About Sump, Water-Removal, Condensate, and Submersible Pumps

More

How to Prime Your Pump

More

How to Determine Feet of Head

More

About Vacuum Pumps

More

About Process Pumps

More

About Drum Pumps

More

Low-Maintenance Plastic Circulation Pumps for Water and Coolants

Eliminate seal wear and leakage with pumps that use magnets to turn the impeller. They’re often used with electroplating and photographic solutions. Pumps are gravity fed and require an elevated liquid source to fully fill the pump before turning on. Do not run dry or use with solids.

Note: If flow control is needed, place valves or reducers on the discharge side; never restrict the inlet of a pump with a valve or reducer.

Flow Rate, gpm | Intake | Discharge | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Flow Rate, gpm | @ 5 ft. of Head | @ 10 ft. of Head | Max. ft of Head | Max. Pressure, psi | Max. Viscosity, cP | Temp. Range, °F | Current, A | Tube Connection Type | Gender | For Tube ID | Tube Connection Type | Gender | For Tube ID | Lg. | Wd. | Ht. | Each | |

115V AC, Single Phase—With Thermal Overload Protection | ||||||||||||||||||

Plug | ||||||||||||||||||

| 3 | 1 | 0.1 | 10.6 | 4 | 20 | 35° to 150° | 0.8 | Barbed | Male | 1/2" | Barbed | Male | 1/2" | 6 3/4" | 3 3/4" | 4 7/8" | 0000000 | 0000000 |

Flow Rate, gpm | Intake | Discharge | Overall | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Flow Rate, gpm | @ 10 ft. of Head | @ 20 ft. of Head | Max. ft. of Head | Max. Pressure, psi | Max. Viscosity, cP | Temp. Range, °F | hp | Current, A | Pipe Size | Gender | Thread Type | Pipe Size | Gender | Thread Type | Lg. | Wd. | Ht. | Each | |

115V AC, Single Phase—With Thermal Overload Protection | |||||||||||||||||||

Plug | |||||||||||||||||||

| 9 | 5 | __ | 16.1 | 7 | 20 | 35° to 150° | 1/20 hp | 1.4 | 1/2 | Female | NPT | 1/2 | Male | NPT | 8 7/8" | 3 3/4" | 4 7/8" | 0000000 | 0000000 |

| 14 | 11 | 4 | 24.7 | 10 | 20 | 35° to 150° | 1/10 hp | 1.7 | 1 | Female | NPT | 1/2 | Male | NPT | 9 5/8" | 5 1/2" | 4 7/8" | 0000000 | 000000 |

Constant-Flow-Rate Pumps for Water

Also known as gear pumps, these produce a smooth flow of liquid for applications such as cooling engines, powering hydraulic equipment, and extracting liquid from holding tanks. Pumps are self-priming after you fill the pump chamber with liquid. As liquid in the chamber is expelled, a suction force is created which allows the pump to draw liquid upward. Do not use with solids. Pumps can be used in dusty, dirty, and damp environments.

Note: Pumps must be filled with liquid before use. They need a constant flow of liquid and cannot run dry. If flow control is needed, place valves or reducers on the discharge side; never restrict the inlet of a pump with a valve or reducer.

For technical drawings and 3-D models, click on a part number.

Intake (NPT) | Discharge (NPT) | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Flow Rate, gpm | Discharge Pressure, psi | Max. Viscosity, cP | Temp. Range, °F | hp | Current, A | Pipe Size | Gender | Pipe Size | Gender | Motor Enclosure Type | Lg. | Wd. | Ht. | Each | |

115/230V AC, Single Phase—Without Thermal Overload Protection | |||||||||||||||

Hardwire | |||||||||||||||

| 2.1 | 150 | 100,000 | 32° to 140° | 1/2 | 7.4/3.7 | 1/4 | Female | 1/4 | Female | Totally Enclosed | 16 1/16" | 8 3/16" | 8" | 0000000 | 000000000 |

| 8.5 | 150 | 100,000 | 32° to 140° | 1 | 12.8/6.4 | 1/2 | Female | 1/2 | Female | Totally Enclosed | 18 1/8" | 9 3/16" | 9" | 0000000 | 00000000 |

Sanitary Electric Drum Pumps

Commonly used in food, beverage, pharmaceutical, and cosmetic processing, these pumps are designed for sanitary environments. The discharge connection can be easily disassembled for cleaning. Pumps do not include a drum connector.

