Food Industry Vacuum Lifters for Large Surfaces

These lifters have multiple cups to grip, lift, and move large food items as well as other objects with curves, angles, and varied heights in food-processing plants. All of the cups are made of FDA-compliant silicone rubber, so they’re safe for direct contact with food. They also have a flexible, accordion-style design that grips irregular shapes better than flat cups or pads. Those with more bellows are better for handling items that have more variations in shape. The cups come installed on a single manifold, so there’s no need to build your own platform. Use these lifters with compressed air, which the manifold will distribute to the cups. Also known as venturi devices, they generate suction without an installed vacuum system.

These lifters have a lightweight aluminum housing that withstands corrosion. T-slotted mounting rails on the housing make it easy to connect these lifters to T-slotted framing components that are often used with robot-arm tools. A metal filter on all the vacuum ports keeps debris from entering the vacuum passage.

Use the additional port on these lifters with a pressure transmitter (not included). Your transmitter will convert air pressure to an electrical signal for viewing air measurements on remote displays and programmable logic controllers (PLCs).

Use the optional robot adapter plates to attach these lifters to robot arms with ISO mounting patterns. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Vacuum Lifters | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of | O'all | Female Air Connection | Replacement Cups | |||||||||||||||

| Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | Columns | Rows | Bellows | For Use With | Cup Dia., mm | Lg., mm | Wd., mm | Ht., mm | Pipe Size | Thread Type | For T-Slot Wd. | Wt. | Each | Each | ||

Single Bellows Cup—For Smooth and Textured Surfaces | ||||||||||||||||||

White Silicone Rubber | ||||||||||||||||||

| 180.79 lbs. @ 24 in. of Hg | 26 in. of Hg | 4.5 scfm @ 70 psi | 8 | 5 | 1 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 20 | 280 | 118 | 104 | 1/4 | BSPP | 8 mm | 5.3 lbs. / 2.4 kg | 00000000 | 000000000 | 00000000 | 000000 |

| 293.78 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 12 | 5 | 1 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 20 | 416 | 118 | 104 | 1/4 | BSPP | 8 mm | 3.4 lbs. / 3.4 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 316.31 lbs. @ 24 in. of Hg | 26 in. of Hg | 4.5 scfm @ 70 psi | 5 | 3 | 1 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 40 | 280 | 118 | 115 | 1/4 | BSPP | 8 mm | 5.3 lbs. / 2.4 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 406.77 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 16 | 5 | 1 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 20 | 560 | 118 | 104 | 1/4 | BSPP | 8 mm | 9.7 lbs. / 4.4 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 474.46 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 7 | 3 | 1 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 40 | 416 | 118 | 115 | 1/4 | BSPP | 8 mm | 7.3 lbs. / 3.3 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 655.21 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 10 | 3 | 1 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 40 | 560 | 118 | 115 | 1/4 | BSPP | 8 mm | 9.5 lbs. / 4.3 kg | 00000000 | 00000000 | 00000000 | 00000 |

Multiple Bellows Cup—For Smooth and Textured Surfaces | ||||||||||||||||||

White Silicone Rubber | ||||||||||||||||||

| 180.79 lbs. @ 24 in. of Hg | 26 in. of Hg | 4.5 scfm @ 70 psi | 8 | 5 | 2 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 20 | 280 | 118 | 110 | 1/4 | BSPP | 8 mm | 5.3 lbs. / 2.4 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 180.79 lbs. @ 24 in. of Hg | 26 in. of Hg | 4.5 scfm @ 70 psi | 8 | 5 | 4 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 20 | 280 | 118 | 112 | 1/4 | BSPP | 8 mm | 5.1 lbs. / 2.3 kg | 00000000 | 00000000 | 00000000 | 0000 |

| 293.78 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 12 | 5 | 2 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 20 | 416 | 118 | 110 | 1/4 | BSPP | 8 mm | 7.5 lbs. / 3.4 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 293.78 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 12 | 5 | 4 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 20 | 416 | 118 | 112 | 1/4 | BSPP | 8 mm | 6.8 lbs. / 3.1 kg | 00000000 | 00000000 | 00000000 | 0000 |

| 316.31 lbs. @ 24 in. of Hg | 26 in. of Hg | 4.5 scfm @ 70 psi | 5 | 3 | 2 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 40 | 280 | 118 | 132 | 1/4 | BSPP | 8 mm | 5.5 lbs. / 2.5 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 316.31 lbs. @ 24 in. of Hg | 26 in. of Hg | 4.5 scfm @ 70 psi | 5 | 3 | 4 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 40 | 280 | 118 | 123 | 1/4 | BSPP | 8 mm | 5.5 lbs. / 2.5 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 406.77 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 16 | 5 | 2 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 20 | 560 | 118 | 110 | 1/4 | BSPP | 8 mm | 9.9 lbs. / 4.4 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 406.77 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 16 | 5 | 4 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 20 | 560 | 118 | 112 | 1/4 | BSPP | 8 mm | 8.8 lbs. / 4 kg | 00000000 | 00000000 | 00000000 | 0000 |

| 474.46 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 7 | 3 | 2 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 40 | 416 | 118 | 132 | 1/4 | BSPP | 8 mm | 7.7 lbs. / 3.5 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 474.46 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 7 | 3 | 4 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 40 | 416 | 118 | 123 | 1/4 | BSPP | 8 mm | 7.71 lbs. / 3.5 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 655.21 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 10 | 3 | 2 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 40 | 560 | 118 | 132 | 1/4 | BSPP | 8 mm | 9.9 lbs. / 4.5 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 655.21 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 10 | 3 | 4 | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 40 | 560 | 118 | 123 | 1/4 | BSPP | 8 mm | 9.9 lbs. / 4.5 kg | 00000000 | 00000000 | 00000000 | 00000 |

| For Robot Arm Manufacturer (Series/Model Number) | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Bolt Hole Thread Size (No. of) | Length, mm | Width, mm | Height, mm | Each | |

