How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Drill-and-Install Push-to-Connect Tube Fittings for Drinking Water

- Temperature Range: 35° to 150° F

- Tubing: Use with firm or hard nylon plastic or polyethylene plastic

- Specifications Met: NSF/ANSI 51, NSF/ANSI 61

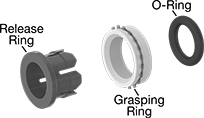

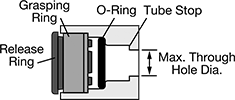

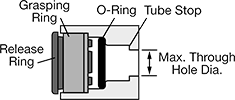

Create a push-to-connect junction between tubing and unthreaded ports in your equipment. As an alternative to installing a threaded port, insert these fittings in equipment such as taps, manifolds, and flow direction splitters. Also known as instant fittings, they have a grasping ring and O-ring that hold your tubing in place, and a release ring that disconnects it. Made of moisture-resistant acetal, these fittings won’t soften and lose strength in high-humidity environments. They meet NSF/ANSI 61 for use in drinking water systems and NSF/ANSI 51 for use with food. Use them in low-pressure applications.

To install, drill a stepped hole in your surface using tools such as a CNC machine or lathe. After removing all debris and burrs from the hole, push the fitting components into place. Then insert your tubing until the tube end is flush against the tube stop. To disconnect, push on the release ring and pull the tubing out.

For technical drawings and 3-D models, click on a part number.

Release Ring | Required Hole Dia. for | Required Hole Dp. for | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Material | Color | Max. Pressure | Grasping Ring | O-Ring | Tube Stop | Grasping Ring | O-Ring | Tube Stop | Hole Dia. Tolerance | Max. Through Hole Dia. | Each | |

| 5/32" | Acetal Plastic | Plastic | Gray | 230 psi @ 72° F | 0.472" | 0.327" | 0.163" | 0.193" | 0.35" | 0.504" | -0.002" to 0.002" | 0.13" | 00000000 | 00000 |

| 1/4" | Acetal Plastic | Plastic | Gray | 230 psi @ 72° F | 0.528" | 0.424" | 0.255" | 0.181" | 0.386" | 0.555" | -0.002" to 0.002" | 0.23" | 0000000 | 0000 |

| 5/16" | Acetal Plastic | Plastic | Gray | 230 psi @ 72° F | 0.544" | 0.47" | 0.32" | 0.215" | 0.4" | 0.59" | -0.002" to 0.002" | 0.29" | 00000000 | 0000 |

| 3/8" | Acetal Plastic | Plastic | Gray | 145 psi @ 72° F | 0.632" | 0.547" | 0.38" | 0.27" | 0.465" | 0.72" | -0.002" to 0.002" | 0.35" | 0000000 | 0000 |

| 1/2" | Acetal Plastic | Plastic | Gray | 145 psi @ 72° F | 0.777" | 0.671" | 0.508" | 0.304" | 0.561" | 0.797" | -0.002" to 0.002" | 0.48" | 0000000 | 0000 |

| 4mm | Acetal Plastic | Plastic | Black | 230 psi @ 72° F | 11.98mm | 8.3mm | 4.13mm | 4.9mm | 8.9mm | 12.8mm | -0.05mm to 0.05mm | 3.3mm | 00000000 | 0000 |

| 5mm | Acetal Plastic | Plastic | Black | 230 psi @ 72° F | 11.98mm | 9.06mm | 5.13mm | 4.9mm | 8.63mm | 12.44mm | -0.05mm to 0.05mm | 4.3mm | 00000000 | 0000 |

| 6mm | Acetal Plastic | Plastic | Black | 230 psi @ 72° F | 13.41mm | 10mm | 6.12mm | 4.6mm | 9.8mm | 14mm | -0.05mm to 0.05mm | 5.3mm | 00000000 | 0000 |

| 8mm | Acetal Plastic | Plastic | Black | 230 psi @ 72° F | 13.82mm | 11.94mm | 8.13mm | 5.46mm | 10.15mm | 15mm | -0.05mm to 0.05mm | 7.4mm | 00000000 | 0000 |

| 10mm | Acetal Plastic | Plastic | Black | 145 psi @ 72° F | 16.05mm | 14mm | 10.15mm | 6.86mm | 11.81mm | 18.17mm | -0.05mm to 0.05mm | 9.2mm | 00000000 | 0000 |

| 12mm | Acetal Plastic | Plastic | Black | 145 psi @ 72° F | 19.74mm | 16.54mm | 12.15mm | 7.72mm | 15.9mm | 23.9mm | -0.05mm to 0.05mm | 11.2mm | 00000000 | 0000 |

Push-to-Connect Tube Fittings for Air

- Temperature Range: 0° to 170° F, except polybutylene plastic fittings are 32° to 140° F

- Tubing: Use with firm (Durometer 95A-45D) polyethylene plastic or polyurethane rubber

- Specifications Met: ISO 14743, except cartridges and polybutylene plastic fittings

Insert tubing into these fittings and an internal gripping ring and O-ring hold the tubing tight. They are also known as instant fittings. To disconnect, push on the release ring and pull the tubing out of the fitting. Fittings have good corrosion resistance. Use them in low-pressure applications.