Pumps that are 3-A certified meet sanitary design standards. Those that are CSA certified meet stringent safety standards.

For technical drawings and 3-D models, click on a part number.

Temp. Range, °F | Intake | Discharge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | Discharge Pressure, psi | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Horsepower | Current, A | For Drum Opening Size, mm | Tube OD | Tube Lg. | Tube Connection Type | For Tube OD | Thermal Protection | Specifications Met | Each | |

115V AC, Single Phase—Hardwire | ||||||||||||||||

Nylon Plastic Housing | ||||||||||||||||

| 31 | 10 | 55 | 1,000 | 15° | 175° | 1 hp | 4.2 | 38 | 1 1/2" | 39" | Quick Clamp | 1 1/2" | With Thermal Overload Protection | 3-A Certified 02-11; CSA Certified | 0000000 | 000000000 |

Easy-Carry Water-Removal Pumps without Switch

These pumps activate when plugged in. You can add a plug-in switch to control when the pump activates. Use the handle to carry pumps from job to job. Install in debris-free water that’s at least 3/4" deep. Pumps are gravity fed and require an elevated liquid source to fully fill the pump before turning on. Do not run dry.

Max. Flow Rate, gpm | Discharge | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 5 Ft. of Head | @ 10 Ft. of Head | @ 15 Ft. of Head | @ 20 Ft. of Head | Max. Ft. of Head, ft. | Removes Water Down To | Temp. Range, °F | Horsepower | Current, A | Pipe Size | Thread Type | Gender | Ht. | Wd. | Lg. | Each | |

115V AC, Single Phase—With Thermal Overload Protection | ||||||||||||||||

Plug with 10 ft. Cord | ||||||||||||||||

| 23 | 20 | 14 | 9 | 26 | 1/8" | 35° to 120° | 1/6 hp | 2 | 1 | NPT | Female | 8" | 6" | 4.3" | 00000000 | 0000000 |

Plug with 25 ft. Cord | ||||||||||||||||

| 18 | 17 | 14 | 9 | 26.3 | 1/8" | 35° to 120° | 1/6 hp | 5 | 1 | NPT | Female | 8" | 7" | 5" | 00000000 | 000000 |

Submersible Pumps for Water

Submerge these pumps to circulate water in small tanks, cooling baths, fountains, and other low-flow applications. Plug in to activate. Do not run dry. Not for use with salt water or flammable liquids.

Max. Flow Rate, gpm | Discharge | Overall | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Electrical Connection Type | @ 1 Ft. of Head | @ 5 Ft. of Head | @ 10 Ft. of Head | Max. Ft. of Head, ft. | Temp. Range, °F | Horsepower | Current, A | Intake Inlet Connection Type | Pipe Size | Thread Type | Gender | Cord Length, ft. | Ht. | Wd. | Dp. | Each | ||

115V AC, Single Phase—With Thermal Overload Protection | ||||||||||||||||||

| B | Plug | 5.6 | 4.3 | 0.8 | 11.1 | 35° to 85° | 1/15 hp | 0.8 | Screened | 1/4 | NPT | Male | 6 | 4" | 3 7/8" | 5 3/8" | 0000000 | 000000 |

| B | Plug | 8.9 | 6.9 | 2.5 | 13 | 35° to 85° | 1/10 hp | 1.2 | Screened | 1/2 | NPT | Male | 6 | 4 1/2" | 4" | 5 5/8" | 0000000 | 000000 |

