About Pipe Size

More

About Pressure Gauges

More

About Gas Regulators

More

Digital High-Accuracy Pressure Gauges

With Bottom

Connection

A four-digit LCD display allows for easy reading of measurements. The LCD shuts off automatically to extend battery life. Gauges are commonly used with pneumatic regulators, compressors, and in critical processes that require high accuracy, such as hydraulic and laboratory applications.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Carbon Dioxide, Hydrogen, Nitrogen, Natural Gas

- Accuracy: ±1% Full Scale (Grade 1A)

Available Pressure Ranges | ||||

|---|---|---|---|---|

Pressure Range | ||||

| psi | bar | kg/cm2 | MPa | Resolution, psi |

| 0 to 145 | 0 to 10 | 0 to 10 | 0 to 1 | 0.1 |

Center Back Connection | ||||||||

|---|---|---|---|---|---|---|---|---|

| Dial Diameter | Pipe Size | Environment Temp. Range, °F | Process Temp. Range, °F | Batteries Included | Mounting Orientation | Features | Each | |

NPT Male | ||||||||

| 1 3/4" | 1/8 | -10° to 140° | -10° to 140° | Yes | Any | 5-min. Automatic Shut-Off | 000000 | 000000 |

| 1 3/4" | 1/4 | -10° to 140° | -10° to 140° | Yes | Any | 5-min. Automatic Shut-Off | 000000 | 00000 |

NPT Male with Calibration Certificate Traceable to NIST | ||||||||

| 1 3/4" | 1/8 | -10° to 140° | -10° to 140° | Yes | Any | 5-min. Automatic Shut-Off | 00000000 | 000000 |

| 1 3/4" | 1/4 | -10° to 140° | -10° to 140° | Yes | Any | 5-min. Automatic Shut-Off | 00000000 | 000000 |

- For Use With: Air, Hydrogen, Nitrogen

- Accuracy: ±1% Full Scale (Not Graded)

Available Pressure Ranges | |||

|---|---|---|---|

Pressure Range | |||

| psi | MPa | bar | Resolution, psi |

| 0 to 30 | 0 to 0.2 | 0 to 2 | 0.01 |

| 0 to 100 | 0 to 0.7 | 0 to 6.9 | 0.1 |

| 0 to 300 | 0 to 2 | 0 to 20.7 | 0.1 |

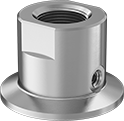

Bottom Connection | ||||||||

|---|---|---|---|---|---|---|---|---|

| Dial Diameter | Pipe Size | Environment Temp. Range, °F | Process Temp. Range, °F | Batteries Included | Mounting Orientation | Features | Each | |

NPT Male | ||||||||

| 2 1/2" | 1/4 | 0° to 185° | 15° to 140° | Yes | Any | 3-min. Automatic Shut-Off, Maximum Reading Recall | 00000000 | 0000000 |

NPT Male with Calibration Certificate Traceable to NIST | ||||||||

| 2 1/2" | 1/4 | 0° to 185° | 15° to 140° | Yes | Any | 3-min. Automatic Shut-Off, Maximum Reading Recall | 00000000 | 000000 |

Low-Pressure Differential Gauges with Color Indicator

A band of green, yellow, and red provides a clear indication of changes in differential pressure. Gauges are commonly used to indicate clogged filters.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid, Carbon Dioxide, Nitrogen, Hydrogen, Argon, and Acetylene

- Accuracy: ±5% Full Scale (Not Graded)

Pressure Range, psi | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Green Band | Yellow Band | Red Band | Max. Pressure, psi | Environment Temp. Range, °F | Process Temp. Range, °F | Ht. | Wd. | Dp. | Case Color | Each | |

