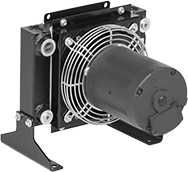

High-Capacity Heat Sinks for Oil

For greater cooling capacity and higher flow rates than other heat sinks for oil, these have a large fan. Also known as oil coolers, they're commonly used to cool hydraulic fluid and lubricating oil in cylinders and compressors. Cooling capacity is based on an initial temperature difference of 50° F.

Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Cap., Btu/hr. | Thread Size | Ht. | Wd. | Dp. | Heat Sink Material | Max. Pressure, psi | Max. Flow Rate, gpm | Max. Temp., °F | SAE Trade Size | Each | |

Female UN/UNF (SAE Straight) Threaded—For Use with Oil | |||||||||||

| 12,000 | 1 1/16"-12 | 13 3/4" | 13 3/4" | 12 9/16" | Aluminum | 377 | 30 | 250° | #12 | 00000000 | 000000000 |

| 20,000 | 1 1/16"-12 | 14 1/2" | 14 1/8" | 16 15/16" | Aluminum | 377 | 35 | 250° | #12 | 0000000 | 00000000 |

Overall | Bolt Hole | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Cap., Btu/hr. | Thread Size | Ht. | Wd. | Dp. | SAE Flange Size | Dia. | No. of | Ctr.-to-Ctr. | Heat Sink Material | Max. Pressure, psi | Max. Flow Rate, gpm | Max. Temp., °F | SAE Trade Size | Each | ||

Female UN/UNF (SAE Straight) Threaded—For Use with Oil | ||||||||||||||||

| A | 7,500 | 1 5/16"-12 | 11 13/16" | 14 13/16" | 20" | __ | __ | __ | __ | Aluminum, Copper | 300 | 20 | 400° | #16 | 00000000 | 000000000 |

| A | 13,800 | 1 5/16"-12 | 13 1/8" | 19" | 19 1/4" | __ | __ | __ | __ | Aluminum, Copper | 300 | 25 | 400° | #16 | 00000000 | 00000000 |

| B | 27,000 | 1 5/16"-12 | 15 15/16" | 16 1/8" | 14 3/16" | __ | __ | __ | __ | Aluminum | 377 | 50 | 250° | #16 | 0000000 | 00000000 |

| B | 32,000 | 1 5/16"-12 | 15 15/16" | 16 9/16" | 16" | __ | __ | __ | __ | Aluminum | 377 | 65 | 250° | #16 | 00000000 | 00000000 |

| B | 44,000 | 1 5/8"-12 | 19 9/16" | 22" | 15 3/8" | __ | __ | __ | __ | Aluminum | 377 | 60 | 250° | #20 | 00000000 | 00000000 |

| B | 76,000 | 1 5/8"-12 | 24" | 25 9/16" | 16 3/4" | __ | __ | __ | __ | Aluminum | 377 | 65 | 250° | #20 | 0000000 | 00000000 |

| B | 90,000 | 1 5/8"-12 | 24" | 26 3/8" | 18" | __ | __ | __ | __ | Aluminum | 377 | 75 | 250° | #20 | 0000000 | 00000000 |

| B | 126,000 | 1 5/8"-12 | 25 7/8" | 30 5/16" | 19 1/2" | __ | __ | __ | __ | Aluminum | 377 | 80 | 250° | #20 | 00000000 | 00000000 |

SAE Flange—For Use with Oil | ||||||||||||||||

| B | 205,000 | __ | 30 3/16" | 37" | 23 3/16" | 2 | 0.51" | 4 | 1.688", 3.062" | Aluminum | 377 | 115 | 250° | __ | 00000000 | 00000000 |

| B | 238,000 | __ | 33 1/4" | 39" | 23 3/8" | 2 | 0.51" | 4 | 1.688", 3.062" | Aluminum | 377 | 120 | 250° | __ | 00000000 | 00000000 |

| B | 356,000 | __ | 38 3/8" | 43 5/8" | 29 1/2" | 2 | 0.51" | 4 | 1.688", 3.062" | Aluminum | 250 | 150 | 250° | __ | 00000000 | 000000000 |

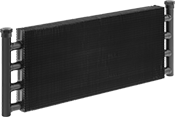

Heat Sinks for Oil

Dozens of fins and coolant tubes quickly dissipate excess heat. Also known as oil coolers, these heat sinks cool hydraulic fluid and lubricating oil in cylinders and compressors. Cooling and flow capacities are based on 50 SSU oil, 1,000 feet per minute of air, a 50° F initial temperature difference, and a 10 psi pressure drop.

