About Structural Adhesives

More

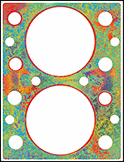

Pressure Recording Film

Create an instant, permanent image of pressure distribution and magnitude. These sheets of film help you identify uneven pressure that can lead to leaks and stress fractures. Use them between any two surfaces that touch each other, such as bolted joints, welding fixtures, and jigs. Tiny capsules within the film burst at specific pressure levels, causing the film to change color. This produces an instant map of pressure variation, similar to a heat map. For a custom size, cut the film with scissors.

0.008" thick film includes two 0.004" thick sheets that must be used together.

Pressure variance analysis kits include a sheet of pressure film and instructions on how to send your film to the manufacturer for analysis. The manufacturer runs the analysis through specialized software. This software gives you more accurate results than the color correlation manual. Within a few days of sending your sample in, you’ll receive an email with a full report on the force distribution and magnitude.

Use a color correlation manual (sold separately) with pressure film to determine the magnitude of the pressure measurements. The manual includes best practices and color correlation charts to help you match the colors on your film readout to the correct values.

A color sample pack includes a color correlation manual and one 3" × 4" piece of film in each of these pressure ranges: 28-85, 70-350, 350-1,400, 1,400-7,100, and 7,100-18,500 psi.

Film | Color Correlation Manual | Color Sample Pack | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pressure Range, psi | Image Produced | Resolution | Temp. Range, °F | Accuracy | Each | Each | Pkg. | |||

Pressure Film | ||||||||||

10 5/8" × 12" | ||||||||||

0.004" Thick. | ||||||||||

| 1,400-7,100 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 000000 | 00000000 | 000000 |

| 7,100-18,500 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

0.008" Thick. | ||||||||||

| 28-85 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

| 70-350 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

| 350-1,400 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

0.02" Thick. | ||||||||||

| 18,500-43,200 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

10 5/8" × 24" | ||||||||||

0.004" Thick. | ||||||||||

| 1,400-7,100 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

| 7,100-18,500 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

0.008" Thick. | ||||||||||

| 28-85 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 70-350 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 350-1,400 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

0.02" Thick. | ||||||||||

| 18,500-43,200 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

10 5/8" × 36" | ||||||||||

0.004" Thick. | ||||||||||

| 1,400-7,100 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 7,100-18,500 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

0.008" Thick. | ||||||||||

| 28-85 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 70-350 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 350-1,400 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

0.02" Thick. | ||||||||||

| 18,500-43,200 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

10 5/8" × 48" | ||||||||||

0.004" Thick. | ||||||||||

| 1,400-7,100 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

0.008" Thick. | ||||||||||

| 28-85 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 70-350 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 350-1,400 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

11" × 17" | ||||||||||

0.02" Thick. | ||||||||||

| 2-20 | Grayscale | __ | 0° to 150° | Not Rated | 0000000 | 00000 | 000000 | 00 | 000000 | 00 |

12" × 21 1/4" | ||||||||||

0.315" Thick. | ||||||||||

| 28-85 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 70-350 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 350-1,400 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 00000 | 000000000 | 00000 | 00000000 | 00000 |

12 5/8" × 12" | ||||||||||

0.004" Thick. | ||||||||||

| 8-28 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 000000 | 00 |

0.008" Thick. | ||||||||||

| 0.9-7.2 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 000000 | 00 |

12 5/8" × 24" | ||||||||||

0.004" Thick. | ||||||||||

| 8-28 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 000000 | 00 |

12 5/8" × 36" | ||||||||||

0.004" Thick. | ||||||||||

| 8-28 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 000000 | 00 |

12 5/8" × 48" | ||||||||||

0.004" Thick. | ||||||||||

| 8-28 | Color | 5-15 μ | 70° to 95° | ±15% | 000000000 | 000000 | 000000000 | 00000 | 000000 | 00 |

Pressure Variance Analysis Kit | ||||||||||

10 5/8" × 12" | ||||||||||

0.004" Thick. | ||||||||||

| 1,400-7,100 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 7,100-18,500 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