Aluminum | |||||||

|---|---|---|---|---|---|---|---|

| Denso (VM 6083, 60B1) FANUC (M-10iA; M-20iA; M20-iB; M-710iC) Kawasaki (RS 010N, 010L, 015X, 020N) Mitsubishi (RV 13F, 13FL, 13FR, 13FRL, 20F, 20FR) Toshiba (TV 1000H) Yaskawa/Motoman (HP 20F; MH 50II-20) | 40 mm (ISO 40) 63 mm (ISO 63) 90 mm (ISO 90) | M6 (4, 7) M6 (4) M10 (10) | 125 | 125 | 25 | 00000000 | 0000000 |

| FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; M-710iC; R-1000iA) Kawasaki (RS/RD 030N, 050N, 080N) Mitsubishi (RV 35F, 50F, 70F) Toshiba (TVM 900, 1200, 1500) Universal Robots (UR3, UR3e, UR5, UR5e, UR10, UR10e) | 31.5 mm (ISO 31.5) 50 mm (ISO 50) 80 mm (ISO 80) 100 mm (ISO 100) | M6 (4) M6 (4) M8 (6) M10 (10) | 125 | 125 | 25 | 00000000 | 000000 |

| FANUC (M-10iA; M-20iA) Yaskawa/Motoman (HP 20F; MH 50II-20) | 56 mm (ISO 56) | M4 (8, 15) | 125 | 125 | 25 | 00000000 | 000000 |

Food Industry Vacuum Lifters for Curved and Irregularly Shaped Items

Grip, lift, and move food as well as other items with curves, angles, and varied heights in food-processing plants. All of these lifters have a flexible balloon-like cup that’s made of FDA-compliant silicone rubber, so they’re safe for direct contact with food. Unlike other more rigid lifters, these are designed to conform to irregular shapes for a secure hold. Use these lifters with compressed air. Also known as venturi devices, they generate suction without an installed vacuum system.

All of these lifters have a lightweight aluminum housing that withstands corrosion. The cup is secured to the housing with two stainless steel spring bands. The bands stand up to rust and can be easily removed to replace a worn cup. Inside the cup is a rubber cushion that protects items from damage if they come in contact with the housing as they are lifted. One replacement cup is included. These lifters also have a metal filter, which keeps contaminants from entering the vacuum passage.

Use the additional port on these lifters with a pressure transmitter (not included). Your transmitter will convert air pressure to an electrical signal for viewing air measurements on remote displays and programmable logic controllers (PLCs). You can also use the port to create a burst of air for removing debris in the vacuum passage or releasing items that didn’t drop when the vacuum stopped.

Metal-detectable lifters have a cup that contains metal additives that will set off metal detectors if the cup or any piece of it falls into your food line. Use them to help you comply with Hazard Analysis and Critical Control Point (HACCP) programs.

To connect these lifters to robot arms, drill holes in robot tool mounts to match the mounting holes on the lifter. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility. All of these mounts resist corrosion. Aluminum mounts are lightweight, helping your robot arm stay under its payload limit, or the total capacity a robot can lift. They’re also more machinable than stainless steel. 304 stainless steel mounts are often used in washdown environments, such as food-processing plants, since they won't corrode from frequent washdowns. They’re stronger than aluminum, but also heavier and less machinable.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Cup | Air Connection | End of Robot Arm | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Dia., mm | Ht., mm | O'all Ht., mm | Pipe Size | Thread Size | Thread Type | Gender | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Hole Thread Size (No. of) | Mount. Fasteners Included | Wt. | Each | |

Single Bellows Cup—For Smooth and Textured Surfaces | ||||||||||||||||

Blue Silicone Rubber | ||||||||||||||||

| 5.13 lbs. @ 27 in. of Hg | 25 in. of Hg | 0.5 scfm @ 45 psi | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 42.5 | 31 | 70 | __ | M5 | Metric | Female | 20 mm (ISO 20) | M4 (4) | No | 0.35 lbs. / 0.16 kg | 00000000 | 0000000 |

| 13 lbs. @ 27 in. of Hg | 25 in. of Hg | 0.9 scfm @ 45 psi | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 71 | 45 | 82 | 1/8 | __ | BSPT | Female | 25 mm (ISO 25) | M4 (4) | No | 0.75 lbs. / 0.34 kg | 00000000 | 00000000 |

Gray Silicone Rubber—Metal Detectable | ||||||||||||||||

| 5.93 lbs. @ 27 in. of Hg | 25 in. of Hg | 0.5 scfm @ 45 psi | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 42.5 | 31 | 70 | __ | M5 | Metric | Female | 20 mm (ISO 20) | M4 (4) | No | 0.35 lbs. / 0.16 kg | 00000000 | 000000 |

| 14.55 lbs. @ 27 in. of Hg | 25 in. of Hg | 0.9 scfm @ 45 psi | Bagged Material, Cardboard, Electronics, Food, Glass, Plastic, Sheet Metal | 71 | 45 | 82 | 1/8 | __ | BSPT | Female | 25 mm (ISO 25) | M4 (4) | No | 0.75 lbs. / 0.34 kg | 00000000 | 00000000 |

Robot Tool | End of Robot Arm (Bolt On) | |||||||

|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model Number) | Mount Type | Mounting Fasteners Included | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mounting Fasteners Included | Wt. | Max. Load Cap. | Each | |

Black Anodized Aluminum | ||||||||

| ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1520ID; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Omron (TM 5, 12, 14) Precise Automation (PAVP6; PF3400; PP100) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S; HC 10T; SIA 10D, 10F) | Blank | No | 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) 63 mm (ISO 63) | Yes | 0.4 lbs./ 0.18 kg | 110 lbs./ 50 kg | 0000000 | 0000000 |

Non-Contact Vacuum Lifters

Lift and move porous, uneven, and delicate items without damaging them. Unlike other vacuum lifters, which seal to the surface of your workpiece, these lifters pick up items without touching them. Also known as Bernoulli lifters, they use a compressed air source to create suction, so you don’t need a separate vacuum generator. They’re also low-maintenance—they don’t use vacuum cups, and the durable steel housing is built for a long service life.