Identification rings (sold separately) snap over the release ring so you can color-code your lines.

Clips (sold separately) align and organize your tubing and fittings.

For technical drawings and 3-D models, click on a part number.

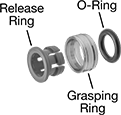

Cartridges fit into unthreaded ports in your equipment to create a push-to-connect junction with tubing. Install them in equipment such as taps, manifolds, and flow direction splitters as an alternative to installing a threaded port. They have a release ring, a grasping ring for securing the tubing, and an O-ring.

Release Ring | Required Hole Dia. For | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Material | Color | Max. Pressure | Grasping Ring | O-Ring | Tube Stop | Hole Dia. Tolerance | Max. Through Hole Dia. | Each | |

| 1/8" | Nickel-Plated Brass | Plastic | Black | 290 psi @ 72° F | 0.28" | 0.244" | 0.128" | -0.001" to 0.002" | 0.1" | 00000000 | 00000 |

| 5/32" | Nickel-Plated Brass | Plastic | Black | 290 psi @ 72° F | 0.327" | 0.278" | 0.161" | -0.002" to 0.002" | 0.12" | 00000000 | 0000 |

| 1/4" | Nickel-Plated Brass | Plastic | Black | 290 psi @ 72° F | 0.417" | 0.368" | 0.254" | -0.001" to 0.002" | 0.2" | 00000000 | 0000 |

| 5/16" | Nickel-Plated Brass | Plastic | Black | 290 psi @ 72° F | 0.482" | 0.427" | 0.322" | -0.001" to 0.002" | 0.26" | 00000000 | 0000 |

| 3/8" | Nickel-Plated Brass | Plastic | Black | 290 psi @ 72° F | 0.593" | 0.516" | 0.38" | -0.001" to 0.001" | 0.3" | 00000000 | 0000 |

| 4mm | Brass | Plastic | Black | 290 psi @ 72° F | 8.3mm | 7.05mm | 4.1mm | -0.04mm to 0.05mm | 3mm | 00000000 | 0000 |

| 6mm | Brass | Plastic | Black | 290 psi @ 72° F | 10.3mm | 9.1mm | 6.1mm | -0.02mm to 0.04mm | 5mm | 00000000 | 0000 |

| 8mm | Brass | Plastic | Black | 290 psi @ 72° F | 12.25mm | 10.85mm | 8.17mm | -0.03mm to 0.04mm | 6.5mm | 00000000 | 0000 |

| 10mm | Brass | Plastic | Black | 290 psi @ 72° F | 15.08mm | 13.2mm | 10.15mm | -0.03mm to 0.04mm | 8.5mm | 00000000 | 0000 |

| 12mm | Brass | Plastic | Black | 290 psi @ 72° F | 17.7mm | 15.5mm | 12.17mm | -0.01mm to 0.05mm | 9.5mm | 00000000 | 00000 |

| 14mm | Brass | Plastic | Black | 290 psi @ 72° F | 20.05mm | 17.8mm | 14.15mm | -0.05mm to 0.05mm | 10mm | 00000000 | 00000 |

Low-Temperature/High-Pressure D.O.T. Push-to-Connect Tube Fittings for Air

- Temperature Range: -40° to 200° F

- Tubing: Use with hard (Durometer 65D) nylon plastic

- Specifications Met:

Cartridges: D.O.T. FMVSS 571, SAE J2494-4, SAE J1131

All other fittings: D.O.T. FMVSS 571

Connect high-pressure brake lines with fittings that won’t crack in frigid temperatures. Often used on commercial trucks and trailers, these fittings meet Department of Transportation FMVSS 571 safety standards. Also known as instant fittings, they connect to tubing with a simple push, and an internal gripping ring and O-ring will hold the tubing tight. A built-in tube support slips inside the tubing to prevent it from collapsing. To disconnect, push on the release ring and pull the tubing out of the fitting. All have good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Straight cartridge fittings create a push-to-connect junction between equipment and tubing in your system. They’re designed to be used in unthreaded 6061 aluminum ports. If you want to use them in a different material, you may need to adjust the hole size for optimum performance. To install them, create a hole in your surface and push the fitting’s components into place before inserting the tubing until it’s flush against the tube stop.

