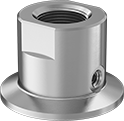

Sanitary Gauge Guards

Keeping corrosive substances from touching pressure gauges used in food-processing and pharmaceutical plants, these guards have a sanitary design. Made of 316 stainless steel, they won’t rust from frequent washdowns with harsh cleaners and sanitizers. They have continuously-welded seams and polished surfaces, so there aren’t any pits for bacteria to grow in. Removing them for cleaning and maintenance is easy thanks to their quick-clamp connection, which is sometimes called a tri-clamp.

Also known as isolators and diaphragm seals, these guards have a 316 stainless steel gasket to shield the pressure gauges from corrosion. Before use, fill the guards with fluid such as glycerin or silicone that’s suitable for food contact.

For technical drawings and 3-D models, click on a part number.

Outlet Quick-Clamp Tube Connection | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inlet Pipe Connection | For Tube OD | Flange OD | Gasket Material | For Use With | Minimum Pressure, psi | Maximum Pressure | Maximum Temperature | Height | Interior Smoothness, Ra | Each | |

316 Stainless Steel Body | |||||||||||

| 1/4 NPT Female | 1 1/2" | 1.984" | 316 Stainless Steel | Acetylene, Air, Ammonia, Beverage, Boric Acid, Carbon Dioxide, Diesel Fuel, Ethanol, Food, Gasoline, Hydraulic Fluid, Hydrogen, Oxygen, Pharmaceuticals, Wastewater, Water | 30 | Not Rated | Not Rated | 1 3/8" | 32 | 0000000 | 0000000 |

| 1/4 NPT Female | 2" | 2.516" | 316 Stainless Steel | Acetylene, Air, Ammonia, Beverage, Boric Acid, Carbon Dioxide, Diesel Fuel, Ethanol, Food, Gasoline, Hydraulic Fluid, Hydrogen, Oxygen, Pharmaceuticals, Wastewater, Water | 30 | Not Rated | Not Rated | 1 1/8" | 32 | 0000000 | 000000 |

| 1/2 NPT Female | 1 1/2" | 1.984" | 316 Stainless Steel | Acetylene, Air, Ammonia, Beverage, Boric Acid, Carbon Dioxide, Diesel Fuel, Ethanol, Food, Gasoline, Hydraulic Fluid, Hydrogen, Oxygen, Pharmaceuticals, Wastewater, Water | 30 | Not Rated | Not Rated | 1 3/8" | 32 | 0000000 | 000000 |

Pressure-Regulating Valves with

Push-to-Connect Fittings for Food and Beverage

- For Use With: Food and Beverage

- Temperature Range: 35° to 125° F

Insert plastic or soft metal tubing into the push-to-connect fittings on these valves for a low-pressure seal in food and beverage lines. They automatically reduce a high, variable inlet pressure to a lower, stable outlet pressure. Adjust the outlet pressure within the range. They have two gauge ports.

For technical drawings and 3-D models, click on a part number.

Inlet | Outlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tube Connection Type | For Tube OD | Location | Max. Pressure, psi | For Tube OD | Location | Pressure Adjustment Method | End-to-End Length | Specifications Met | Choose an Outlet Pressure Range, psi | Each | |

Push-to-Connect Female | |||||||||||

Noryl PPO Body—Buna-N Diaphragm and Seal | |||||||||||

| Push to Connect | 1/4" | Side | 300 | 1/4" | Side | Screw | 2 13/16" | NSF/ANSI 61 | 0000000 | 0000000 | |

Pressure-Regulating Valves with Compression Fittings for Food and Beverage

- For Use With: Food and Beverage

- Temperature Range: 35° to 125° F

Compression fittings bite down on hard metal and plastic tubing for a tighter seal than push-to-connect fittings. These valves automatically reduce a high, variable inlet pressure to a lower, stable outlet pressure. Adjust the outlet pressure within the range. The Buna-N/stainless steel diaphragm and EPDM seal are FDA compliant 21 CFR 177.2600.

For technical drawings and 3-D models, click on a part number.

Inlet | Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Location | Max. Pressure, psi | For Tube OD | Location | Pressure Adjustment Method | End-to-End Lg. | Specifications Met | Choose an Outlet Pressure Range, psi | Each | |

Compression Female | ||||||||||

Acetal Body—Buna-N/Stainless Steel Diaphragm and EPDM Seal | ||||||||||

| 1/4" | Side | 250 | 1/4" | Side | Knob | 2" | FDA Compliant 21 CFR 177.2600 | 0000000 | 0000000 | |

Threaded Pressure-Regulating Valves for Food and Beverage

- For Use With: Food and Beverage

- Temperature Range: 35° to 125° F

These valves are often used to regulate pressure in food and beverage lines. They automatically reduce a high, variable inlet pressure to a lower, stable outlet pressure. Adjust the outlet pressure within the range. Valves have two gauge ports and come with plugs to close the unused ports.

Valves with knob have a Buna-N/Nylon diaphragm which is FDA Compliant 21 CFR 177.2600.

For technical drawings and 3-D models, click on a part number.

