How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About On/Off Valves

More

Low-Pressure Iron and Steel Threaded Pipe Fittings

Use these fittings for low-pressure applications in noncorrosive environments.

180° bend connectors are also known as U-bends.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Specifications Met:

1 Pipe Size: ASME B1.20.1, ASME B16.3

All other sizes: ASME B1.20.1, ASME B16.3, UL Listed - Pipe Nipples and Pipe: Use Schedule 40 steel

| Pipe Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Female | |||||

|---|---|---|---|---|---|

| 1/2 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 000000 |

| 3/4 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 1/4 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 1/2 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 000000 |

| 2 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 000000 |

Low-Pressure Galvanized Iron and Steel Threaded Pipe Fittings

The galvanized finish on these fittings provides fair corrosion resistance. Fittings are for use in low-pressure applications.

180° bend connectors are also known as U-bends.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 150

- Specifications Met: ASTM A197, UL Listed, ASME B16.3, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 40 galvanized steel

- Flanges: Use Class 150 galvanized steel

| Pipe Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Female | |||||

|---|---|---|---|---|---|

| 3/4 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | 00000000 | 000000 |

| 1 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | 00000000 | 00000 |

| 1 1/2 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | 00000000 | 000000 |

| 2 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | 00000000 | 000000 |

Standard-Wall Butt-Weld Steel Unthreaded Pipe Fittings

Butt-weld fittings allow for a smooth connection that provides maximum flow. They have beveled ends that, when flush to pipe, create a trough for a strong, permanent weld. Fittings are also known as Schedule 40. They are for use in noncorrosive environments.

180° bend connectors are also known as U-bends.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Specifications Met: ASTM A234, ASME B16.9

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Flanges: Use Class 150 steel

| Pipe Size | Wall Thickness | Construction | Each | |

| 3/4 | 0.113" | Seamless | 000000000 | 0000000 |

| 1 | 0.133" | Seamless | 000000000 | 000000 |

| 1 1/4 | 0.14" | Seamless | 000000000 | 000000 |

| 1 1/2 | 0.145" | Seamless | 000000000 | 000000 |

| 2 | 0.154" | Seamless | 000000000 | 000000 |

| 2 1/2 | 0.203" | Seamless | 000000000 | 000000 |

| 3 | 0.216" | Seamless | 000000000 | 000000 |

| 4 | 0.237" | Seamless | 000000000 | 000000 |

| 6 | 0.28" | Seamless | 000000000 | 000000 |

Thick-Wall Butt-Weld Steel Unthreaded Pipe Fittings

With thicker, stronger walls than our standard-wall butt-weld pipe fittings, these fittings stand up to your high strength applications. Weld them flush against pipe for a smooth connection that permits maximum flow. These fittings have beveled ends that create a trough for a leak-resistant, permanent weld. Made of steel, they’re for use in noncorrosive environments.

180° bend connectors are also known as U-bends.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Specifications Met: ASTM A234

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Flanges: Use Class 300 steel

Low-Pressure Aluminum Threaded Pipe Fittings

In addition to being lightweight, these aluminum fittings offer good corrosion resistance. Use them in low-pressure flow applications. To prevent cracking, do not tighten more than a 1/4-turn past hand tight.

180° bend connectors are also known as U-bends.

For technical drawings and 3-D models, click on a part number.

Drain, Waste, and Vent ABS Pipe Fittings for Chemicals

These Schedule 40 fittings are an economical option for gravity-flow chemical waste systems. They are ABS plastic, which has excellent strength and impact resistance and good chemical resistance. Fittings meet ASTM D2661, ASTM D3311, ASTM D3965, and ASTM F1498 specifications and testing requirements for material quality and product dimensions.

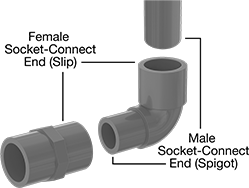

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with ABS cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

For technical drawings and 3-D models, click on a part number.

- For Use With: Sodium Hydroxide

- Maximum Temperature: 180° F

- Specifications Met: ASTM D2661, ASTM D3311, ASTM D3965, ASTM F1498

- Pipe Nipples and Pipe: Use Schedule 40 ABS Plastic

- Flanges: Use Schedule 40 ABS Plastic

180° bend fittings are also known as drum taps.