Heat sinks with a bypass prevent damage to the cooling fins by diverting pressurized oil. They’re often used in machines that are started up while cold. Once the oil heats up and the pressure drops, flow through the cooling tubes resumes.

Mounting kits (sold separately) are required for installation.

Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Cap., Btu/hr. | Pipe Size | Thread Type | Gender | Ht. | Wd. | Dp. | Heat Sink Material | Max. Pressure, psi | Max. Flow Rate, gpm | Max. Temp., °F | No. of Mount. Kits Required | Each | |

Copper Tube—For Use with Oil | |||||||||||||

| 3,300 | 1/2 | NPT | Female | 4 1/2" | 15" | 1 1/2" | Aluminum | 300 | 7 | 350° | 2 | 0000000 | 0000000 |

| 6,100 | 1/2 | NPT | Female | 6 1/2" | 18" | 1 1/2" | Aluminum | 300 | 9 | 350° | 4 | 0000000 | 000000 |

| 8,100 | 1/2 | NPT | Female | 6 1/2" | 24" | 1 1/2" | Aluminum | 300 | 7 | 350° | 4 | 0000000 | 000000 |

| 9,600 | 1/2 | NPT | Female | 8 1/2" | 21" | 1 1/2" | Aluminum | 300 | 11 | 350° | 4 | 0000000 | 000000 |

| 11,800 | 3/4 | NPT | Female | 12 3/4" | 18" | 1 1/2" | Aluminum | 300 | 19 | 350° | 4 | 0000000 | 000000 |

| 24,000 | 3/4 | NPT | Female | 18 3/4" | 24" | 1 1/2" | Aluminum | 300 | 22 | 350° | 6 | 0000000 | 000000 |

| 31,000 | 1 | NPT | Female | 25" | 24" | 1 1/2" | Aluminum | 300 | 28 | 350° | 8 | 0000000 | 000000 |

| 49,000 | 1 | NPT | Female | 31" | 30" | 1 1/2" | Aluminum | 300 | 30 | 350° | 8 | 0000000 | 00000000 |

| 57,000 | 1 1/4 | NPT | Female | 37 7/16" | 30" | 1 1/2" | Aluminum | 300 | 36 | 350° | 8 | 0000000 | 00000000 |

Copper Tube with Bypass—For Use with Oil | |||||||||||||

| 3,400 | 1/2 | NPT | Female | 4 1/2" | 15" | 1 1/2" | Aluminum | 300 | 7 | 350° | 2 | 00000000 | 000000 |

| 6,300 | 1/2 | NPT | Female | 6 1/2" | 18 1/4" | 1 1/2" | Aluminum | 300 | 9 | 350° | 4 | 00000000 | 000000 |

| 10,000 | 1/2 | NPT | Female | 8 1/2" | 21" | 1 1/2" | Aluminum | 300 | 11 | 350° | 4 | 00000000 | 000000 |

| 12,000 | 3/4 | NPT | Female | 12 3/4" | 18" | 1 1/2" | Aluminum | 300 | 9 | 350° | 4 | 00000000 | 000000 |

| Includes | Each | |

| Two Carriage Bolts, Two Flat Washers, Two Lock Washers, Two Nuts, Two Rubber Blocks | 0000000 | 000000 |

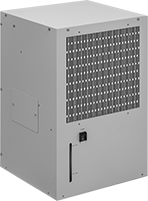

Heat Sinks with Internal Pump for Water

To provide a more consistent flow of cooled water than other heat sinks for water, these have a built-in pump and reservoir. The internal fan-cooled heat exchanger dissipates heat. Btu/hr. cooling capacity is based on water with an initial temperature difference of 77° F.

For technical drawings and 3-D models, click on a part number.

Overall | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Cap., Btu/hr. | Pipe Size | Thread Type | Gender | Ht. | Wd. | Dp. | Heat Sink Material | Max. Pressure, psi | Max. Flow Rate, gpm | Max. Temp., °F | Voltage (Electrical Phase) | Current | NEMA Style | Cord Lg., ft. | Each | |

For Use with Water, Noncorrosive Liquids | ||||||||||||||||

| 12,000 | 1/2 | NPT | Female | 24" | 15" | 15" | Copper | 60 | 1.8 | 130° | 120V AC (Single) | 5.8A | 5-15 | 8 | 00000000 | 000000000 |

Heat Pipes

Protect computers, sensitive electronic components, lighting, injection molders, and HVAC systems from damage by routing heat away from them and toward a heat sink, where the heat can be dissipated. For best results, heat pipes should be soldered to heat sinks and other components. For small jobs and prototypes, however, they can be joined with thermal epoxy. Cooling capacity is the amount of heat that a heat pipe can carry.