115V AC, Single Phase—Without Thermal Overload Protection | ||||||||||||||||||

| B | Plug | 3.5 | 1.5 | __ | 7.1 | 35° to 85° | 1/25 hp | 0.5 | Screened | 1/4 | NPT | Male | 6 | 3 7/8" | 3 1/2" | 4 5/8" | 0000000 | 00000 |

Max. Flow Rate, gpm | Discharge | Overall | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Electrical Connection Type | @ 1 Ft. of Head | @ 5 Ft. of Head | @ 10 Ft. of Head | Max. Ft. of Head, ft. | Temp. Range, °F | Horsepower | Current, A | Intake Inlet Connection Type | Pipe Size | Thread Type | Gender | Cord Length, ft. | Ht. | Wd. | Dp. | Each | ||

115V AC, Single Phase—With Thermal Overload Protection | ||||||||||||||||||

| E | Plug | 20 | 12 | 4 | 15 | 35° to 85° | 1/15 hp | 1 | Screened | 3/4 | NPT | Male | 15 | 5 1/4" | 3 3/4" | 6 3/8" | 00000000 | 0000000 |

Fixed-Flow-Rate Metering Pumps for Chemicals

Also known as peristaltic pumps and tubing pumps, these maintain a fixed flow rate. Pumps are self-priming, which means they create a suction force to draw liquid upward and fill the pump chamber. Mount them up to 25 feet above your liquid source. All can run dry. Do not use with solids.

Pumps with Tygon 2375 lining resist harsh substances such as isopropyl alcohol and sodium chloride.

Pumps with Viton® fluoroelastomer tubing withstand oil such as gasoline and hydraulic oil.

Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gal./day (For Tube ID) | Max. Pressure, psi | Max. Viscosity, cP | Temp. Range, °F | Horsepower | Current, A | Lg. | Wd. | Ht. | Includes | Each | |

115V AC,Single Phase—Plug | |||||||||||

Polypropylene Plastic and Tygon Wetted Parts Material | |||||||||||

| 0.07 (1/16") 0.25 (1/8") | 30 | 800 | 32° to 122° | Subfractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 4 1/2" Lg. of 1/16" ID Tygon Tubing with Tygon 2375 Lining (Shore A60), 4 1/2" Lg. of 1/8" ID Tygon Tubing with Tygon 2375 Lining (Shore A60) | 000000000 | 0000000 |

| 0.34 (1/16") 1.25 (1/8") | 30 | 800 | 32° to 122° | Subfractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 4 1/2" Lg. of 1/16" ID Tygon Tubing with Tygon 2375 Lining (Shore A60), 4 1/2" Lg. of 1/8" ID Tygon Tubing with Tygon 2375 Lining (Shore A60) | 000000000 | 000000 |

| 0.87 (1/16") 3.53 (1/8") 6.84 (3/16") | 30 | 800 | 32° to 122° | Subfractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 6" Lg. of 1/16" ID Tygon Tubing with Tygon 2375 Lining (Shore A60), 6" Lg. of 1/8" ID Tygon Tubing with Tygon 2375 Lining (Shore A60), 6" Lg. of 3/16" ID Tygon Tubing with Tygon 2375 Lining (Shore A60) | 000000000 | 000000 |

| 1.75 (1/16") 7.07 1/8") 13.68 (3/16") | 30 | 800 | 32° to 122° | Subfractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 6" Lg. of 1/16" ID Tygon Tubing with Tygon 2375 Lining (Shore A60), 6" Lg. of 1/8" ID Tygon Tubing with Tygon 2375 Lining (Shore A60), 6" Lg. of 3/16" ID Tygon Tubing with Tygon 2375 Lining (Shore A60) | 000000000 | 000000 |