If your workpiece is uneven, it may touch the lifter surface as it moves. To create a soft area for your object to touch, add anti-slip adapters to the lifter face. These rubber discs gently press against your workpiece, adding enough friction to keep it from slipping and dropping.

Capacity and air consumption are based on lifting a flat workpiece horizontally.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Lifters | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pad | Air Connection | Temp., °F | Anti-Slip Adapters | |||||||||||||

| Capacity @ 70 psi | Air Consumption @ 70 psi | For Use With | Dia., mm | Ht., mm | Bolt Circle Dia., mm | Wt. | Thread Size | Pipe Size | Thread Type | Gender | Min. | Max. | Each | Each | ||

For Oily, Smooth, and Textured Surfaces | ||||||||||||||||

Steel Pads | ||||||||||||||||

| 0.29 lbs. / 0.13 kg | 2.8 scfm | Electronics, Plastic | 20 | 16 | 15 | 0.03 lbs. / 0.01 kg | M5 | __ | Metric | Female | 32° | 140° | 0000000 | 0000000 | 0000000 | 000000 |

| 0.29 lbs. / 0.13 kg | 2.8 scfm | Electronics, Plastic | 20 | 16 | 15 | 0.03 lbs. / 0.01 kg | M5 | __ | NPS | Female | 32° | 140° | 0000000 | 000000 | 0000000 | 00000 |

| 1.15 lbs. / 0.52 kg | 4 scfm | Electronics, Plastic | 40 | 20 | 30 | 0.13 lbs. / 0.06 kg | __ | 1/8 | BSPT | Female | 32° | 140° | 0000000 | 000000 | 0000000 | 00000 |

| 1.15 lbs. / 0.52 kg | 4 scfm | Electronics, Plastic | 40 | 20 | 30 | 0.13 lbs. / 0.06 kg | __ | 1/8 | NPS | Female | 32° | 140° | 0000000 | 000000 | 0000000 | 00000 |

| 1.91 lbs. / 0.87 kg | 4.7 scfm | Electronics, Plastic | 60 | 20 | 30, 50, 50 | 0.23 lbs. / 0.1 kg | __ | 1/8 | BSPT | Female | 32° | 140° | 0000000 | 000000 | 0000000 | 00000 |

| 1.91 lbs. / 0.87 kg | 4.7 scfm | Electronics, Plastic | 60 | 20 | 30, 50, 50 | 0.23 lbs. / 0.1 kg | __ | 1/8 | NPS | Female | 32° | 140° | 0000000 | 000000 | 0000000 | 00000 |

| 5.51 lbs. / 2.5 kg | 8.6 scfm | Electronics, Plastic | 80 | 25 | 30, 70, 70 | 0.38 lbs. / 0.17 kg | __ | 1/4 | BSPT | Female | 32° | 140° | 0000000 | 000000 | 0000000 | 00000 |

| 5.51 lbs. / 2.5 kg | 8.6 scfm | Electronics, Plastic | 80 | 25 | 30, 70, 70 | 0.38 lbs. / 0.17 kg | __ | 1/4 | NPS | Female | 32° | 140° | 0000000 | 000000 | 0000000 | 00000 |

| 8.81 lbs. / 4 kg | 8.6 scfm | Electronics, Plastic | 100 | 25 | 30, 90, 90 | 0.51 lbs. / 0.23 kg | __ | 1/4 | BSPT | Female | 32° | 140° | 0000000 | 000000 | 0000000 | 00000 |

| 8.81 lbs. / 4 kg | 8.6 scfm | Electronics, Plastic | 100 | 25 | 30, 90, 90 | 0.51 lbs. / 0.23 kg | __ | 1/4 | NPS | Female | 32° | 140° | 0000000 | 000000 | 0000000 | 00000 |

Anti-Slip Adapters for Non-Contact Vacuum Lifters

Stick these adapters onto Non-Contact Vacuum Lifters to create a soft area for your workpiece to touch while it’s in motion. These rubber discs gently press against your object, adding enough friction to keep it from slipping and dropping. Choose an adapter that matches the manufacturer and model number of your vacuum lifter.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Temp., °F | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD, mm | ID, mm | Thickness, mm | Mount Type | For Use With | Min. | Max. | For Manufacturer (Series/Model No.) | Each | |

For Oily, Smooth, and Textured Surfaces | |||||||||

Buna-N Rubber | |||||||||

| 5 | __ | 0.5 | Adhesive Back | Electronics, Plastic | 32° | 140° | Convum (COP-20) | 0000000 | 000000 |

| 16 | 5 | 0.5 | Adhesive Back | Electronics, Plastic | 32° | 140° | Convum (COP-40) | 0000000 | 00000 |

| 18 | __ | 1 | Adhesive Back | Electronics, Plastic | 32° | 140° | Convum (COP-60) | 0000000 | 00000 |

| 35 | 18 | 1 | Adhesive Back | Electronics, Plastic | 32° | 140° | Convum (COP-80) | 0000000 | 00000 |

| 55 | 35 | 1 | Adhesive Back | Electronics, Plastic | 32° | 140° | Convum (COP-100) | 0000000 | 00000 |

Robot-Ready Vacuum Lifters for Large Surfaces

These large-surface lifters come with software, robot tool mounts, and connectors for quick setup and use with FANUC CRX robot arms. Using compressed air through multiple suction ports, they lift larger and heavier items than standard vacuum lifters. Also known as venturi devices, they generate suction without an installed vacuum system. To view data and adjust settings in a smartphone app, hold a phone that can read near-field communication (NFC) up to one of the NFC tags on these lifters. A digital display lets you read measurements while standing next to them.

These lifters have an IP40 rating, meaning that they keep out objects 1 mm or larger—such as wire—to protect their inner parts. They also meet ISO/TS 15066—with no pinch points or sharp edges, you can safely use them on robots that will be near people.

Lifters with cups grip irregularly shaped items better than lifters with a pad.

