Air-Powered Grippers

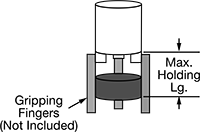

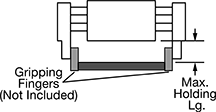

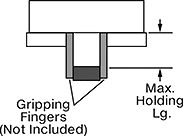

Combine these grippers with your gripping fingers to lift and move items in pick-and-place applications.

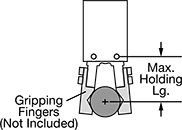

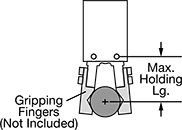

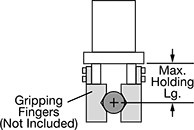

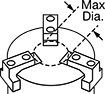

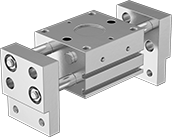

Angular grippers allow a more secure grip on irregularly shaped loads. Parallel grippers handle most shapes, including square, circular, and angled objects. Circular grippers are best for a snug grip on round objects.

Grippers with a spring jaw return have a single air port to close the jaws and grip items from the outside. An internal spring opens the jaws to release the grip. Grippers with a forced-air jaw return have two air ports: one to move the jaws open and another to move them closed. The jaws grip items from the outside as well as the inside.

Grippers with steel jaws are harder and stronger than aluminum. Grippers with stainless steel jaws withstand corrosion.

Note: Choose a gripper with a holding force at least 10 times your item's weight.

Warning: Never use to lift people or items over people.

Angle | O'all | Port | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| External Gripping Force | Max. Gripping Cap. | Max. | Min. | Max. Holding Lg., mm | Wt. | Lg., mm | Wd., mm | Dp., mm | Max. Pressure, psi | Thread Size | Thread Type | Manufacturer (Series/Model No.) | Each | |

Aluminum Housing | ||||||||||||||

| 0.9 lbs. @ 72.5 psi | 0.04 lbs. / 0.02 kg | 30° | -10° | 29 | 0.09 lbs./ 0.04 kg | 53 | 23 | 17 | 85 | M3 × 0.5 | Metric | SMC (MHC2 10) | 0000000 | 0000000 |

| 3.4 lbs. @ 72.5 psi | 0.17 lbs. / 0.07 kg | 30° | -10° | 39 | 0.21 lbs./ 0.1 kg | 62 | 30 | 24 | 85 | M5 × 0.8 | Metric | SMC (MHC2 16) | 0000000 | 000000 |

| 6.3 lbs. @ 72.5 psi | 0.31 lbs. / 0.14 kg | 30° | -10° | 59 | 0.41 lbs./ 0.19 kg | 79 | 42 | 28 | 85 | M5 × 0.8 | Metric | SMC (MHC2 20) | 0000000 | 000000 |

| 12.6 lbs. @ 72.5 psi | 0.63 lbs. / 0.28 kg | 30° | -10° | 80 | 0.7 lbs./ 0.32 kg | 93 | 52 | 34 | 85 | M5 × 0.8 | Metric | SMC (MHC2 25) | 0000000 | 000000 |

Angle | O'all | Port | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| External Gripping Force | Internal Gripping Force | Max. Gripping Cap. | Max. | Min. | Max. Holding Lg., mm | Wt. | Lg., mm | Wd., mm | Dp., mm | Max. Pressure, psi | Thread Size | Thread Type | Manufacturer (Series/Model No.) | Each | |

Aluminum Housing | |||||||||||||||

| 2.5 lbs. @ 72.5 psi | 2.5 lbs. @ 72.5 psi | 0.12 lbs./ 0.05 kg | 30° | -10° | 29 | 0.09 lbs./ 0.04 kg | 53 | 23 | 17 | 85 | M3 × 0.5 | Metric | SMC (MHC2 10) | 0000000 | 0000000 |

| 7.6 lbs. @ 72.5 psi | 7.6 lbs. @ 72.5 psi | 0.38 lbs./ 0.17 kg | 30° | -10° | 39 | 0.21 lbs./ 0.1 kg | 62 | 30 | 24 | 85 | M5 × 0.8 | Metric | SMC (MHC2 16) | 0000000 | 000000 |

| 9.5 lbs. @ 72.5 psi | 9.5 lbs. @ 72.5 psi | 0.47 lbs./ 0.21 kg | 30° | -10° | 59 | 0.4 lbs./ 0.18 kg | 79 | 42 | 28 | 85 | M5 × 0.8 | Metric | SMC (MHC2 20) | 0000000 | 000000 |

| 14.6 lbs. @ 72.5 psi | 14.6 lbs. @ 72.5 psi | 0.73 lbs./ 0.33 kg | 30° | -10° | 80 | 0.7 lbs./ 0.32 kg | 93 | 52 | 34 | 85 | M5 × 0.8 | Metric | SMC (MHC2 25) | 0000000 | 000000 |