| 22.80 (3/16") 38.00 (1/4") | 15 | 500 | 32° to 122° | Subfractional | 0.52 | 5" | 5" | 7" | 6" Lg. of 3/16" ID Tygon Tubing with Tygon 2375 Lining (Shore A60), 6" Lg. of 1/4" ID Tygon Tubing with Tygon 2375 Lining (Shore A60) | 000000000 | 000000 |

| 45.6 (3/16") 76.00 (1/4") | 15 | 200 | 32° to 122° | Subfractional | 0.65 | 5" | 5" | 7" | 6" Lg. of 3/16" ID Tygon Tubing with Tygon 2375 Lining (Shore A60), 6" Lg. of 1/4" ID Tygon Tubing with Tygon 2375 Lining (Shore A60) | 000000000 | 000000 |

| 228.00 (3/16") 380.00 (1/4") | 15 | 50 | 32° to 122° | Subfractional | 1.74 | 5" | 5" | 7" | 6" Lg. of 3/16" ID Tygon Tubing with Tygon 2375 Lining (Shore A60), 6" Lg. of 1/4" ID Tygon Tubing with Tygon 2375 Lining (Shore A60) | 000000000 | 000000 |

PVDF Plastic and Viton® Fluoroelastomer Rubber Wetted Parts Material | |||||||||||

| 0.02 (1/32") 0.07 (1/16") 0.25 (1/8") | 30 | 800 | 32° to 122° | Subfractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 4 1/2" Lg. of 1/32" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 |

| 0.11 (1/32") 0.34 (1/16") 1.25 (1/8") | 30 | 800 | 32° to 122° | Subfractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 4 1/2" Lg. of 1/32" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 |

| 0.87 (1/16") 3.53 (1/8") 6.84 (3/16") | 30 | 800 | 32° to 122° | Subfractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 6" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 |

| 1.75 (1/16") 7.07 1/8") 13.68 (3/16") | 30 | 800 | 32° to 122° | Subfractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 6" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 |

| 22.80 (3/16") 38.00 (1/4") | 15 | 500 | 32° to 122° | Subfractional | 0.52 | 5" | 5" | 7" | 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 1/4" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 |

| 45.6 (3/16") 76.00 (1/4") | 15 | 200 | 32° to 122° | Subfractional | 0.65 | 5" | 5" | 7" | 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 1/4" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 |

| 228.00 (3/16") 380.00 (1/4") | 15 | 50 | 32° to 122° | Subfractional | 1.74 | 5" | 5" | 7" | 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 1/4" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 |

| For Flow Rate, gal./day | Each | |

For Polypropylene Plastic and Tygon Wetted Parts Material | ||

|---|---|---|

| 0.06-0.34 | 000000000 | 000000 |

| 0.24-1.25 | 000000000 | 00000 |

| 0.87-1.75 | 000000000 | 00000 |

| 3.53-7.07 | 000000000 | 00000 |

| 6.84-13.68 | 000000000 | 00000 |

| 22.8-228 | 000000000 | 00000 |

| 38-380 | 000000000 | 00000 |

For PVDF Plastic and Viton® Fluoroelastomer Wetted Parts Material | ||

| 0.02-0.11 | 000000000 | 00000 |

| 0.06-0.34 | 000000000 | 00000 |

| 0.24-1.25 | 000000000 | 00000 |

| 0.87-1.75 | 000000000 | 00000 |

| 3.53-7.07 | 000000000 | 00000 |

| 6.84-13.68 | 000000000 | 00000 |

| 22.8-228 | 000000000 | 00000 |

| 38-380 | 000000000 | 00000 |

Oil-Free Electric Vacuum Pumps

Since these pumps don't require lubrication, there’s no risk of oil contamination. Maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum.

Style C pumps withstand harsh operating conditions. Use to service machinery and refrigeration and circulation systems.

