Air-Powered Hold-Down Toggle Clamps

Use for repetitive clamping and in production environments. Air from one inlet port engages the clamp, and air from the other inlet port disengages it. Clamps maintain the full-rated holding capacity even with a loss of air pressure. Fittings (not included) are required to connect the clamp's ports to a control valve and an air line.

Clamps with open arm allow you to move the holding screw to any position along the arm. To achieve maximum holding capacity, position the screw closest to the base. Capacity decreases by as much as 65% when the screw is positioned at the end of the arm.

For technical drawings and 3-D models, click on a part number.

Arm | When Clamped | Holding Screws | Air Inlet and Outlet | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Holding Capacity, lbs. | Max. Clamping Clearance | Ht. | Lg. | Opening Angle | O'all Lg. | O'all Ht. | No. of | Tip Material | Thread Size | Max. Air Inlet Pressure, psi | Pipe Size | Thread Size | Thread Type | Gender | Temperature Range, °F | Body Material | Each | |

With Open Arm | ||||||||||||||||||

| 100 | 3/8" | 3/4" | 1 1/8" | 95° | 5 5/8" | 1 5/8" | 2 | Steel, Rubber | M5 | 40 | __ | M5 | Metric | Female | -10° to 165° | Steel | 0000000 | 0000000 |

| 200 | 5/8" | 1 1/8" | 1 3/4" | 100° | 7 3/4" | 2 5/8" | 2 | Steel, Rubber | M6 | 30 | 1/8 | __ | NPT | Female | -10° to 165° | Steel | 0000000 | 000000 |

| 375 | 29/32" | 1 3/8" | 2 1/2" | 100° | 9 3/8" | 3" | 2 | Steel, Rubber | 5/16"-18 | 45 | 1/8 | __ | NPT | Female | -10° to 165° | Steel | 0000000 | 000000 |

| 600 | 1 7/32" | 1 7/8" | 3 5/8" | 95° | 11 3/4" | 3 7/8" | 2 | Steel, Rubber | 3/8"-16 | 50 | 1/8 | __ | NPT | Female | -10° to 165° | Steel | 0000000 | 000000 |

| 1,000 | 1 15/32" | 2 1/4" | 4 7/8" | 90° | 15 1/4" | 4 1/2" | 2 | Steel, Rubber | 1/2"-13 | 75 | 1/4 | __ | NPT | Female | -10° to 165° | Steel | 0000000 | 000000 |

With Solid Arm | ||||||||||||||||||

| 4,000 | 3 7/8" | 3 7/8" | 4 13/16" | 95° | 17 1/2" | 7 1/8" | __ | __ | __ | 145 | 1/4 | __ | NPT | Female | -14° to 194° | Steel | 0000000 | 000000 |

Long-Life Dual-Mount Air-Powered Hold-Down Toggle Clamps

These clamps have double the service life of other air-powered toggle clamps. Use for repetitive clamping and in production environments. They have two sets of holes for mounting on the bottom or side. Air from one inlet port engages the clamp, and air from the other inlet port disengages it. Clamps maintain the full-rated holding capacity even with a loss of air pressure. Capacity decreases by as much as 65% when mounting at the end of the arm. Fittings (not included) are required to connect the clamp’s ports to a control valve and an air line.

For technical drawings and 3-D models, click on a part number.

Arm | When Clamped | Air Inlet and Outlet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Holding Capacity, lbs. | Max. Clamping Clearance | Ht. | Lg. | Opening Angle | O'all Lg. | O'all Ht. | Max. Air Inlet Pressure, psi | Thread Size | Thread Type | Gender | Temperature Range, °F | Body Material | Each | |

With Solid Arm | ||||||||||||||

| 220 | 3/16" | 3/16" | 1 9/16" | 120° | 2 1/2" | 4 1/16" | 87 | M5 | Metric | Male | -14° to 194° | 6061 Aluminum | 000000 | 0000000 |

| 530 | 1/4" | 1/4" | 2" | 120° | 3" | 4 11/16" | 87 | M5 | Metric | Male | -14° to 194° | 6061 Aluminum | 000000 | 000000 |

| 885 | 3/8" | 3/8" | 2 1/8" | 120° | 3 1/2" | 5 15/16" | 87 | M5 | Metric | Male | -14° to 194° | 6061 Aluminum | 000000 | 000000 |

