How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

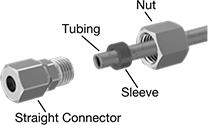

Vibration-Resistant Compression Fittings for Stainless Steel Tubing

- For Use With: Acetylene, Air, Butane, Compressed Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Helium, Hydraulic Fluid (Petroleum Base), Kerosene, Mineral Oil, Natural Gas, Nitrogen, Propane, Soap Solutions

- Temperature Range: -10° to 400° F

- Tubing: Use with seamless 316Ti or 321 stainless steel

- Specifications Met: DIN 3861

Instead of a metal sleeve (ferrule), these fittings have a rubber sleeve that cushions tubing and absorbs vibration to maintain a tight seal, even when connected to large pumps. However, rubber sleeves can’t withstand temperatures as high as metal ones. To create the strong seal, tighten the included nut. These fittings are made of 316 stainless steel, so they have excellent corrosion resistance. They’re also known as flareless fittings. All meet DIN 3861, which is an international standard for compression tube fitting specifications.

BSPP and metric male threads have a gasket to prevent leaks.

For technical drawings and 3-D models, click on a part number.

Male Threads with

Gasket and Washer

For Tube | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Pipe Size | Thread Size | Thread Pitch, mm | Material | Gasket Material | Maximum Pressure | Each | |

NPT Threads | |||||||||

| 6 | 1 | 1/8 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 6 | 1 | 1/4 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 00000 |

| 8 | 1 | 1/4 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 00000 |

| 10 | 1 | 1/4 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 10 | 1 | 3/8 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 12 | 1.5 | 1/4 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 12 | 1.5 | 1/2 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 15 | 1.5 | 1/2 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 18 | 2 | 1/2 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

BSPP Threads | |||||||||

| 6 | 1 | 1/8 | __ | __ | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

| 6 | 1 | 1/4 | __ | __ | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

Metric Threads | |||||||||

| 8 | 1 | __ | M12 | 1.5 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 000000 |

| 10 | 1 | __ | M14 | 1.5 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Nut Material | Maximum Pressure | Each | |

| 6 | 1 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 000000 |

| 8 | 1 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

| 10 | 1 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

| 12 | 1.5 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

| 15 | 1.5 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

| 18 | 2 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

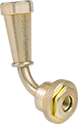

Couplers for High-Pressure Fill Valves

Fill tanks and recharge struts—these couplers join hose to high-pressure fill valves with Schrader threads.

Some couplers meet SAE AS4395, an automotive industry standard for flared fitting dimensions.

70° elbow couplers are angled to access hard-to-reach valves.

Couplers with a shut-off valve let you control the flow of air by hand. When used with Schrader valves that have a core, the core depressor pin in these couplers press valves open to let air flow in.

For technical drawings and 3-D models, click on a part number.

Female Threaded Hose ×

NPT Female Threaded Pipe

Female Threaded Hose ×

NPT Threaded Male Pipe

Threaded Hose × UN/UNF

Male Flared Tube

Female Threaded Hose ×

UN/UNF Male Flared Tube

Female Threaded Hose ×

UN/UNF Male Flared Tube

Inlet | Outlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Material | Thread Size | Material | Flared Angle | For Tube OD | Material | Max. Pressure, psi | Temp. Range, °F | Features | Specifications Met | Each | |

Straight | ||||||||||||

| 0.305"-32 | Zinc-Plated Steel | 7/16"-20 | Stainless Steel | 37° | 1/4" | __ | 5,000 | -20° to 250° | __ | SAE AS4395 | 000000 | 000000 |

70° Elbow | ||||||||||||

| 0.305"-32 | __ | 7/16"-20 | __ | 37° | 1/4" | Brass | 5,000 | Not Rated | __ | __ | 000000 | 00000 |

90° Elbow with a Shut-Off Valve | ||||||||||||

| 0.305"-32 | __ | 3/8"-24 | __ | 37° | 3/16" | Brass | 3,000 | -40° to 160° | Core Depressor Pin | SAE AS4395 | 000000 | 00000 |

| 0.485"-26 | __ | 3/8"-24 | __ | 37° | 3/16" | Brass | 3,000 | -40° to 160° | Core Depressor Pin | __ | 000000 | 00000 |

Air Chucks

Attach these chucks to your air hose so you can connect the hose to Schrader valves. Most often recognized from car and bike tires, Schrader valves are also commonly found on compressed air tanks and high-pressure hydraulic systems. Those for a 0.305”-32 thread size fit standard-bore Schrader valves. Those for a 0.485”-26 thread size fit large-bore Schrader valves. Do not use these air chucks with tire inflator gauges.

