About Composites

More

About Plastic

More

View a wire gauge conversion chart.

About Carbon Steel, Alloy Steel, Spring Steel, and Cast Iron

More

PVC-Coated Steel Wire

- Heat Treatment: Annealed (Softened)

- Heat Treatable: No

- Tensile Strength: 45,000 psi

- Specifications Met: ASTM A853

Coated with PVC for corrosion resistance, this carbon steel wire will stand up to outdoor use. It will stay in place when bent and is commonly used for bundling and as tag wire.

For technical drawings and 3-D models, click on a part number.

Finish | ||||||||

|---|---|---|---|---|---|---|---|---|

| Dia. | Lg., ft. | Thick. | Color | Max. Temperature, °F | Weight, lbs. | Container Type | Each | |

| 0.063" | 23 | 0.082" | Gold | 250° | 0.25 | Spool | 00000000 | 00000 |

| 0.063" | 95 | 0.082" | Gold | 250° | 1 | Spool | 00000000 | 0000 |

| 0.063" | 285 | 0.082" | Gold | 250° | 3 | Spool | 0000000 | 00000 |

| 0.063" | 950 | 0.082" | Gold | 250° | 10 | Spool | 00000000 | 00000 |

| 0.080" | 14 | 0.09" | Gold | 250° | 0.25 | Spool | 00000000 | 0000 |

| 0.080" | 58 | 0.09" | Gold | 250° | 1 | Spool | 00000000 | 0000 |

| 0.080" | 174 | 0.09" | Gold | 250° | 3 | Spool | 00000000 | 00000 |

| 0.080" | 580 | 0.09" | Gold | 250° | 10 | Spool | 00000000 | 00000 |

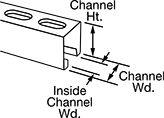

Strut Channel

PVC-coated steel channel has mild corrosion resistance. Its coating reduces slipping and won’t mar attachments.

For technical drawings and 3-D models, click on a part number.

Channel | 10 ft. | |||||

|---|---|---|---|---|---|---|

| Material | Ht. | Wd. | Thick. | Inside Channel Wd. | Each | |

| PVC-Coated Steel | 1 5/8" | 1 5/8" | 0.11" | 7/8" | 00000000 | 0000000 |

Easy-to-Form PVC-Coated Galvanized Steel Wire Cloth

Build screens, barriers, and enclosures that last—the PVC coating on this wire cloth provides excellent corrosion and wear resistance for a long service life. The welded joints keep opening sizes uniform and prevent fraying as you bend this wire cloth.

For technical drawings and 3-D models, click on a part number.

| Mesh Size | Opening Size | Open Area | Wire Dia. | 12" × 12" | 12" × 24" | 12" × 36" | 12" × 48" | 24" × 24" | 36" × 36" | 36" × 48" | 36" × 60" | 48" × 48" | |

Black | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 × 0.5 | 1.895" | 88% | 0.105" | 0000000 | |||||||||

| 0.67 × 0.67 | 1.395" | 85% | 0.105" | 0000000 | |||||||||

| 1 × 1 | 0.92" | 85% | 0.08" | 0000000 | |||||||||

| 1 × 1 | 0.895" | 80% | 0.105" | 0000000 | |||||||||

| 2 × 2 | 0.437" | 76% | 0.063" | 0000000 | |||||||||

Yellow | |||||||||||||

| 0.5 × 0.5 | 1.895" | 88% | 0.105" | 0000000 | |||||||||

| 0.67 × 0.67 | 1.395" | 85% | 0.105" | 0000000 | |||||||||

| 1 × 1 | 0.895" | 80% | 0.105" | 0000000 | |||||||||

| 2 × 2 | 0.437" | 76% | 0.063" | 0000000 | |||||||||

Recycled Plastic and Metal Composite Sheets

- Color: Gray

- Maximum Temperature: 230° F

- Tensile Strength: Not Rated

- Impact Strength: Not Rated

- Hardness: Not Rated

- Yield Strength: Not Rated

- For Use Outdoors: Yes

Made of recycled steel mill scale and reground plastic, these sheets are a sustainable, low-cost alternative to standard composites often used as counterweights, such as lead and steel. They are also the highest density product replacement to steel counterweights, although they’re not as dense as steel. Use them in cabinets, appliances, vehicles, signage, and industrial equipment. With a low carbon footprint, these sheets can help you meet criteria for sustainability certifications, such as LEED and Envision, or comply with company environmental initiatives. They’re extruded, so they won’t create dust, unlike concrete.

For technical drawings and 3-D models, click on a part number.

Metal-Backed Slippery PTFE

- Color: Black

- Temperature Range: -330° to 480° F

- For Use Outdoors: No

A layer of tin-plated steel adds structural support and makes this PTFE easy to form. Bend it to fit inside V-blocks and other channels, or cut it to form wear strips and thrust bearings. PTFE is naturally slippery, so it works well in parts that slide and roll.

For technical drawings and 3-D models, click on a part number.

Rebar Caps

Keep personnel safe from protruding rebar and pipe. Made of rigid plastic, these durable safety caps are bright orange or yellow for excellent visibility. All have flexible interior ridges to fit a range of ODs.

Style 2 caps have a flanged head that extends beyond the diameter of your rebar for added protection.

Style 3 caps have a reinforcing steel insert to protect against punctures when covering sharp ends of material. They help you meet OSHA Compliant 29 CFR 1926.701 requirements for protruding rebar.

For technical drawings and 3-D models, click on a part number.

Head | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | For OD | Inside Ht. | Dia. | Lg. | Wd. | Insert Material | Max. Temp., °F | Color | Specifications Met | Pkg. Qty. | Pkg. | |

Rigid Plastic | ||||||||||||

| 1 | 7/8"-2 1/4" | 2" | __ | __ | __ | __ | 120° | Orange | __ | 10 | 0000000 | 00000 |

| 2 | 3/8"-1" | 1 3/4" | 2 1/8" | __ | __ | __ | 120° | Orange | __ | 10 | 0000000 | 0000 |

| Each | ||||||||||||

| 3 | 3/8"-7/8" | 2 1/2" | __ | 4" | 4" | Steel | 120° | Orange | OSHA Compliant 29 CFR 1926.701 | __ | 0000000 | 0000 |

| 3 | 7/8"-1 3/8" | 2 3/4" | __ | 4" | 4" | Steel | 120° | Yellow | OSHA Compliant 29 CFR 1926.701 | __ | 0000000 | 0000 |