High-Strength Corrosion-Resistant HTD Timing Belt Pulleys

Move belts forward and backward or stop and start them in precise positions, especially in areas where rust is a concern. The curved teeth on these high-torque drive (HTD) pulleys have more surface contact with belts than traditional trapezoidal teeth, which allows you to apply more torque without damaging belts. These teeth fit together seamlessly to prevent backlash, or unwanted movement of the belt on the pulley, for a smooth, quiet cycle. These pulleys are often used in 3D printing, machine tool drives, robotics, and other applications where precision is essential. They are also known as curvilinear belt pulleys.

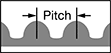

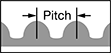

Pair pulleys with an HTD timing belt that has the same pitch. The width of your belt should not be larger than the maximum belt width listed.

Aluminum pulleys will not rust in damp or humid environments, but water left on the surface will cause them to corrode. Stainless steel pulleys can be wetted repeatedly without rusting or staining.

Bushing-mount pulleys grip the shaft more securely than press-fit pulleys, but require a quick-disconnect (QD) bushing or a split-tapered bushing (not included).

For technical drawings and 3-D models, click on a part number.

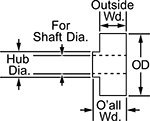

| OD, mm | Number of Teeth | Pitch, mm | For Shaft Dia. | Bore Type | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Hub Dia., mm | Manufacturer Series | Each | |

For 6 mm Max. Belt Wd. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 13.9 | 16 | 2 | 5mm | Finished | 7 | 8.2 | 15.5 | 9.68 | 1 | Machined | 13.9 | Gates PowerGrip 2GT | 0000000 | 00000 |

| 15 | 20 | 2 | 5mm | Finished | 7 | 8.2 | 16 | 12.22 | 1 | Machined | 15 | Gates PowerGrip 2GT | 0000000 | 0000 |

| 18.03 | 16 | 3 | 3/16" | Finished | 7.11 | 9.36 | 14.53 | 15.29 | 2 | Machined | 18.03 | __ | 00000000 | 00000 |

| 20.06 | 18 | 3 | 1/4" | Finished | 7.11 | 9.8 | 17.55 | 17.2 | 2 | Machined | 11.23 | __ | 00000000 | 00000 |

| 22.73 | 20 | 3 | 1/4" | Finished | 7.11 | 9.8 | 17.55 | 19.1 | 2 | Machined | 12.7 | __ | 00000000 | 00000 |

| 26.04 | 24 | 3 | 1/4" | Finished | 7.11 | 9.8 | 17.55 | 22.91 | 2 | Machined | 15.88 | __ | 00000000 | 00000 |

| 29.79 | 28 | 3 | 1/4" | Finished | 7.11 | 9.8 | 17.55 | 26.75 | 2 | Machined | 17.81 | __ | 00000000 | 00000 |

| 33.6 | 32 | 3 | 1/4" | Finished | 7.11 | 9.8 | 17.55 | 30.56 | 2 | Machined | 21.62 | __ | 00000000 | 00000 |

| 37.41 | 36 | 3 | 1/4" | Finished | 7.11 | 10.34 | 18.11 | 34.37 | 2 | Machined | 25.4 | __ | 00000000 | 00000 |

| 41.28 | 40 | 3 | 1/4" | Finished | 7.11 | 10.34 | 18.11 | 38.2 | 2 | Machined | 29.21 | __ | 00000000 | 00000 |

