How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Ultra-Corrosion-Resistant Yor-Lok Fittings for Nickel Alloy Tubing

- For Use With: Acetic Acid, Air, Bleach, Cutting Oil, Diesel Fuel, Formic Acid, Fuel Oil, Gasoline, Hydraulic Fluid, Iron Chlorides, Mineral Oil, Salt Water, Steam, Water

- Temperature Range: 0° to 1000° F

- Tubing: Use with seamless soft C276 nickel

- Specifications Met: ASME B31.3

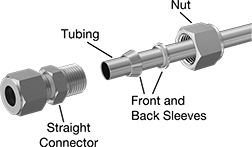

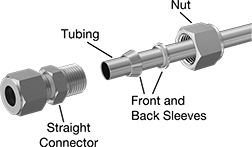

With the best corrosion resistance of any metal tube fittings we offer, these C276 nickel Hastelloy fittings stand up to aggressive chemicals and resist pitting and cracking from stress. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They include a nut with two sleeves (ferrules). The sleeves bite into tubing as you tighten the nut, creating a strong, leak-resistant seal. Fittings are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

For technical drawings and 3-D models, click on a part number.

Acid-Resistant Yor-Lok Fittings for Nickel Alloy Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Hydrofluoric Acid, Mineral Oil, Salt Water, Steam, Sulfuric Acid, Water

- Temperature Range: -325° to 900° F

- Tubing: Use with seamless soft 400 nickel

- Specifications Met: See table

Made of 400 nickel, these Monel fittings have the corrosion resistance to handle hydrofluoric and sulfuric acid. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They include a nut with two sleeves (ferrules). The sleeves bite into tubing as you tighten the nut, creating a strong, leak-tight seal. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

For technical drawings and 3-D models, click on a part number.

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

NPT Threads | |||||||

| 1/4" | 0.035" | 1/4 | 400 Nickel | 4,800 psi @ 72° F | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM B164 | 00000000 | 000000 |

| 3/8" | 0.035" | 1/4 | 400 Nickel | 3,100 psi @ 72° F | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM B164 | 00000000 | 00000 |

| 3/8" | 0.035" | 3/8 | 400 Nickel | 3,100 psi @ 72° F | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM B164 | 00000000 | 00000 |

| 1/2" | 0.035" | 1/2 | 400 Nickel | 2,300 psi @ 72° F | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM B164 | 00000000 | 00000 |

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

NPT Threads | |||||||

| 1/4" | 0.035" | 1/4 | 400 Nickel | 4,800 psi @ 72° F | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM B164 | 00000000 | 000000 |

| 3/8" | 0.035" | 1/4 | 400 Nickel | 3,100 psi @ 72° F | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM B164 | 00000000 | 00000 |

| 3/8" | 0.035" | 3/8 | 400 Nickel | 3,100 psi @ 72° F | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM B164 | 00000000 | 00000 |

| 1/2" | 0.035" | 1/2 | 400 Nickel | 2,300 psi @ 72° F | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM B164 | 00000000 | 000000 |

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

NPT Threads | |||||||

| 1/4" | 0.035" | 1/4 | 400 Nickel | 4,800 psi @ 72° F | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM B564 | 00000000 | 000000 |

| 3/8" | 0.035" | 1/4 | 400 Nickel | 3,100 psi @ 72° F | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM B564 | 00000000 | 00000 |

| 3/8" | 0.035" | 3/8 | 400 Nickel | 3,100 psi @ 72° F | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM B564 | 00000000 | 000000 |

| 1/2" | 0.035" | 1/2 | 400 Nickel | 2,300 psi @ 72° F | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM B564 | 00000000 | 000000 |

Grease Fittings

Thread these fittings into motors, bearings, engine blocks, and other machinery to create a lubrication point. They’re also known as hydraulic grease fittings.

400 nickel fittings are the most corrosion resistant and can be used in caustic environments, such as those involving salt water, sulfuric acid, and alkalies.

Fittings with a check valve prevent grease from leaking when pressure causes backward flow. The valve stays closed when not in use to keep out dirt and other contaminants.

PTF-SAE and NPTF (Dryseal) threads are compatible with NPT threads. SAE-LT threads are tapered but designed to be installed into a 1/4"-28 straight-thread UNF hole.

For technical drawings and 3-D models, click on a part number.

Male

Threads

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

1/4"-28 SAE-LT Threads | ||||||||||

| 400 Nickel | 17/32" | 3/16" | 3/16" | 5/16" | 10,000 | Ball | 1 | 0000000 | 00000 | 00000 |

1/8 PTF-SAE Threads | ||||||||||

| 400 Nickel | 5/8" | 9/32" | 9/32" | 7/16" | 10,000 | Ball | 1 | 0000000 | 00000 | 00000 |

| 400 Nickel | 3/4" | 5/16" | 5/16" | 7/16" | 10,000 | Ball | 1 | 0000000 | 00000 | 00000 |

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

1/8 PTF-SAE Threads | ||||||||||

| 400 Nickel | 61/64" | 11/32" | 11/32" | 7/16" | 10,000 | Ball | 1 | 0000000 | 000000 | 000000 |

Pkg. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Overall Ht. | Thread Lg. | Shank Lg. | Hex Size | Max. Pressure, psi | Check Valve Type | Pkg. Qty. | 1-9 | 10-Up | |

1/8 PTF-SAE Threads | ||||||||||

| 400 Nickel | 1 1/4" | 11/32" | 11/32" | 7/16" | 10,000 | Ball | 1 | 0000000 | 000000 | 000000 |