0.008" Thick. | ||||||||||

| 28-85 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 70-350 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 350-1,400 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

0.02" Thick. | ||||||||||

| 18,500-43,200 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

12" × 21 1/4" | ||||||||||

0.315" Thick. | ||||||||||

| 28-85 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 70-350 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

| 350-1,400 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

12 5/8" × 12" | ||||||||||

0.008" Thick. | ||||||||||

| 0.9-7.2 | Color | 5-15 μ | 70° to 95° | ±4% | 000000000 | 000000 | 000000000 | 00000 | 00000000 | 00000 |

Roller impression analysis kits are also known as NIP impression kits. They include three sheets of film, a color correlation manual specific to roller systems, and a shipping envelope to send your film in for analysis. The manufacturer runs the analysis through specialized software. This software gives you more accurate results than the color correlation manual. Within a few days of sending your sample in, you’ll receive an email with a full report on the force distribution and magnitude.

| Pressure Range, psi | Image Produced | Resolution | Temp. Range, °F | Accuracy | Includes | Each | |

12" × 10" | |||||||

|---|---|---|---|---|---|---|---|

0.004" Thick. | |||||||

| 70-7,100 | Color | 5-15 μ | 70° to 95° | ±4% | Color Correlation Manual, Shipping Envelope, Three Sheets | 000000000 | 0000000 |

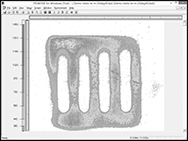

Pressure Testing Analysis Systems

Take lab-quality scans of pressure recording film for frequent onsite measurements. These systems detect color changes in the film to spot issues that can cause leaks and stress fractures. They’re often used with bolted joints, metal stamping, and nip rollers to measure and adjust for uneven pressure when setting up a new job. They’re also known as TOPAQ analysis systems. The scanner comes calibrated for reading pressure recording film.

The included software renders color pressure images in detail for more accurate results than visual inspection with a color correlation manual. You can create 3D images, grids, and graphs. Zoom in for a closer look at the pressure distribution throughout your system.

This is not a finite element analysis (FEA) tool. While an FEA tool uses models to predict stress and potential failures, these evaluate pressure based on your actual system. This means you’re more likely to catch issues caused by material imperfections, environmental conditions, and other real-world factors.

For Sheet | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Scanner Resolution | Lg. | Wd. | Paper Size | Scan Speed | Accuracy | Lg. | Wd. | Ht. | Data Connection Type | Wattage | Voltage | Cord Lg., ft. | Plug Type | Includes | Each | |

| 200 dpi | 8 1/2" | 11" | Letter | 40 Seconds | ±4% | 11 1/2" | 17" | 2" | USB-A | 20W | 120V AC | 10 | Two Prong | 6 ft. Long USB Cord, Scanner, Windows Compatible Software | 0000000 | 000000000 |

Glue-on-a-Roll

Apply this glue-like tape for a no-mess alternative to liquid adhesives, hot melts, and staples. Also known as adhesive transfer tape, these rolls have a thin film of pressure-sensitive glue on a peel-away liner. They are thinner and more conformable than tape with adhesive on both sides.

467MP and 468MP resist solvents and UV rays.

9082 and 9085 can work in the highest temperatures. They’re a good choice for use under the hood of a piece of equipment or on a circuit board you’re soldering.

9482PC and 9485PC are a good choice for precise applications, even on slippery plastics. They're reinforced with fiber so they keep their shape and don’t ooze out, unlike softer adhesives.

