How to Measure Threaded Pipe Size

More

How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

High-Temperature PTFE Pipe Fittings for Chemicals

Extreme temperatures are no problem for these fittings—they’re made of PTFE, so they can withstand a wider temperature range than any of our other plastic pipe fittings for chemicals. They have the chemical resistance to stand up to acid and solvents. Fittings have thick, Schedule 80 walls for heavy duty industrial applications. The material won’t leach contaminates into the line, so these fittings are commonly used in high-purity processes, such as semiconductor and clean room applications. They have a super-smooth interior for unrestricted flow. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns. Fittings meet ASTM D1710 specifications and testing requirements for material quality.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

For technical drawings and 3-D models, click on a part number.

- For Use With: Deionized Water, Hydrochloric Acid, Solvents

- Temperature Range: -450° to 550° F

- Specifications Met: ASTM D1710

- Pipe Nipples and Pipe: Use Schedule 80 PTFE Plastic

- Flanges: Use Class 150 PTFE Plastic

| Pipe Size (A) | Pipe Size (B) | Material | Color | Max. Pressure | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/4 | 1/8 | PTFE Plastic | White | 90 psi @ 72° F | 000000000 | 000000 |

| 3/8 | 1/8 | PTFE Plastic | White | 60 psi @ 72° F | 000000000 | 00000 |

| 3/8 | 1/4 | PTFE Plastic | White | 60 psi @ 72° F | 000000000 | 00000 |

| 1/2 | 1/4 | PTFE Plastic | White | 60 psi @ 72° F | 000000000 | 00000 |

| 1/2 | 3/8 | PTFE Plastic | White | 60 psi @ 72° F | 000000000 | 00000 |

| 3/4 | 3/8 | PTFE Plastic | White | 50 psi @ 72° F | 000000000 | 000000 |

| 3/4 | 1/2 | PTFE Plastic | White | 50 psi @ 72° F | 000000000 | 000000 |

| 1 | 1/2 | PTFE Plastic | White | 35 psi @ 72° F | 000000000 | 000000 |

| 1 | 3/4 | PTFE Plastic | White | 35 psi @ 72° F | 000000000 | 000000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

- For Use With: Deionized Water, Hydrochloric Acid, Solvents

- Temperature Range: -450° to 550° F

- Specifications Met: ASTM D1710

- Pipe Nipples and Pipe: Use Schedule 80 PTFE Plastic

- Flanges: Use Schedule 150 PTFE Plastic

- For Use With: Deionized Water, Hydrochloric Acid, Solvents

- Temperature Range: -450° to 550° F

- Specifications Met: ASTM D1710

- Pipe Nipples and Pipe: Use Schedule 80 PTFE Plastic

- Flanges: Use Class 150 PTFE Plastic

| Pipe Size (A) | Pipe Size (B) | Material | Color | Max. Pressure | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/4 | 1/8 | PTFE Plastic | White | 90 psi @ 72° F | 000000000 | 000000 |

| 3/8 | 1/8 | PTFE Plastic | White | 60 psi @ 72° F | 000000000 | 00000 |

| 3/8 | 1/4 | PTFE Plastic | White | 60 psi @ 72° F | 000000000 | 00000 |

| 1/2 | 1/4 | PTFE Plastic | White | 60 psi @ 72° F | 000000000 | 00000 |

| 1/2 | 3/8 | PTFE Plastic | White | 60 psi @ 72° F | 000000000 | 00000 |

| 3/4 | 3/8 | PTFE Plastic | White | 50 psi @ 72° F | 000000000 | 00000 |

| 3/4 | 1/2 | PTFE Plastic | White | 50 psi @ 72° F | 000000000 | 00000 |

| 1 | 1/2 | PTFE Plastic | White | 35 psi @ 72° F | 000000000 | 00000 |

| 1 | 3/4 | PTFE Plastic | White | 35 psi @ 72° F | 000000000 | 00000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

- For Use With: Deionized Water, Hydrochloric Acid, Solvents

- Temperature Range: -450° to 550° F

- Specifications Met: ASTM D1710

- Pipe Nipples and Pipe: Use Schedule 80 PTFE Plastic

- Flanges: Use Class 150 PTFE Plastic

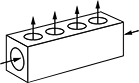

Right-Angle Flow Rectangular Manifolds

Distribute air or fluid to multiple locations from a single supply source with these manifolds. They are also known as headers. They have mounting holes, so you can mount from the top or side.

PTFE manifolds have the best chemical and corrosion resistance of all the plastic and metal manifolds we offer, so they’re the best choice for acids and other highly corrosive substances. Do not use with deonized water at temperatures above 120° F.

Use a plug (sold separately) to close off any unused inlets and outlets.

For technical drawings and 3-D models, click on a part number.

- For Use With: Acetic Acid, Acetone, Bleach, Deionized Water, Hydrochloric Acid, Nitric Acid, Phosphoric Acid, Sulfuric Acid

- Temperature Range: -20° to 180° F

- Maximum Pressure: 120 psi @ 72° F

| No. of Outlets | Inlet Pipe Size | Outlet Pipe Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Color | Each | |

Outlets on One Side—Standard Outlet Spacing | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2 | 1/4 | 1/8 | 1 3/4" | 1" | 1" | 3/4" | White | 0000000 | 000000 |

| 2 | 3/8 | 1/4 | 2 3/8" | 1 1/4" | 1 1/4" | 7/8" | White | 0000000 | 00000 |

| 2 | 1/2 | 3/8 | 2 3/4" | 1 1/2" | 1 1/2" | 1" | White | 0000000 | 00000 |

| 4 | 1/4 | 1/8 | 3 1/4" | 1" | 1" | 3/4" | White | 0000000 | 00000 |

| 4 | 3/8 | 1/4 | 4 1/8" | 1 1/4" | 1 1/4" | 7/8" | White | 0000000 | 00000 |

| 4 | 1/2 | 3/8 | 4 3/4" | 1 1/2" | 1 1/2" | 1" | White | 0000000 | 000000 |

Nickel-Plated Brass Low-Pressure Barbed Tube Fittings for Air and Water

The nickel plating on these brass fittings provides extra protection against corrosive environments. The plating won’t peel or chip, so the fittings keep a bright, polished appearance. The barbs grip onto tubing, providing a secure hold with no clamp required.