Required Hole | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Max. Pressure | Dia. | Dp. | Hole Dia. Tolerance | Min. Plate Thick. | Each | |

| 1/4" | Brass | 250 psi @ 72° F | 0.504" | 0.5" | -0.002" to 0.002" | 0.5" | 00000000 | 000000 |

| 1/4" | Brass | 250 psi @ 72° F | 0.775" | 0.78" | -0.002" to 0.002" | 0.78" | 00000000 | 00000 |

| 3/8" | Brass | 250 psi @ 72° F | 0.65" | 0.65" | -0.002" to 0.002" | 0.65" | 00000000 | 00000 |

| 3/8" | Brass | 250 psi @ 72° F | 0.775" | 0.78" | -0.002" to 0.002" | 0.78" | 00000000 | 00000 |

| 1/2" | Brass | 250 psi @ 72° F | 0.775" | 0.78" | -0.002" to 0.002" | 0.78" | 00000000 | 00000 |

Drill-and-Install Push-to-Connect Fittings for Copper and Brass Tubing

- For Use With: Air, Beverage, Cutting Oil, Drinking Water, Food, Mineral Oil, Water

- Temperature Range: 0° to 150° F

- Tubing: Use with brass, copper

- Specifications Met: NSF/ANSI 51, NSF/ANSI 61

Add a push-to-connect junction to unthreaded ports for easy connections with tubing. As an alternative to installing a threaded port, insert these fittings in equipment such as taps, manifolds, and flow direction splitters. Also known as instant fittings, they have a grasping ring and O-ring that hold your tubing in place, and a release ring that disconnects it. Made of brass, these fittings have good corrosion resistance. They meet NSF/ANSI 61 for use in drinking water systems and NSF/ANSI 51 for use with food. Use them in low-pressure applications with firm or hard tubing.

To install, drill a stepped hole in your surface using tools such as a CNC machine or lathe. After removing all debris and burrs from the hole, push the fitting components into place. Then insert your tubing until the tube end is flush against the tube stop. To disconnect, push on the release ring and pull the tubing out.

For technical drawings and 3-D models, click on a part number.

Required Hole Dia. for | Required Hole Dp. for | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Release Ring Material | Release Ring Color | Max. Pressure | Grasping Ring | O-Ring | Tube Stop | Grasping Ring | O-Ring | Tube Stop | Hole Dia. Tolerance | Max. Through Hole Dia. | Min. Plate Thick. | Each | |

| 5/32" | Brass | Plastic | Gray | 230 psi @ 72° F | 0.492" | 0.327" | 0.163" | 0.193" | 0.35" | 0.504" | -0.002" to 0.002" | 0.13" | 0.555" | 0000000 | 00000 |

| 3/16" | Brass | Plastic | Gray | 230 psi @ 72° F | 0.472" | 0.348" | 0.193" | 0.193" | 0.34" | 0.49" | -0.002" to 0.002" | 0.16" | 0.555" | 0000000 | 0000 |

| 1/4" | Brass | Plastic | Gray | 230 psi @ 72° F | 0.528" | 0.424" | 0.255" | 0.181" | 0.386" | 0.555" | -0.002" to 0.002" | 0.23" | 0.605" | 0000000 | 0000 |

| 5/16" | Brass | Plastic | Gray | 230 psi @ 72° F | 0.544" | 0.47" | 0.32" | 0.215" | 0.4" | 0.59" | -0.002" to 0.002" | 0.29" | 0.64" | 0000000 | 0000 |

| 3/8" | Brass | Plastic | Gray | 140 psi @ 72° F | 0.632" | 0.547" | 0.38" | 0.27" | 0.465" | 0.72" | -0.002" to 0.002" | 0.35" | 0.77" | 0000000 | 0000 |

| 1/2" | Brass | Plastic | Gray | 140 psi @ 72° F | 0.777" | 0.671" | 0.508" | 0.304" | 0.561" | 0.797" | -0.002" to 0.002" | 0.48" | 0.847" | 0000000 | 0000 |

| 4mm | Brass | Plastic | Gray | 230 psi @ 72° F | 12.5mm | 8.3mm | 4.14mm | 4.9mm | 8.9mm | 12.8mm | -0.05mm to 0.05mm | 3.3mm | 15mm | 0000000 | 0000 |

| 6mm | Brass | Plastic | Black | 230 psi @ 72° F | 13.41mm | 10mm | 6.12mm | 4.6mm | 9.8mm | 14mm | -0.05mm to 0.05mm | 5.3mm | 16mm | 0000000 | 0000 |

| 8mm | Brass | Plastic | Gray | 230 psi @ 72° F | 13.82mm | 11.94mm | 8.13mm | 5.46mm | 10.15mm | 15mm | -0.05mm to 0.05mm | 7.4mm | 17mm | 0000000 | 0000 |