About Plastic and Rubber Tubing

More

How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Barbed Tube Fittings for Drinking Water

- Temperature Range: 32° to 180° F

- Tubing:

All Fittings: Use with hard polyethylene plastic

Socket-Connect Fittings: Use with hard polyethylene plastic or copper - Specifications Met: See table

Connect these fittings to tubing with a ring and a crimping tool (both sold separately). They have multiple barbs that grip onto tubing for a secure hold. Fittings are compatible with Viega PEX tubing. Safe to use with drinking water, these fittings meet the strict standards of NSF/ANSI 61.

Brass fittings offer good corrosion resistance.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

For technical drawings and 3-D models, click on a part number.

| For Tube ID | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 3/8" | 1/2 | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 00000 |

| 1/2" | 1/2 | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 0000000 | 0000 |

| 1/2" | 3/4 | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 0000 |

| 3/4" | 1/2 | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 0000 |

| 3/4" | 3/4 | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 0000000 | 0000 |

| 3/4" | 1 | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 00000 |

| 1" | 3/4 | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 00000 |

| 1" | 1 | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 0000 |

| For Tube ID | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 3/8" | 1/2 | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 00000 |

| 1/2" | 3/4 | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 0000 |

| 1/2" | 1/2 | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 0000000 | 0000 |

| 3/4" | 3/4 | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 0000000 | 0000 |

| 3/4" | 1 | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 00000 |

| 1" | 1 | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 00000 |

Crimp or solder a female press-connect or solder-connect tube fitting onto the male socket-connect end of this fitting to create a leak-tight connection. To crimp, you’ll need a press-connect crimping tool. Solder-connect fittings are also known as sweat fittings.

Socket-Connect | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube ID (Barbed) | Copper Tube Size | Tube OD | Type | Material | Max. Pressure | Specifications Met | Each | |

| 1/2" | 1/2 | 5/8" | Press, Solder | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 0000000 | 00000 |

| 3/4" | 3/4 | 7/8" | Press, Solder | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 0000000 | 0000 |

| 1" | 1 | 1 1/8" | Press, Solder | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 00000 |

Use a press-connect crimping tool to secure the press-connect end to tubing or the male socket-connect tube end of a fitting without heat or soldering. They have an internal O-ring that creates a leak-tight connection.

Socket-Connect | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube ID (Barbed) | Copper Tube Size | For Tube OD | Type | Material | Max. Pressure | Specifications Met | Each | |

| 1/2" | 1/2 | 5/8" | Press | Bronze | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 00000 |

| 1/2" | 3/4 | 7/8" | Press | Bronze | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 00000 |

| 3/4" | 1/2 | 5/8" | Press | Bronze | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 0000 |

| 3/4" | 3/4 | 7/8" | Press | Bronze | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 00000 |

| 1" | 1 | 1 1/8" | Press | Bronze | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 00000 |

Solder-connect fittings create a permanent, leak-tight connection to tubing or the male socket-connect tube end of another fitting. They are also known as sweat fittings.

Socket-Connect | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube ID (Barbed) | Copper Tube Size | For Tube OD | Type | Material | Max. Pressure | Specifications Met | Each | |

| 1/2" | 1/2 | 5/8" | Solder | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 0000000 | 00000 |

| 3/4" | 3/4 | 7/8" | Solder | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 0000000 | 0000 |

| 1" | 1 | 1 1/8" | Solder | Brass | 160 psi @ 72° F | ASTM F1807, NSF/ANSI 61 | 00000000 | 0000 |

These adapters have a mounting base to anchor the fitting.

Solder-connect fittings create a permanent, leak-tight connection to tubing or the male socket-connect tube end of another fitting. They are also known as sweat fittings.

| For Tube ID (A) | For Tube ID (B) | Material | Max. Pressure | Specifications Met | Each | |

| 3/4" | 1/2" | PPSU | 160 psi @ 72° F | ASTM F2159, NSF/ANSI 61 | 00000000 | 00000 |

Inline tees are also known as branch tees.

| For Tube ID (A) | For Tube ID (B) | Material | Max. Pressure | Specifications Met | Each | |

| 1/2" | 3/4" | PPSU | 160 psi @ 72° F | ASTM F2159, NSF/ANSI 61 | 0000000 | 00000 |

| 3/4" | 1/2" | PPSU | 160 psi @ 72° F | ASTM F2159, NSF/ANSI 61 | 00000000 | 0000 |

| 3/4" | 1" | PPSU | 160 psi @ 72° F | ASTM F2159, NSF/ANSI 61 | 00000000 | 0000 |

| 1" | 3/4" | PPSU | 160 psi @ 72° F | ASTM F2159, NSF/ANSI 61 | 00000000 | 0000 |

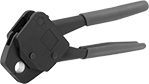

Crimping Tools for Barbed Tube Fittings for Drinking Water

Use these tools with a crimping ring (sold separately) to connect barbed tube fittings for drinking water to tubing. Compatible with Viega PEX fittings.