Intake | Discharge | O'all | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Temp. Range, °F | Volume, dBA | Horsepower | Current, A | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Lg. | Wd. | Ht. | Each | |

NEMA 5-15 Plug | |||||||||||||||||

| C | 27.5 | 1.75 | 35° to 100° | 70 | 1/6 hp | 3.5 | 1/4 | NPT | Female | 1/4 | NPT | Female | 11 1/2" | 5 5/8" | 8 5/8" | 000000 | 0000000 |

Intake | Discharge | O'all | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Temp. Range, °F | Volume, dBA | Horsepower | Current, A | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Lg. | Wd. | Ht. | Each | |

NEMA 5-15 Plug | |||||||||||||||||

| C | 27.5 | 5 | 35° to 100° | 75 | 1/2 hp | 6/12 | 1/4 | NPT | Female | 1/4 | NPT | Female | 13 1/4" | 12 3/8" | 9" | 000000 | 000000000 |

Hardwire | |||||||||||||||||

| C | 27.5 | 10.5 | 35° to 100° | 75 | 1 1/2 hp | 10/21 | 1/4 | NPT | Female | 1/4 | NPT | Female | 21" | 12 1/4" | 8 1/2" | 000000 | 00000000 |

Electric Vacuum Pumps

| NEMA 5-15 |

NEMA 6-15 |

Use these pumps in applications such as degassing and servicing refrigeration and freezer systems. Maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum. Tube and fitting ID will also affect flow.

Intake | Discharge | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Vacuum | Max. Flow Rate, cfm | Temp. Range, °F | Volume, dBA | Horsepower | Current, A | Port Size | Tube Connection Type | Gender | Pipe Size | Thread Type | Gender | Lg. | Wd. | Ht. | Oil Capacity, oz. | Each | |

115V AC, Single Phase—With Thermal Overload Protection | |||||||||||||||||

NEMA 5-15 Plug | |||||||||||||||||

| 1.5×10 -2 torr @ 72° F | 3 | 30° to 180° | 70 | 1/2 hp | 7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 14 1/2" | 5 5/8" | 12" | 27 | 0000000 | 0000000 |

| 1.5×10 -2 torr @ 72° F | 5 | 30° to 180° | 70 | 1/2 hp | 7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 14 1/2" | 5 5/8" | 12" | 21 | 0000000 | 000000 |

| 1.5×10 -2 torr @ 72° F | 7 | 30° to 180° | 70 | 1/2 hp | 7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 14 1/2" | 5 5/8" | 12" | 23 | 0000000 | 000000 |

| 1.5×10 -2 torr @ 72° F | 10 | 30° to 180° | 70 | 1/2 hp | 7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 14 1/2" | 5 5/8" | 12" | 26 | 0000000 | 000000 |

115V AC/230V AC, Single Phase—With Thermal Overload Protection | |||||||||||||||||

NEMA 6-15 Plug | |||||||||||||||||

| 1.5×10 -2 torr @ 72° F | 3 | 30° to 180° | 70 | 1/2 hp | 3.5/7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 14 1/2" | 5 5/8" | 12" | 27 | 0000000 | 000000 |

| 1.5×10 -2 torr @ 72° F | 5 | 30° to 180° | 70 | 1/2 hp | 3.5/7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 14 1/2" | 5 5/8" | 12" | 21 | 0000000 | 000000 |

| 1.5×10 -2 torr @ 72° F | 7 | 30° to 180° | 70 | 1/2 hp | 3.5/7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 14 1/2" | 5 5/8" | 12" | 21 | 0000000 | 000000 |

| 1.5×10 -2 torr @ 72° F | 10 | 30° to 180° | 70 | 1/2 hp | 3.5/7 | 1/4", 3/8", 1/2" | Flared | Male | 1/2 | NPT | Male | 16" | 5 5/8" | 12" | 26 | 0000000 | 000000 |

Electric High-Vacuum Pumps

Achieve powerful vacuum and continuous flow for applications such as vacuum drying, solvent evaporation, and distillation. Maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum. Tube and fitting ID will also affect flow.