NPT Female | ||||||||||||

| 1/4 | 0-2 | 2-2.5 | 2.5-3.5 | 300 | -40° to 200° | -40° to 200° | 3 1/4" | 3 1/4" | 1 1/2" | Black | 0000000 | 0000000 |

| 1/4 | 0-3 | 3-4.5 | 4.5-5 | 300 | -40° to 200° | -40° to 200° | 3 1/4" | 3 1/4" | 1 1/2" | Black | 0000000 | 000000 |

| 1/4 | 0-6 | 6-9 | 9-12 | 300 | -40° to 200° | -40° to 200° | 3 1/4" | 3 1/4" | 1 1/2" | Black | 0000000 | 000000 |

| 1/4 | 0-7.5 | 7.5-12 | 12-15 | 300 | -40° to 200° | -40° to 200° | 3 1/4" | 3 1/4" | 1 1/2" | Black | 0000000 | 000000 |

| 1/4 | 0-13 | 13-20 | 20-30 | 300 | -40° to 200° | -40° to 200° | 3 1/4" | 3 1/4" | 1 1/2" | Black | 0000000 | 000000 |

| 1/4 | 0-19.5 | 19.5-29.5 | 29.5-43 | 300 | -40° to 200° | -40° to 200° | 3 1/4" | 3 1/4" | 1 1/2" | Black | 0000000 | 000000 |

Low-Pressure Differential Gauges with U-Tube

Also known as manometers, these gauges come with indicating liquid that moves up and down two columns—the difference in height between them is your pressure. They are commonly used to indicate clogged filters.

Magnet-mount gauges can be moved for use in multiple locations. Gauges with barbed tube connection have a flexible body that rolls up for storage or transport.

- For Use With: Air, Argon, Carbon Dioxide, and Hydrogen

- Accuracy: Not Rated (Not Graded)

| Pressure Range, in. of H₂O | Scale Range, in. of H₂O | Numeric Increments, in. of H₂O | Graduation Marks, in. of H₂O | Max. Pressure | Ht. | Max. Process Temp., °F | Gender | Mount Type | Each | |

With Barbed Tube Connection for 3/16" Tube ID | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0-8 | 4-0-4 | 1 | 0.1 | Not Rated | 17" | 130° | Male | Magnet | 0000000 | 0000000 |

| 0-12 | 6-0-6 | 1 | 0.1 | Not Rated | 21" | 130° | Male | Magnet | 0000000 | 000000 |

| 0-16 | 8-0-8 | 1 | 0.1 | Not Rated | 25" | 130° | Male | Magnet | 0000000 | 000000 |

| 0-24 | 12-0-12 | 1 | 0.1 | Not Rated | 33" | 130° | Male | Magnet | 0000000 | 000000 |

| 0-30 | 15-0-15 | 1 | 0.1 | Not Rated | 39" | 130° | Male | Magnet | 0000000 | 000000 |

| 0-36 | 18-0-18 | 1 | 0.1 | Not Rated | 45" | 130° | Male | Magnet | 0000000 | 000000 |

| 0-48 | 24-0-24 | 1 | 0.1 | Not Rated | 57" | 130° | Male | Magnet | 0000000 | 000000 |

| 0-60 | 30-0-30 | 1 | 0.1 | Not Rated | 69" | 130° | Male | Magnet | 0000000 | 000000 |

| 0-72 | 36-0-36 | 1 | 0.1 | Not Rated | 81" | 130° | Male | Magnet | 0000000 | 000000 |

- For Use With: Air, Argon, Carbon Dioxide, and Hydrogen

- Accuracy: Not Rated (Not Graded)

| Pressure Range, in. of H₂O | Scale Range, in. of H₂O | Numeric Increments, in. of H₂O | Graduation Marks, in. of H₂O | Max. Pressure, psi | Ht. | Gender | Mount Type | Each | |

With Compression Tube Connection for 1/4" Tube OD | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0-8 | 4-0-4 | 1 | 0.1 | 100 | 20" | Female | Magnet | 0000000 | 0000000 |

| 0-12 | 6-0-6 | 1 | 0.1 | 100 | 25" | Female | Magnet | 0000000 | 000000 |

| 0-16 | 8-0-8 | 1 | 0.1 | 100 | 30" | Female | Magnet | 0000000 | 000000 |

| 0-20 | 10-0-10 | 1 | 0.1 | 100 | 34" | Female | Magnet | 0000000 | 000000 |

| 0-24 | 12-0-12 | 1 | 0.1 | 100 | 39" | Female | Magnet | 0000000 | 000000 |

| 0-36 | 18-0-18 | 1 | 0.1 | 100 | 58" | Female | Magnet | 0000000 | 000000 |

Gauge Guards

Also known as isolators or diaphragm seals, these protect gauges from corrosive process media. Fill guards with hydraulic oil (not included) before use.