Inlet | Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Adjustment Method | End-to-End Lg. | Specifications Met | Choose an Outlet Pressure Range, psi | Each | |

NPT Female | ||||||||||

Acetal Body—Buna-N/Nylon Diaphragm and EPDM Seal with Knob | ||||||||||

| 1/4 | Side | 150 | 1/4 | Side | Knob | 1 5/8" | FDA Compliant 21 CFR 177.2600, NSF/ANSI 61 | 0000000 | 000000 | |

Noryl PPO Body—Buna-N Diaphragm and Seal with Screw | ||||||||||

| 1/4 | Side | 300 | 1/4 | Side | Screw | 1 9/16" | NSF/ANSI 61 | 0000000 | 000000 | |

Sanitary Pressure-Regulating Valves

- For Use With: Food and Beverage

- Temperature Range: -40° to 120°F

- Specifications Met: 3-A Certified 64-00, ANSI/FCI 70-2 Class III, FDA Compliant 21 CFR 177.2600

Regulate air, gas, and liquid pressure on food, beverage, and pharmaceutical lines with these valves—they’re 3-A certified to meet sanitary design standards. Attach them to your line to reduce a high, variable inlet pressure to a lower, stable outlet pressure.

Twist the T-handle on top of the valve to adjust the outlet pressure. When the valve is closed, a seal on the outlet prevents leaks and helps maintain consistent pressure. These valves meet ANSI/FCI 70-2 Class III, which means a maximum of 0.1% of fluid, gas, or air can escape while they are fully closed. The spring and valve mechanism are sealed behind the diaphragm, so contaminants can’t enter. Both the diaphragm and seals hold up to water, detergents, and chemicals. They’re also FDA compliant for direct contact with food.

Made of 316 stainless steel, these valves won’t corrode from frequent washdowns with harsh cleaners. They connect to your line with quick-clamp sanitary fittings, also known as tri-clamp connections, which are easier to remove and sanitize than threaded connections. The polished interior is extremely smooth, so there’s nowhere for bacteria to hide. They’re also self-draining, so liquids drain completely and don’t contaminate your line. Keep these valves open during clean-in-place (CIP) cycles with a locking pin.

For technical drawings and 3-D models, click on a part number.

Inlet | Outlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Location | Max. Pressure, psi | For Tube OD | Flange OD | Location | Pressure Adjustment Method | End-to-End Lg. | Choose an Outlet Pressure Range, psi | Each | |

Quick Clamp | |||||||||||

316 Stainless Steel Body—EPDM Diaphragm and EPDM Seal | |||||||||||

| 3/4" | 0.984" | Bottom | 200 | 3/4" | 0.984" | Side | T-Handle | 8 5/8" | 0000000 | 000000000 | |

| 1" | 1.984" | Bottom | 200 | 1" | 1.984" | Side | T-Handle | 8 5/8" | 0000000 | 00000000 | |

316 Stainless Steel Body—PTFE Plastic Diaphragm and EPDM Seal | |||||||||||

| 1 1/2" | 1.984" | Bottom | 125 | 1 1/2" | 1.984" | Side | T-Handle | 13 3/8" | 0000000 | 00000000 | |

| 2" | 2.516" | Bottom | 100 | 2" | 2.516" | Side | T-Handle | 16 1/8" | 0000000 | 00000000 | |

Sanitary Back-Pressure-Regulating Valves

- For Use With: Food and Beverage

- Temperature Range: -40° to 120°F

- Specifications Met: 3-A Certified 64-00, ANSI/FCI 70-2 Class III, FDA Compliant 21 CFR 177.2600

Designed to meet 3-A sanitary standards, these valves regulate liquid, gas, and air pressure in hygienic zones of food and beverage plants. They’re often used at the end of pipelines on processing and sanitizing equipment. Made of 316 stainless steel, they won't corrode from frequent washdowns with harsh cleaners. With an extremely smooth interior that self-drains, bacteria won't have time or space to grow. The spring and internal valve mechanisms are sealed off behind the diaphragm, which also prevents contamination. They connect with quick-clamp fittings, so disassembling to clean your line takes little time.

These valves obstruct flow to maintain sufficient operating pressure in your system. If the system pressure exceeds the set pressure, they exhaust through the outlet. They meet ANSI/FCI 70-2 Class III standards for shut-off valves, meaning a maximum of 0.1% of fluid, gas, or air will escape through the outlet when they’re closed. An integrated T-handle lets you set the outlet pressure without additional tools. The diaphragm and seal resist repeated exposure to water, and they’re FDA compliant for direct contact with food.

For technical drawings and 3-D models, click on a part number.

Inlet | Outlet | Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Location | Max. Pressure, psi | For Tube OD | Flange OD | Location | End-to-End | Port-to-Port | Choose an Outlet Pressure Range, psi | Each | |

Quick Clamp | |||||||||||

316 Stainless Steel Body—EPDM Diaphragm and EPDMSeal | |||||||||||

| 3/4" | 0.984" | Side | 200 | 3/4" | 0.984" | Bottom | 6 5/8" | 3 9/32" | 000000 | 000000000 | |

| 1" | 1.984" | Side | 200 | 1" | 1.984" | Bottom | 6 11/16" | 3 5/16" | 000000 | 00000000 | |

316 Stainless Steel Body—PTFE Plastic Diaphragm and EPDMSeal | |||||||||||

| 2" | 2.516" | Side | 100 | 2" | 2.516" | Bottom | 11 5/8" | 5 3/4" | 000000 | 00000000 | |