Aboveground Standard-Wall PVC Pipe Fittings for Drain, Waste, and Vent

- For Use With: Water

- Max. Temperature: 140° F

- Specifications Met: ASTM D1784, ASTM D2665

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Schedule 40 PVC Plastic

These Schedule 40 fittings are the industry standard for gravity-flow drain, waste, and vent (DWV) applications. Fittings are PVC, which has good corrosion resistance. They meet ASTM D1784 and ASTM D2665 specifications and testing requirements for material quality.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

Solder-Connect Fittings for Copper Tubing

- Temperature Range: 32° to 200° F

Solder these fittings to copper tubing or the tube end of another fitting for a permanent, leak-tight connection. They are also known as sweat fittings. Fittings have good corrosion resistance. To adhere to safety standards for drinking water systems, use fittings that meet NSF/ANSI 61 or EN 1057.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water

- Tubing: Use with K, M, L copper

- Specifications Met: ASME B16.22, MSS-SP104, NSF/ANSI 61

180° bend connectors are also known as U-bends.

| Copper Tube Size | For Tube OD | Material | Max. Pressure | Each | |

| 1/4 | 3/8" | Copper | 400 psi @ 72° F | 00000000 | 00000 |

| 3/8 | 1/2" | Copper | 400 psi @ 72° F | 00000000 | 0000 |

| 1/2 | 5/8" | Copper | 400 psi @ 72° F | 00000000 | 0000 |

| 5/8 | 3/4" | Copper | 400 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 7/8" | Copper | 400 psi @ 72° F | 00000000 | 00000 |

| 1 | 1 1/8" | Copper | 400 psi @ 72° F | 00000000 | 00000 |

| 1 1/4 | 1 3/8" | Copper | 400 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | 1 5/8" | Copper | 400 psi @ 72° F | 00000000 | 00000 |

| 2 | 2 1/8" | Copper | 300 psi @ 72° F | 00000000 | 000000 |

Cleaned and Bagged Solder-Connect Fittings for Copper Tubing

- For Use With: Drinking Water

- Temperature Range: 32° to 200° F

- Tubing: Use with K, M, L copper

- Specifications Met: ASME B16.22, MSS-SP104, NSF/ANSI 61

When cleanliness is crucial to your application, choose these fittings that are individually cleaned and bagged to prevent contamination. Solder the socket end to copper tubing or the tube end of another fitting for a permanent, leak-tight connection. They are also known as sweat fittings. Fittings have good corrosion resistance. They meet NSF/ANSI 61 safety standards for use with drinking water systems.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

For technical drawings and 3-D models, click on a part number.

Stainless Steel Barbed Tube Fittings for Food and Beverage

- Temperature Range: -20° to 750° F

- Tubing: Use with soft or firm (Durometer 65A-90A) polyurethane rubber or PVC plastic

- Specifications Met: See table

Made of stainless steel, these fittings are more durable than plastic barbed tube fittings for food and beverage. They have single or multiple barbs that grip onto tubing.

For technical drawings and 3-D models, click on a part number.

Fast-Acting Panel-Mount Threaded On/Off Valves

Start or stop flow with the flip of a toggle switch or the push of a button. These valves are often used in testing and sampling applications where you need to dispense a small amount of liquid. They fit through a cutout, so the body of the valve stays safe inside your instrumentation panel.

Nickel-plated brass valves resist corrosion better than plain brass valves. Spring-return valves automatically close when you release the toggle or push button. They’re ideal for intermittent use and precise flow control to prevent spills.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Stem

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon

- Seal Material: Buna-N Rubber Seal

| Thread Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Valve Starting Position | Return Actuation | Push-Button Material | Port-to-Port Lg. | Panel Cutout Dia. | Each | |

UNF Female × UNF Female | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10-32 | 0.1 | 125 psi @ 70° F | -40° to 180° | Normally Closed | Spring | Plastic | 5/16" | 15/32" | 0000000 | 000000 |