Lifters with a pad are better at lifting porous items than lifters with cups, and are also less likely to damage delicate surfaces.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Female Air Connection | End of Robot Arm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model No.) | Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Pipe Size | Thread Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Signal Output Type | Communication Standard | Specifications Met | Each | |

For Smooth and Textured Surfaces—Silicone Rubber Cups | |||||||||||||

Schmalz FXCB Series | |||||||||||||

| FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) | 18 lbs. @ 17.7 in. of Hg | 17.7 in. of Hg | 7.7 scfm @ 80 psi | Bagged Material, Cardboard, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 50 mm (ISO 50) | Yes | PNP | IO Link, NFC | ISO/TS 15066 | 0000000 | 000000000 |

Female Air Connection | End of Robot Arm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model No.) | Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Pipe Size | Thread Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Signal Output Type | Communication Standard | Specifications Met | Each | |

For Smooth and Textured Surfaces—EPDM Foam Pad | |||||||||||||

Schmalz FXCB Series | |||||||||||||

| FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) | 18 lbs. @ 17.7 in. of Hg | 17.7 in. of Hg | 7.7 scfm @ 80 psi | Bagged Material, Cardboard, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 50 mm (ISO 50) | Yes | PNP | IO Link, NFC | ISO/TS 15066 | 0000000 | 000000000 |

| Number of Bellows | Cup Dia., mm | Compressed Cup Ht., mm | Cup Ht., mm | Mount. Hole Dia., mm | Each | |

Silicone Rubber | ||||||

|---|---|---|---|---|---|---|

| 2 | 43.5 | 27 | 47 | 4.6 | 00000000 | 000000 |

Number of | |||||

|---|---|---|---|---|---|

| Columns | Rows | Lg., mm | Wd., mm | Each | |

EPDM Foam | |||||

| 15 | 3 | 300 | 130 | 00000000 | 0000000 |

Robot-Ready Vacuum Lifters

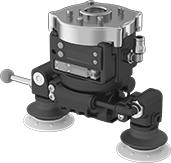

With robot tool mounts and connectors, these vacuum lifters come ready to attach to robot arms with standard ISO mounting hole patterns. Use them with compressed air to grip, lift, and move items with curves, angles, and varied heights. Also known as venturi devices, they generate suction without an installed vacuum system. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility.

Lifters and lifters with cups have two arms with vacuum cup connections. You can adjust the width of the arms to handle large items as well as tilt them to better grip uneven shapes. You can even remove an arm for applications that require only one cup. All of these lifters have a digital display for viewing the status of the lifter and controlling the vacuum. They’re protected from dust and water splashes. Lifters don’t include cups. Add vacuum cups that meet your specific needs. Lifters with cups include eight silicone and polyurethane rubber cups with different sizes and number of bellows. Cups with more bellows are better for handling items that have more variations in shape.

Lifters with a foam pad have an EPDM foam pad that’s soft enough to conform to items without damaging them. They’re best for delicate surfaces as well as porous surfaces where cups cannot obtain an airtight grip. They are not protected from dust and water splashes. Those with a sensor communicate the grip position of your lifter to a controller. They have LED status indicators, so you can quickly see the status of the lifters.

Lifters with PNP signal output communicate proximity with a positive signal, while those with NPN signal output send a negative signal.

UR+ certified lifters have been tested and approved to work seamlessly with Universal Robots (UR) arms. Plug the included software directly into your teach pendant to program the lifter.

Choose lifters with an additional port if you’d like to add a pressure transmitter (not included). Your transmitter will convert air pressure to an electrical signal for viewing air measurements on remote displays and programmable logic controllers (PLCs).

Optional sensors can be added to lifters with a foam pad for communicating the grip position to a controller. They require an A-code micro M12 power cord (sold separately).

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Female Air Connection | End of Robot Arm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model Number) | Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Pipe Size | Thread Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Signal Output Type | Each | |

For Smooth and Textured Surfaces | |||||||||||

With Additional Port | |||||||||||

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 31.5 mm (ISO 31.5) | No | NPN, PNP | 00000000 | 000000000 |

| ABB (IRB 1520ID) Yaskawa/Motoman (HC 10T; SIA 10D, 10F) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 63.5 mm (ISO 63) | No | NPN, PNP | 00000000 | 00000000 |

| ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 50 mm (ISO 50) | No | NPN, PNP | 00000000 | 00000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 40 mm (ISO 40) | No | NPN, PNP | 00000000 | 00000000 |

Female Air Connection | End of Robot Arm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model Number) | Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Pipe Size | Thread Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Signal Output Type | Each | |

For Smooth and Textured Surfaces—Polyurethane and Silicone Rubber Cups | |||||||||||

With Additional Port | |||||||||||

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 31.5 mm (ISO 31.5) | No | NPN, PNP | 00000000 | 000000000 |

| ABB (IRB 1520ID) Yaskawa/Motoman (HC 10T; SIA 10D, 10F) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 63.5 mm (ISO 63) | No | NPN, PNP | 00000000 | 00000000 |

| ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 50 mm (ISO 50) | No | NPN, PNP | 00000000 | 00000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 40 mm (ISO 40) | No | NPN, PNP | 00000000 | 00000000 |

Female Air Connection | End of Robot Arm | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model Number) | Pad Ht., mm | Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Pipe Size | Thread Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Signal Output Type | Each | |

For Smooth and Textured Surfaces—EPDM Foam Pad | ||||||||||||

With Additional Port | ||||||||||||

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 10 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 31.5 mm (ISO 31.5) | No | __ | 00000000 | 000000000 |

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 20 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 31.5 mm (ISO 31.5) | No | __ | 00000000 | 00000000 |

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 30 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 31.5 mm (ISO 31.5) | No | __ | 00000000 | 00000000 |

| ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2) | 10 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 50 mm (ISO 50) | No | __ | 00000000 | 00000000 |

| ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2) | 20 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 50 mm (ISO 50) | No | __ | 00000000 | 00000000 |

| ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2) | 30 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 50 mm (ISO 50) | No | __ | 00000000 | 00000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 10 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 40 mm (ISO 40) | No | __ | 00000000 | 00000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 20 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 40 mm (ISO 40) | No | __ | 00000000 | 00000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 30 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 40 mm (ISO 40) | No | __ | 00000000 | 00000000 |

With Sensor | ||||||||||||

| Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 10 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 50 mm (ISO 50) | No | NPN, PNP | 00000000 | 00000000 |

| Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 20 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 50 mm (ISO 50) | No | NPN, PNP | 00000000 | 00000000 |

| Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 30 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 50 mm (ISO 50) | No | NPN, PNP | 00000000 | 00000000 |

| Output Voltage | Connection Type | Gender | Housing Thread Size | Number of Poles | Each | |

| 1-5V DC | Nano M8 | Male | M8 | 8 | 00000000 | 0000000 |

Vacuum Lifters

These all-in-one lifters include a rubber vacuum cup and a device to generate suction without an installed vacuum system. Also known as venturi devices, they connect to any compressed air source.

