How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

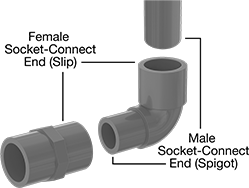

Thick-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 80 pipe. With thicker, stronger walls than standard-wall fittings, they can handle heavy duty supply applications, such as water processing, wastewater treatment, and irrigation. Fittings are plastic for good corrosion resistance. They meet ASTM specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

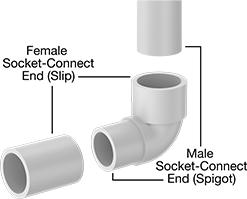

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Fittings that meet ASTM D1784, ASTM D1785, and ASTM D4066 adhere to specifications and testing requirements for material quality.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, ASTM D1785, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

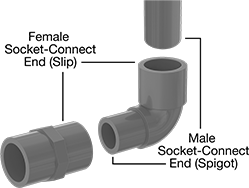

Drain, Waste, and Vent ABS Pipe Fittings for Chemicals

These Schedule 40 fittings are an economical option for gravity-flow chemical waste systems. They are ABS plastic, which has excellent strength and impact resistance and good chemical resistance. Fittings meet ASTM D2661, ASTM D3311, ASTM D3965, and ASTM F1498 specifications and testing requirements for material quality and product dimensions.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with ABS cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

For technical drawings and 3-D models, click on a part number.

- For Use With: Sodium Hydroxide

- Maximum Temperature: 180° F

- Specifications Met: ASTM D2661, ASTM D3311, ASTM D3965, ASTM F1498

- Pipe Nipples and Pipe: Use Schedule 40 ABS Plastic

- Flanges: Use Schedule 40 ABS Plastic

Gravity-Flow Polypropylene Pipe Fittings for Corrosive Chemical Waste

- For Use With: Deionized Water, Hydrochloric Acid, Oil, Phosphoric Acid, Salt Water, Solvents

- Maximum Temperature: 220° F

- Specifications Met: ASTM D4101, ASTM D635, ASTM F1412, UL 94 V-2

- Compatible with Gravity-Flow Polypropylene Pipe for Corrosive Chemical Waste

Made of polypropylene, these gravity-flow fittings withstand organic solvents, such as acetone, that would dissolve CPVC pipe. They also stand up to highly corrosive acids, such as hydrochloric acid, and alkalies. All meet UL and ASTM standards for flame retardance and self-extinguishment in the case of fire. They also meet strict ASTM specifications and testing requirements for material quality and product dimensions. They’re compatible with Orion Blueline No-Hub and Orion Rionfuse chemical waste pipe and pipe fittings.

For technical drawings and 3-D models, click on a part number.

Aboveground Standard-Wall PVC Pipe Fittings for Drain, Waste, and Vent

- For Use With: Water

- Max. Temperature: 140° F

- Specifications Met: ASTM D1784, ASTM D2665

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Schedule 40 PVC Plastic

These Schedule 40 fittings are the industry standard for gravity-flow drain, waste, and vent (DWV) applications. Fittings are PVC, which has good corrosion resistance. They meet ASTM D1784 and ASTM D2665 specifications and testing requirements for material quality.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

Universal-Thread Push-to-Connect Tube Fittings for Air and Water

Threads

with Gasket

- Temperature Range: 0° to 175° F

- Tubing: Use with firm (Durometer 85A-100A) nylon plastic or polyurethane rubber

- Specifications Met: ISO 14743

Make lightweight connections without the hassle of matching the exact thread type—these fittings connect to NPT, NPTF, BSPP, BSPT, and other universal threads. With a nylon body and nickel-plated brass threads, these fittings are lighter than most metal fittings, and withstand corrosion better than plain brass threads. They also have a reusable gasket to guard against leaks. Connect the tube ends to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect them, push the release ring and pull the tubing out of the fitting. These fittings are sometimes known as instant fittings. All meet ISO 14743, which is an international standard for push-to-connect fittings for plastic tubing.

For technical drawings and 3-D models, click on a part number.

Threads

with Gasket

Release Ring | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | For Tube OD | Pipe Connection Material | Tube Connection Material | Gasket Material | Color | Material | Color | Maximum Pressure | Each | |

BSPP, BSPT, NPT, NPTF, Universal Threads | ||||||||||

| 1/8 | 5/32" | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Blue | 250 psi @ 72° F | 0000000 | 000000 |

| 1/8 | 1/4" | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Blue | 250 psi @ 72° F | 00000000 | 00000 |

| 1/8 | 4mm | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Black | 250 psi @ 72° F | 00000000 | 00000 |

| 1/8 | 6mm | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Black | 250 psi @ 72° F | 00000000 | 00000 |

| 1/4 | 5/32" | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Blue | 250 psi @ 72° F | 0000000 | 00000 |

| 1/4 | 1/4" | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Blue | 250 psi @ 72° F | 00000000 | 00000 |

| 1/4 | 4mm | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Black | 250 psi @ 72° F | 00000000 | 00000 |

| 1/4 | 6mm | Nickel-Plated Brass | Nylon Plastic | Buna-N Rubber | Black | Plastic | Black | 250 psi @ 72° F | 00000000 | 00000 |

Push-to-Connect Fittings for Food and Beverage

- Temperature Range: 35° to 140° F

- Tubing: See table

- Specifications Met: See table

Also known as instant fittings, these connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect fittings with a release ring, push on the release ring and pull the tubing out of the fitting.

Polypropylene fittings have excellent impact and abrasion resistance. They meet NSF/ANSI standards for safe use with food. Some are also FDA compliant for indirect contact with food.

For technical drawings and 3-D models, click on a part number.

| For Tube OD (A) | For Tube OD (B) | Material | Release Ring Color | Max. Pressure | For Tube Hardness Rating | For Tube Hardness | Specifications Met | Each | |

White | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 3/8" | 1/4" | Polypropylene Plastic | White | 150 psi @ 72° F | Firm, Hard | Durometer 50D-90D | NSF/ANSI 51, NSF/ANSI 61 | 00000000 | 00000 |

Wye-Shaped On/Off Valves with Garden Hose Threads

Convert one faucet into two, four, or five convenient outlets. Each outlet has individually operated shutoff valves.

Plastic valves are lighter than brass or zinc valves, and are durable enough to hold up to impacts and abrasion. They have good corrosion resistance.

Zinc valves have good corrosion resistance. Some also have a TPR rubber or plastic coating to protect your hands—the coating keeps valves from getting hot in the sun or cold in the winter.

Brass valves are softer than zinc and plastic, so they’re easier to thread together. They’re also corrosion resistant.

For technical drawings and 3-D models, click on a part number.

| No. of Outlets | Max. Pressure | Temp. Range, °F | Includes | Each | |

Plastic | |||||

|---|---|---|---|---|---|

| 4 | 60 psi @ 100° F | 35° to 100° | Washers | 0000000 | 000000 |

Zinc | |||||

| 4 | 60 psi @ 100° F | 35° to 100° | Washers | 0000000 | 00000 |

Zinc with TPR Rubber Coating | |||||

| 4 | 60 psi @ 100° F | 35° to 100° | Washers, Support Brace | 0000000 | 00000 |

Zinc with Plastic Coating | |||||

| 5 | 60 psi @ 100° F | 35° to 100° | Washers, Support Brace, Mounting Hardware | 0000000 | 00000 |

Brass | |||||

| 4 | 60 psi @ 100° F | 35° to 100° | Washers | 0000000 | 00000 |