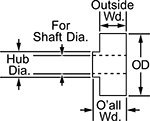

T Series Timing Belt Pulleys

Made of aluminum, these pulleys have good corrosion resistance. The teeth match up with the grooves along the inside diameter of a timing belt in order to move components forward or backward. Select a pulley with a maximum belt width that’s the same or larger than your timing belt width. Pulleys without a shaft diameter have a pilot bore, so you can customize them to your needs.

For technical drawings and 3-D models, click on a part number.

| OD, mm | Number of Teeth | Pitch, mm | Bore Type | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Material | Hub Dia., mm | Each | |

For 16 mm Max. Belt Wd. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 42 | 12 | 10 | Plain | 16 | 21 | 31 | 38.35 | 2 | Machined | Aluminum | 28 | 0000000 | 000000 |

| 48 | 14 | 10 | Plain | 16 | 21 | 31 | 44.7 | 2 | Machined | Aluminum | 32 | 0000000 | 00000 |

For 25 mm Max. Belt Wd. | |||||||||||||

| 42 | 12 | 10 | Plain | 25 | 30 | 40 | 38.35 | 2 | Machined | Aluminum | 28 | 0000000 | 00000 |

| 51 | 15 | 10 | Plain | 25 | 30 | 40 | 47.9 | 2 | Machined | Aluminum | 32 | 0000000 | 00000 |

| 60 | 18 | 10 | Plain | 25 | 30 | 40 | 57.45 | 2 | Machined | Aluminum | 40 | 0000000 | 00000 |

| 66 | 19 | 10 | Plain | 25 | 30 | 40 | 60.6 | 2 | Machined | Aluminum | 44 | 0000000 | 00000 |

| 66 | 20 | 10 | Plain | 25 | 30 | 40 | 63.8 | 2 | Machined | Aluminum | 46 | 0000000 | 00000 |

| 75 | 22 | 10 | Plain | 25 | 30 | 40 | 70.15 | 2 | Machined | Aluminum | 52 | 0000000 | 00000 |

| 83 | 24 | 10 | Plain | 25 | 30 | 40 | 76.55 | 2 | Machined | Aluminum | 58 | 0000000 | 00000 |

| 93 | 28 | 10 | Plain | 25 | 30 | 40 | 89.25 | 2 | Machined | Aluminum | 60 | 0000000 | 00000 |

| 97 | 30 | 10 | Plain | 25 | 30 | 40 | 96.65 | 2 | Machined | Aluminum | 60 | 0000000 | 000000 |

| 120 | 36 | 10 | Plain | 25 | 30 | 40 | 114.75 | 2 | Machined | Aluminum | 70 | 0000000 | 000000 |

For 50 mm Max. Belt Wd. | |||||||||||||

| 60 | 18 | 10 | Plain | 50 | 56 | 66 | 57.45 | 2 | Machined | Aluminum | 40 | 0000000 | 00000 |

| 66 | 19 | 10 | Plain | 50 | 56 | 66 | 60.65 | 2 | Machined | Aluminum | 44 | 0000000 | 00000 |

| 83 | 24 | 10 | Plain | 50 | 56 | 66 | 76.55 | 2 | Machined | Aluminum | 58 | 0000000 | 000000 |

| 87 | 26 | 10 | Plain | 50 | 56 | 66 | 82.9 | 2 | Machined | Aluminum | 60 | 0000000 | 000000 |

| 97 | 30 | 10 | Plain | 50 | 56 | 66 | 95.65 | 2 | Machined | Aluminum | 60 | 0000000 | 000000 |

| 106 | 32 | 10 | Plain | 50 | 56 | 66 | 102 | 2 | Machined | Aluminum | 65 | 0000000 | 000000 |

| 120 | 36 | 10 | Plain | 50 | 56 | 66 | 114.75 | 2 | Machined | Aluminum | 70 | 0000000 | 000000 |

| 150.95 | 48 | 10 | Plain | __ | 56 | 66 | 152.95 | __ | Machined | Aluminum | 95 | 0000000 | 000000 |

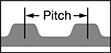

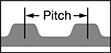

T Series Dust-Free Timing Belts

Belts are abrasion-resistant urethane, so they don’t create dust while they run. They have steel reinforcement, which has very high strength, low stretch, and excellent shock resistance.

For technical drawings and 3-D models, click on a part number.

| Belt Trade Number | Outer Circle, mm | Number of Teeth | Pitch, mm | Material | Color | Temperature Range, °F | Each | |

16 mm Wd. | ||||||||

|---|---|---|---|---|---|---|---|---|

| T10-320-16 | 320 | 32 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 000000 |

| T10-340-16 | 340 | 34 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-370-16 | 370 | 37 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-390-16 | 390 | 39 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-400-16 | 400 | 40 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-410-16 | 410 | 41 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-440-16 | 440 | 44 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-450-16 | 450 | 45 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-460-16 | 460 | 46 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-480-16 | 480 | 48 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-510-16 | 510 | 51 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-530-16 | 530 | 53 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-540-16 | 540 | 54 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-550-16 | 550 | 55 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-560-16 | 560 | 56 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-580-16 | 580 | 58 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-600-16 | 600 | 60 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

25 mm Wd. | ||||||||

| T10-320-25 | 320 | 32 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-340-25 | 340 | 34 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-370-25 | 370 | 37 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-390-25 | 390 | 39 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-400-25 | 400 | 40 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-410-25 | 410 | 41 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-440-25 | 440 | 44 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-450-25 | 450 | 45 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-460-25 | 460 | 46 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-480-25 | 480 | 48 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-510-25 | 510 | 51 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-530-25 | 530 | 53 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-540-25 | 540 | 54 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-550-25 | 550 | 55 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-560-25 | 560 | 56 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-580-25 | 580 | 58 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |

| T10-600-25 | 600 | 60 | 10 | Urethane | Gray | -10° to 175° | 0000000 | 00000 |