Warning: Never use to lift people or items over people.

Lifters | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Air Connection | Temp., °F | Replacement Cups | |||||||||||||||

| Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Surface Type | For Use With | Cup Color | Cup Dia. | Ht. | Wd. | Housing Material | Pipe Size | Thread Type | Gender | Min. | Max. | Each | Each | ||

Flat Cup—For Smooth Surfaces | ||||||||||||||||||

Polyurethane Rubber | ||||||||||||||||||

| 21 lbs. @ 27 in. of Hg | 27 in. of Hg | 1 scfm @ 45 psi | Flat | Sheet Metal, Plastic | Green | 1.97" | 2.11" | 4 3/8" | Aluminum | 1/8 | BSPP | Female | 50° | 120° | 0000000 | 0000000 | 0000000 | 000000 |

| 55 lbs. @ 27 in. of Hg | 27 in. of Hg | 1 scfm @ 45 psi | Flat | Sheet Metal, Plastic | Green and Yellow | 3.03" | 1 3/4" | 4 3/8" | Aluminum | 1/8 | BSPP | Female | 50° | 120° | 0000000 | 000000 | 0000000 | 00000 |

Single Bellows Cup—For Smooth and Textured Surfaces | ||||||||||||||||||

Polyurethane Rubber | ||||||||||||||||||

| 41 lbs. @ 27 in. of Hg | 27 in. of Hg | 1 scfm @ 45 psi | Flat, Angled, Varied Height | Sheet Metal, Plastic | Green and Yellow | 3.11" | 2.71" | 4 3/8" | Aluminum | 1/8 | BSPP | Female | 50° | 120° | 0000000 | 000000 | 0000000 | 00000 |

Vacuum Lifters for Large Surfaces

With multiple suction ports, these lifters can grip, lift, and move large items with a variety of surfaces. The suction ports come installed on a single manifold, so there’s no need to build your own platform. All of these lifters are designed for use with compressed air, which the manifold distributes to the ports. Also known as venturi devices, they generate suction without an installed vacuum system.

These lifters have a lightweight aluminum housing that withstands corrosion. T-slotted mounting rails on the housing make it easy to connect these lifters to T-slotted framing components that are often used with robot-arm tools. A metal filter on all the vacuum ports keeps debris from entering the vacuum passage.

Use the additional port on these lifters with a pressure transmitter (not included). Your transmitter will convert air pressure to an electrical signal for viewing air measurements on remote displays and programmable logic controllers (PLCs).

Lifters with cups have flexible accordion-style cups that are best for gripping irregular shapes. Those with more bellows are better for handling items that have more variations in shape. Made of Buna-N rubber, all of the cups stand up to abrasion and oil.

Lifters with a foam pad have an EPDM foam pad that’s soft enough to conform to items without damaging them. They’re best for delicate surfaces as well as porous surfaces where cups cannot obtain an airtight grip.

Use the optional robot adapter plates to attach these lifters to robot arms with ISO mounting patterns. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Vacuum Lifters | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of | O'all | Female Air Connection | Replacement Cups | |||||||||||||||

| Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | Columns | Rows | Bellows | For Use With | Cup Dia., mm | Lg., mm | Wd., mm | Ht., mm | Pipe Size | Thread Type | For T-Slot Wd. | Wt. | Each | Each | ||

Single Bellows Cup—For Smooth and Textured Surfaces | ||||||||||||||||||

Black Buna-N Rubber | ||||||||||||||||||

| 180.79 lbs. @ 24 in. of Hg | 26 in. of Hg | 4.5 scfm @ 70 psi | 8 | 5 | 1 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 20 | 280 | 118 | 104 | 1/4 | BSPP | 8 mm | 5.3 lbs. / 2.4 kg | 00000000 | 000000000 | 00000000 | 00000 |

| 293.78 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 12 | 5 | 1 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 20 | 416 | 118 | 104 | 1/4 | BSPP | 8 mm | 7.5 lbs. / 3.4 kg | 00000000 | 00000000 | 00000000 | 0000 |

| 316.31 lbs. @ 24 in. of Hg | 26 in. of Hg | 4.5 scfm @ 70 psi | 5 | 3 | 1 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 40 | 280 | 118 | 115 | 1/4 | BSPP | 8 mm | 5.3 lbs. / 2.4 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 406.77 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 16 | 5 | 1 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 20 | 560 | 118 | 104 | 1/4 | BSPP | 8 mm | 9.7 lbs. / 4.4 kg | 00000000 | 00000000 | 00000000 | 0000 |

| 474.46 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 7 | 3 | 1 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 40 | 416 | 118 | 115 | 1/4 | BSPP | 8 mm | 7.3 lbs. / 3.3 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 655.21 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 10 | 3 | 1 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 40 | 560 | 118 | 115 | 1/4 | BSPP | 8 mm | 9.5 lbs. / 4.3 kg | 00000000 | 00000000 | 00000000 | 00000 |