316 stainless steel guards provide excellent corrosion and chemical resistance and can handle higher temperatures and pressures than plastic guards.

Guards with drain port allow you to remove process media.

For technical drawings and 3-D models, click on a part number.

Pipe Connections | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Gasket Material | For Use With | Min. Pressure, psi | Max. Pressure | Max. Temp., °F | Ht. | Each | |

316 Stainless Steel Body | |||||||||

| 1/4 NPT Female | 1/4 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 1 3/4" | 0000000 | 0000000 |

| 1/2 NPT Female | 1/4 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 1 3/4" | 0000000 | 000000 |

| 1/2 NPT Female | 1/2 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 1 1/2" | 0000000 | 000000 |

316 Stainless Steel Body with 1/4 NPT Female Drain Port | |||||||||

| 1/4 NPT Female | 1/4 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 2" | 0000000 | 000000 |

| 1/2 NPT Female | 1/4 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 2" | 0000000 | 000000 |

| 1/2 NPT Female | 1/2 NPT Female | 316 Stainless Steel | Acetylene, Air, Ammonia, Argon, Bleach, Boric Acid, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Ethyl Alcohol, Gasoline, Hydraulic Fluid, Hydraulic Oil, Hydrogen, Liquid Nitrogen, Mineral Oil, Natural Gas, Nitrogen, Oxygen, Refrigerant, Salt Water, Steam, Water | 60 | 2,500 psi @ 72° F | 300° | 2" | 0000000 | 000000 |

Sanitary Gauge Guards

Keeping corrosive substances from touching pressure gauges used in food-processing and pharmaceutical plants, these guards have a sanitary design. Made of 316 stainless steel, they won’t rust from frequent washdowns with harsh cleaners and sanitizers. They have continuously-welded seams and polished surfaces, so there aren’t any pits for bacteria to grow in. Removing them for cleaning and maintenance is easy thanks to their quick-clamp connection, which is sometimes called a tri-clamp.

Also known as isolators and diaphragm seals, these guards have a 316 stainless steel gasket to shield the pressure gauges from corrosion. Before use, fill the guards with fluid such as glycerin or silicone that’s suitable for food contact.

For technical drawings and 3-D models, click on a part number.

Outlet Quick-Clamp Tube Connection | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inlet Pipe Connection | For Tube OD | Flange OD | Gasket Material | For Use With | Minimum Pressure, psi | Maximum Pressure | Maximum Temperature | Height | Interior Smoothness, Ra | Each | |

316 Stainless Steel Body | |||||||||||

| 1/4 NPT Female | 1 1/2" | 1.984" | 316 Stainless Steel | Acetylene, Air, Ammonia, Beverage, Boric Acid, Carbon Dioxide, Diesel Fuel, Ethanol, Food, Gasoline, Hydraulic Fluid, Hydrogen, Oxygen, Pharmaceuticals, Wastewater, Water | 30 | Not Rated | Not Rated | 1 3/8" | 32 | 0000000 | 0000000 |

| 1/4 NPT Female | 2" | 2.516" | 316 Stainless Steel | Acetylene, Air, Ammonia, Beverage, Boric Acid, Carbon Dioxide, Diesel Fuel, Ethanol, Food, Gasoline, Hydraulic Fluid, Hydrogen, Oxygen, Pharmaceuticals, Wastewater, Water | 30 | Not Rated | Not Rated | 1 1/8" | 32 | 0000000 | 000000 |

| 1/2 NPT Female | 1 1/2" | 1.984" | 316 Stainless Steel | Acetylene, Air, Ammonia, Beverage, Boric Acid, Carbon Dioxide, Diesel Fuel, Ethanol, Food, Gasoline, Hydraulic Fluid, Hydrogen, Oxygen, Pharmaceuticals, Wastewater, Water | 30 | Not Rated | Not Rated | 1 3/8" | 32 | 0000000 | 000000 |

Easy-Read Tank-Mount Pressure-Regulating Valves with Flowmeter for Inert Gas

Flowmeters let you see the gas flow rate from a distance. These valves automatically reduce a high inlet pressure from compressed gas tanks to a lower, stable outlet pressure. All have Compressed Gas Association (CGA) numbered inlet fittings for secure connections to compressed gas tanks. Choose a valve with the same CGA number as your tank and other system components. They have a gauge for monitoring inlet pressure from the tank.