Chucks with a clip-on Schrader connection attach to the valve stem, so you don’t need to hold them as the valve fills.

Chucks with a sleeve-lock Schrader connection grab onto the valve by sliding the sleeve forward onto the valve. To disconnect, slide the sleeve back and pull out the valve.

Chucks with a threaded Schrader connection screw onto valves for a secure connection that you don’t need to hold in place.

Chucks with 2 outlets can be used at different angles and have an extended reach, so they’re ideal if your valve is hard to reach or in an awkward spot.

Outlet | Inlet | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shape | No. of | For Thread Size | For Thread Type | Gender | Connection Style | Connection Type | Barbed Connection Type | Pipe Size | Thread Type | For Tube ID | Gender | Lg. | Max. Pressure, psi | Washer Material | Each | ||

| A | Angled | 1 | 0.305"-32 | Schrader | Female | Threaded | Pipe | __ | 1/4 | NPT | __ | Female | 1 1/4" | 150 | __ | 0000000 | 00000 |

| B | Straight | 1 | 0.305"-32 | Schrader | Female | Threaded | Pipe | __ | 1/4 | NPT | __ | Female | 3 1/4" | 150 | Nitrile Rubber | 0000000 | 00000 |

| C | Angled | 2 | 0.305"-32 | Schrader | Female | Threaded | Pipe | __ | 1/4 | NPT | __ | Female | 5 1/4" | 150 | Buna-N Rubber | 0000000 | 00000 |

| D | Straight, Angled | 2 | 0.305"-32 | Schrader | Female | Threaded | Pipe | __ | 1/4 | NPT | __ | Female | 5 1/4" | 150 | Buna-N Rubber | 00000000 | 00000 |

| E | Angled | 1 | 0.305"-32 | Schrader | Female | Barbed | Tube | Barbed | __ | __ | 1/4" | Male | 2 1/4" | 150 | __ | 0000000 | 0000 |

| E | Angled | 1 | 0.305"-32 | Schrader | Female | Barbed | Tube | Barbed | __ | __ | 3/8" | Male | 1 1/4" | 150 | __ | 0000000 | 0000 |

Outlet | Inlet | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shape | No. of | For Thread Size | For Thread Type | Gender | Connection Style | Connection Type | Barbed Connection Type | Pipe Size | Thread Type | For Tube ID | Gender | Lg. | Clip Lg. | Max. Pressure, psi | Each | ||

| F | Angled | 1 | 0.305"-32 | Schrader | Female | Threaded | Pipe | __ | 1/4 | NPT | __ | Female | 2 3/4" | 1 3/4" | 150 | 0000000 | 000000 |

| G | Angled | 1 | 0.305"-32 | Schrader | Female | Barbed | Tube | Barbed | __ | __ | 1/4" | Male | 2 1/4" | 1 1/2" | 150 | 0000000 | 00000 |

| H | Straight | 1 | 0.305"-32 | Schrader | Female | Barbed | Tube | Barbed | __ | __ | 1/4" | Male | 1 1/2" | 1 1/4" | 150 | 00000000 | 0000 |