Multiple Bellows Cup—For Smooth and Textured Surfaces | ||||||||||||||||||

Black Buna-N Rubber | ||||||||||||||||||

| 180.79 lbs. @ 24 in. of Hg | 26 in. of Hg | 4.5 scfm @ 70 psi | 8 | 5 | 2 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 20 | 280 | 118 | 110 | 1/4 | BSPP | 8 mm | 5.3 lbs. / 2.4 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 293.78 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 12 | 5 | 2 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 20 | 416 | 118 | 110 | 1/4 | BSPP | 8 mm | 7.5 lbs. / 3.4 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 316.31 lbs. @ 24 in. of Hg | 26 in. of Hg | 4.5 scfm @ 70 psi | 5 | 3 | 2 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 40 | 280 | 118 | 132 | 1/4 | BSPP | 8 mm | 5.5 lbs. / 2.5 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 406.77 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 16 | 5 | 2 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 20 | 560 | 118 | 110 | 1/4 | BSPP | 8 mm | 9.7 lbs. / 4.4 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 474.46 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 7 | 3 | 2 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 40 | 416 | 118 | 132 | 1/4 | BSPP | 8 mm | 7.7 lbs. / 3.5 kg | 00000000 | 00000000 | 00000000 | 00000 |

| 655.21 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 10 | 3 | 2 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 40 | 560 | 118 | 132 | 1/4 | BSPP | 8 mm | 9.9 lbs. / 4.5 kg | 00000000 | 00000000 | 00000000 | 00000 |

Vacuum Lifters | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of | O'all | Female Air Connection | Replacement Pads | ||||||||||||||

| Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | Columns | Rows | For Use With | Pad Ht., mm | Lg., mm | Wd., mm | Ht., mm | Pipe Size | Thread Type | For T-Slot Wd. | Wt. | Each | Each | ||

For Smooth and Textured Surfaces | |||||||||||||||||

Black EPDM Foam | |||||||||||||||||

| 158.18 lbs. @ 24 in. of Hg | 26 in. of Hg | 4.5 scfm @ 70 psi | 5 | 3 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 20 | 280 | 118 | 90 | 1/4 | BSPP | 8 mm | 4.6 lbs. / 2.1 kg | 00000000 | 000000000 | 00000000 | 0000000 |

| 180.79 lbs. @ 24 in. of Hg | 26 in. of Hg | 4.5 scfm @ 70 psi | 8 | 5 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 20 | 280 | 118 | 90 | 1/4 | BSPP | 8 mm | 4.6 lbs. / 2.1 kg | 00000000 | 00000000 | 00000000 | 000000 |

| 237.29 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 7 | 3 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 20 | 416 | 118 | 90 | 1/4 | BSPP | 8 mm | 6.2 lbs. / 2.8 kg | 00000000 | 00000000 | 00000000 | 000000 |

| 293.78 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 12 | 5 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 20 | 416 | 118 | 90 | 1/4 | BSPP | 8 mm | 6.4 lbs. / 2.9 kg | 00000000 | 00000000 | 00000000 | 000000 |

| 310.73 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 10 | 3 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 20 | 560 | 118 | 90 | 1/4 | BSPP | 8 mm | 5.3 lbs. / 3.6 kg | 00000000 | 00000000 | 00000000 | 000000 |

| 406.77 lbs. @ 24 in. of Hg | 26 in. of Hg | 8.4 scfm @ 70 psi | 16 | 5 | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 20 | 560 | 118 | 90 | 1/4 | BSPP | 8 mm | 8.2 lbs. / 3.7 kg | 00000000 | 00000000 | 00000000 | 000000 |

| For Robot Arm Manufacturer (Series/Model Number) | Bolt Circle Dia. (Mounting Hole Pattern Compatibility) | Bolt Hole Thread Size (No. of) | Length, mm | Width, mm | Height, mm | Each | |

Aluminum | |||||||

|---|---|---|---|---|---|---|---|

| Denso (VM 6083, 60B1) FANUC (M-10iA; M-20iA; M20-iB; M-710iC) Kawasaki (RS 010N, 010L, 015X, 020N) Mitsubishi (RV 13F, 13FL, 13FR, 13FRL, 20F, 20FR) Toshiba (TV 1000H) Yaskawa/Motoman (HP 20F; MH 50II-20) | 40 mm (ISO 40) 63 mm (ISO 63) 90 mm (ISO 90) | M6 (4, 7) M6 (4) M10 (10) | 125 | 125 | 25 | 00000000 | 0000000 |

| FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; M-710iC; R-1000iA) Kawasaki (RS/RD 030N, 050N, 080N) Mitsubishi (RV 35F, 50F, 70F) Toshiba (TVM 900, 1200, 1500) Universal Robots (UR3, UR3e, UR5, UR5e, UR10, UR10e) | 31.5 mm (ISO 31.5) 50 mm (ISO 50) 80 mm (ISO 80) 100 mm (ISO 100) | M6 (4) M6 (4) M8 (6) M10 (10) | 125 | 125 | 25 | 00000000 | 000000 |

Vacuum Lifters for Curved and Irregularly Shaped Items

The flexible balloon-like cup on these lifters use compressed air to grip, lift, and move items with curves, angles, and varied heights. Unlike other more rigid lifters, these are designed to conform to irregular shapes for a secure hold. Also known as venturi devices, they generate suction without an installed vacuum system.

These lifters have a lightweight aluminum housing that withstands corrosion and a Buna-N rubber cup that resists abrasion and oil. The cup is secured to the housing with two stainless steel spring bands. The bands won’t rust and can be easily removed to replace a worn cup. Inside the cup is a rubber cushion that protects items from damage if they come in contact with the housing as they are lifted. One replacement cup is included. These lifters also have a metal filter, which keeps contaminants from entering the vacuum passage.

Use the additional port on these lifters with a pressure transmitter (not included). Your transmitter will convert air pressure to an electrical signal for viewing air measurements on remote displays and programmable logic controllers (PLCs). You can also use the port to create a burst of air for removing debris in the vacuum passage or releasing items that didn’t drop when the vacuum stopped.