Dual-Mount Air-Powered Hold-Down Toggle Clamps

Two sets of holes allow mounting on the bottom or side. Use these clamps for repetitive clamping and in production environments. Air from one inlet port engages the clamp, and air from the other inlet port disengages it. Clamps maintain the full-rated holding capacity even with a loss of air pressure. They have an open arm, so you can move the holding screw to any position along the arm. To achieve maximum holding capacity, position the screw closest to the base. Capacity decreases by as much as 65% when the screw is positioned at the end of the arm. Fittings (not included) are required to connect the clamp’s ports to a control valve and an air line.

For technical drawings and 3-D models, click on a part number.

Arm | When Clamped | Holding Screws | Air Inlet and Outlet | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Holding Capacity, lbs. | Max. Clamping Clearance | Ht. | Lg. | Opening Angle | O'all Lg. | O'all Ht. | No. of | Tip Material | Thread Size | Max. Air Inlet Pressure, psi | Pipe Size | Thread Type | Gender | Temperature Range, °F | Body Material | Each | |

With Open Arm | |||||||||||||||||

| 350 | 1 5/8" | 2 11/16" | 2 3/8" | 95° | 6 1/4" | 7 1/2" | 2 | Steel, Rubber | 5/16"-18 | 145 | 1/8 | NPT | Female | -14° to 194° | Steel | 0000000 | 0000000 |

| 600 | 2 5/8" | 3 7/8" | 3 1/4" | 85° | 8 5/8" | 9" | 2 | Steel, Rubber | 3/8"-16 | 145 | 1/8 | NPT | Female | -14° to 194° | Steel | 0000000 | 000000 |

Air-Powered Hold-Down Fixture Clamps

Adjust the air pressure to quickly and consistently clamp and release parts. The arm on these clamps rotates 90° into position over the workpiece and then moves straight down to clamp. Disengage to rotate the arm out of the way and load or unload parts. Also known as swing clamps, they are used with a solid state switch or Reed function switch with M8 male 3-pin connectors. Connect the clamp's ports to a control valve and an air line. Clamps mount with screws.

Clamps with rubber-tipped holding screw are nonmarring. Tip is removable.

For technical drawings and 3-D models, click on a part number.

Body | Holding Screw | Female Air Inlet and Outlet | Mount. Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Clamping Clearance | Vertical Travel During Rotation | Max. Clamping Stroke | Holding Cap., lbs. | Reach | Wd. | Dp. | O'all Ht. | Thread Size | Tip Material | Pipe Size | Thread Size | Thread Type | Mount. Fasteners Included | No. of | Dia. | Material | Each | |

90° Clockwise Rotation | ||||||||||||||||||

| 4 3/8" | 15/32" | 3/8" | 35 | 1 1/8" | 1 1/4" | 1 1/4" | 4 3/4" | 10-32 | Steel | __ | 10-32 | UNF | No | 6 | 3/16" | Aluminum | 00000000 | 0000000 |

| 5 1/2" | 3/4" | 1/2" | 130 | 2" | 2" | 3" | 6 3/8" | 3/8"-16 | Rubber | 1/8 | __ | NPT | No | 6 | 11/32" | Aluminum | 00000000 | 000000 |

90° Counterclockwise Rotation | ||||||||||||||||||

| 4 3/8" | 15/32" | 3/8" | 35 | 1 1/8" | 1 1/4" | 1 1/4" | 4 3/4" | 10-32 | Steel | __ | 10-32 | UNF | No | 6 | 3/16" | Aluminum | 00000000 | 000000 |

| 5 1/2" | 3/4" | 1/2" | 130 | 2" | 2" | 3" | 6 3/8" | 3/8"-16 | Rubber | 1/8 | __ | NPT | No | 6 | 11/32" | Aluminum | 00000000 | 000000 |