Hard Plastic Tubing for Drinking Water

Tubing meets NSF/ANSI Standard 61 for drinking water. It is made without plasticizers like DEHP, so it won’t impart tastes or odors to the fluid running through it. A lightweight alternative to copper tubing, it connects to fittings with no heat or soldering required. Tubing is opaque, so you cannot see inside the line.

Polyethylene tubing is compatible with Viega PEX tubing. It connects to barbed fittings with a crimping tool and crimping ring (both sold separately). Tubing is semi-flexible, so it is good for gradual bends. It meets ASTM F876 and ASTM F877 specification and testing requirements for material quality and dimensions of polyethylene (PEX) tubing. It is IAPMO certified to comply with the International Association for Plumbing and Mechanical Officials product performance standards and the Uniform Plumbing Code (UPC) for installation and repair of plumbing systems.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

For technical drawings and 3-D models, click on a part number.

- Semi-Flexible

- Compatible with Barbed Tube Fittings

- Hard

- Temperature Range: 72° to 180° F

| Copper Tube Size | ID | OD | Wall Thick. | Bend Radius | Max. Pressure | Specifications Met | Choose a Color | Lengths, ft. | Per Ft. | |

| 1/4 | 1/4" | 3/8" | 1/16" | 3" | 160 psi @ 72° F | ASTM F876, ASTM F877, IAPMO Certified, NSF/ANSI 61 | White | 00000000 | 00000 | |

| 3/8 | 3/8" | 1/2" | 1/16" | 4" | 160 psi @ 72° F | ASTM F876, ASTM F877, IAPMO Certified, NSF/ANSI 61 | 00000000 | 000 | ||

| 1/2 | 1/2" | 5/8" | 1/16" | 5" | 160 psi @ 72° F | ASTM F876, ASTM F877, IAPMO Certified, NSF/ANSI 61 | 00000000 | 000 | ||

| 3/4 | 11/16" | 7/8" | 3/32" | 7" | 160 psi @ 72° F | ASTM F876, ASTM F877, IAPMO Certified, NSF/ANSI 61 | 00000000 | 0000 | ||

| 1 | 7/8" | 1 1/8" | 1/8" | 9" | 160 psi @ 72° F | ASTM F876, ASTM F877, IAPMO Certified, NSF/ANSI 61 | 00000000 | 0000 |

Color-Coded Quarter-Turn Shut-Off Valves for Hot and Cold Water

Quickly identify hot and cold water lines with these red or blue valves. The low-profile elbow shape and small handle are made to fit into tight spaces, such as plumbing outlet boxes (sold separately). Connect the NH/NST threads to a water hose on a washing machine or commercial plumbing fixture.

Valves with a barbed inlet are compatible with Viega PEX tubing; attach them to your line with a crimping tool and crimping ring (both sold separately).

Inlet—For

Hot Water

Inlet—For

Cold Water

90° Elbow | |||||||

|---|---|---|---|---|---|---|---|

| For Inlet Tube ID | Outlet Hose Size | Handle Material | Compatible With | Specifications Met | Choose a Handle Color | Each | |

Brass | |||||||

| 1/2" | 3/4 | Powder-Coated Aluminum | Viega PEX | ASTM F1807 | 0000000 | 000000 | |

| Wd. | Ht. | Dp. | Material | Mounting Fasteners Included | Number of Mounting Holes | Mounting Hole Dia. | Each | |

| 10 1/4" | 6 3/4" | 2 1/2" | PVC Plastic | No | 36 | 1/8" | 0000000 | 000000 |

Polyethylene (PEX) Tube Cutters

Cut PEX tubing with one or two twists. These cutters automatically adjust pressure during cutting to prevent distorting the tube end, so it's easy to attach fittings.