For 9 mm Max. Belt Wd. | ||||||||||||||

| 15 | 20 | 2 | 5mm | Finished | 11 | 12.2 | 20 | 12.22 | 1 | Machined | 15 | Gates PowerGrip 2GT | 0000000 | 0000 |

| 18.03 | 16 | 3 | 3/16" | Finished | 10.16 | 12.38 | 17.55 | 15.29 | 2 | Machined | 18.03 | __ | 00000000 | 00000 |

| 20.07 | 18 | 3 | 1/4" | Finished | 10.16 | 12.85 | 20.62 | 17.2 | 2 | Machined | 11.23 | __ | 00000000 | 00000 |

| 22.73 | 20 | 3 | 1/4" | Finished | 10.16 | 12.85 | 20.62 | 19.1 | 2 | Machined | 12.7 | __ | 00000000 | 00000 |

| 26.04 | 24 | 3 | 1/4" | Finished | 10.16 | 12.85 | 20.62 | 22.91 | 2 | Machined | 15.88 | __ | 00000000 | 00000 |

| 27.79 | 16 | 5 | 1/4" | Finished | 11.68 | 13.89 | 20.24 | 25.48 | 2 | Machined | 14.3 | __ | 00000000 | 00000 |

| 29.79 | 28 | 3 | 1/4" | Finished | 10.16 | 12.85 | 20.62 | 26.75 | 2 | Machined | 17.81 | __ | 00000000 | 00000 |

| 31.75 | 18 | 5 | 1/4" | Finished | 11.68 | 13.89 | 20.24 | 28.65 | 2 | Machined | 17.45 | __ | 00000000 | 00000 |

| 33.6 | 32 | 3 | 1/4" | Finished | 10.16 | 12.85 | 20.62 | 30.56 | 2 | Machined | 21.62 | __ | 00000000 | 00000 |

| 34.93 | 20 | 5 | 1/4" | Finished | 11.68 | 13.72 | 20.07 | 31.83 | 2 | Machined | 20.62 | __ | 00000000 | 00000 |

| 37.41 | 36 | 3 | 1/4" | Finished | 10.16 | 13.39 | 21.16 | 34.37 | 2 | Machined | 25.4 | __ | 00000000 | 00000 |

| 41.28 | 24 | 5 | 1/4" | Finished | 11.68 | 13.72 | 21.64 | 38.2 | 2 | Machined | 25.4 | __ | 00000000 | 00000 |

| 41.28 | 40 | 3 | 1/4" | Finished | 10.16 | 13.39 | 21.16 | 38.2 | 2 | Machined | 29.21 | __ | 00000000 | 00000 |

| 47.63 | 28 | 5 | 1/4" | Finished | 11.68 | 13.72 | 21.64 | 44.55 | 2 | Machined | 30.15 | __ | 00000000 | 00000 |

| 53.98 | 32 | 5 | 1/4" | Finished | 11.68 | 13.72 | 21.64 | 50.93 | 2 | Machined | 31.75 | __ | 00000000 | 00000 |

| 56.16 | 36 | 5 | 5/16" | Finished | __ | 13.87 | 23.8 | 57.3 | 0 | Machined | 38.1 | __ | 00000000 | 00000 |

| 62.51 | 40 | 5 | 5/16" | Finished | __ | 13.87 | 23.8 | 63.65 | 0 | Machined | 38.1 | __ | 00000000 | 00000 |

For 12 mm Max. Belt Wd. | ||||||||||||||

| 15 | 20 | 2 | 5mm | Finished | 13 | 14.5 | 22 | 12.22 | 1 | Machined | 15 | Gates PowerGrip 2GT | 0000000 | 0000 |

| OD, mm | Number of Teeth | Pitch, mm | For Shaft Dia. | Bore Type | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Hub Dia., mm | Each | |

For 15 mm Max. Belt Wd. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 53.98 | 32 | 5 | 1/2" | Plain | 17.78 | 21.34 | 47.63 | 49.784 | 2 | Machined | 39.37 | 0000000 | 0000000 |

| 58.17 | 34 | 5 | 1/2" | Plain | 16.51 | 21.34 | 47.63 | 52.959 | 2 | Machined | 42.68 | 0000000 | 000000 |

| 66.37 | 36 | 5 | 1/2" | Plain | 16.51 | 21.34 | 47.63 | 56.159 | 2 | Machined | 45.72 | 0000000 | 000000 |

