How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

How to Measure Threaded Pipe Size

More

UV-Resistant Polypropylene Pipe Fittings for Chemicals

Made of polypropylene, these fittings won’t deteriorate when exposed to the damaging effects of ultraviolet light and are suitable to use outdoors. They have the chemical resistance to withstand a wide variety of acids, solvents, and other harsh substances. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Schedule 40 fittings have thinner walls than Schedule 80 fittings and are typically used in commercial and residential applications.

Schedule 80 fittings have thicker, stronger walls than Schedule 40 fittings for heavy duty, industrial chemical processing applications.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

For technical drawings and 3-D models, click on a part number.

- For Use With: Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide, Sulfuric Acid (30%), Water

- Temperature Range: 0° to 150° F

- Pipe Nipples and Pipe: Use Schedule 80 Polypropylene Plastic

- Flanges: Use Class 150 Polypropylene Plastic

| Pipe Size (A) | Pipe Size (B) | Schedule | Material | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1 | 3/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 00000 |

| 1 1/2 | 1 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 00000 |

| 1 1/2 | 1 1/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 00000 |

| 2 | 1/2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 00000 |

| 2 | 1 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 00000 |

| 2 | 1 1/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 00000 |

| 2 | 1 1/2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 00000 |

| 3 | 2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 00000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

- For Use With: Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide, Sulfuric Acid (30%), Water

- Temperature Range: See table

- Pipe Nipples and Pipe: Use Schedule 80 Polypropylene Plastic

- Flanges: Use Class 150 Polypropylene Plastic

| Pipe Size (A) | Pipe Size (B) | Schedule | Material | Color | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4 | 3/8 | 80 | Polypropylene Plastic | Black | 150 psi @ 72° F | 32° to 140° | 000000000 | 00000 |

| 1/2 | 1/4 | 80 | Polypropylene Plastic | Black | 150 psi @ 72° F | 32° to 140° | 000000000 | 000 |

| 1/2 | 3/8 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 3/4 | 3/8 | 80 | Polypropylene Plastic | Black | 150 psi @ 72° F | 32° to 140° | 000000000 | 000 |

| 3/4 | 1/2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1 | 1/2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1 | 3/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1 1/4 | 3/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1 1/4 | 1 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1 1/2 | 1 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1 1/2 | 1 1/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 2 | 1 1/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 2 | 1 1/2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 3 | 2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 00000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

- For Use With: Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide, Sulfuric Acid (30%), Water

- Temperature Range: See table

- Pipe Nipples and Pipe: Use Schedule 80 Polypropylene Plastic

- Flanges: Use Class 150 Polypropylene Plastic

| Pipe Size (A) | Pipe Size (B) | Schedule | Material | Color | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4 | 1/8 | 80 | Polypropylene Plastic | Black | 150 psi @ 72° F | 32° to 140° | 000000000 | 00000 |

| 3/8 | 1/8 | 80 | Polypropylene Plastic | Black | 150 psi @ 72° F | 32° to 140° | 000000000 | 0000 |

| 3/8 | 1/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1/2 | 1/8 | 80 | Polypropylene Plastic | Black | 150 psi @ 72° F | 32° to 140° | 000000000 | 0000 |

| 1/2 | 1/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1/2 | 3/8 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 3/4 | 1/8 | 80 | Polypropylene Plastic | Black | 150 psi @ 72° F | 0° to 140° | 000000000 | 0000 |

| 3/4 | 1/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 3/4 | 3/8 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 3/4 | 1/2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1 | 1/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1 | 1/2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1 | 3/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1 1/4 | 3/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1 1/4 | 1 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1 1/2 | 3/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1 1/2 | 1 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 1 1/2 | 1 1/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 2 | 3/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 2 | 1 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 2 | 1 1/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 2 | 1 1/2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 0000 |

| 3 | 1 1/2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 00000 |

| 3 | 2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 00000 |

| 4 | 3 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 0° to 150° | 000000000 | 00000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

- For Use With:

Pipe Sizes 1/8 to 1/2: Air, Calcium Chloride, Sodium Chloride, Water

Pipe Sizes 3/4 to 3: Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide, Sulfuric Acid (30%), Water - Temperature Range: 32° to 140° F

- Pipe Nipples and Pipe: Use Schedule 80 Polypropylene Plastic

- Flanges: Use Class 150 Polypropylene Plastic

| Pipe Size | Schedule | Drive Size | Material | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/8 | 40 | 5/8" | Polypropylene Plastic | Black | 150 psi @ 72° F | 00000000 | 00000 |

| 1/4 | 40 | 5/8" | Polypropylene Plastic | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 3/8 | 40 | 3/4" | Polypropylene Plastic | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1/2 | 40 | 1" | Polypropylene Plastic | Black | 150 psi @ 72° F | 00000000 | 0000 |

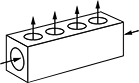

Right-Angle Flow Rectangular Manifolds

Distribute air or fluid to multiple locations from a single supply source with these manifolds. They are also known as headers. They have mounting holes, so you can mount from the top or side.