Outlet | Inlet | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shape | No. of | For Thread Size | For Thread Type | Gender | Connection Style | Connection Type | Barbed Connection Type | For Tube ID | Gender | Lg. | Max. Pressure, psi | Each | ||

| K | Straight | 1 | 0.305"-32 | Schrader | Female | Barbed | Tube | Barbed | 7/32" | Male | 1" | 120 | 000000 | 00000 |

| Clip Lg. | Material | Each | |

| 1 1/2" | Metal | 00000000 | 000000 |

| Material | Pkg. Qty. | Pkg. | |

| Nitrile Rubber | 10 | 00000000 | 00000 |

| Material | Pkg. Qty. | Pkg. | |

| Buna-N Rubber | 10 | 00000000 | 00000 |

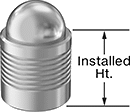

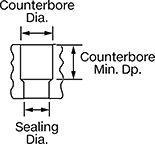

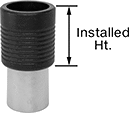

Push-In Bore Sealing Plugs

Permanently seal unthreaded, counterbored holes in manifolds and other pneumatic or hydraulic components. These plugs resist vibration better than threaded plugs and don’t require thread sealant. They consist of a serrated sleeve with a ball bearing inside. When installed, the bearing is pushed inside the sleeve. This expands the sleeve so its serrations bite into the walls of the hole, sealing it shut.

Unlike plugs that install with an air- or hydraulic-powered tool, these plugs don’t require power to install. However, they’re harder to fit into angled or deep holes. To install, drive the installation tool (sold separately) into the plug with a hammer or arbor press.

Plugs with an aluminum sleeve are ideal for plugging holes in aluminum manifolds. They resist corrosion in wet environments. These plugs are also lighter in weight than our other plugs, but they won’t handle pressures as high.

Plugs with a steel sleeve can handle higher pressures than aluminum-sleeved plugs, but not as much as those with a stainless steel sleeve. They’re zinc plated for corrosion resistance in wet environments, but they’ll corrode from salt water and chemicals.

Plugs with a stainless steel sleeve work in the highest pressures of any sleeve material, so they’re the best choice for hydraulic applications. They also have good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

Counterbore | ||||||||

|---|---|---|---|---|---|---|---|---|

| Sealing Dia. | Dia. | Min. Dp. | Installed Ht. | Max. Pressure, psi | Max. Temp., °F | Pkg. Qty. | Pkg. | |