For 20 mm Max. Belt Wd. | |||||||||||||

| 65.08 | 22 | 8 | 1/2" | Plain | 22.35 | 28.58 | 44.45 | 54.66 | 2 | Machined | 41.28 | 0000000 | 000000 |

For 30 mm Max. Belt Wd. | |||||||||||||

| 65.08 | 22 | 8 | 1/2" | Plain | 31.75 | 38.1 | 53.98 | 54.66 | 2 | Machined | 41.28 | 0000000 | 000000 |

| 69.85 | 24 | 8 | 1/2" | Plain | 31.75 | 38.1 | 53.98 | 59.74 | 2 | Machined | 46.04 | 0000000 | 000000 |

| 74.6 | 26 | 8 | 1/2" | Plain | 31.75 | 38.1 | 57.15 | 64.846 | 2 | Machined | 50.8 | 0000000 | 000000 |

| OD, mm | Number of Teeth | Pitch, mm | ID | Bore Type | For Bushing Style | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Each | |

For 15 mm Max. Belt Wd. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 67.57 | 40 | 5 | 1.375" | Finished | Quick Disconnect Style JA | 16.51 | 21.34 | 21.34 | 62.509 | 2 | Machined | 0000000 | 0000000 |

For 20 mm Max. Belt Wd. | |||||||||||||

| 70 | 26 | 8 | 1.374" | Finished | Quick Disconnect Style JA | 22.35 | 28.58 | 28.58 | 62.22 | 2 | Machined | 0000000 | 000000 |

| 80.17 | 28 | 8 | 1.625" | Finished | Split Tapered Style H | 22.35 | 28.58 | 28.58 | 71.3 | 2 | Machined | 0000000 | 000000 |

| 84.94 | 30 | 8 | 1.625" | Finished | Split Tapered Style H | 22.35 | 28.58 | 28.58 | 76.4 | 2 | Machined | 0000000 | 000000 |

| 95.25 | 34 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 22.35 | 28.58 | 28.58 | 86.59 | 2 | Machined | 0000000 | 000000 |

| 110.34 | 40 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 22.35 | 28.58 | 28.58 | 101.854 | 2 | Machined | 000000 | 000000 |

| 120.65 | 44 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.58 | 28.58 | 112.04 | 2 | Machined | 0000000 | 000000 |

| 130.99 | 48 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.58 | 28.58 | 122.22 | 2 | Machined | 0000000 | 000000 |

| 150.8 | 56 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 22.35 | 28.58 | 28.58 | 141.224 | 2 | Machined | 0000000 | 000000 |

For 30 mm Max. Belt Wd. | |||||||||||||

| 78.49 | 28 | 8 | 1.625" | Finished | Split Tapered Style H | 33.32 | 38.1 | 38.1 | 71.3 | 2 | Machined | 0000000 | 000000 |

| 84.94 | 30 | 8 | 1.625" | Finished | Split Tapered Style H | 31.75 | 38.1 | 38.1 | 76.4 | 2 | Machined | 0000000 | 000000 |

| 90.48 | 32 | 8 | 1.625" | Finished | Split Tapered Style H | 31.75 | 38.1 | 38.1 | 81.48 | 2 | Machined | 0000000 | 000000 |

| 95.25 | 34 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 31.75 | 38.1 | 38.1 | 86.59 | 2 | Machined | 000000 | 000000 |

| 110.34 | 40 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 31.75 | 38.1 | 38.1 | 101.854 | 2 | Machined | 0000000 | 000000 |

| 120.65 | 44 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.75 | 38.1 | 38.1 | 112.04 | 2 | Machined | 0000000 | 000000 |

| 130.99 | 48 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.75 | 38.1 | 38.1 | 122.22 | 2 | Machined | 0000000 | 000000 |

| 150.8 | 56 | 8 | 2.187" | Finished | Quick Disconnect Style SDS | 31.75 | 38.1 | 38.1 | 142.6 | 2 | Machined | 0000000 | 000000 |