Single-stage valves reduce pressure in one step, which causes the outlet pressure to fluctuate slightly as you empty the tank. They’re best for applications where a constant outlet pressure isn’t critical.

Valves with one flowmeter are for one piece of equipment on a tank. The flowmeter has a single scale.

Adapters (sold separately) change 5/8"-18 outlets to 9/16"-18 male connections, and vice versa.

Inlet | Outlet | Material | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CGA Number | Location | Thread Direction | Pressure Gauge Range, psi | Stage | Thread Size | Location | Thread Direction | Flow Range, scfh | Number of Flowmeters | Body | Seal | Diaphragm | Each | |

UNF Female Outlet × NGO Male Inlet | ||||||||||||||

| CGA 580 | Side | Right Hand | 0 to 4,000 | Single | 5/8"-18 | Side | Right Hand | 0 to 100 (Helium), 0 to 140 (Hydrogen) | 1 | Brass | PTFE | Neoprene | 000000000 | 0000000 |

| Optional Adapter | 00000000 | Each | 000000 |

Inlet | Outlet | Material | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CGA Number | Location | Thread Direction | Pressure Gauge Range, psi | Stage | Thread Size | Location | Thread Direction | Flow Range, scfh | Number of Flowmeters | Body | Seal | Diaphragm | Each | |

UNF Male Outlet × NGO Female Inlet | ||||||||||||||

| CGA 350 | Side | Left Hand | 0 to 3,000 | Single | 9/16"-18 | Side | Left Hand | 0 to 40 | 1 | Brass | PTFE | Neoprene | 000000000 | 0000000 |

| Optional Adapter | 00000000 | Each | 000000 |

Tank-Mount Pressure-Regulating Valves for Fuel Gases

- For Use With: See Table

- Temperature Range: -20° to 120° F

Attach these valves to acetylene, hydrogen, methane, propane, or propylene tanks to reduce a high inlet pressure to a lower, stable outlet pressure. They have Compressed Gas Association (CGA) numbered inlet fittings for secure connections to compressed gas tanks. Choose a valve with the same CGA number as your tank and other system components. Valves come with a gauge to monitor outlet pressure and a gauge to monitor inlet pressure from the tank.

Choose a valve with a maximum outlet pressure that’s approximately twice your application’s normal operating pressure. Your operating pressure should never exceed 75% of the valve’s maximum outlet pressure.

Single-stage valves reduce pressure in one step, which causes the outlet pressure to fluctuate slightly as you empty the tank. They’re best for applications where a constant outlet pressure isn’t critical.

Two-stage valves progressively reduce pressure over two steps for more consistent outlet pressure at all times. They’re often used in applications that require a constant outlet pressure regardless of the tank level.

Valves with a brass body have a longer service life than valves with a brass and steel body.

Inlet | Outlet | Material | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CGA Number | Location | Thread Direction | Pressure Gauge Range, psi | Thread Size | Location | Thread Direction | Pressure Range, psi | Pressure Adjustment Method | Body | Seal | Diaphragm | Each | |

For Use With Hydrogen | |||||||||||||

UNF Male Outlet × NGO Female Inlet | |||||||||||||

| CGA 350 | Side | Left Hand | 0 to 4,000 | 9/16"-18 | Side | Left Hand | 0 to 125 | T-Handle | Brass | PTFE | Rubber | 000000 | 0000000 |

Inlet | Outlet | Material | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CGA Number | Location | Thread Direction | Pressure Gauge Range, psi | Thread Size | Location | Thread Direction | Pressure Range, psi | Body | Seal | Diaphragm | Each | |

For Use With Hydrogen and Methane | ||||||||||||

UNF Male Outlet × NGO Female Inlet | ||||||||||||

| CGA 350 | Side | Left Hand | 0 to 4,000 | 9/16"-18 | Side | Left Hand | 2 to 40 | Brass | Neoprene | Rubber | 0000000 | 0000000 |