Flat heat pipes, often called vapor chambers, can be embedded into your heat sink to spread heat uniformly across the base, helping the heat to dissipate faster.

Heat pipes with a grooved wick transfer heat better than those with a sintered wick, meaning they can carry more heat. They are not good, however, for applications that will require many bends in the pipe. Position them horizontally, since they do not work well against gravity.

Heat pipes with a sintered wick handle high fluctuations in temperature better than those with a grooved wick. They’re also best for applications that will require many bends in the pipe. Position them horizontally or vertically—they work well in both orientations.

Use optional heat pipe benders to create smooth, accurate bends in round heat pipe. These specially designed tools allow a smooth bending motion to reduce marks on your pipe, which ordinary pliers can often leave behind. All have graduation markings to prevent over bending, which can reduce the ability of your heat pipe to transfer heat. Every 45° bend in a heat pipe will reduce the cooling capacity of the heat pipe by about 2.5%. Place these tools on benches, vises, and workstations without scratching them—all have rubber mounting feet.

Heat Pipes | Heat Pipe Benders | |||||||

|---|---|---|---|---|---|---|---|---|

| Length, mm | Cooling Capacity (Installed Length) | Temperature Range, °F | Material | Working Fluid | Each | Each | ||

Grooved Wick | ||||||||

4 mm OD | ||||||||

| 200 | 100 Btu/hr. (125 mm), 130 Btu/hr. (100 mm), 90 Btu/hr. (150 mm) | 90° to 245° | Copper | Water | 0000000 | 000000 | 0000000 | 0000000 |

| 300 | 60 Btu/hr. (200 mm), 90 Btu/hr. (150 mm), 50 Btu/hr. (250 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 | 0000000 | 000000 |

6 mm OD | ||||||||

| 200 | 170 Btu/hr. (125 mm), 210 Btu/hr. (100 mm), 140 Btu/hr. (150 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 | 0000000 | 000000 |

| 300 | 130 Btu/hr. (200 mm), 180 Btu/hr. (150 mm), 100 Btu/hr. (250 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 | 0000000 | 000000 |

Sintered Wick | ||||||||

4 mm OD | ||||||||

| 100 | 210 Btu/hr. (40 mm), 170 Btu/hr. (50 mm), 140 Btu/hr. (60 mm) | 90° to 245° | Copper | Water | 0000000 | 0000 | 0000000 | 000000 |

| 150 | 140 Btu/hr. (60 mm), 110 Btu/hr. (75 mm), 90 Btu/hr. (90 mm) | 90° to 245° | Copper | Water | 0000000 | 0000 | 0000000 | 000000 |

| 200 | 100 Btu/hr. (80 mm), 80 Btu/hr. (100 mm), 70 Btu/hr. (120 mm) | 90° to 245° | Copper | Water | 0000000 | 0000 | 0000000 | 000000 |

| 250 | 80 Btu/hr. (100 mm), 60 Btu/hr. (125 mm), 50 Btu/hr. (150 mm) | 90° to 245° | Copper | Water | 0000000 | 0000 | 0000000 | 000000 |

6 mm OD | ||||||||

| 70 | 650 Btu/hr. (28 mm), 520 Btu/hr. (35 mm), 430 Btu/hr. (42 mm) | 90° to 245° | Copper | Water | 0000000 | 0000 | 0000000 | 000000 |

| 100 | 450 Btu/hr. (40 mm), 360 Btu/hr. (50 mm), 300 Btu/hr. (60 mm) | 90° to 245° | Copper | Water | 0000000 | 0000 | 0000000 | 000000 |

| 150 | 300 Btu/hr. (60 mm), 240 Btu/hr. (75 mm), 200 Btu/hr. (90 mm) | 90° to 245° | Copper | Water | 0000000 | 0000 | 0000000 | 000000 |

| 250 | 180 Btu/hr. (100 mm), 140 Btu/hr. (125 mm), 120 Btu/hr. (150 mm) | 90° to 245° | Copper | Water | 0000000 | 0000 | 0000000 | 000000 |

| 350 | 120 Btu/hr. (140 mm), 100 Btu/hr. (175 mm), 80 Btu/hr. (210 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 | 0000000 | 000000 |