Threaded Air-Powered Hold-Down Fixture Clamps

Screw these clamps directly into a tapped hole and use air pressure to quickly and consistently clamp and release parts. The arm rotates 90° into position over the workpiece and then moves straight down to clamp. Disengage to rotate the arm out of the way and load or unload parts. Also known as swing clamps, they're used with a solid state switch or Reed function switch with M8 male 3-pin connectors. Connect the clamp's ports to a control valve and an air line. To hold clamps in an untapped hole, use a mounting block (sold separately).

Clamps with rubber-tipped holding screw are nonmarring. Tip is removable.

For technical drawings and 3-D models, click on a part number.

Body | Holding Screw | Female Air Inlet and Outlet | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Clamping Clearance | Vertical Travel During Rotation | Max. Clamping Stroke | Holding Cap., lbs. | Reach | Thread Size | Thread Lg. | O'all Ht. | Thread Size | Tip Material | Pipe Size | Thread Size | Thread Type | Material | Each | |

90° Clockwise Rotation | |||||||||||||||

| 4 3/8" | 15/32" | 3/8" | 35 | 1 1/8" | 1 1/8"-16 | 2 7/8" | 4 3/4" | 10-32 | Steel | __ | 10-32 | UNF | Aluminum | 00000000 | 0000000 |

| 5 5/16" | 3/4" | 1/2" | 95 | 1 5/8" | 1 3/4"-12 | 3 1/4" | 6 1/8" | 3/8"-16 | Rubber | 1/8 | __ | NPT | Aluminum | 00000000 | 000000 |

90° Counterclockwise Rotation | |||||||||||||||

| 4 3/8" | 15/32" | 3/8" | 35 | 1 1/8" | 1 1/8"-16 | 2 7/8" | 4 3/4" | 10-32 | Steel | __ | 10-32 | UNF | Aluminum | 00000000 | 000000 |

| 5 5/16" | 3/4" | 1/2" | 95 | 1 5/8" | 1 3/4"-12 | 3 1/4" | 6 1/8" | 3/8"-16 | Rubber | 1/8 | __ | NPT | Aluminum | 00000000 | 000000 |

Air-Powered Push Toggle Clamps

Use for repetitive clamping and in production environments. These clamps secure when the plunger is fully extended to hold a workpiece from the side. Air from one inlet port engages the clamp, and air from the other inlet port disengages it. Clamps maintain the full-rated holding capacity even with a loss of air pressure. They have a threaded plunger to accommodate threaded holding screws and other threaded fixtures (not included). Fittings (not included) are required to connect the clamp's ports to a control valve and an air line.

For technical drawings and 3-D models, click on a part number.

Plunger | When Clamped | Air Inlet and Outlet | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Holding Capacity, lbs. | Lg. | Ht. | Travel | Dia. | Thread Size | Thread Lg. | O'all Ht. | O'all Lg. | Max. Air Inlet Pressure, psi | Pipe Size | Thread Type | Gender | Temperature Range, °F | Body Material | Each | |

| 600 | 1 1/4" | 1 1/8" | 3/4" | 7/16" | 5/16"-18 | 1" | 3" | 9 7/8" | 60 | 1/8 | NPT | Female | -10° to 165° | Steel | 0000000 | 0000000 |

| 2,500 | 2" | 1 1/8" | 1 1/4" | 5/8" | 3/8"-16 | 1 1/4" | 3 5/8" | 13 1/2" | 145 | 1/8 | NPT | Female | -10° to 165° | Steel | 0000000 | 000000 |

| 16,000 | 3 3/8" | 2 5/8" | 2" | 1" | 5/8"-11 | 2" | 7 1/4" | 20 5/8" | 145 | 1/4 | NPT | Female | -10° to 165° | Steel | 0000000 | 000000 |

Air-Powered Locating Pin Retractors

A good choice for automated clamping, these retractors use compressed air to extend and retract a locating pin, protecting the pin from damage in applications where fixtures move through a process, such as along a conveyor belt. Commonly used in automated welding applications, the highly accurate air cylinder ensures repeatable locating. Each retractor has two air inlet ports, one extends the pin and the other retracts.