To connect these lifters to robot arms, drill holes in robot tool mounts to match the mounting holes on the lifter. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility. All of these mounts resist corrosion. Aluminum mounts are lightweight, helping your robot arm stay under its payload limit, or the total capacity a robot can lift. They’re also more machinable than stainless steel. 304 stainless steel mounts are often used in washdown environments, such as food-processing plants, since they won't corrode from frequent washdowns. They’re stronger than aluminum, but also heavier and less machinable.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Cup | Air Connection | End of Robot Arm | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Dia., mm | Ht., mm | O'all Ht., mm | Pipe Size | Thread Size | Thread Type | Gender | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Hole Thread Size (No. of) | Mount. Fasteners Included | Wt. | Each | |

Single Bellows Cup—For Smooth and Textured Surfaces | ||||||||||||||||

Black Buna-N Rubber | ||||||||||||||||

| 6.72 lbs. @ 27 in. of Hg | 25 in. of Hg | 0.5 scfm @ 45 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 42.5 | 31 | 70 | __ | M5 | Metric | Female | 20 mm (ISO 20) | M4 (4) | No | 0.35 lbs. / 0.16 kg | 00000000 | 0000000 |

| 16.14 lbs. @ 27 in. of Hg | 25 in. of Hg | 0.9 scfm @ 45 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 71 | 45 | 82 | 1/8 | __ | BSPT | Female | 25 mm (ISO 25) | M4 (4) | No | 0.75 lbs. / 0.34 kg | 00000000 | 00000000 |

Robot Tool | End of Robot Arm (Bolt On) | |||||||

|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model Number) | Mount Type | Mount. Fasteners Included | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Wt. | Max. Load Cap. | Each | |

Black Anodized Aluminum | ||||||||

| ABB (IRB 360 6/1600, 8/1130; IRB 120; IRB 140; IRB 1200; IRB 1410; IRB 1520ID; IRB 1600; IRB 2400; IRB 2600) FANUC (CR 4iA, 7iA; CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA; LR Mate 200iD/7L; M-20 iA) KUKA Robotics (KR 10 R1100-2) Omron (TM 5, 12, 14) Precise Automation (PAVP6; PF3400; PP100) Productive Robotics (OB7) Staubli (TX2 90) Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S; HC 10T; SIA 10D, 10F) | Blank | No | 31.5 mm (ISO 31.5) 40 mm (ISO 40) 50 mm (ISO 50) 63 mm (ISO 63) | Yes | 0.4 lbs./ 0.18 kg | 110 lbs./ 50 kg | 0000000 | 0000000 |

Robot-Ready Electric Vacuum Lifters

Pick up and move items using suction created by electricity—a good option when compressed air isn't available. Choose from complete kits that include everything you need to connect to your robot and start moving items, or individual components to build your own assembly and replace parts.

Warning: Never use to lift people or items over people.

For technical drawings and 3-D models, click on a part number.

Lifter kits include a vacuum generator, cables, and cups. Check the status of your lifter and adjust the vacuum levels right on the lifter. The integrated vacuum sensor sends information about an item's position to your controller, as well as triggers LED status indicators that show whether the arm is picking it up or releasing it. These lifters have near-field communication (NFC), so you can use a smartphone to read data, instructions, and error messages when you’re near the arm. Lifters don’t have pinch points or sharp edges, so you can use them on robots that will be near people. They help you meet ISO/TS 15066 international safety standards. Rated IP40, they're protected from wires and other objects 1 mm or larger. They're configured to work with specific robot arms, so choose the kit that matches your arm's manufacturer and model. Lifters for FANUC CRX arms are FANUC approved, and lifters for Universal Robots (UR) arms are UR+ certified, so they've been tested to work seamlessly. Install the included software directly into your controller to program the lifter.

Use standard vacuum lifter kits to move small- and medium-sized items with curves, angles, and varied heights. They share information with your controller using both discrete I/O and IO-link communication. Discrete I/O communication is a wired connection between the lifter and the controller, while IO-link connects to an IO-link controller, which can communicate remotely over multiple networks. This remote connection shares more data than discrete I/O, so you can monitor energy use and predict when you'll need maintenance. Swap out or change the configuration using the parts listed here.

Miniature vacuum lifter kits are smaller and lighter than standard kits, so they won't weigh down your robot arm. However, the small size means they create less suction, so they're limited to smaller, lighter items than the standard kits. They use discrete I/O to communicate directly with your controller. Note: the additional parts listed here are not compatible with these kits.

O'all | Flat Cup | Single-Bellow Cup | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model No.) | Cap. @ Vacuum | Max. Vacuum, in. of Hg | Dia., mm | Ht., mm | Bolt Circle Dia., mm | Wt. | For Surface Type | For Use With | Cup Dia., mm | Cup Ht., mm | For Surface Type | For Use With | Cup Dia., mm | Cup Ht., mm | Each | |

Standard Vacuum Lifter Kits with LED Display—Schmalz ECBPi Series | ||||||||||||||||

8-Pole Micro M12 Plug—24V DC | ||||||||||||||||

| Doosan (M0609, M0617, M1013, M1509) | 22 lbs. @ 17 in. of Hg | 17 | 151.5 | 188.8 | __ | 2.6 lbs./ 1.18 kg | Curved Flat | Cardboard Metal Plastic | 42 | 15 | Angled Curved Flat | Cardboard Metal Plastic | 42 | 30 | 0000000 | 000000000 |

| FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) | 22 lbs. @ 17 in. of Hg | 17 | 151.5 | 188.8 | __ | 2.6 lbs./ 1.18 kg | Curved Flat | Cardboard Metal Plastic | 42 | 15 | Angled Curved Flat | Cardboard Metal Plastic | 42 | 30 | 0000000 | 00000000 |

| FANUC (CR 4ia, 7ia; LR Mate) | 22 lbs. @ 17 in. of Hg | 17 | 151.5 | 188.8 | __ | 2.8 lbs./ 1.27 kg | Curved Flat | Cardboard Metal Plastic | 42 | 15 | Angled Curved Flat | Cardboard Metal Plastic | 42 | 30 | 0000000 | 00000000 |