Polypropylene manifolds have better moisture resistance than other plastic manifolds, so they won’t soften and lose strength in high-humidity applications. Use a plug (sold separately) to close off any unused inlets and outlets.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water

- Temperature Range: 32° to 230° F

- Maximum Pressure: 150 psi @ 72° F

| No. of Outlets | Inlet Pipe Size | Outlet Pipe Size | Lg. | Wd. | Ht. | Outlet Ctr.-to-Ctr. | Color | Each | |

Outlets on One Side—Standard Outlet Spacing | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2 | 1/4 | 1/8 | 1 3/4" | 1" | 1" | 3/4" | White | 00000000 | 000000 |

| 2 | 3/8 | 1/4 | 2 3/8" | 1 1/4" | 1 1/4" | 7/8" | White | 00000000 | 00000 |

| 2 | 1/2 | 3/8 | 2 3/4" | 1 1/2" | 1 1/2" | 1" | White | 00000000 | 00000 |

| 3 | 1/4 | 1/8 | 2 1/2" | 1" | 1" | 3/4" | White | 00000000 | 00000 |

| 3 | 3/8 | 1/4 | 3 1/4" | 1 1/4" | 1 1/4" | 7/8" | White | 00000000 | 00000 |

| 3 | 1/2 | 3/8 | 3 3/4" | 1 1/2" | 1 1/2" | 1" | White | 00000000 | 00000 |

| 4 | 1/4 | 1/8 | 3 1/4" | 1" | 1" | 3/4" | White | 00000000 | 00000 |

| 4 | 3/8 | 1/4 | 4 1/8" | 1 1/4" | 1 1/4" | 7/8" | White | 00000000 | 00000 |

| 4 | 1/2 | 3/8 | 4 3/4" | 1 1/2" | 1 1/2" | 1" | White | 00000000 | 00000 |

| 5 | 1/4 | 1/8 | 4" | 1" | 1" | 3/4" | White | 00000000 | 00000 |

| 5 | 3/8 | 1/4 | 5" | 1 1/4" | 1 1/4" | 7/8" | White | 00000000 | 00000 |

| 6 | 1/4 | 1/8 | 4 3/4" | 1" | 1" | 3/4" | White | 00000000 | 00000 |

| 6 | 3/8 | 1/4 | 5 7/8" | 1 1/4" | 1 1/4" | 7/8" | White | 00000000 | 00000 |

| 6 | 1/2 | 3/8 | 6 3/4" | 1 1/2" | 1 1/2" | 1" | White | 00000000 | 00000 |

| 8 | 1/4 | 1/8 | 6 1/4" | 1" | 1" | 3/4" | White | 00000000 | 00000 |

| 8 | 3/8 | 1/4 | 7 5/8" | 1 1/4" | 1 1/4" | 7/8" | White | 00000000 | 00000 |

| 8 | 1/2 | 3/8 | 8 3/4" | 1 1/2" | 1 1/2" | 1" | White | 00000000 | 00000 |

| 10 | 1/4 | 1/8 | 7 3/4" | 1" | 1" | 3/4" | White | 00000000 | 00000 |

| 10 | 3/8 | 1/4 | 9 3/8" | 1 1/4" | 1 1/4" | 7/8" | White | 00000000 | 00000 |

| 10 | 1/2 | 3/8 | 10 3/4" | 1 1/2" | 1 1/2" | 1" | White | 00000000 | 00000 |

Plastic Barbed Hose Fittings for Water

Made of polypropylene, these fittings have good corrosion and abrasion resistance, and are lighter in weight than metal barbed hose fittings. Slide the barbed end into plastic or rubber hose and secure with a clamp.

Fittings with a threaded end are also known as hose nipples.

For technical drawings and 3-D models, click on a part number.

Hose × Male

Threaded Pipe

- Maximum Pressure: See table

- Temperature Range: 10° to 150° F

- Attachment Type: Use Worm-Drive Clamps or Bolt Clamps

| For Hose ID | Pipe Size | Color | Max. Pressure | Each | |

Polypropylene Plastic | |||||

|---|---|---|---|---|---|

| 1/4" | 1/8 | Black | 150 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 1/4 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1/4" | 3/8 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1/4" | 1/2 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1/4" | 3/4 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 5/16" | 1/4 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 5/16" | 3/8 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 1/8 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 1/4 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 3/8 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 3/4 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 1/4 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 3/8 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 1/2 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 3/4 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 1 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 5/8" | 3/8 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 5/8" | 1/2 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 5/8" | 3/4 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 3/4" | 1/2 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 3/4" | 3/4 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 3/4" | 1 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1" | 3/4 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1" | 1 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1" | 1 1/4 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1 1/4" | 1 1/4 | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1 1/2" | 1 1/2 | Black | 150 psi @ 72° F | 00000000 | 00000 |

| 2" | 2 | Black | 150 psi @ 72° F | 00000000 | 00000 |