Retractors have a position sensor with an M12 connection for activating relays and controllers in automated processes.

Secure a locating pin to the top of the retractor using four M5 set screws (not included). For easy alignment, shoulder-style locating pins are recommended.

Force | Overall | Locating Pin | Air Inlet and Outlet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stroke Lg. | Stroke | Retraction | Lateral Tolerance | Lg. | Wd. | Ht. When Retracted | For Max. Shank Dia. | Mounting Hole Thread Size | Max. Pressure, psi | Pipe Size | Thread Type | Gender | Sensor Cable Lg. | Each | |

Aluminum Body | |||||||||||||||

with A-Code, 4-Pole, Male Sensor Connection | |||||||||||||||

| 0.787" | 76 lbs. @ 72 psi | 56 lbs. @ 72 psi | 0.003" | 1 7/8" | 1 3/4" | 6 7/8" | 5/8" | M16 | 87 | 1/8 | BSPP | Female | 4 3/4" | 0000000 | 0000000 |

| 1.575" | 76 lbs. @ 72 psi | 56 lbs. @ 72 psi | 0.005" | 1 7/8" | 1 3/4" | 8 1/2" | 5/8" | M16 | 87 | 1/8 | BSPP | Female | 4 3/4" | 0000000 | 000000 |

Vacuum Workholding Plates

Also known as vacuum chucks, these plates secure thin and flexible parts that can’t be held with vises or clamps for milling, drilling, routing, and finishing operations. Connect the system to your shop’s compressed air supply and it's ready to use. For applications requiring only part of the plate surface, use the gasket cord to seal off the area.

Air Inlet | Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Ht. | Max. Vacuum, in. of Hg | Recommended Operating Air Pressure, psi | Air Consumption | Connection Type | Quick-Disconnect Shape | Coupling Size | Gender | No. of | Dia. | Ctr.-to-Ctr. | Includes | Each | |

| 17 3/4" | 9 1/2" | 1" | 27.9 | 58-110 | 3.4 scfm @ 58 psi | Hose | Industrial | 1/4 | Male | 2 | 1/2" | 15 3/8" | Vacuum Generator, 15 ft. Vacuum Hose, 10 ft. EPDM Foam Gasketing | 0000000 | 000000000 |

| 17 3/4" | 12" | 1" | 27.9 | 58-110 | 3.4 scfm @ 58 psi | Hose | Industrial | 1/4 | Male | 2 | 1/2" | 15 3/8" | Vacuum Generator, 15 ft. Vacuum Hose, 15 ft. EPDM Foam Gasketing | 0000000 | 00000000 |

| 17 3/4" | 14" | 1" | 27.9 | 58-110 | 3.4 scfm @ 58 psi | Hose | Industrial | 1/4 | Male | 2 | 1/2" | 15 3/8" | Vacuum Generator, 15 ft. Vacuum Hose, 15 ft. EPDM Foam Gasketing | 0000000 | 00000000 |

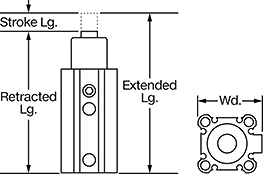

Short-Stroke Clamping Air Cylinders

Also known as air clamps, these cylinders are used to apply force in holding applications. All are single acting with air-extend actuation—also known as push style, air extends the rod and cylinders have a spring that returns the rod to its original position.

For technical drawings and 3-D models, click on a part number.

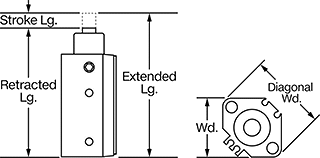

Rotary Clamping Air Cylinders

Clamp items in place to complete a step in your manufacturing process. These air cylinders rotate while actuating, so you can position, assemble, and inspect items. The body of these air cylinders has threaded through-holes on the face and sides, so you can mount them directly to equipment and thread accessories on. The rod is internally threaded, allowing you to attach an arm as needed for your application.