8 mm OD | ||||||||

| 70 | 940 Btu/hr. (28 mm), 760 Btu/hr. (35 mm), 630 Btu/hr. (42 mm) | 90° to 245° | Copper | Water | 0000000 | 0000 | 0000000 | 000000 |

| 100 | 660 Btu/hr. (40 mm), 530 Btu/hr. (50 mm), 440 Btu/hr. (60 mm) | 90° to 245° | Copper | Water | 0000000 | 0000 | 0000000 | 000000 |

| 150 | 440 Btu/hr. (60 mm), 350 Btu/hr. (75 mm), 290 Btu/hr. (90 mm) | 90° to 245° | Copper | Water | 0000000 | 0000 | 0000000 | 000000 |

| 200 | 330 Btu/hr. (80 mm), 260 Btu/hr. (100 mm), 220 Btu/hr. (120 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 | 0000000 | 000000 |

| 350 | 190 Btu/hr. (140 mm), 150 Btu/hr. (175 mm), 120 Btu/hr. (210 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 | 0000000 | 000000 |

| Length, mm | Thickness, mm | Cooling Capacity (Installed Length) | Temperature Range, °F | Material | Working Fluid | Each | |

Sintered Wick | |||||||

|---|---|---|---|---|---|---|---|

5.1 mm Width | |||||||

| 70 | 2.5 | 160 Btu/hr. (42 mm), 130 Btu/hr. (53 mm), 110 Btu/hr. (63 mm) | 90° to 245° | Copper | Water | 0000000 | 000000 |

| 100 | 2.5 | 110 Btu/hr. (60 mm), 90 Btu/hr. (75 mm), 70 Btu/hr. (90 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 |

| 150 | 2.5 | 70 Btu/hr. (90 mm), 60 Btu/hr. (113 mm), 50 Btu/hr. (135 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 |

| 200 | 2.5 | 50 Btu/hr. (120 mm), 40 Btu/hr. (150 mm), 30 Btu/hr. (180 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 |

6.44 mm Width | |||||||

| 70 | 3 | 220 Btu/hr. (42 mm), 170 Btu/hr. (53 mm), 150 Btu/hr. (63 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 |

| 100 | 3 | 150 Btu/hr. (60 mm), 120 Btu/hr. (75 mm), 100 Btu/hr. (90 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 |

| 150 | 3 | 100 Btu/hr. (90 mm), 80 Btu/hr. (113 mm), 60 Btu/hr. (135 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 |

| 200 | 3 | 70 Btu/hr. (120 mm), 60 Btu/hr. (150 mm), 50 Btu/hr. (180 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 |

9.45 mm Width | |||||||

| 75 | 5 | 380 Btu/hr. (45 mm), 310 Btu/hr. (56 mm), 250 Btu/hr. (68 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 |

| 150 | 5 | 190 Btu/hr. (90 mm), 150 Btu/hr. (113 mm), 120 Btu/hr. (135 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 |

| 200 | 5 | 140 Btu/hr. (120 mm), 110 Btu/hr. (150 mm), 90 Btu/hr. (180 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 |

| 350 | 5 | 80 Btu/hr. (210 mm), 60 Btu/hr. (263 mm), 50 Btu/hr. (315 mm) | 90° to 245° | Copper | Water | 0000000 | 00000 |

High-Efficiency Heat Exchangers

Stacked, corrugated plates maximize contact with liquid or steam flowing through these brazed plate heat exchangers for faster heat transfer than shell and tube heat exchangers. Plates are brazed in a vacuum furnace to ensure 100% sealed construction.

Copper-brazed heat exchangers have a Btu/hr. cooling capacity based on cooling water from 120° to 100° F using 70° F water.

ASME BPVC VIII.1 copper-brazed heat exchangers have a Btu/hr. cooling capacity based on cooling 100 SSU oil to 125° F using 85° F water.

Nickel-brazed heat exchangers have a Btu/hr. cooling capacity based on cooling oil from 140° to 120° F using 70° F water.

ASME BPVC VIII.1 heat exchangers meet the ASME Boiler and Pressure Vessel Code (BPVC) for construction of pressure vessels.

For technical drawings and 3-D models, click on a part number.

Overall | Mounting Hole | Mounting Stud | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Heating/Cooling Cap., Btu/hr. | Surface Area, sq. ft. | Temp. Range, °F | Pipe Size | Thread Type | Gender | Flow Cap., gpm | Max. Pressure, psi | Ht. | Wd. | Dp. | No. of | Dia. | No. of | Thread Size | Lg. | Each | |