For 50 mm Max. Belt Wd. | |||||||||||||

| 95.25 | 34 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 53.98 | 60.33 | 60.33 | 86.59 | 2 | Machined | 0000000 | 000000 |

| 100 | 36 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 53.98 | 60.33 | 60.33 | 91.67 | 2 | Machined | 0000000 | 000000 |

| 110.34 | 40 | 8 | 1.871" | Finished | Quick Disconnect Style SH | 53.98 | 60.33 | 60.33 | 101.854 | 2 | Machined | 0000000 | 000000 |

High-Strength HTD Timing Belt Idler Pulleys

Keep high torque drive (HTD) timing belt systems running tightly with these idler pulleys. Made with built-in, free-spinning ball bearings, they're installed on shafts or belt tensioners (not included) to remove slack from timing belts. By maintaining tension on the belt, these pulleys reduce wear and vibration in 3D printing, machine tool drives, robotics, and other linear motion applications that require precise positioning.

When replacing an idler pulley, be sure the pulley matches your belt's trade size.

Toothed pulleys are shaped to mesh with the teeth on a timing belt, which reduces wear on the belt's teeth.

Smooth pulleys have no teeth; they're used with the smooth side of the belt.

For technical drawings and 3-D models, click on a part number.

| Manufacturer Series | OD | Number of Teeth | For Shaft Dia. | Dia. | Wd. | Groove Dp. | Shaft Mount Type | Bore Type | Number of Flanges | Fabrication | Material | Bearing Type | Each | |

For 6 mm Max. Belt Wd. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gates PowerGrip 2GT | 15mm | 20 | 3mm | 12.22mm | 10mm | 1.39 mm | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 00000000 | 00000 |

| Gates PowerGrip 2GT | 15mm | 20 | 5mm | 12.22mm | 10mm | 1.39 mm | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 0000000 | 0000 |

For 9 mm Max. Belt Wd. | ||||||||||||||

| Gates PowerGrip 2GT | 15mm | 20 | 3mm | 12.22mm | 14mm | 1.39 mm | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 00000000 | 0000 |

| Gates PowerGrip 2GT | 15mm | 20 | 5mm | 12.22mm | 14mm | 1.39 mm | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 0000000 | 0000 |

For 12 mm Max. Belt Wd. | ||||||||||||||

| Gates PowerGrip 2GT | 15mm | 20 | 3mm | 12.22mm | 16mm | 1.39 mm | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 00000000 | 0000 |

| Gates PowerGrip 2GT | 15mm | 20 | 5mm | 12.22mm | 16mm | 1.39 mm | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 0000000 | 0000 |

| Manufacturer Series | OD, mm | For Shaft Dia., mm | Dia., mm | Wd., mm | Groove Dp., mm | Shaft Mount Type | Bore Type | Number of Flanges | Fabrication | Material | Bearing Type | Each | |

For 6 mm Max. Belt Wd. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gates PowerGrip 2GT | 15 | 3 | 12 | 10 | 1.5 | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 00000000 | 00000 |

| Gates PowerGrip 2GT | 15 | 5 | 12 | 10 | 1.5 | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 0000000 | 0000 |

For 9 mm Max. Belt Wd. | |||||||||||||

| Gates PowerGrip 2GT | 15 | 3 | 12 | 14 | 1.5 | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 00000000 | 0000 |

| Gates PowerGrip 2GT | 15 | 5 | 12 | 14 | 1.5 | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 0000000 | 0000 |

For 12 mm Max. Belt Wd. | |||||||||||||

| Gates PowerGrip 2GT | 15 | 3 | 12 | 16 | 1.5 | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 00000000 | 0000 |

| Gates PowerGrip 2GT | 15 | 5 | 12 | 16 | 1.5 | Slip Fit | Finished | 2 | Machined | Aluminum | Ball | 0000000 | 0000 |

High-Strength HTD Timing Belt Pulleys with Hex Bore

Mount these high torque drive (HTD) pulleys onto a hex shaft. They have curved teeth for greater contact with belts than trapezoidal teeth, so you can apply more torque without damaging the belt. The teeth fit together seamlessly to prevent unwanted belt movement for a smooth, quiet cycle. Made of aluminum, these pulleys won’t corrode in damp or humid environments. However, prolonged direct contact with water will cause corrosion over time.