The piston is magnetic, so you can use these slides with sensors (not included) to activate relays and controllers. When the piston moves past a sensor, the sensor activates. You can use multiple sensors—one for each action you want to trigger.

For technical drawings and 3-D models, click on a part number.

Lg. | Air Inlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stroke | Retracted | Extended | Diagonal Wd. | Force @ 100 psi, lbs. | Body Material | Rod Thread Size | Pipe Size | Thread Size | Thread Type | Gender | Each | |

90° Clockwise Shaft Rotation | ||||||||||||

Sensor-Ready Base Mount | ||||||||||||

16mm Bore Size (29mm Wd.) | ||||||||||||

| 20mm | 88mm | 115mm | __ | 8 | Aluminum | M5 x 0.8 mm | __ | M5 × 0.8 | Metric | Female | 0000000 | 0000000 |

20mm Bore Size (36mm Wd.) | ||||||||||||

| 10mm | 92mm | 112mm | 47mm | 44 | Aluminum | M8 × 1.25 mm | __ | M5 × 0.8 | Metric | Female | 0000000 | 000000 |

| 20mm | 112mm | 142mm | 47mm | 44 | Aluminum | M8 × 1.25 mm | __ | M5 × 0.8 | Metric | Female | 0000000 | 000000 |

25mm Bore Size (40mm Wd.) | ||||||||||||

| 10mm | 93mm | 113mm | 52mm | 78 | Aluminum | M8 × 1.25 mm | __ | M5 × 0.8 | Metric | Female | 0000000 | 000000 |

| 20mm | 113mm | 143mm | 52mm | 78 | Aluminum | M8 × 1.25 mm | __ | M5 × 0.8 | Metric | Female | 0000000 | 000000 |

32mm Bore Size (49mm Wd.) | ||||||||||||

| 10mm | 113mm | 138mm | __ | 122 | Aluminum | M10 x 1.5 mm | 1/8 | __ | BSPT | Female | 0000000 | 000000 |

| 20mm | 133mm | 168mm | __ | 122 | Aluminum | M10 x 1.5 mm | 1/8 | __ | BSPT | Female | 0000000 | 000000 |

90° Counterclockwise Shaft Rotation | ||||||||||||

Sensor-Ready Base Mount | ||||||||||||

16mm Bore Size (29mm Wd.) | ||||||||||||

| 20mm | 88mm | 115mm | __ | 8 | Aluminum | M5 x 0.8 mm | __ | M5 × 0.8 | Metric | Female | 0000000 | 000000 |

20mm Bore Size (36mm Wd.) | ||||||||||||

| 10mm | 92mm | 112mm | 47mm | 44 | Aluminum | M8 × 1.25 mm | __ | M5 × 0.8 | Metric | Female | 0000000 | 000000 |

| 20mm | 112mm | 142mm | 47mm | 44 | Aluminum | M8 × 1.25 mm | __ | M5 × 0.8 | Metric | Female | 0000000 | 000000 |

25mm Bore Size (40mm Wd.) | ||||||||||||

| 10mm | 93mm | 113mm | 52mm | 78 | Aluminum | M8 × 1.25 mm | __ | M5 × 0.8 | Metric | Female | 0000000 | 000000 |

| 20mm | 113mm | 143mm | 52mm | 78 | Aluminum | M8 × 1.25 mm | __ | M5 × 0.8 | Metric | Female | 0000000 | 000000 |

32mm Bore Size (49mm Wd.) | ||||||||||||

| 10mm | 113mm | 138mm | __ | 122 | Aluminum | M10 x 1.5 mm | 1/8 | __ | BSPT | Female | 0000000 | 000000 |

| 20mm | 133mm | 168mm | __ | 122 | Aluminum | M10 x 1.5 mm | 1/8 | __ | BSPT | Female | 0000000 | 000000 |