Heat Exchangers | |||||||||||||||||

Copper-Brazed 316 Stainless Steel Plate | |||||||||||||||||

| 69,000 | 2.2 | -320° to 350° | 3/4 | NPT | Male | 7 | 450 | 9 1/8" | 3 1/2" | 2 5/8" | __ | __ | 2 | M8 | 20mm | 00000000 | 0000000 |

| 80,000 | 3 | -320° to 350° | 1 | NPT | Male | 8 | 450 | 13 3/16" | 5" | 1 1/4" | __ | __ | 4 | M10 | 20mm | 00000000 | 000000 |

| 185,000 | 6.8 | -320° to 350° | 1 | NPT | Male | 19 | 450 | 13 3/16" | 5" | 2" | __ | __ | 4 | M8 | 20mm | 00000000 | 000000 |

| 390,000 | 14.3 | -320° to 350° | 1 | NPT | Male | 40 | 450 | 13 3/16" | 5" | 4" | __ | __ | 4 | M10 | 20mm | 00000000 | 000000 |

| 570,000 | 21.9 | -320° to 350° | 1 1/4 | NPT | Male | 58 | 450 | 13 3/16" | 5" | 5 3/4" | __ | __ | 4 | M8 | 20mm | 00000000 | 00000000 |

| 998,000 | 36.8 | -320° to 350° | 2 | NPT | Male | 105 | 300 | 20 5/16" | 9 13/16" | 3.06" | __ | __ | 4 | 1/2"-13 | 1 1/2" | 00000000 | 00000000 |

| 1,710,000 | 63 | -320° to 350° | 2 | NPT | Male | 170 | 300 | 20 5/16" | 9 13/16" | 4.86" | __ | __ | 4 | 1/2"-13 | 1 1/2" | 00000000 | 00000000 |

Nickel-Brazed 316 Stainless Steel Plate | |||||||||||||||||

| 16,000 | 3.1 | -320° to 390° | 1 | NPT | Male | 4 | 360 | 13 3/16" | 4 7/8" | 2 3/16" | __ | __ | 4 | M10 | 13/16" | 0000000 | 000000 |

| 37,000 | 6.8 | -320° to 390° | 1 | NPT | Male | 9 | 360 | 13 3/16" | 4 7/8" | 3 1/16" | __ | __ | 4 | M10 | 13/16" | 0000000 | 00000000 |

| 56,000 | 10.6 | -320° to 390° | 1 | NPT | Male | 13 | 360 | 13 3/16" | 4 7/8" | 4" | __ | __ | 4 | M10 | 13/16" | 0000000 | 00000000 |

| 74,000 | 14.3 | -320° to 390° | 1 | NPT | Male | 18 | 360 | 13 3/16" | 4 7/8" | 4 7/8" | __ | __ | 4 | M10 | 13/16" | 0000000 | 00000000 |

| 120,000 | 40.7 | -320° to 390° | 2 | NPT | Male | 30 | 390 | 20 15/16" | 10 11/16" | 4 1/16" | __ | __ | 4 | M12 | 1 3/16" | 0000000 | 00000000 |

ASME BPVC.VIII.1 Heat Exchangers | |||||||||||||||||

Copper-Brazed 316 Stainless Steel Plate | |||||||||||||||||

| 5,000 | 4.8 | -310° to 450° | 3/4 | NPT | Male | 27 | 435 | 8 7/16" | 3 3/16" | 4 7/16" | 2 | 9/32" | __ | __ | __ | 0000000 | 000000 |

| 12,000 | 7.9 | -310° to 450° | 1 | NPT | Male | 29 | 435 | 12 3/16" | 4 3/8" | 4 1/4" | 2 | 13/32" | __ | __ | __ | 0000000 | 000000 |

| 17,000 | 10.7 | -310° to 450° | 1 | NPT | Male | 37 | 435 | 12 3/16" | 4 3/8" | 5 1/4" | 2 | 13/32" | __ | __ | __ | 0000000 | 000000 |

| 50,000 | 15.6 | -310° to 450° | 1 | NPT | Male | 22 | 435 | 20 11/16" | 4 3/8" | 4 1/4" | 2 | 13/32" | __ | __ | __ | 0000000 | 000000 |

| 75,000 | 26.8 | -310° to 450° | 1 | NPT | Male | 34 | 435 | 20 11/16" | 4 3/8" | 6 3/16" | 2 | 13/32" | __ | __ | __ | 0000000 | 00000000 |

| 125,000 | 29.7 | -310° to 450° | 2 | NPT | Male | 57 | 435 | 24 5/16" | 7 1/2" | 5 3/4" | 2 | 1/2" | __ | __ | __ | 0000000 | 00000000 |

| 380,000 | 82.8 | -310° to 450° | 2 | NPT | Male | 141 | 435 | 24 5/16" | 7 1/2" | 11 1/2" | 2 | 1/2" | __ | __ | __ | 0000000 | 00000000 |