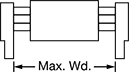

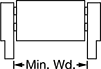

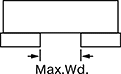

Wd., mm | O'all | Port | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| External Gripping Force | Max. Gripping Cap. | Max. | Min. | Max. Holding Lg., mm | Wt. | Lg., mm | Wd., mm | Dp., mm | Max. Pressure, psi | Thread Size | Thread Type | Manufacturer (Series/Model No.) | Each | |

Aluminum Housing | ||||||||||||||

| 1.59 lbs. @ 72.5 psi | 0.07 lbs./ 0.03 kg | 15 | 11 | 29 | 0.13 lbs./ 0.06 kg | 57 | 29 | 17 | 100 | M3 × 0.5 | Metric | SMC (MHZ2 10) | 00000000 | 0000000 |

| 6.06 lbs. @ 72.5 psi | 0.3 lbs./ 0.13 kg | 21 | 15 | 35 | 0.26 lbs./ 0.12 kg | 67 | 38 | 24 | 100 | M5 × 0.8 | Metric | SMC (MHZ2 16) | 00000000 | 000000 |

| 7.41 lbs. @ 72.5 psi | 0.37 lbs./ 0.16 kg | 26 | 16 | 54 | 0.52 lbs./ 0.24 kg | 85 | 50 | 28 | 100 | M5 × 0.8 | Metric | SMC (MHZ2 20) | 00000000 | 000000 |

Wd., mm | O'all | Port | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| External Gripping Force | Internal Gripping Force | Max. Gripping Cap. | Max. | Min. | Max. Holding Lg., mm | Wt. | Lg., mm | Wd., mm | Dp., mm | Max. Pressure, psi | Thread Size | Thread Type | Manufacturer (Series/Model No.) | Each | |

Aluminum Housing | |||||||||||||||

| 2.47 lbs. @ 72.5 psi | 3.82 lbs. @ 72.5 psi | 0.12 lbs./ 0.05 kg | 15 | 11 | 29 | 0.13 lbs./ 0.06 kg | 57 | 29 | 17 | 100 | M3 × 0.5 | Metric | SMC (MHZ2 10) | 0000000 | 0000000 |

| 7.64 lbs. @ 72.5 psi | 10.11 lbs. @ 72.5 psi | 0.38 lbs./ 0.17 kg | 21 | 15 | 35 | 0.26 lbs./ 0.12 kg | 67 | 38 | 24 | 100 | M5 × 0.8 | Metric | SMC (MHZ2 16) | 0000000 | 000000 |

| 9.44 lbs. @ 72.5 psi | 14.83 lbs. @ 72.5 psi | 0.47 lbs./ 0.21 kg | 26 | 16 | 54 | 0.51 lbs./ 0.23 kg | 85 | 50 | 28 | 100 | M5 × 0.8 | Metric | SMC (MHZ2 20) | 0000000 | 000000 |

Dia., mm | O'all | Port | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| External Gripping Force | Internal Gripping Force | Max. Gripping Cap. | Max. | Min. | Max. Holding Lg., mm | Wt. | Lg., mm | Dia., mm | Max. Pressure, psi | Thread Size | Thread Type | Manufacturer (Series/Model No.) | Each | |

Aluminum Housing | ||||||||||||||

| 3.15 lbs. @ 72.5 psi | 3.6 lbs. @ 72.5 psi | 0.24 lbs./ 0.1 kg | 14 | 10 | 29 | 0.14 lbs./ 0.06 kg | 35 | 30 | 85 | M3 × 0.5 | Metric | SMC (MHS3 16) | 0000000 | 0000000 |

| 5.62 lbs. @ 72.5 psi | 6.29 lbs. @ 72.5 psi | 0.43 lbs./ 0.19 kg | 16 | 12 | 35 | 0.23 lbs./ 0.1 kg | 38 | 36 | 85 | M5 × 0.8 | Metric | SMC (MHS3 20) | 0000000 | 000000 |

| 9.44 lbs. @ 72.5 psi | 10.57 lbs. @ 72.5 psi | 0.72 lbs./ 0.32 kg | 20 | 14 | 39 | 0.31 lbs./ 0.14 kg | 40 | 42 | 85 | M5 × 0.8 | Metric | SMC (MHS3 25) | 0000000 | 000000 |

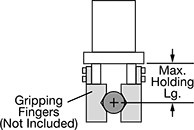

Wd., mm | O'all | Port | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| External Gripping Force | Internal Gripping Force | Max. Gripping Cap. | Max. | Min. | Max. Holding Lg., mm | Wt. | Lg., mm | Wd., mm | Dp., mm | Max. Pressure, psi | Pipe Size | Thread Size | Thread Type | Manufacturer (Series/Model No.) | Each | |