For technical drawings and 3-D models, click on a part number.

- Temperature Range: -40° to 230° F

- Tubing: Use with hard (Durometer 60D-90D) Buna-N rubber, EVA Plastic, Nylon Plastic, Polyethylene Plastic, Polypropylene Plastic, Polyurethane Rubber, PTFE Plastic, PVC Plastic, PVDF Plastic, Silicone Rubber

| For Tube ID | Material | Max. Pressure | Each | |

| 2mm × 1 mm | Nickel-Plated Brass | 120 psi @ 72° F | 0000000 | 000000 |

| 6mm × 2 mm | Nickel-Plated Brass | 120 psi @ 72° F | 0000000 | 0000 |

| 6mm × 4 mm | Nickel-Plated Brass | 120 psi @ 72° F | 0000000 | 0000 |

| 8mm × 4 mm | Nickel-Plated Brass | 120 psi @ 72° F | 0000000 | 0000 |

| 8mm × 6 mm | Nickel-Plated Brass | 120 psi @ 72° F | 0000000 | 0000 |

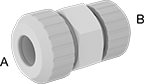

Stainless Steel Push-to-Connect Tube Fittings for Chemicals

- For Use With: Alcohol, Bleach, Lubricated Air, Nitric Acid, Sodium Carbonate, Sulfuric Acid

- Temperature Range: 0° to 175° F

- Tubing: Use with firm or hard (Durometer 80A-60D) FEP, polyethylene, or PTFE plastic

Fittings are 316 stainless steel, which has excellent chemical resistance and is more durable than plastic. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. Instead of a release ring, these fittings have a release sleeve that slides back to disconnect tubing.

For technical drawings and 3-D models, click on a part number.

| For Tube OD (A) | For Tube OD (B) | Material | Max. Pressure | Each | |

| 3/8" | 1/4" | 316 Stainless Steel | 345 psi @ 72° F | 00000000 | 000000 |

| 1/2" | 1/4" | 316 Stainless Steel | 345 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 3/8" | 316 Stainless Steel | 345 psi @ 72° F | 00000000 | 000000 |

| 8mm | 6mm | 316 Stainless Steel | 345 psi @ 72° F | 00000000 | 00000 |

| 10mm | 6mm | 316 Stainless Steel | 345 psi @ 72° F | 00000000 | 000000 |

| 10mm | 8mm | 316 Stainless Steel | 345 psi @ 72° F | 00000000 | 00000 |

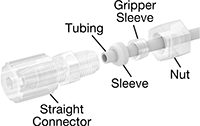

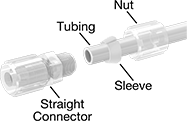

Compression Fittings for Plastic Tubing—Chemicals

- For Use With: PFA Plastic: Hydrochloric Acid, Sulfuric Acid

PTFE Plastic: Alcohol, Ammonia, Benzoic Acid, Bleach, Bromine, Coolant, Fluoboric Acid, Hydrochloric Acid, Hydrofluoric Acid, Nitric Acid, Organic Solvents, Sodium Carbonate, Sulfuric Acid - Temperature Range: PFA Plastic: 0° to 350° F

PTFE Plastic: -40° to 185° F - Tubing: PFA Plastic: Use with hard (Durometer 50D-65D) PFA or PTFE plastic

PTFE Plastic: Use with hard (Durometer 60D) PFA or PTFE plastic

A sleeve (ferrule) compresses the tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless fittings. Fittings that include a gripper sleeve on the tubing create an even tighter seal.

PFA fittings stand up to harsh substances. They’re made through a melting process. PTFE fittings are highly resistant to most acids, alcohols, detergents, and solvents. They’re made by machining. Their nut is made of PVDF, which is resistant to halogens such as chlorine and bromine, strong acids such as hydrofluoric and nitric acids, and organic solvents.

For technical drawings and 3-D models, click on a part number.

| For Tube OD (A) | For Tube OD (B) | Material | Color | Max. Pressure | Each | |

| 1/4" | 1/8" | PFA Plastic | White | 125 psi @ 72° F | 000000000 | 0000000 |

| 3/8" | 1/4" | PFA Plastic | White | 125 psi @ 72° F | 000000000 | 000000 |

| 1/2" | 1/8" | PFA Plastic | White | 125 psi @ 72° F | 000000000 | 000000 |

| 1/2" | 1/4" | PFA Plastic | White | 125 psi @ 72° F | 000000000 | 000000 |

| 1/2" | 3/8" | PFA Plastic | White | 125 psi @ 72° F | 000000000 | 000000 |

| 3/4" | 1/2" | PFA Plastic | White | 125 psi @ 72° F | 000000000 | 000000 |

| 6mm | 4mm | PTFE Plastic | White | 100 psi @ 72° F | 000000000 | 000000 |

| 10mm | 6mm | PTFE Plastic | White | 100 psi @ 72° F | 000000000 | 000000 |

| 10mm | 8mm | PTFE Plastic | White | 100 psi @ 72° F | 000000000 | 000000 |