Select a pulley with a maximum belt width that’s the same or larger than your timing belt width.

For technical drawings and 3-D models, click on a part number.

| OD, mm | Number of Teeth | Pitch, mm | Hex Wd. | Bore Type | Inside Wd., mm | Outside Wd., mm | Overall Wd., mm | Pitch Dia., mm | Number of Flanges | Fabrication | Material | Each | |

For 9 mm Max. Belt Wd. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 32 | 18 | 5 | 1/2" | Finished | 10.29 | 13.03 | 14.29 | 28.65 | 2 | Machined | Black-Anodized Aluminum | 0000000 | 000000 |

| 42 | 24 | 5 | 1/2" | Finished | 10.29 | 12.95 | 14.29 | 38.2 | 2 | Machined | Black-Anodized Aluminum | 0000000 | 00000 |

| 51 | 30 | 5 | 1/2" | Finished | 10.29 | 13.03 | 14.29 | 47.75 | 2 | Machined | Black-Anodized Aluminum | 0000000 | 00000 |

| 60 | 36 | 5 | 1/2" | Finished | 10.29 | 12.95 | 14.29 | 57.3 | 2 | Machined | Black-Anodized Aluminum | 0000000 | 00000 |

For 15 mm Max. Belt Wd. | |||||||||||||

| 28 | 15 | 5 | 1/2" | Finished | 19.05 | 20.96 | 22.23 | 23.87 | 2 | Machined | Black-Anodized Aluminum | 0000000 | 00000 |

| 32 | 18 | 5 | 1/2" | Finished | 18.23 | 20.96 | 22.23 | 28.65 | 2 | Machined | Black-Anodized Aluminum | 0000000 | 00000 |

| 42 | 24 | 5 | 1/2" | Finished | 18.23 | 20.96 | 22.23 | 38.2 | 2 | Machined | Black-Anodized Aluminum | 0000000 | 00000 |

| 51 | 30 | 5 | 1/2" | Finished | 18.23 | 20.96 | 22.23 | 47.75 | 2 | Machined | Black-Anodized Aluminum | 0000000 | 00000 |

| 60 | 36 | 5 | 1/2" | Finished | 18.23 | 20.96 | 22.23 | 57.3 | 2 | Machined | Black-Anodized Aluminum | 0000000 | 00000 |

High-Strength HTD Cut-to-Length Timing Belts

Curved teeth made from fiberglass-reinforced neoprene make these HTD (high-torque drive) belts stronger and quieter than belts with trapezoidal teeth. Also known as curvilinear and synchronous belts, their teeth have more surface contact than trapezoidal teeth, so they stay in contact with the pulley longer. This means these belts stay tight for accuracy required in applications with precise starts and stops, such as 3D printers, machine tool drives, and robotics.

Because these belts are fiberglass-reinforced neoprene, they resist stretching over time. They are also coated in nylon to reduce wear and improve grip.

These belts do not require end plates. Cut them to the length you need and attach them directly to your printer head or other equipment.

For technical drawings and 3-D models, click on a part number.

| Belt Trade Number | Manufacturer Equivalent Number | Pitch, mm | Material | Color | Temperature Range, °F | 500 mm Lg. | 1,000 mm Lg. | 2,000 mm Lg. | 3,000 mm Lg. | |

6 mm Wd. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LL2MR06 | Gates PowerGrip 2GT | 2 | Neoprene | Black | -30° to 175° | 000000 | ||||

9 mm Wd. | ||||||||||

| LL2MR09 | Gates PowerGrip 2GT | 2 | Neoprene | Black | -30° to 175° | 000000 | ||||

12 mm Wd. | ||||||||||

| LL2MR12 | Gates PowerGrip 2GT | 2 | Neoprene | Black | -30° to 175° | 000000 | ||||