Rolls that meet MIL-P-19834 Type I are certified to withstand movement between parts and insulate against electric current for military and aerospace applications. Rolls that meet ASTM E595, a standard set by NASA, will produce almost no volatile emissions, even in a high vacuum. They’re a great choice for use around sensitive electronics. They’ve even been used in space simulations. FDA-compliant rolls are safe for indirect contact with food.

| Mfr. Model No. | Wd. | Lg., yd. | Thick. | Temp. Range, °F | Color | Specifications Met | For Joining | Each | |

3M Glue | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 465 | 1/4" | 60 | 0.002" | Not Rated to 180° | Clear | MIL-P-19834 Type I | Cardboard, Glass, Wood | 0000000 | 00000 |

| 465 | 1/2" | 60 | 0.002" | Not Rated to 180° | Clear | MIL-P-19834 Type I | Cardboard, Glass, Wood | 0000000 | 00000 |

| 465 | 3/4" | 60 | 0.002" | Not Rated to 180° | Clear | MIL-P-19834 Type I | Cardboard, Glass, Wood | 0000000 | 00000 |

| 465 | 1" | 60 | 0.002" | Not Rated to 180° | Clear | MIL-P-19834 Type I | Cardboard, Glass, Wood | 0000000 | 00000 |

| 465 | 1 1/4" | 60 | 0.002" | Not Rated to 180° | Clear | MIL-P-19834 Type I | Cardboard, Glass, Wood | 0000000 | 00000 |

| 465 | 1 1/2" | 60 | 0.002" | Not Rated to 180° | Clear | MIL-P-19834 Type I | Cardboard, Glass, Wood | 0000000 | 00000 |

| 465 | 2" | 60 | 0.002" | Not Rated to 180° | Clear | MIL-P-19834 Type I | Cardboard, Glass, Wood | 0000000 | 00000 |

| 465 | 3" | 60 | 0.002" | Not Rated to 180° | Clear | MIL-P-19834 Type I | Cardboard, Glass, Wood | 0000000 | 000000 |

| 467MP | 1/2" | 60 | 0.002" | Not Rated to 300° | Clear | ASTM E595 | Metal, Plastic, Rubber | 0000000 | 00000 |

| 467MP | 3/4" | 60 | 0.002" | Not Rated to 300° | Clear | ASTM E595 | Metal, Plastic, Rubber | 0000000 | 00000 |

| 467MP | 1" | 60 | 0.002" | Not Rated to 300° | Clear | ASTM E595 | Metal, Plastic, Rubber | 0000000 | 00000 |

| 467MP | 2" | 60 | 0.002" | Not Rated to 300° | Clear | ASTM E595 | Metal, Plastic, Rubber | 00000000 | 00000 |

| 467MP | 3" | 60 | 0.002" | Not Rated to 300° | Clear | ASTM E595 | Metal, Plastic, Rubber | 00000000 | 00000 |

| 468MP | 1/2" | 60 | 0.005" | -40° to 300° | Clear | __ | Cardboard, Ceramic, Composites, Foam, Glass, Metal, Plastic, Wood | 0000000 | 00000 |

| 468MP | 1" | 60 | 0.005" | -40° to 300° | Clear | __ | Cardboard, Ceramic, Composites, Foam, Glass, Metal, Plastic, Wood | 0000000 | 00000 |

| 966 | 1" | 60 | 0.002" | Not Rated to 300° | Clear | __ | Metal | 0000000 | 00000 |

| 9082 | 1/4" | 60 | 0.002" | Not Rated to 350° | Clear | __ | Metal | 0000000 | 00000 |

| 9085 | 1/4" | 60 | 0.005" | Not Rated to 350° | Clear | __ | Metal | 0000000 | 00000 |

| 9482PC | 1/2" | 60 | 0.002" | Not Rated to 250° | Clear | __ | Plastic | 0000000 | 00000 |

| 9482PC | 3/4" | 60 | 0.002" | Not Rated to 250° | Clear | __ | Plastic | 0000000 | 00000 |

| 9482PC | 1" | 60 | 0.002" | Not Rated to 250° | Clear | __ | Plastic | 0000000 | 00000 |

| 9485PC | 1/2" | 60 | 0.005" | Not Rated to 250° | Clear | __ | Plastic | 0000000 | 00000 |

| 9485PC | 3/4" | 60 | 0.005" | Not Rated to 250° | Clear | __ | Plastic | 0000000 | 00000 |

| 9485PC | 1" | 60 | 0.005" | Not Rated to 250° | Clear | __ | Plastic | 0000000 | 00000 |