Aluminum Sleeve | ||||||||

| 1/8" | 5/32" | 0.113" | 1/8" | 2,100 | 300° | 5 | 0000000 | 000000 |

| 1/8" | 5/32" | 0.149" | 5/32" | 3,000 | 300° | 5 | 0000000 | 00000 |

| 5/32" | 3/16" | 0.17" | 3/16" | 2,100 | 300° | 5 | 0000000 | 00000 |

| 5/32" | 3/16" | 0.208" | 7/32" | 3,000 | 300° | 5 | 0000000 | 00000 |

| 3/16" | 7/32" | 0.17" | 3/16" | 2,100 | 300° | 1 | 0000000 | 0000 |

| 3/16" | 7/32" | 0.208" | 7/32" | 3,000 | 300° | 1 | 0000000 | 0000 |

| 7/32" | 1/4" | 0.196" | 7/32" | 2,100 | 300° | 1 | 0000000 | 0000 |

| 7/32" | 1/4" | 0.247" | 1/4" | 3,000 | 300° | 1 | 0000000 | 0000 |

| 1/4" | 9/32" | 0.233" | 1/4" | 2,100 | 300° | 1 | 0000000 | 0000 |

| 1/4" | 9/32" | 0.287" | 19/64" | 3,000 | 300° | 1 | 0000000 | 0000 |

| 9/32" | 5/16" | 0.255" | 9/32" | 2,100 | 300° | 1 | 0000000 | 0000 |

| 9/32" | 5/16" | 0.326" | 21/64" | 3,000 | 300° | 5 | 0000000 | 00000 |

| 5/16" | 11/32" | 0.275" | 5/16" | 2,100 | 300° | 5 | 0000000 | 00000 |

| 5/16" | 11/32" | 0.385" | 25/64" | 3,000 | 300° | 5 | 0000000 | 00000 |

| 11/32" | 3/8" | 0.385" | 25/64" | 3,000 | 300° | 5 | 0000000 | 00000 |

| 3/8" | 13/32" | 0.308" | 23/64" | 2,100 | 300° | 1 | 0000000 | 0000 |

| 3/8" | 13/32" | 0.425" | 7/16" | 3,000 | 300° | 1 | 0000000 | 0000 |

| 13/32" | 7/16" | 0.503" | 33/64" | 3,000 | 300° | 1 | 0000000 | 0000 |

| 2.3mm | 3mm | 2.9mm | 3.18mm | 3,000 | 300° | 5 | 0000000 | 00000 |

| 3.3mm | 4mm | 3.8mm | 4mm | 3,000 | 300° | 5 | 0000000 | 00000 |

| 4.3mm | 5mm | 5.3mm | 5.5mm | 3,000 | 300° | 5 | 0000000 | 00000 |

| 5.3mm | 6mm | 6.3mm | 6.5mm | 3,000 | 300° | 1 | 0000000 | 0000 |

| 6.2mm | 7mm | 7.3mm | 7.5mm | 3,000 | 300° | 1 | 0000000 | 0000 |

| 7.2mm | 8mm | 8.3mm | 8.5mm | 3,000 | 300° | 1 | 0000000 | 0000 |

| 8.2mm | 9mm | 9.8mm | 10mm | 3,000 | 300° | 5 | 0000000 | 00000 |

| 9.2mm | 10mm | 10.8mm | 11mm | 3,000 | 300° | 5 | 0000000 | 00000 |

| 11mm | 12mm | 12.8mm | 13mm | 1,500 | 300° | 1 | 0000000 | 0000 |

Zinc-Plated Steel Sleeve | ||||||||

| 2.2mm | 3mm | 3.4mm | 3.6mm | 4,600 | 300° | 5 | 0000000 | 00000 |

| 3.3mm | 4mm | 3.8mm | 4mm | 4,600 | 300° | 5 | 0000000 | 0000 |

| 4.3mm | 5mm | 5.3mm | 5.5mm | 4,600 | 300° | 5 | 0000000 | 0000 |

| 5.3mm | 6mm | 6.3mm | 6.5mm | 4,600 | 300° | 5 | 0000000 | 0000 |

| 6.4mm | 7mm | 7.3mm | 7.5mm | 4,600 | 300° | 5 | 0000000 | 00000 |

| 7.4mm | 8mm | 8.3mm | 8.5mm | 4,600 | 300° | 1 | 0000000 | 0000 |

| 8.4mm | 9mm | 9.8mm | 10mm | 4,600 | 300° | 1 | 0000000 | 0000 |

| 9.4mm | 10mm | 10.8mm | 11mm | 4,600 | 300° | 1 | 0000000 | 0000 |

| 10.6mm | 12mm | 12.8mm | 13mm | 3,600 | 300° | 1 | 0000000 | 0000 |

| 12.7mm | 14mm | 14.5mm | 15mm | 3,600 | 300° | 1 | 0000000 | 00000 |

| 14.7mm | 16mm | 16.5mm | 17mm | 3,600 | 300° | 1 | 0000000 | 00000 |

| 16.7mm | 18mm | 18.5mm | 19mm | 3,600 | 300° | 1 | 0000000 | 00000 |

| 18.7mm | 20mm | 21.5mm | 22mm | 3,600 | 300° | 1 | 0000000 | 00000 |

| 20.7mm | 22mm | 24.5mm | 25mm | 3,600 | 300° | 1 | 0000000 | 00000 |

18-8 Stainless Steel Sleeve | ||||||||

| 1/16" | 3/32" | 0.081" | 3/32" | 5,500 | 300° | 5 | 00000000 | 0000 |