Aluminum Housing | ||||||||||||||||

| 10.12 lbs. @ 72.5 psi | 10.12 lbs. @ 72.5 psi | 0.5 lbs./ 0.22 kg | 98 | 68 | 80 | 1.29 lbs./ 0.59 kg | 58 | 128 | 55 | 85 | __ | M5 × 0.8 | Metric | SMC (MHL2 16) | 000000 | 0000000 |

| 29.45 lbs. @ 72.5 psi | 29.45 lbs. @ 72.5 psi | 1.47 lbs./ 0.66 kg | 150 | 100 | 119 | 3.725 lbs./ 1.69 kg | 81 | 196 | 76 | 85 | __ | M5 × 0.8 | Metric | SMC (MHL2 25) | 000000 | 000000 |

| 51.25 lbs. @ 72.5 psi | 51.25 lbs. @ 72.5 psi | 2.56 lbs./ 1.16 kg | 220 | 150 | 139 | 6.41 lbs./ 2.91 kg | 100 | 272 | 82 | 85 | 1/8 | __ | BSPT | SMC (MHL2 32) | 000000 | 000000 |

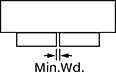

Wd., mm | O'all | Port | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| External Gripping Force | Internal Gripping Force | Max. Gripping Cap. | Max. | Min. | Max. Holding Lg., mm | Wt. | Lg., mm | Wd., mm | Dp., mm | Max. Pressure, psi | Thread Size | Thread Type | Manufacturer (Series/Model No.) | Each | |

Aluminum Housing | |||||||||||||||

| 10.79 lbs. @ 72.5 psi | 10.79 lbs. @ 72.5 psi | 0.53 lbs./ 0.24 kg | 12 | 0 | 29 | 0.34 lbs./ 0.16 kg | 25 | 52 | 40 | 100 | M5 × 0.8 | Metric | SMC (MHF2 12) | 00000000 | 0000000 |

| 10.79 lbs. @ 72.5 psi | 10.79 lbs. @ 72.5 psi | 0.53 lbs./ 0.24 kg | 24 | 0 | 29 | 0.42 lbs./ 0.19 kg | 25 | 70 | 40 | 100 | M5 × 0.8 | Metric | SMC (MHF2 12) | 00000000 | 000000 |

| 10.79 lbs. @ 72.5 psi | 10.79 lbs. @ 72.5 psi | 0.53 lbs./ 0.24 kg | 48 | 0 | 29 | 0.61 lbs./ 0.28 kg | 25 | 106 | 40 | 100 | M5 × 0.8 | Metric | SMC (MHF2 12) | 00000000 | 000000 |

| 20.23 lbs. @ 72.5 psi | 20.23 lbs. @ 72.5 psi | 1.01 lbs./ 0.45 kg | 16 | 0 | 40 | 0.77 lbs./ 0.35 kg | 33 | 71 | 50 | 100 | M5 × 0.8 | Metric | SMC (MHF2 16) | 00000000 | 000000 |

| 20.23 lbs. @ 72.5 psi | 20.23 lbs. @ 72.5 psi | 1.01 lbs./ 0.45 kg | 32 | 0 | 40 | 0.98 lbs./ 0.45 kg | 33 | 95 | 50 | 100 | M5 × 0.8 | Metric | SMC (MHF2 16) | 00000000 | 000000 |

| 20.23 lbs. @ 72.5 psi | 20.23 lbs. @ 72.5 psi | 1.01 lbs./ 0.45 kg | 64 | 0 | 40 | 1.43 lbs./ 0.65 kg | 33 | 143 | 50 | 100 | M5 × 0.8 | Metric | SMC (MHF2 16) | 00000000 | 000000 |

| 31.69 lbs. @ 72.5 psi | 31.69 lbs. @ 72.5 psi | 1.58 lbs./ 0.71 kg | 20 | 0 | 54 | 1.42 lbs./ 0.65 kg | 41 | 87 | 62 | 100 | M5 × 0.8 | Metric | SMC (MHF2 20) | 00000000 | 000000 |

| 31.69 lbs. @ 72.5 psi | 31.69 lbs. @ 72.5 psi | 1.58 lbs./ 0.71 kg | 40 | 0 | 54 | 1.87 lbs./ 0.85 kg | 41 | 117 | 62 | 100 | M5 × 0.8 | Metric | SMC (MHF2 20) | 00000000 | 000000 |

| 31.69 lbs. @ 72.5 psi | 31.69 lbs. @ 72.5 psi | 1.58 lbs./ 0.71 kg | 80 | 0 | 54 | 2.7 lbs./ 1.23 kg | 41 | 177 | 62 | 100 | M5 × 0.8 | Metric | SMC (MHF2 20) | 00000000 | 000000 |