recommended for holes with a keyway or other breaks in the surface.

Carbide-Tipped Tool Steel—Since these reamers retain a sharper, harder edge at higher temperatures than high-speed steel and cobalt steel, they can be used on hard materials, such as iron, hardened steel, and steel alloys. They aren't as brittle as solid carbide reamers, so they can be used in less rigid setups, such as a hand-held drill.

Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Dia. | Material | Flute | Overall | No. of Flutes | Cutting Dia. Tolerance | Recommended Expansion Limit | For Use On | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4375" (7/16") | Carbide-Tipped Tool Steel | 1" | 7" | 4 | 0" to 0.0003" | 0.006" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel, Hardened Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Square Shank

Turn these reamers by hand with an adjustable wrench or straight-handle tap wrench (sold separately).

Straight Flute—The most common flute style, these reamers are suitable for a wide range of applications, but not recommended for holes with a keyway or other breaks in the surface.

Spiral Flute—Since these reamers clear chips better than straight flutes, they leave holes with a smoother finish. They're better for holes with breaks in the surface, such as a keyway, because they cut continuously across the breaks instead of moving in and out.

High-Speed Steel—Durable and wear resistant, these are good for general purpose reaming in most materials.

Left-Hand Spiral—These reamers push chips downward as they cut, so they're often used in through holes.

Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Dia. | Material | Square Shank Size | Flute | Overall | No. of Flutes | Spiral Direction | Cutting Dia. Tolerance | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4375" (7/16") | High-Speed Steel | 0.330" | 2 3/4" | 5 1/2" | 6 | — | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4375" (7/16") | High-Speed Steel | 0.330" | 2 3/4" | 5 1/2" | 6 | Left Hand | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

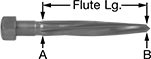

Reamers for Hole Alignment

Enlarge holes to correct misalignment and overlap. Misaligned holes often have a narrow entry, so the tapered shape is easier to insert and makes more contact to remove the overlapping material. These are also known as bridge and car reamers.

Round Shank

|

Spiral Flute |

|

Spiral Flute Depth Limiting |

These reamers fit in the chuck of drill presses, turret lathes, and other machine and power tools, making them the most common shank type.

Spiral Flute—Since these reamers clear chips better than straight flutes, they leave holes with a smoother finish. They're better for holes with breaks in the surface, such as a keyway, because they cut continuously across the breaks instead of moving in and out.

High-Speed Steel—Durable and wear resistant, these are good for general purpose reaming in most materials.

Left-Hand Spiral—These reamers push chips downward as they cut, so they're often used in through holes.

Depth Limiting—A collar on the shank prevents these reamers from going too deep into material, protecting your tool's chuck from damage.

Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Dia. (A) | Reamer Dia. (B) | Material | Flute | Overall | Spiral Direction | Cutting Dia. Tolerance | Performance | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4375" (7/16") | 0.2188" | High-Speed Steel | 3 1/8" | 5 1/4" | Left Hand | 0" to 0.005" | Depth Limiting | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4375" (7/16") | 0.2500" | High-Speed Steel | 3 1/4" | 5 3/8" | Left Hand | 0" to 0.01" | — | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.7760" (25/32") | 0.4375" | High-Speed Steel | 5" | 6 7/8" | Left Hand | 0" to 0.0005" | Depth Limiting | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8125" (13/16") | 0.4375" | High-Speed Steel | 4 1/2" | 6 7/8" | Left Hand | 0" to 0.01" | — | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hex Shank

|

Spiral Flute |

The shank fits hex impact sockets, so you can use an impact wrench to both ream the hole and install a fastener.

Spiral Flute—Since these reamers clear chips better than straight flutes, they leave holes with a smoother finish. They're better for holes with breaks in the surface, such as a keyway, because they cut continuously across the breaks instead of moving in and out.

High-Speed Steel—Durable and wear resistant, these are good for general purpose reaming in most materials.

Left-Hand Spiral—These reamers push chips downward as they cut, so they're often used in through holes.

Strong Hold—Magnets on the shank’s end keep these reamers from accidentally falling out of your tool.

Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Dia. (A) | Reamer Dia. (B) | Material | Hex Shank Size | Flute | Overall | Spiral Direction | Cutting Dia. Tolerance | Performance | For Use On | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4375" (7/16") | 0.2656" | High-Speed Steel | 1 1/4" | 4 3/8" | 7 1/8" | Left Hand | 0" to 0.01" | Strong Hold | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Morse Taper Shank

|

Spiral Flute |

These reamers work with machine tools that have a Morse taper-spindle hole, such as a drill press or lathe.

Spiral Flute—Since these reamers clear chips better than straight flutes, they leave holes with a smoother finish. They're better for holes with breaks in the surface, such as a keyway, because they cut continuously across the breaks instead of moving in and out.

High-Speed Steel—Durable and wear resistant, these are good for general purpose reaming in most materials.

Left-Hand Spiral—These reamers push chips downward as they cut, so they're often used in through holes.

Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Dia. (A) | Reamer Dia. (B) | Material | Machine Taper No. | Flute | Overall | Spiral Direction | Cutting Dia. Tolerance | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.4375" (7/16") | 0.2500" | High-Speed Steel | Morse 2 | 4 3/8" | 8 1/4" | Left Hand | 0" to 0.01" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reamer Sets

Keep a variety of reamer sizes on hand for finishing holes.

Round Shank

|

These reamers fit in the chuck of drill presses, turret lathes, and other machine and power tools, making them the most common shank type.

Straight Flute—The most common flute style, these reamers are suitable for a wide range of applications, but not recommended for holes with a keyway or other breaks in the surface.

Spiral Flute—Since these reamers clear chips better than straight flutes, they leave holes with a smoother finish. They're better for holes with breaks in the surface, such as a keyway, because they cut continuously across the breaks instead of moving in and out.

High-Speed Steel—Durable and wear resistant, these are good for general purpose reaming in most materials.

Right-Hand Spiral—These reamers pull chips upward as they cut, so they're often used in blind holes.

Jobbers' Length—The same length as jobbers' drill bits, these reamers save setup time when you want to drill and ream on the same machine, such as a drill press or bench lathe.

Sizes Included | No. of Pieces | Material | Spiral Direction | Lg. Class | Container Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Straight Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/4" (Increments of 1/64") | 13 | High-Speed Steel | — | Jobbers | Metal Case | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/2" (Increments of 1/64") | 29 | High-Speed Steel | — | — | Metal Case | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/2" (Increments of 1/64") | 29 | High-Speed Steel | — | — | Wood Case | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/2" (Increments of 1/64") | 29 | High-Speed Steel | — | Jobbers | Metal Case | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/2" (Increments of 1/32") | 15 | High-Speed Steel | — | — | Roll-Up Pouch | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/2" (Increments of 1/64") | 29 | High-Speed Steel | Right Hand | — | Metal Case | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/2" (Increments of 1/32") | 15 | High-Speed Steel | Right Hand | Jobbers | Metal Case | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

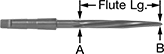

Reaming Drill Bits for Carbon Fiber, Fiberglass, and Graphite

Drill and finish holes in abrasive material with the same bit. The tapered tip gradually pierces the surface to reduce friction, and the straight flutes make clean cuts without chipping or peeling the edge of the hole. Bits are made of carbide to retain a sharp edge on tough workpieces, even after after hundreds of cuts.

Carbide

Shank | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Size | Overall Lg. | Max. Drilling Dp. | Type | Dia. | Bit Style | No. of Flutes | Cutting Dia. Tolerance | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 6" | 3.44" | Round | 0.437" | Fluted | 4 | 0" to 0.0005" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||