Glue | |||||||||

| __ | 1/2" | 60 | 0.002" | 0° to 180° | Clear | FDA Compliant 21 CFR 175.105 | Plastic, Rubber | 00000000 | 00000 |

| __ | 3/4" | 60 | 0.002" | 0° to 180° | Clear | FDA Compliant 21 CFR 175.105 | Plastic, Rubber | 00000000 | 00000 |

| __ | 1" | 60 | 0.002" | 0° to 180° | Clear | FDA Compliant 21 CFR 175.105 | Plastic, Rubber | 00000000 | 00000 |

High-Temperature Glue-on-a-Roll

This silicone glue withstands high temperatures and bonds slippery plastics. Also known as adhesive transfer tape, these rolls have a thin film of pressure-sensitive glue on a peel-away liner. They are thinner and more conformable than tape with adhesive on both sides.

0.001" Thick. | 0.002" Thick. | |||||||

|---|---|---|---|---|---|---|---|---|

| Wd. | Lg., yd. | Temp. Range, °F | Color | For Joining | Each | Each | ||

| 1/4" | 60 | -100° to 500° | Clear | Plastic | 00000000 | 000000 | 00000000 | 000000 |

| 1/2" | 60 | -100° to 500° | Clear | Plastic | 00000000 | 00000 | 0000000 | 00000 |

| 3/4" | 60 | -100° to 500° | Clear | Plastic | 00000000 | 000000 | 0000000 | 000000 |

| 1" | 60 | -100° to 500° | Clear | Plastic | 00000000 | 000000 | 0000000 | 000000 |

High-Strength Glue-on-a-Roll

The 3M VHB adhesive on these rolls offers a strong hold that can replace rivets, spot welds, and other permanent fasteners. Also known as adhesive transfer tape, these rolls have a thin film of pressure-sensitive glue on a peel-away liner. They’re more conformable than tape with adhesive on both sides.

F9473PC are our thickest option, so they’re the best at adhering to gaps and crevices on uneven surfaces.

Rolls that meet ASTM E595, a standard used by NASA, release almost no volatile emissions that could damage sensitive electronics, even in a vacuum.

![]() Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Mfr. Model No. | Wd. | Lg., yd. | Thick. | Max. Temp., °F | Color | Specifications Met | For Joining | Each | |

3M Glue | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| F9460PC | 1/2" | 60 | 0.002" | 300° | Clear | ASTM E595 | Ceramic, Composites, Glass, Metal | 0000000 | 000000 |

| F9460PC | 3/4" | 60 | 0.002" | 300° | Clear | ASTM E595 | Ceramic, Composites, Glass, Metal | 0000000 | 00000 |

| F9460PC | 1" | 60 | 0.002" | 300° | Clear | ASTM E595 | Ceramic, Composites, Glass, Metal | 0000000 | 00000 |

| F9460PC | 1 1/4" | 180 | 0.002" | 300° | Clear | ASTM E595 | Ceramic, Composites, Glass, Metal | 0000000 | 000000 |

| F9469PC | 1/2" | 60 | 0.005" | 300° | Clear | __ | Ceramic, Composites, Glass, Metal | 0000000 | 00000 |

| F9473PC | 1/2" | 60 | 0.01" | 300° | Clear | __ | Ceramic, Composites, Glass, Metal | 0000000 | 00000 |

| F9473PC | 3/4" | 60 | 0.01" | 300° | Clear | __ | Ceramic, Composites, Glass, Metal | 0000000 | 000000 |

| F9473PC | 1" | 60 | 0.01" | 300° | Clear | __ | Ceramic, Composites, Glass, Metal | 0000000 | 000000 |

Glue-on-a-Roll for Dispensing Guns

Designed for use with 3M dispensing guns, these rolls have a thin film of pressure-sensitive glue on a peel-away liner. They are thinner and more conformable than tape with adhesive on both sides. Also known as adhesive transfer tape.