| 3/32" | 1/8" | 0.113" | 1/8" | 5,500 | 300° | 5 | 00000000 | 0000 |

| 1/8" | 5/32" | 0.13" | 5/32" | 5,500 | 300° | 5 | 00000000 | 00000 |

| 5/32" | 3/16" | 0.152" | 13/64" | 5,500 | 300° | 5 | 00000000 | 00000 |

| 3/16" | 7/32" | 0.187" | 7/32" | 5,500 | 300° | 5 | 00000000 | 00000 |

| 7/32" | 1/4" | 0.212" | 17/64" | 5,500 | 300° | 5 | 00000000 | 00000 |

| 1/4" | 9/32" | 1/4" | 9/32" | 5,500 | 300° | 5 | 00000000 | 00000 |

| 9/32" | 5/16" | 0.327" | 21/64" | 5,500 | 300° | 5 | 00000000 | 00000 |

| 5/16" | 11/32" | 0.385" | 25/64" | 5,500 | 300° | 1 | 00000000 | 0000 |

| 11/32" | 3/8" | 0.425" | 25/64" | 5,500 | 300° | 1 | 00000000 | 0000 |

| 3/8" | 13/32" | 0.425" | 7/16" | 4,000 | 300° | 1 | 00000000 | 0000 |

| 13/32" | 7/16" | 0.503" | 33/64" | 4,000 | 300° | 1 | 00000000 | 0000 |

| 7/16" | 15/32" | 0.504" | 33/64" | 4,000 | 300° | 1 | 00000000 | 0000 |

| 2.2mm | 3mm | 3.4mm | 3.6mm | 5,500 | 300° | 1 | 0000000 | 0000 |

| 3.3mm | 4mm | 3.8mm | 4mm | 5,500 | 300° | 1 | 0000000 | 0000 |

| 4.3mm | 5mm | 5.3mm | 5.5mm | 5,500 | 300° | 1 | 0000000 | 0000 |

| 5.3mm | 6mm | 6.3mm | 6.5mm | 5,500 | 300° | 1 | 0000000 | 0000 |

| 6.4mm | 7mm | 7.3mm | 7.5mm | 5,500 | 300° | 1 | 0000000 | 00000 |

| 7.4mm | 8mm | 8.3mm | 8.5mm | 5,500 | 300° | 1 | 0000000 | 00000 |

| 8.4mm | 9mm | 9.8mm | 10mm | 5,500 | 300° | 1 | 0000000 | 00000 |

| 9.4mm | 10mm | 10.8mm | 11mm | 5,500 | 300° | 1 | 0000000 | 00000 |

| 10.6mm | 12mm | 12.8mm | 13mm | 4,100 | 300° | 1 | 0000000 | 00000 |

| 12.7mm | 14mm | 14.5mm | 15mm | 4,100 | 300° | 1 | 0000000 | 00000 |

| For Counterbore Dia. | Dia. | Lg. | Each | |

Steel | ||||

|---|---|---|---|---|

| 3/32" | 3/8" | 5" | 00000000 | 000000 |

| 1/8", 3mm | 3/8" | 5" | 00000000 | 00000 |

| 5/32", 4mm | 3/8" | 5" | 00000000 | 00000 |

| 3/16" | 3/8" | 5" | 00000000 | 00000 |

| 7/32", 5mm | 3/8" | 5" | 00000000 | 00000 |

| 1/4", 6mm | 3/8" | 5" | 00000000 | 00000 |

| 9/32", 7mm | 3/8" | 5" | 00000000 | 00000 |

| 5/16", 8mm | 3/8" | 5" | 00000000 | 00000 |

| 11/32", 9mm | 5/8" | 5" | 00000000 | 00000 |

| 3/8" | 5/8" | 5" | 00000000 | 00000 |

| 13/32", 10mm | 5/8" | 5" | 00000000 | 00000 |

| 7/16" | 5/8" | 5" | 00000000 | 00000 |

| 15/32", 12mm | 5/8" | 5" | 00000000 | 00000 |

| 9/16", 14mm | 3/4" | 5" | 0000000 | 000000 |

| 5/8", 16mm | 3/4" | 5" | 0000000 | 000000 |

| 11/16", 18mm | 3/4" | 5" | 0000000 | 000000 |

| 25/32", 20mm | 1" | 5" | 0000000 | 000000 |

| 7/8", 22mm | 1" | 5" | 0000000 | 000000 |

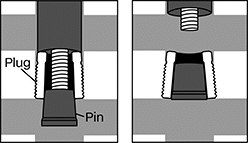

Pull-Through Bore Sealing Plugs

Permanently plug unused holes–even deep or angled ones—in manifolds and other hydraulic or pneumatic components. The required installation tool reaches inside holes to expand these plugs with the pull of a trigger, making them a good choice for high-volume assembly. The tool lets you install them without risking damage to your equipment, unlike most plugs that have to be hammered in place. These plugs resist vibration better than threaded plugs and don’t require thread sealant.