Intake | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Vacuum | Max. Flow Rate, cfm | Temp. Range, °F | Volume, dBA | Horsepower | Current, A | Connection Style | Gender | Discharge Connection Style | Lg. | Wd. | Ht. | Oil Capacity, qt. | Each | |

115V AC, Single Phase—With Thermal Overload Protection | ||||||||||||||

NEMA 5-15 Plug | ||||||||||||||

| 1.5×10 -3 torr @ 72° F | 2.8 | 50° to 100° | 50 | 1/2 hp | 5.3 | Quick Clamp | Female | Quick Clamp Hose | 18 1/4" | 6 1/8" | 9 1/8" | 1.22 | 0000000 | 000000000 |

| 3 × 10 -3 torr @ 72° F | 12.8 | 50° to 100° | 55 | 1 hp | 8 | Quick Clamp | Female | Quick Clamp Hose | 22 3/8" | 8 1/8" | 11 3/8" | 2.55 | 0000000 | 00000000 |

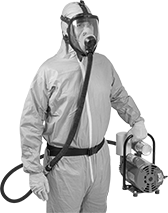

Pumps for Supplied-Air Respirators

Connect these oil-free portable pumps to your respirators for a continuous supply of low-pressure breathable air.

For No. Of | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate | Hood Respirators | Helmet Respirators | Full-Face Respirators | Max. Supply Pressure, psi | Max. Span, ft. | Connection Type | Quick-Disconnect Shape | Coupling Size | Motor Type | Motor Power, hp | Voltage | Current, A | Plug Type | Each | |

| 10 cfm @ 5 psi | 1 | 1 | 2 | 15 | 300 | Quick-Disconnect Hose Coupling | Industrial | 1/2 | Open Dripproof | 3/4 | 115V AC | 10.8 | Three Prong | 00000000 | 000000000 |

Supplied-Air Hood Respirators for Air Pumps

When connected to an air pump, respirators provide a continuous supply of clean air. They have a chemical-resistant Tychem 2000 (formerly known as Tyvek QC) hood that protects against light liquid splashes. Tuck the hood with outer bib and inner bib into your clothing for splash protection.

Pinlock suspension hats adjust with interlocking straps. Ratchet suspensions adjust with an easy-turn knob.

Add extension hose (sold separately) to increase your span up to 300 ft. To maintain NIOSH approval, respirators must be used with the hoses listed.

Lens | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Use With | NIOSH Approval | Adjustment Style | Hat Size | Material | Ht. | Wd. | Required Flow Rate, cfm | Flow Rate | Hose Lg., ft. | Motor Type | Power Source | Motor Power, hp | Voltage | Plug Type | Cord Lg., ft. | Each | |

| Solid Particles, Organic Vapors, Acid Gases, Ammonia, Formaldehyde, Methylamine | TC-19C-0154 | Pinlock | 6 1/2-8 | Acetate Plastic | 6" | 16" | 6-15 | 10 cfm @ 5 psi | 50 | Open Dripproof | Electric | 3/4 | 115V AC | Three Prong | 8 | 0000000 | 000000000 |

Supplied-Air Full-Face Respirators for Air Pumps

The portable pump on these respirators provides a continuous supply of clean air for one person.

Add extension hose (sold separately) to increase your span up to 300 ft. To maintain NIOSH approval, respirators must be used with the hoses listed.

Lens | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Use With | NIOSH Approval | Size | Mask Material | Material | Ht. | Wd. | Flow Rate | Hose Lg., ft. | Max. Span, ft. | Motor Type | Power Source | Motor Power | Voltage | Plug Type | Cord Lg., ft. | Each | |

| Solid Particles, Organic Vapors, Acid Gases, Ammonia, Formaldehyde, Methylamine | TC-19C-0322 | M/L | Silicone Rubber | Polycarbonate Plastic | 10" | 7" | 10 cfm @ 5 psi | 50 | 300 | Open Dripproof | Electric | 3/4 hp | 115V AC | Three Prong | 8 | 0000000 | 000000000 |