High-Purity Tank-Mount Pressure-Regulating Valves for Fuel Gases

- For Use With: Hydrogen, Methane

- Temperature Range: -20° to 120° F

Designed to reduce contaminants in high-purity applications using hydrogen and methane gas, these valves have a stainless steel and brass body with a smooth finish to reduce dust collection and internal components designed to protect the seal and diaphragm from contamination. They’re often used in research sample systems, emission monitoring systems, and chromatography. Valves automatically reduce a high inlet pressure from compressed gas tanks to a lower, stable outlet pressure. All have Compressed Gas Association (CGA) numbered inlet fittings for secure connections to compressed gas tanks. Choose a valve with the same CGA number as your tank and other system components. Outlet fittings are Swagelok® for a leak-free seal around hard metal tubing in high-pressure lines. Also known as instrumentation fittings, Swagelok® fittings are compatible with Parker A-Lok, Gyrolok, Bilok, and Tylok fittings. Valves come with a gauge to monitor outlet pressure and a gauge to monitor inlet pressure from the tank.

Choose a valve with a maximum outlet pressure that’s approximately twice your application’s normal operating pressure. Your operating pressure should never exceed 75% of the valve’s maximum outlet pressure.

Single-stage valves reduce pressure in one step, which causes the outlet pressure to fluctuate slightly as you empty the tank. They’re best for applications where a constant outlet pressure isn’t critical.

Two-stage valves progressively reduce pressure over two steps for more consistent outlet pressure at all times. They’re often used in applications that require a constant outlet pressure regardless of the tank level.

Inlet | Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CGA Number | Location | Thread Direction | Pressure Gauge Range, psi | Stage | For Tube OD | Location | Pressure Range, psi | Pressure Adjustment Method | Each | |

Swagelok® Female Outlet × NGO Female Inlet | ||||||||||

Brass/Stainless Steel Body—316 Stainless Steel Diaphragm and PTFE Seal with Relief Valve | ||||||||||

| CGA 350 | Side | Left Hand | 0 to 4,000 | Single | 1/4" | Side | 0 to 15 | Knob | 0000000 | 0000000 |

| CGA 350 | Side | Left Hand | 0 to 4,000 | Single | 1/4" | Side | 0 to 125 | Knob | 0000000 | 000000 |

| CGA 350 | Side | Left Hand | 0 to 4,000 | Two | 1/4" | Side | 0 to 15 | Knob | 0000000 | 000000 |

| CGA 350 | Side | Left Hand | 0 to 4,000 | Two | 1/4" | Side | 0 to 125 | Knob | 0000000 | 000000 |

| CGA 350 | Side | Left Hand | 0 to 4,000 | Two | 1/4" | Side | 0 to 500 | Knob | 0000000 | 000000 |

Pressure-Regulating Valves for Fuel Gases

- For Use With: See Table

- Temperature Range: See Table

Install these valves directly in gas distribution pipelines for acetylene, hydrogen, or propane. They automatically reduce a high inlet pressure to a lower, stable outlet pressure. Valves have two outlets to fit various pipe configurations and come with a plug to close the unused outlet. The gauge monitors outlet pressure. All valves are single stage and reduce pressure in one step, which causes the outlet pressure to fluctuate.

Choose a valve with a maximum outlet pressure that’s approximately twice your application’s normal operating pressure. Your operating pressure should never exceed 75% of the valve’s maximum outlet pressure.

Inlet | Outlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Use With | Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Adjustment Method | Pressure Gauge Range, psi | Temperature Range, ° F | End-to-End Lg. | Port-to-Port Lg. | Each | |

NPT Female | ||||||||||||

Brass Body—Stainless Steel Diaphragm and Neoprene Seal | ||||||||||||

| Hydrogen, Propane | 1/4 | Side | 500 | 1/4 | Bottom, Side | T-Handle | 0 to 60 | 0° to 120° | 2.40" | 1.01" | 0000000 | 0000000 |

| Hydrogen, Propane | 1/4 | Side | 500 | 1/4 | Bottom, Side | T-Handle | 0 to 200 | 0° to 120° | 2.40" | 1.01" | 0000000 | 000000 |