They consist of a serrated sleeve with an internally threaded pin inside it. To install, you’ll need the installation tool fitted with a mandrel and nosepiece set (both sold separately). Thread your plug onto the mandrel, then position the plug within your hole. Press the tool’s trigger to pull the plug’s pin through the sleeve, expanding it. The outer serrations will bite into the hole to seal it shut. After expanding, the tool will automatically reverse its spin to pull away from the pin.

Aluminum-sleeved plugs weigh less than steel-sleeved plugs, and they’re better at resisting corrosion from air and water. However, they won’t handle pressures as high as steel-sleeved plugs. They’re ideal for plugging aluminum manifolds.

Steel-sleeved plugs handle pressures more than twice as high as aluminum-sleeved plugs. This makes them a better choice for hydraulic components.

For technical drawings and 3-D models, click on a part number.

| Sealing Dia. | Installed Ht. | Max. Pressure, psi | Max. Temp., °F | Thread Size | Pkg. Qty. | Pkg. | |

Aluminum Sleeve | |||||||

|---|---|---|---|---|---|---|---|

| 13/64" | 11/64" | 2,000 | 300° | 4-40 | 5 | 0000000 | 000000 |

| 6mm | 5mm | 2,000 | 300° | M3 × 0.5 mm | 5 | 0000000 | 00000 |

| 8mm | 6.5mm | 2,000 | 300° | M4 × 0.7 mm | 5 | 0000000 | 00000 |

| 10mm | 6.5mm | 2,000 | 300° | M5 × 0.8 mm | 5 | 0000000 | 00000 |

Black-Oxide Steel Sleeve | |||||||

| 13/64" | 7/32" | 4,500 | 300° | 4-40 | 5 | 0000000 | 00000 |

| 15/64" | 1/4" | 4,500 | 300° | 6-32 | 5 | 0000000 | 00000 |

| 4.5mm | 4mm | 4,500 | 300° | M2 × 0.4 mm | 5 | 0000000 | 00000 |

| 8mm | 8.5mm | 4,500 | 300° | M4 × 0.7 mm | 5 | 0000000 | 00000 |

| 10mm | 10.5mm | 4,500 | 300° | M6 × 1 mm | 5 | 0000000 | 00000 |

Air Connection | Body | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Thread Size | Stroke Lg. | Operating Pressure, psi | Pulling Force, lbs. | Wt., lbs. | Pipe Size | Thread Type | Gender | Dia. | Wd. | Head Lg. | Overall Ht. | Each | |

| 4-40, 6-32, M2, M3, M4, M5, M6 | 0.04"-0.28" | 75-100 | 5,000 | 4 | 1/4 | NPT | Female | 4 5/16" | 1" | 10 1/4" | 10 1/2" | 0000000 | 000000000 |

| For Thread Size | Max. Thread Lg. | Includes | Each | |

| 4-40 | 45/64" | Mandrel, Anvil, Hex Driver, Lock Nut, Sleeve | 0000000 | 0000000 |

| 6-32 | 49/64" | Mandrel, Anvil, Hex Driver, Lock Nut, Sleeve | 0000000 | 000000 |

| M2 × 0.4 mm | 6mm | Mandrel, Anvil, Hex Driver, Lock Nut, Sleeve | 0000000 | 000000 |

| M3 × 0.5 mm | 11.8mm | Mandrel, Anvil, Hex Driver, Lock Nut, Sleeve | 0000000 | 000000 |

| M4 × 0.7 mm | 14.8mm | Mandrel, Anvil, Hex Driver, Lock Nut, Sleeve | 0000000 | 000000 |

| M5 × 0.8 mm | 15.6mm | Mandrel, Anvil, Hex Driver, Lock Nut, Sleeve | 0000000 | 000000 |

| M6 × 1 mm | 27.4mm | Mandrel, Anvil, Hex Driver, Lock Nut, Sleeve | 0000000 | 000000 |