| KUKA Robotics (iiwa 7, 14) | 22 lbs. @ 17 in. of Hg | 17 | 151.5 | 188.8 | __ | 2.6 lbs./ 1.18 kg | Curved Flat | Cardboard Metal Plastic | 42 | 15 | Angled Curved Flat | Cardboard Metal Plastic | 42 | 30 | 0000000 | 00000000 |

| Omron (TM 5, 12, 14) | 22 lbs. @ 17 in. of Hg | 17 | 151.5 | 202.6 | __ | 2.9 lbs./ 1.32 kg | Curved Flat | Cardboard Metal Plastic | 42 | 15 | Angled Curved Flat | Cardboard Metal Plastic | 42 | 30 | 0000000 | 00000000 |

| Techman (TM5 700, 900) | 22 lbs. @ 17 in. of Hg | 17 | 151.5 | 202.6 | __ | 2.9 lbs./ 1.32 kg | Curved Flat | Cardboard Metal Plastic | 42 | 15 | Angled Curved Flat | Cardboard Metal Plastic | 42 | 30 | 0000000 | 00000000 |

| Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 22 lbs. @ 17 in. of Hg | 17 | 151.5 | 188.8 | __ | 2.6 lbs./ 1.18 kg | Curved Flat | Cardboard Metal Plastic | 42 | 15 | Angled Curved Flat | Cardboard Metal Plastic | 42 | 30 | 0000000 | 00000000 |

| Yaskawa/Motoman (HC10DT) | 22 lbs. @ 17 in. of Hg | 17 | 151.5 | 205.2 | __ | 3 lbs./ 1.36 kg | Curved Flat | Cardboard Metal Plastic | 42 | 15 | Angled Curved Flat | Cardboard Metal Plastic | 42 | 30 | 0000000 | 00000000 |

Miniature Vacuum Lifter Kits with LED Scale Display—Schmalz ECBPM Series | ||||||||||||||||

8-Pole M8 Plug—24V DC | ||||||||||||||||

| FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) | 4.4 lbs. @ 17 in. of Hg | 17 | 63 | 112.4 | 50 | 1.1 lbs./ 0.5 kg | Flat | Plastic | 20 | 12.8 | Angled Curved Flat | Cardboard Metal Plastic | 32 | 23 | 0000000 | 00000000 |

| Omron (TM5 700, 900) | 4.4 lbs. @ 17 in. of Hg | 17 | 63 | 112.4 | 50 | 1.1 lbs./ 0.5 kg | Flat | Plastic | 20 | 12.8 | Angled Curved Flat | Cardboard Metal Plastic | 32 | 23 | 0000000 | 00000000 |

| Techman (TM5 700, 900) | 4.4 lbs. @ 17 in. of Hg | 17 | 63 | 112.4 | 50 | 1.1 lbs./ 0.5 kg | Flat | Plastic | 20 | 12.8 | Angled Curved Flat | Cardboard Metal Plastic | 32 | 23 | 0000000 | 00000000 |

| Universal Robots (UR3; UR3e; UR5; UR5e) | 4.4 lbs. @ 17 in. of Hg | 17 | 63 | 112.4 | 50 | 1.1 lbs./ 0.5 kg | Flat | Plastic | 20 | 12.8 | Angled Curved Flat | Cardboard Metal Plastic | 32 | 23 | 0000000 | 00000000 |

| Universal Robots (UR10; UR10e; UR16; UR16e) | 4.4 lbs. @ 17 in. of Hg | 17 | 63 | 112.4 | 50 | 1.1 lbs./ 0.5 kg | Flat | Plastic | 20 | 12.8 | Angled Curved Flat | Cardboard Metal Plastic | 32 | 23 | 0000000 | 00000000 |

Cup assemblies connect to the cup mount. Choose the number of cups on the assembly based on the items you're lifting. All assemblies include two styles of cups: flat cups work well with flat materials such as metal and cardboard, and cups with bellows that give you a tight hold on uneven workpieces. When your vacuum cups become worn or damaged, choose from our selection of vacuum cups.

Flat Cup | Single-Bellow Cup | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cup Configuration | Cap. @ Vacuum | Wt. | For Surface Texture | For Surface Type | For Use With | Cup Dia., mm | Cup Ht., mm | For Surface Texture | For Surface Type | For Use With | Cup Dia., mm | Cup Ht, mm | Temp. Range, °F | Each | |

For Schmalz ECBPi, VEE Series | |||||||||||||||

Polyurethane Rubber Cups with Quick-Release Clamp | |||||||||||||||

| 1-Cup | 22 lbs. @ 17 in. of Hg | 0.57 lbs. / 0.26 kg | Smooth | Curved Flat | Cardboard Metal Plastic | 42 | 15 | Smooth | Angled Curved Flat | Cardboard Metal Plastic | 42 | 30 | -10° to 175° | 00000000 | 0000000 |

| 2-Cup | 22 lbs. @ 17 in. of Hg | 0.86 lbs. / 0.39 kg | Smooth | Curved Flat | Cardboard Metal Plastic | 42 | 15 | Smooth | Angled Curved Flat | Cardboard Metal Plastic | 42 | 30 | -10° to 175° | 00000000 | 000000 |

| 4-Cup | 22 lbs. @ 17 in. of Hg | 1.2 lbs. / 0.55 kg | Smooth | Curved Flat | Cardboard Metal Plastic | 42 | 15 | Smooth | Angled Curved Flat | Cardboard Metal Plastic | 42 | 30 | -10° to 175° | 00000000 | 00000000 |

| Sensor Response Time, ms | Mounting Fasteners Included | Temp. Range, °F | Environmental Rating | Includes | Specifications Met | Environment | Each | |

Polyurethane Foam | ||||||||

|---|---|---|---|---|---|---|---|---|

| 9 | Yes | 40° to 100° | IP50 | One Controller-to-Padding Cable (5 m Lg), One Padding-to-Padding Cable (400 mm Lg), Safety Padding Controller | ISO/TS 15066, ISO 13849-1 PLe, IEC 62061, TUV Rheinland Certified, C-TUV Rheinland Certified, UL 94 V-2, CE Marked | Dusty | 00000000 | 000000000 |