928 has a permanent adhesive on one side and a removable adhesive on the other.

969 is a high-tack glue that bonds quickly to glossy coatings and plastics.

![]() Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number and product shelf life are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Mfr. Model No. | For 3M Gun Model No. | Wd. | Lg., yd. | Thick. | Max. Temp., °F | Color | For Joining | Each | |

3M Glue | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 924 | ATG714, ATG700 | 1/4" | 60 | 0.002" | 180° | Clear | Cardboard, Glass, Wood | 00000000 | 000000 |

| 924 | ATG700 | 1/2" | 36 | 0.002" | 180° | Clear | Cardboard, Glass, Wood | 00000000 | 0000 |

| 924 | ATG700 | 1/2" | 60 | 0.002" | 180° | Clear | Cardboard, Glass, Wood | 0000000 | 00000 |

| 924 | ATG700 | 3/4" | 36 | 0.002" | 180° | Clear | Cardboard, Glass, Wood | 00000000 | 00000 |

| 924 | ATG700 | 3/4" | 60 | 0.002" | 180° | Clear | Cardboard, Glass, Wood | 0000000 | 00000 |

| 924 | ATG3662 | 2" | 60 | 0.002" | 180° | Clear | Cardboard, Glass, Wood | 0000000 | 00000 |

| 926 | ATG700 | 1/2" | 18 | 0.005" | 300° | Clear | Metal | 00000000 | 00000 |

| 926 | ATG700 | 3/4" | 18 | 0.005" | 300° | Clear | Metal | 0000000 | 00000 |

| 926 | ATG3662 | 2" | 36 | 0.005" | 300° | Clear | Metal | 0000000 | 00000 |

| 928 | ATG700 | 1/2" | 18 | 0.002" | 120° | White | Foam | 00000000 | 00000 |

| 928 | ATG700 | 3/4" | 18 | 0.002" | 120° | White | Foam | 00000000 | 00000 |

| 969 | ATG714, ATG700 | 1/4" | 18 | 0.005" | 180° | Clear | Plastic, Rubber | 00000000 | 0000 |

| 969 | ATG714, ATG700 | 1/4" | 36 | 0.005" | 180° | Clear | Plastic, Rubber | 00000000 | 00000 |

| 969 | ATG700 | 1/2" | 18 | 0.005" | 180° | Clear | Plastic, Rubber | 00000000 | 00000 |

| 969 | ATG700 | 3/4" | 18 | 0.005" | 180° | Clear | Plastic, Rubber | 00000000 | 00000 |

| 969 | ATG3662 | 1 1/2" | 36 | 0.005" | 180° | Clear | Plastic, Rubber | 0000000 | 00000 |

| 969 | ATG3662 | 2" | 36 | 0.005" | 180° | Clear | Plastic, Rubber | 0000000 | 00000 |

Conductive Adhesives for Electronics

An alternative to solder, these flexible, silver-filled adhesives accommodate joint movement. Use them to bond electrical components and repair circuits.

Thermoplastic adhesives are one-part adhesives that don’t need to be mixed. Dry to the touch and faster and easier to apply than two-part adhesives, they’re best for use on automated assembly lines. Often used to join solar cells in solar panels, these adhesives make instant electrical connections without flux at lower temperatures than soldering. Since they attach to solar cells with heat and slight pressure, they limit stress cracks that can form when soldering. These adhesives can also be used as a bridge between multiple solar panels.

| Lg. | Wd. | Thick. | Melting Temp., °F | Max. Temp., °F | Begins to Harden | Reaches Full Strength | Thermal Conductivity, W/m-K | Surface Resistivity, ohms-cm | Consistency | For Joining | Each | |

Strip with Adhesive on One Side | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 12" | 1/16" | 0.002" | 250° | 300° | 5 sec. | 5 sec. | 12 | 0.0001 | Film | Metal | 00000000 | 00000 |